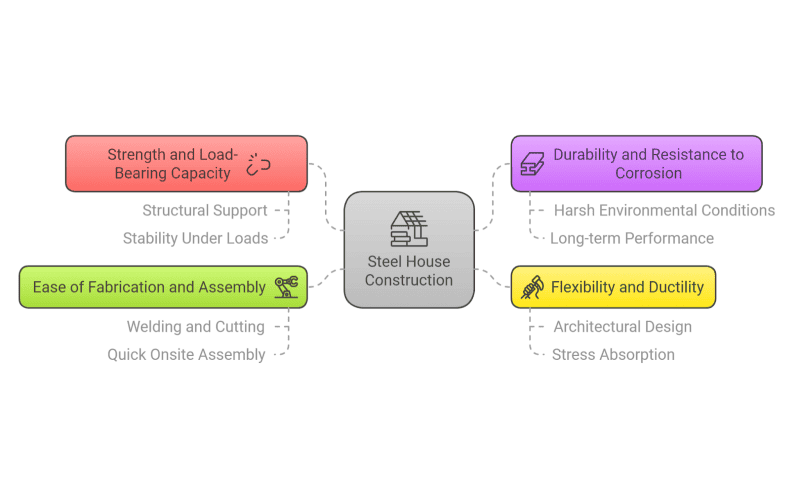

Key Requirements for Steel House Construction

Steel-frame houses are fundamentally different from traditional concrete or wood-frame homes in their design, construction, and performance expectations. To meet these unique demands, the steel used must satisfy the following critical requirements:

- Strength and Load-Bearing Capacity – The steel must possess a high strength-to-weight ratio to support the structural framework, including walls, roofs, and floors, while maintaining stability under diverse loads such as wind and snow.

- Durability and Resistance to Corrosion – Steel-structure houses often face exposure to harsh environmental conditions. The material must resist corrosion in humid or coastal regions through protective coatings or galvanization to ensure long-term performance and minimal maintenance.

- Flexibility and Ductility – Steel must offer flexibility and workability to accommodate modern architectural designs. Additionally, ductility is critical for absorbing stresses caused by external forces, such as earthquakes or strong winds, ensuring structural safety.

- Ease of Fabrication and Assembly – Steel should be easy to weld, cut, and shape, supporting prefabrication and quick onsite assembly. This feature is essential for modular steel houses, enabling faster construction timelines without compromising precision.

Steel Types Commonly Used for Steel House Construction

1. Structural Steel

Main Composition: Low-to-medium carbon steel with small amounts of manganese and silicon for strength and weldability.

Key Benefits and Features:

- High strength-to-weight ratio, ideal for load-bearing frameworks.

- Easy to weld and assemble, suitable for prefabrication.

- Reliable for both static and dynamic loads, ensuring long-term durability.

Applications:

Structural steel is the backbone of steel-structure houses. It is used in primary frameworks such as beams, columns, and trusses, supporting the entire structure’s weight. Its adaptability makes it ideal for both single-story homes and multistory residential projects.

Common Grades: Q235, Q345; ASTM A36; EN S355

2. Galvanized Steel

Main Composition: Carbon steel with a protective zinc coating to prevent corrosion.

Key Benefits and Features:

- Rust-resistant, especially in humid or coastal environments.

- Affordable and durable, requiring minimal maintenance.

- Suitable for weather-exposed components.

Applications:

Galvanized steel is widely used for parts of steel-structure houses that are directly exposed to the elements, such as roofs, external cladding, and secondary supports. It is especially effective in environments with high humidity or salt exposure.

Common Grades: DX51D+Z, SGCC, ASTM A653

3. Mild Steel

Main Composition: Low carbon content (0.05% – 0.25%), making it soft and malleable.

Key Benefits and Features:

- Easy to cut, weld, and shape, suitable for custom designs.

- Budget-friendly, ideal for cost-sensitive projects.

- Flexible for diverse applications in construction.

Applications:

Mild steel is commonly used for non-load-bearing components, such as interior frames, wall supports, and decorative elements. Its affordability and workability make it a go-to option for secondary structures in smaller residential projects.

Common Grades: Q195, Q235, EN S235

4. Weathering Steel

Main Composition: Low carbon steel with added copper and nickel to form a self-protective rust layer.

Key Benefits and Features:

- Naturally resistant to rust without additional coatings.

- Distinctive industrial aesthetic with a protective oxide surface.

- Long-lasting with minimal maintenance.

Applications:

Weathering steel is ideal for outdoor components of steel-structure houses, such as exterior walls, roofs, and decorative features. It is particularly popular in modern designs where durability and aesthetics are equally important.

Common Grades: Corten A, Corten B, Q355GNH

5. Stainless Steel

Main Composition: High chromium content (10%-20%) with optional additions of nickel and molybdenum for enhanced corrosion resistance.

Key Benefits and Features:

- Exceptional corrosion resistance, especially in coastal or high-humidity areas.

- Sleek and polished appearance, perfect for modern designs.

- Durable and low-maintenance over time.

Applications:

Stainless steel is often used for decorative and functional elements, such as window and door frames, railings, or cladding in steel-structure houses. It is most commonly used in environments with high exposure to moisture or salt.

Common Grades: 304, 316L, 430

6. High Strength Low Alloy Steel (HSLA)

Main Composition: Carbon steel alloyed with small amounts of vanadium, titanium, and other elements to increase strength and toughness.

Key Benefits and Features:

- Strong yet lightweight, reducing overall structural weight.

- Excellent toughness, ideal for dynamic loads.

- Resistant to fatigue, ensuring long-term performance.

Applications:

HSLA steel is commonly used for houses requiring lightweight yet durable materials, such as large-span frameworks or multistory residential buildings. It is particularly effective in reducing material usage without sacrificing safety or performance.

Common Grades: Q460, EN S460, ASTM A572

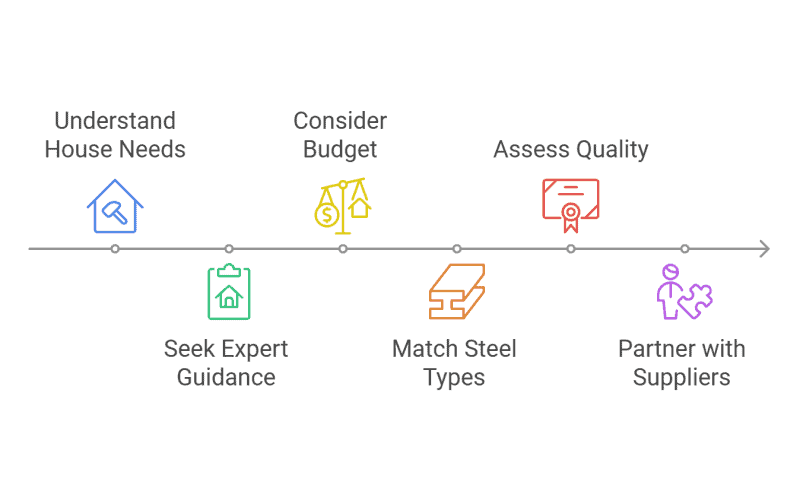

How to Choose the Best Steel for Your Steel House

Selecting the right steel for your steel house can feel challenging, but breaking the process into clear, actionable steps can make it much easier. Here’s how to choose the best steel based on your house’s unique requirements and project goals:

1. Understand Your House’s Needs

Start by assessing your specific project requirements:

- Structure Type: Single-story houses can use lighter steel like Q235, while multistory or heavy-load structures require stronger options such as Q345 or EN S355.

- Design Complexity: If your design involves open spaces, large spans, or modular construction, opt for flexible and lightweight materials like HSLA steel.

- Environmental Conditions: Coastal or humid areas demand corrosion-resistant steel, such as galvanized steel or stainless steel, to ensure longevity.

2. Seek Expert Guidance

Consulting structural engineers or architects early in the process is essential. They can:

- Calculate load requirements to determine the necessary steel strength.

- Recommend the best steel types and grades for your design and budget.

- Address specific environmental concerns, like corrosion or thermal resistance.

3. Consider Budget and Long-Term Costs

Balancing initial costs with long-term value is crucial:

- Cost-Effective Options: Mild steel (e.g., Q195, Q235) is suitable for non-structural components and budget-sensitive projects.

- Long-Term Savings: While stainless steel or galvanized steel may have higher upfront costs, they reduce maintenance expenses, especially in harsh environments.

4. Match Steel Types and Grades to Specific Members

Different parts of your house require specific steel types and grades:

- Main Framework: Structural steel (e.g., Q235, Q345) is ideal for beams, columns, and trusses, providing the necessary strength and stability.

- Roof and External Cladding: Galvanized steel is highly resistant to rust and perfect for weather-exposed areas like roofs or walls.

- Decorative Features: Stainless steel is best for door and window frames, railings, or other visible elements that prioritize aesthetics and durability.

- Steel Grades:

- Q235 or ASTM A36: Cost-effective for lighter loads.

- Q345 or EN S355: Suitable for heavy-duty and multistory houses.

- 316L Stainless Steel: Excellent for high-moisture environments or coastal structures.

5. Assess Quality and Certifications

Before purchasing steel, evaluate its quality to avoid costly errors later:

- Surface Inspection: Ensure the steel is free of rust, cracks, or visible defects.

- Standard Compliance: Check for certifications like ISO 9001 or compliance with local building codes (e.g., GB standards, ASTM, or EN equivalents).

- Consistency: Verify uniform weight, thickness, and dimensions to maintain structural balance and precision.

6. Partner with Reputable Suppliers

Choosing the right supplier is as important as choosing the steel itself:

- Certifications: Work with suppliers offering certified steel that meets international or local standards.

- Experience: Opt for suppliers with proven expertise in steel-structure housing materials.

- Support: Select suppliers who provide detailed product information, technical assistance, and custom solutions tailored to your needs.

Need A One-Stop Steel House Construction Solution?

Confused about choosing the right steel for your house? We’ve got you covered. With 1,000+ successful steel structure projects and 500,000 MT/year annual steel capacity, SteelPRO PEB offers high-quality steel, faster delivery, and better pricing—no middleman involved.

From planning (material selection included) to design, manufacturing, and shipping, we provide a complete solution for your steel house. Whether you’re looking for a fully customized design or one of our convenient Steel Home Kits, we simplify the process and deliver results you can trust. Get in touch with us today to get started!