Steel columns are the backbone of every pre-engineered and industrial steel structure — from warehouses and factories to commercial buildings and workshops. Choosing the right type and specification of column is critical for achieving the best balance between strength, cost efficiency, and long-term durability.

Each steel column type has its own load-bearing characteristics, material properties, and installation requirements. Understanding these differences helps engineers, builders, and project owners design safer, more economical buildings.At SteelPRO PEB, we focus on precision-manufactured columns and structural components that meet ISO and CE standards, ensuring reliability and consistency across global construction projects.

What is Steel Column?

A steel column is a vertical structural element made of steel that is designed to transfer loads from the upper parts of a building (such as beams, floors, and roofs) to the foundation. They are designed to withstand tremendous weight and force, ensuring that the structure remains stable and safe, and are commonly used in buildings, bridges, and other large structures.

Steel columns can be designed as slender columns (tall and thin) or short, thick columns (used for heavy loads). In modular and prefabricated construction, steel columns are often part of the modular units that are pre-manufactured and then assembled on-site.

In industrial construction, steel columns are often integrated within PEB (Pre-Engineered Building) structures, manufactured under strict ISO and CE standards to ensure precision and strength for global projects.

Materials of Steel Columns

Common materials for steel columns include carbon steel, alloy steel and stainless steel. Carbon steel is the most commonly used, with high strength, suitable for general buildings and bridges. Alloy steel has stronger corrosion resistance and bearing capacity, suitable for high-rise buildings and extreme environments. Stainless steel has excellent corrosion resistance and is suitable for humid, marine and chemical environments.

Common Specifications of Steel Columns

Typical steel column specifications range from 100×100×5 mm for light structures to 400×400×16 mm for heavy-load industrial use. The exact section depends on the load design, building span, and type of structure.

The specifications of steel columns vary. The following are several common types and their application scenarios:

- Square Tube: Excellent torsion resistance, suitable for building frames and curtain wall support structures, such as 100×100×5 mm square tube columns.

- H-beam: Wide flange and strong bearing capacity, suitable for high-rise buildings and large-span structures such as bridges and industrial plants. Common specifications include H200×200×8×12 mm.

- I-beam: Ideal for structures that bear vertical loads, such as floor support beams and frame columns. Typical specifications include I200×100×7×10 mm.

- C-Channel: Lightweight and suitable for secondary structural support, such as roof purlins and wall keels, with specifications like C100×50×20×2 mm.

What are the Different Types of Steel Columns?

| Classification | Types |

| Based on Load-Bearing Capacity | – Short Columns |

| – Long Columns | |

| – Intermediate Columns | |

| Based on Shape and Section | – Solid (Rolled) Sections: I-beams, channels, angles, t-shape columns. |

| – Hollow Sections (Box columns): Rectangular or circular. | |

| – Built-up Sections: Assembled from steel plates or angles. | |

| Based on Function | – Compression Columns |

| – Axially Loaded Columns。 | |

| – Bending Loaded Columns | |

| Based on Connection and Support | – Pinned Columns |

| – Fixed Columns | |

| – Cantilever Columns | |

| For Seismic Applications | – Base-Isolated Columns |

| – Seismic-Resistant Steel Columns |

1. Metal Building Column Types Based on Load-Bearing Capacity

Short Columns: These are columns that are relatively short compared to their lateral dimensions and typically experience compressive forces. Short columns are designed to carry axial loads without significant lateral instability.

Long Columns (Slender Columns): These columns are taller and have a higher length-to-width ratio. They are prone to buckling and require more detailed design considerations, often using the effective length factor or slenderness ratio for stability.

Intermediate Columns: These columns fall between short and long columns in terms of their slenderness ratio. The design requires careful consideration of both axial load and buckling resistance.

2. Types of Structural Steel Columns Based on Shape and Section

Solid (Rolled) Sections: These columns are made from a single piece of steel, typically in the form of I-beams (wide flange beams), channels, or angles. They provide excellent strength and stability for a wide range of applications.

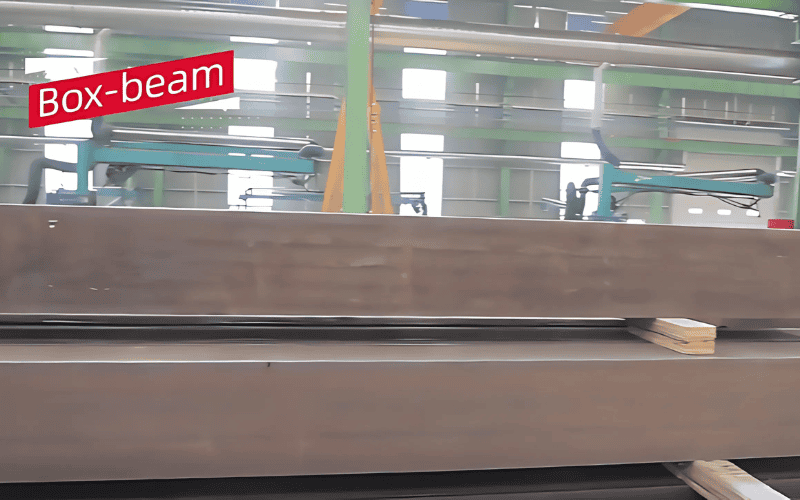

Hollow Sections (Box Sections): Hollow steel columns, including rectangular or circular sections, are commonly used in modern design because they are lighter and have a higher strength-to-weight ratio. They also offer superior resistance to torsion.

Built-up Sections: These are columns made by welding or bolting together individual pieces of steel, such as plates or angles. Built-up sections are commonly used for large structures where standard shapes may not provide the necessary strength or size.

3. Types of Steel Building Column Based on Function

Compression Columns: These are the most common type of steel column, designed primarily to carry compressive loads. They are found in most building structures, such as high-rise buildings, bridges, and industrial facilities.

Axially Loaded Columns: These columns experience loads along the axis of the column. The design for these columns primarily focuses on resisting axial compression and ensuring stability.

Lateral-Torsional Buckling Columns: These columns are subjected to combined axial and bending loads, making them vulnerable to lateral-torsional buckling. They require more advanced design methods, including lateral bracing or the use of stronger steel grades.

4. Types of Steel Structure Columns Based on Connection and Support Conditions

Pinned Columns: Pinned at both ends, these columns are designed assuming no moment transfer at the column ends, and they primarily carry axial load. The buckling behavior of these columns is based on their effective length.

Fixed Columns: Fixed at one or both ends, these columns experience both axial load and bending moment. The increased moment capacity reduces the effective length and provides greater stability against buckling.

Cantilever Columns: These columns are fixed at one end and free at the other, often subjected to bending in addition to axial load. This type of column needs to account for both axial compression and bending in the design.

5. Innovative Prefab Columns for Seismic Applications

Base-Isolated Columns: In earthquake-resistant designs, columns may be designed with base isolators that allow movement during seismic events. These isolators help absorb shock and reduce the forces transmitted to the structure.

Seismic-Resistant Steel Columns: Columns designed to absorb seismic forces effectively often include additional bracing, energy-dissipating devices, or advanced materials that enhance their resistance to lateral forces during an earthquake.

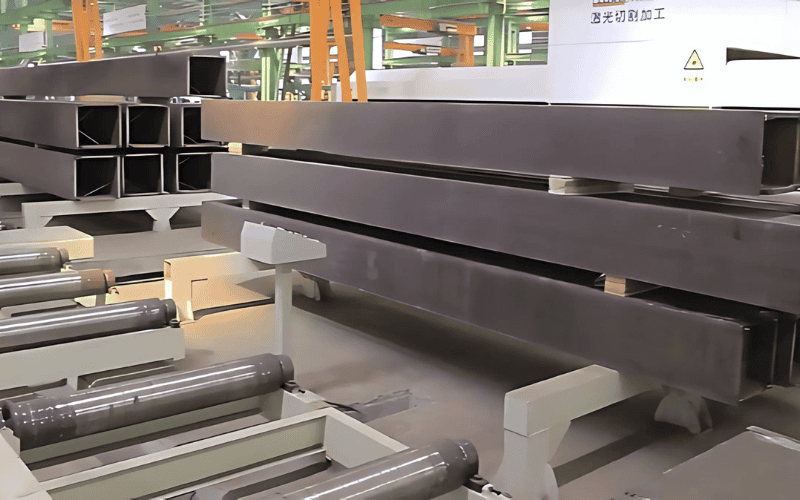

Manufacturing and Processing Technology of Steel Columns

The manufacturing of steel columns includes key steps such as rolling, welding, cutting, drilling, and coating. Hot-rolled steel columns are formed by high-temperature rolling and have good strength and uniformity, while cold rolling provides higher dimensional accuracy.

Welded steel columns (such as H-shaped welded and box-shaped columns) are suitable for large load-bearing requirements, but the manufacturing cost is high. In contrast, rolled H-shaped steel has a fast production speed and is suitable for standardized construction.

Surface treatment is a key link in the anti-corrosion of steel columns. In marine, chemical, and high-humidity environments, galvanizing or weathering steel treatment can effectively extend the service life, while painting can provide basic protection. Reasonable manufacturing and surface treatment processes can improve the durability and adaptability of steel columns.

Steel Column Structure and Load Design Parameters

The load-bearing performance of a steel column depends on its cross-section, thickness, and material grade. When designing or selecting structural columns, these parameters determine how the column resists axial and bending stresses in industrial and PEB applications.

- Thickness:

Typical column thickness ranges from 6 mm to 25 mm, depending on the height of the building and the load it supports. Heavier industrial structures may require thicker box or H-section columns for added stiffness and stability. - Material Grade:

Common steel grades include Q235B, Q355B, ASTM A36, and ASTM A572. Higher-strength steels are recommended for tall or seismic-resistant buildings. - Section Form:

Steel columns are generally produced as H-sections, box columns, or lattice columns.- H-section columns are widely used for workshops and warehouses.

- Box columns provide higher torsion resistance for heavy-load zones.

- Lattice or cruciform columns are chosen for architectural or seismic applications.

Properly designed column steel structures ensure stability under combined axial and bending stress, maintaining both safety and efficiency throughout the building’s lifespan.

Installation and Maintenance of Steel Columns

The installation of steel columns includes several key steps such as transportation, lifting, and fixing. It is necessary to ensure accurate alignment and secure connections during assembly to prevent installation errors. Safety measures must always be implemented, including the use of anti-fall equipment and load control during lifting operations to minimize the risk of accidents.

During maintenance, regular inspections of anti-corrosion coatings, bolted joints, and welded seams are essential to prevent rust and degradation. In high-temperature environments, fire-resistant coatings or refractory materials can be applied to improve fire resistance and ensure long-term safety.

To guarantee accuracy and quality, installation layout and leveling should comply with design drawings and international construction standards. Routine maintenance schedules help extend the service life of both the columns and the overall structure.Our engineering team follows AISC, GB, and Eurocode standards for column installation and inspection. For overseas projects, SteelPRO PEB provides on-site installation guidance and after-sales support, ensuring precise alignment and long-term performance of every steel structure.

Principles of Layout of Steel Columns in Steel Structures

In steel structure design, it is crucial to arrange steel columns reasonably to ensure the stability, load-bearing capacity and economy of the structure. The following are key layout principles:

Building space and use requirements: The layout should meet the functions of indoor space, such as avoiding main passages, elevator shafts, and lighting areas to ensure convenience of use.

Load requirements: Calculate the required load capacity based on the building function, floor and use. Ensure that the column can withstand the expected load (self-weight, live load, wind load, earthquake) and maintain stability. Select the column type accordingly – short columns bear axial loads, and long columns require buckling analysis.

Section type selection

- Solid sections (I-beams, channel steels) are suitable for light loads and small spans.

- Hollow sections (circular, rectangular tubes) provide high strength and lightness for large spans.

- When needed, built-up sections can be welded for added strength.

Buckling and stability: Long columns are susceptible to buckling, depending on their length, shape, materials, and bracing. Use effective length factors to ensure stability. Short columns focus primarily on axial load capacity.

Steel type selection: Choose based on strength, corrosion resistance, and fire resistance—options include carbon steel, low-alloy steel, and high-strength steel.

Fire protection: Fire weakens steel; apply fire-resistant coatings or cladding to maintain structural integrity in high-temperature environments.

Seismic design: In earthquake-prone areas, improve seismic performance with buckling-restrained braces or dampers to enhance durability.

Cost and construction feasibility: Balance material and labor costs. Prefabricated or standard steel sections can reduce expenses and simplify installation.

Environmental suitability: Use corrosion-resistant steel or coatings in wet/marine areas. Consider thermal expansion and contraction in extreme temperatures.

Comply with standards: Ensure compliance with AISC, European, and Chinese building codes to ensure structural safety and performance.

If you need expert guidance on how to choose the right steel columns, feel free to contact us!

What is the Use of Steel Columns?

Steel columns are essential components in modern construction, providing strong and flexible support for a variety of structural systems such as high-rise buildings, industrial facilities, and bridges.

In high-rise construction, steel columns form the main load-bearing framework, supporting floors and roofs while maintaining structural stability under vertical and lateral loads. They are also widely used in bridge engineering, serving as piers and supports to distribute dynamic and static loads safely to the foundation.

In industrial applications, steel columns play a key role in warehouses, factories, logistics centers, and workshops, where long spans and heavy loads require high-strength structural support. The use of prefabricated and modular steel columns allows for faster assembly and lower labor costs while maintaining precision and safety.

In addition to traditional structures, steel columns are widely used in prefabricated warehouses, PEB factories, and modular workshops for their strength and rapid installation advantages. If you are planning an industrial warehouse, PEB factory, or steel frame building, our engineering team can provide customized design assistance and load optimization to improve efficiency and reduce overall project cost.

What type of steel grade is best for columns?

Carbon steel such as Q235B, Q355B, or ASTM A36 is most commonly used due to its high strength and cost efficiency. For humid or marine environments, stainless or alloy steel provides enhanced corrosion resistance and longer service life.

What is the best shape for a steel column?

The optimal shape depends on the application. H-beam (I-beam) columns are ideal for general building frames due to their strength and material efficiency, while box or tubular columns offer superior torsion resistance, making them suitable for heavy industrial and high-rise structures.

How thick should a steel column be?

The thickness depends on the design load and structure height. For small buildings, thickness may start at 6–8 mm, while industrial or multi-storey structures often require 16–25 mm. It’s best to consult a structural engineer to confirm the correct section size and safety factor.

What are the standard specifications for steel columns in industrial buildings?

Standard steel column specifications range from H200×200×8×12 mm to H400×400×16×25 mm depending on the load, span, and design type. In PEB or modular construction, box columns and lattice columns are often used to achieve high stiffness and structural efficiency.

How do I choose between box and H-beam columns?

Choose H-beams for lighter structures or shorter spans where economy is key. Use box columns for heavy loads, long spans, or when torsion resistance is crucial (e.g., crane-support frames, tall warehouses). Box sections also provide better fire resistance and aesthetic uniformity for architectural projects.

What is the difference between a steel beam and a steel column?

Columns transfer vertical loads to the foundation, while beams carry horizontal loads between supports. Both are essential for the stability and rigidity of any steel structure, but they serve different roles in the frame system.

Get Expert Support for Your Steel Column Project

Need expert guidance on choosing steel columns for your next warehouse, factory, or industrial building project? Our engineering team provides customized design support, precise structural detailing, and complete fabrication and installation services.

As a certified steel structure manufacturer, SteelPRO PEB delivers high-quality components with factory-direct pricing, ensuring efficiency, strength, and reliability from design to installation.Contact us today to discuss your project specifications or request a free consultation — our engineers are ready to help you build with confidence.