A metal cladding system is an outer covering made from steel or aluminum panels that protects and enhances modern buildings. At SteelPRO PEB, we specialize as a Steel Structures & PEB Manufacturer and Cladding Producer, offering factory-direct, wholesale-certified cladding systems for industrial warehouses, agricultural facilities, and commercial projects worldwide.

These systems not only protect against weather, fire, and corrosion but also improve insulation, reduce noise, and add architectural value. With flexible installation methods and multiple design options, our cladding solutions are ideal for PEB structures, steel frame warehouses, and agricultural buildings where durability and cost-effectiveness are essential.

By choosing SteelPRO PEB, clients benefit from certified quality, competitive wholesale pricing, and direct support from the manufacturer.

What is a Metal Cladding System?

A metal cladding system is a type of outer covering made from metal materials that is used on building walls or roofs. It usually includes metal panels, supporting structures, and connectors. These systems are designed to protect buildings from weather, improve insulation, reduce noise, and enhance the overall look of a building. Many metal panels are flexible and can be shaped in different ways, allowing for a variety of installation methods and design options.

Metal cladding systems are an important part of a building’s exterior and help improve the building’s performance. When paired with glass and glazing materials, they can boost energy efficiency, soundproofing, and aesthetic appeal. This makes metal cladding popular for large projects like industrial plants, commercial buildings, sports stadiums, and airports.

Key functions include:

- Building Protection: Metal cladding protects buildings from natural elements such as wind, rain, and UV rays. It also serves as a rain-screen system, helping to prevent water from penetrating the building. To understand how steel structures enhance this protection, refer to our hub article on steel structure systems.

- Insulation: Metal cladding systems improve thermal insulation, helping to keep buildings warmer in winter and cooler in summer. They also reduce noise transmission, making spaces more comfortable.

- Design Flexibility: Thanks to their malleable nature, metal panels can be shaped and installed in various ways, offering a wide range of design options to fit different architectural styles.

- Fire Resistance: Some metal cladding materials, like aluminum and steel, provide excellent fire resistance, which helps improve the safety of buildings.

- Privacy and Security: Metal cladding can offer extra privacy and security by providing an additional barrier against unauthorized access, depending on the type and installation method.

Different Types of Metal Cladding Systems

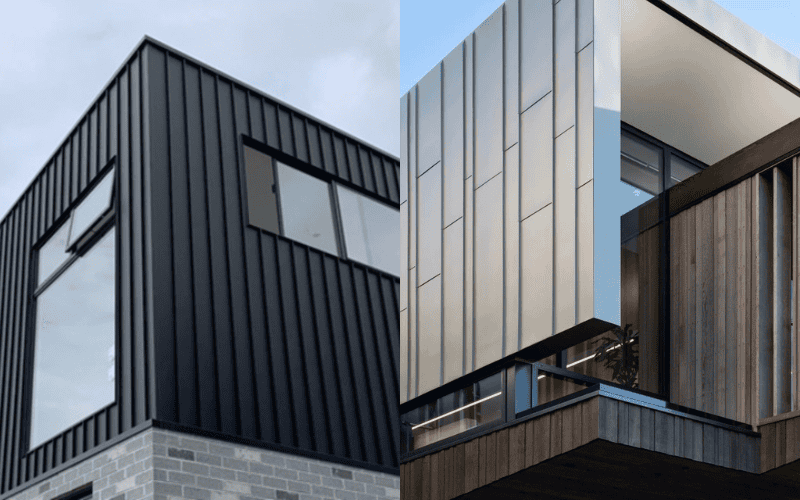

Metal cladding systems can be categorized into various types based on the connection methods and installation techniques of metal panels. Below are some common types of metal cladding systems:

Standing Seam: Raised seams connect metal panels, forming a screw-free, waterproof surface. Ideal for large roofs and high-wind areas, it’s commonly used in commercial, public, and residential buildings. Available in materials like aluminum, stainless steel, and weathering steel (Cor-ten), offering both durability and aesthetic flexibility. This system is particularly popular in steel roof systems due to its ability to withstand extreme weather conditions and provide long-lasting protection.

Snaplock: Metal panels “snap” together without special tools, making installation quick and cost-effective. It is suitable for small to medium-span roofs and walls and is widely used in residential and small commercial spaces. Known for its ease of installation and reliable waterproofing.

Interlocking: Panels fit tightly, offering smooth seams and excellent water resistance. They can be arranged horizontally, vertically, or diagonally. Commonly used in industrial and agricultural buildings, it provides both structural reliability and design flexibility.

Flatlock: Panels create a sleek, flush surface with geometric patterns, and can be installed in reverse for deeper seams. Ideal for decorative applications like cultural buildings and high-end residences, offering both aesthetic appeal and long-term durability.

Nailstrip: Hidden clips secure metal panels, creating a screw-free surface. It is often used in modern commercial projects and combines excellent waterproofing with a sleek, minimalist appearance.

Shingle: Metal panels are folded into tile-like shapes, creating a shingled look. Highly decorative, it’s used for smaller areas or complex surfaces like roofs of cultural buildings or high-end residences, offering both style and durability.

Batten Seam: Horizontal battens secure panels, forming a continuous waterproof surface with strong wind resistance. Ideal for large-span roofs in commercial, public, and residential buildings, especially in extreme weather areas.

Custom Folding: Tailored panels for unique design and connection methods. Often used in high-end commercial, cultural, and exhibition projects, offering high design flexibility but at a higher cost due to custom nature.

Steel cladding systems are widely applied in industrial warehouses, agricultural buildings, and commercial PEB structures due to their durability, weather resistance, and cost-effectiveness.

In particular, steel frame wall cladding is frequently used in warehouses and farm buildings, offering strong protection and long service life with factory-certified panels from SteelPRO PEB.

Common Materials for Metal Cladding Panels

The choice of materials for metal cladding systems directly affects their performance, appearance, and suitability. Different metal materials have unique advantages and limitations, and the selection should consider project requirements, climatic conditions, budget, and aesthetic preferences. Below are some common materials used in metal cladding systems:

Stainless Steel

Advantages: Stainless steel naturally forms a thin chromium oxide film on its surface, which prevents oxidation and corrosion, giving it excellent rust resistance. Its smooth, polished appearance makes it an ideal choice for modern architecture, especially for projects requiring high durability and aesthetics.

Limitations: Stainless steel is relatively expensive and may be prone to pitting corrosion in high-chloride environments, such as coastal areas. Additionally, its surface is susceptible to fingerprints and scratches, requiring regular maintenance to retain its appearance.

Galvanized Steel

Advantages: Galvanized steel is coated with a layer of zinc, which protects the underlying steel from rust through sacrificial protection. The crystalline structure of the zinc coating gives the material a unique “spangle” texture, adding a decorative touch. This material is cost-effective and suitable for budget-conscious projects.

Limitations: The durability of the zinc coating is limited and may wear over time, especially in highly corrosive environments. Additionally, its appearance is relatively simple and may not be suitable for high-end or decorative projects.

Weathering Steel

Advantages: Also known as COR-TEN steel, weathering steel forms a stable rust layer when exposed to natural elements, providing protection without the need for additional painting. Its distinctive rusted appearance gives buildings an industrial aesthetic.

Limitations: The rust layer may cause staining on surrounding surfaces, such as vegetation or other building materials. Additionally, the rusting process takes time, and the initial appearance may be uneven.

Aluminum

Advantages: Aluminum is naturally resistant to rust and corrosion, and its lightweight yet strong nature makes it suitable for modern architectural projects. Its excellent strength-to-weight ratio allows for simpler support structures in cladding systems.

Aluminum cladding is lightweight and widely used in industrial warehouses, agricultural facilities, and commercial wall systems. For large-scale PEB projects, it offers a cost-effective solution without compromising durability, making it a popular choice for factory and farm buildings supplied by SteelPRO PEB.

Limitations: Aluminum is prone to scratching and denting and may corrode in certain environments, such as high-salinity areas. Additionally, it has a higher thermal expansion coefficient, requiring careful design to accommodate movement.

What types of aluminum cladding systems are available?

Aluminum cladding can be applied in standing seam, interlocking, and composite panel systems, depending on project needs and architectural design.

How to choose between aluminum and steel cladding for industrial projects?

Steel cladding provides superior strength and fire resistance, while aluminum cladding offers lightweight efficiency and cost-effectiveness. For PEB and agricultural buildings, SteelPRO PEB recommends selecting based on budget, load requirements, and environmental conditions.

Titanium

Advantages: Titanium is favored by architects for its lightweight, high strength, and glossy, reflective surface. Over time, a protective oxide film forms on its surface, enhancing its corrosion resistance.

Limitations: Titanium is extremely expensive and difficult to process, making it suitable only for high-end projects. Additionally, its surface requires regular maintenance to prevent staining or discoloration.

Zinc

Advantages: Zinc is highly weather-resistant and corrosion-resistant, capable of withstanding UV damage. Its oxide layer provides stability and can maintain protective properties even after minor scratches. Zinc develops a unique bluish-gray patina over time, adding character to buildings.

Limitations: Zinc requires careful handling during installation due to its softness, which may lead to panel deformation. Additionally, its initial cost is relatively high, and it may corrode faster in areas with high acid rain levels.

Copper

Advantages: Copper is a lightweight and durable material with excellent corrosion resistance. Over time, its surface oxidizes to form a distinctive green patina, giving buildings a historical and natural aesthetic. Copper is also 100% recyclable, aligning with sustainable development principles.

Limitations: Copper is expensive, and its oxidation process may cause staining on adjacent surfaces, such as stone or concrete. Additionally, its softness makes it susceptible to scratches and dents.

Brass

Advantages: Brass strikes a balance between the cool tones of zinc and the warm hues of copper. It is highly malleable, making it suitable for intricate decorative designs. Over time, brass develops a golden-brown patina as its surface oxidizes, adding unique charm to architectural projects.

Limitations: Brass is relatively expensive, and its oxidation process may result in uneven coloration. Additionally, its lower hardness makes it prone to scratches and wear.

Metal Cladding vs. Other Materials

When selecting an exterior cladding system, metal is just one of many available materials. Other common options include concrete panels, brick, glass, and composite panels. Each material has distinct advantages and limitations, making it essential to compare their performance based on factors such as durability, weight, insulation, and maintenance.

| Material | Durability | Weight | Thermal Insulation | Maintenance | Aesthetic Variety |

| Metal Cladding | High (corrosion-resistant metals like stainless steel and aluminum perform well) | Lightweight | Low (requires insulation layers) | Low (resistant to rot, but may require occasional cleaning) | High (various finishes, patterns, and coatings available) |

| Concrete Panels | Very High (extremely durable and fire-resistant) | Heavy | High (good thermal mass) | Moderate (can crack over time, requiring repairs) | Moderate (limited texture and finish options) |

| Brick and Masonry | Very High (long lifespan, weather-resistant) | Heavy | High (natural insulation) | Low (requires minimal maintenance) | Moderate (traditional aesthetics, but limited variety) |

| Glass Curtain Wall | Moderate (prone to breakage and weathering) | Heavy | Low (poor insulation unless double-glazed) | High (regular cleaning required) | High (modern and sleek appearance) |

| Composite Panels | Moderate (depends on core material, but generally weather-resistant) | Lightweight | Medium (insulation properties vary) | Moderate (may require recoating over time) | High (available in multiple textures and colors) |

Key Takeaways

- Metal cladding stands out for its lightweight nature, design versatility, and low maintenance compared to other materials.

- Concrete and brick offer excellent durability and insulation, but their heaviness increases structural load and installation complexity.

- Glass curtain walls provide a modern aesthetic, but require frequent maintenance and lack insulation.

- Composite panels balance lightweight properties and insulation, but may not be as durable as solid metal options.

When choosing a cladding material, it is essential to consider project-specific requirements, including structural capacity, energy efficiency, climate conditions, and long-term maintenance costs.

Factors to Consider When Choosing Metal Cladding Systems

When selecting a metal cladding system, it is essential to consider multiple factors to ensure its performance, aesthetics, and cost-effectiveness align with project requirements. Below are some key considerations:

Durability

While metal materials are generally highly durable, their hardness varies significantly. For example, aluminum and zinc are relatively soft and prone to scratches or dents, whereas stainless steel and titanium are more robust. When selecting materials, consider the environmental conditions of the project location (e.g., wind, rain, hail) and the expected lifespan of the building. Communicate with manufacturers to clarify durability requirements and ensure the most suitable material is chosen.

Fire Resistance

Metal materials typically offer good fire resistance, but selecting materials that meet the required fire rating for the project is crucial. Additionally, the compatibility of metal cladding with other building materials must be carefully evaluated to avoid potential fire risks. This is particularly important for high-rise buildings, where all materials must comply with safety standards.

Thermal Insulation

Metal cladding systems alone contribute little to the overall thermal insulation of walls. Insulation boards are often required on the exterior of walls to enhance thermal performance. If the project has strict U-value (thermal transmittance) requirements, collaborate with specialized manufacturers to select a system that meets insulation needs.

Acoustic Insulation

Metal cladding systems provide limited sound insulation between the external and internal environments. When selecting a system, consider the acoustic performance of wall infill materials, such as the Rw rating (weighted sound reduction index) or STC (sound transmission class), to ensure the building meets overall acoustic requirements.

Environmental Impact

For large-scale projects, the environmental impact of materials is a critical consideration. Evaluate the material’s impact throughout its lifecycle, including manufacturing, installation, and long-term maintenance. A life cycle assessment (LCA) can provide a comprehensive evaluation to help select the most environmentally friendly cladding system.

Wind Action

Cladding systems must withstand wind loads and transfer them to the main building structure. Refer to relevant standards (e.g., Chapter 30 of ASCE 7-10) to determine wind load impacts and select materials and connection methods that meet wind resistance requirements.

Expansion and Contraction

Some metal materials expand and contract with changes in temperature, humidity, and pressure. If not properly selected, this can lead to permanent building damage. Choose materials suitable for the project’s climate and incorporate design details such as expansion joints to accommodate movement.

Aesthetics and Design

The appearance of metal cladding significantly impacts the overall aesthetics of a building. Different materials (e.g., stainless steel, copper, zinc) offer unique textures and finishes, so select materials that align with the architectural style and design intent. Additionally, the connection method (e.g., standing seam, flat lock) influences the final visual effect.

Cost and Budget

SteelPRO PEB provides factory-direct wholesale pricing for steel and aluminum cladding systems, helping reduce overall project costs compared with third-party distributors. This ensures clients receive certified quality at competitive rates, whether for industrial warehouses or agricultural buildings.

Installation

Proper installation is critical to ensure the durability, weather resistance, and safety of cladding systems.

For agricultural and industrial projects, cladding installation must follow certified procedures to handle wind loads, thermal expansion, and long-term wear.

SteelPRO PEB supports clients with installation guidance and technical assistance, ensuring that every cladding system meets international standards and performs reliably throughout its lifespan.

Metal Cladding Construction: Process & Key Considerations

Metal cladding construction involves the installation of metal panels on a building’s exterior to enhance durability, aesthetics, and insulation. The process includes careful planning, substructure preparation, panel fixing, and finishing treatments to ensure long-term performance. The construction method varies depending on the type of cladding system used, building design, and environmental conditions.

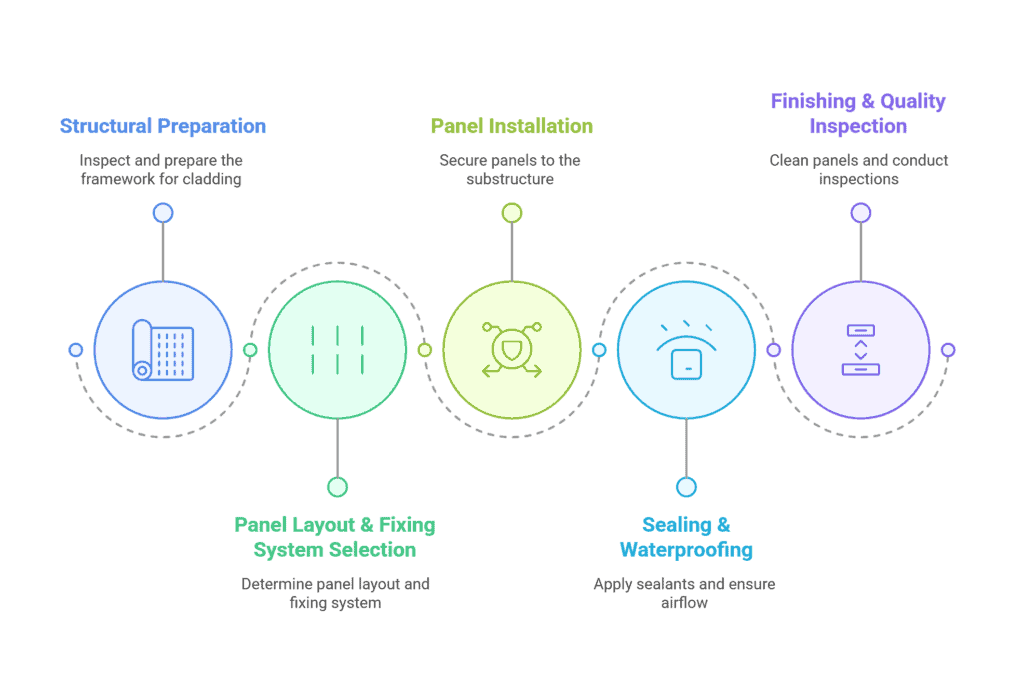

Step-by-Step Metal Cladding Construction Process

The installation of metal cladding generally follows these key steps:

1. Structural Preparation

- Inspect the primary framework to ensure it can support the cladding system.

- Install necessary insulation layers and waterproof membranes if required.

- Set up the substructure (usually aluminum or galvanized steel) to provide attachment points for the panels.

2. Panel Layout & Fixing System Selection

- Determine the best panel layout to optimize aesthetics and minimize material waste.

- Choose a suitable fixing system:

- Visible fixing: Screws or rivets exposed on the panel surface.

- Concealed fixing: Panels interlock or use hidden fasteners for a sleek look.

3. Panel Installation

- Secure panels to the substructure using the selected fixing system.

- Ensure expansion gaps are included to accommodate temperature-induced movement.

- For standing seam or interlocking systems, use specialized tools to secure seams tightly.

4. Sealing & Waterproofing

- Apply sealants or weatherproofing tapes at joints to prevent moisture infiltration.

- For ventilated cladding systems, ensure proper airflow behind the panels to prevent condensation.

5. Finishing & Quality Inspection

- Clean panel surfaces and remove protective films.

- Inspect for alignment, fastening security, and overall visual consistency.

- Conduct weather resistance and fire protection checks as required.

Key Considerations in Metal Cladding Construction

When planning a metal cladding system, the following factors must be considered to ensure structural integrity and long-term durability:

- Wind Load Resistance

Metal cladding must be designed to withstand high wind loads, especially for large industrial and commercial buildings. Fasteners and substructure materials should be chosen based on regional wind pressure regulations. - Thermal Expansion & Contraction

Metals expand and contract due to temperature changes. Expansion joints must be incorporated to prevent buckling or warping over time. - Moisture & Corrosion Protection

Cladding systems should have adequate drainage and ventilation to prevent moisture accumulation, which can lead to corrosion. Selecting coated or corrosion-resistant metals (such as aluminum or stainless steel) is crucial for humid or coastal environments. - Fire Safety Compliance

Fire resistance ratings vary depending on the metal type and any additional insulation layers. Cladding systems must comply with local fire safety regulations, particularly for high-rise buildings. - Maintenance & Durability

While metal cladding requires minimal maintenance, periodic inspections are essential to check for loose fasteners, scratches, or surface oxidation. Protective coatings can be applied to enhance longevity.

Key Takeaways

- Metal cladding construction involves multiple stages, including structural preparation, panel installation, sealing, and quality inspection.

- Choosing the right fixing system, considering wind load resistance, and allowing for thermal movement are essential for a long-lasting cladding system.

- Proper moisture control, fire safety compliance, and routine maintenance enhance the durability and performance of metal cladding systems.

Benefits of Metal Cladding in Industrial & Commercial Buildings

Metal cladding systems are widely used in modern construction due to their exceptional functionality, cost-effectiveness, and aesthetic appeal.

Particularly for PEB structures, warehouses, and agricultural buildings, steel cladding systems from SteelPRO PEB provide certified quality with factory-direct wholesale supply, ensuring both performance and cost savings.

Below are the key benefits of using metal cladding systems:

- Provides strong protection against water and fire, enhancing the safety and durability of the building.

- Helps maintain a comfortable indoor temperature by improving insulation, reducing energy use and operational costs.

- Resistant to corrosion and wear, requiring minimal maintenance, which saves on long-term upkeep costs.

- Standardized installation process that speeds up construction, saving time and reducing delays.

- Available in various materials, shapes, and finishes, making it easy to match different architectural styles.

- Reduces the structural load, ideal for retrofitting or projects with strict weight requirements.

- Made from recyclable materials, helping reduce the environmental impact over the building’s lifecycle.

- Suitable for both new builds and renovations, providing modern performance while preserving the original design.

Future Trends in Architectural Metal Cladding Systems

As architecture and construction industries continue to evolve, metal cladding systems are undergoing significant advancements driven by sustainability, smart technology, and innovative materials. These trends are shaping the future of building facades, making them more efficient, durable, and environmentally friendly.

1. Sustainability & Eco-Friendly Materials

With the increasing demand for green buildings, the use of recyclable metals, energy-efficient coatings, and reduced carbon footprint manufacturing processes is becoming a key trend.

- Recycled and Upcycled Metals: More manufacturers are focusing on using recycled aluminum, steel, and copper, reducing resource extraction and waste.

- Energy-Efficient Coatings: Advanced coatings, such as cool roofing finishes and solar-reflective paints, help reduce heat absorption, enhancing building energy efficiency.

- Carbon-Neutral Production: Manufacturers are adopting low-emission production methods and integrating metal cladding systems into sustainable certifications like LEED (Leadership in Energy and Environmental Design).

Zinc and aluminum are 100% recyclable, making them highly sustainable choices for cladding systems.

2. Smart & Self-Sustaining Cladding Systems

New technologies are integrating functionality and intelligence into metal cladding systems.

- Self-Cleaning Coatings: Hydrophobic (water-repellent) and self-cleaning nano-coatings are being developed to reduce maintenance and keep facades clean from pollutants.

- Integrated Solar Panels: Building-Integrated Photovoltaics (BIPV) allow cladding panels to generate electricity while serving as protective building facades.

- Adaptive Facades: Some next-generation metal cladding systems incorporate dynamic materials that adjust reflectivity based on temperature and sunlight exposure, improving thermal regulation.

Smart cladding with photovoltaic coatings can generate electricity while protecting the structure, making it ideal for net-zero energy buildings.

3. Lightweight & High-Performance Materials

The demand for strong yet lightweight materials is pushing the development of next-generation alloys and composite metal panels.

- Ultra-Lightweight Metal Alloys: New formulations in titanium-aluminum alloys and magnesium composites improve strength while reducing overall weight.

- Antibacterial & Air-Purifying Surfaces: Some advanced coatings now feature antimicrobial properties, preventing bacterial growth—especially beneficial for healthcare and commercial buildings.

- Corrosion-Resistant Innovations: Next-gen superhydrophobic coatings repel water and resist salt damage, making them ideal for coastal and humid environments.

Titanium-clad buildings offer long-lasting durability with minimal maintenance, making them an emerging choice for high-end commercial facades.

4. Prefabrication & Modular Construction

To improve construction efficiency and reduce on-site labor costs, modular metal cladding systems are gaining traction.

- Factory-Preassembled Panels: Prefabricated metal panels are produced in controlled environments, ensuring higher quality, faster installation, and lower waste.

- 3D-Printed Metal Facades: With the rise of additive manufacturing (3D printing), complex metal facade designs can now be custom-produced with reduced material waste.

Prefabricated modular cladding panels enable faster assembly, reducing project timelines by up to 30% compared to traditional on-site installation.

Key Takeaways

- Sustainability is a major driver in metal cladding development, with a focus on recyclable materials and energy-efficient coatings.

- Smart technology integration, including self-cleaning coatings and solar cladding, is transforming metal facades into functional building elements.

- Lightweight, high-performance materials like ultra-durable alloys and antimicrobial surfaces are expanding cladding applications.

- Modular and prefabricated construction methods are making metal cladding systems more cost-effective and efficient for large-scale projects.

As innovation continues, metal cladding systems will play an increasingly vital role in modern, energy-efficient, and sustainable architecture.

Want to Know More?

Contact SteelPro Group today to get a factory-direct quote for certified steel & PEB cladding systems. We provide wholesale supply solutions for industrial, agricultural, and commercial projects worldwide.