A steel structure bracing system is the core framework that keeps industrial and PEB buildings stable under wind and seismic forces. It connects beams, columns, and walls to control lateral movement — ensuring that steel structures stay strong, efficient, and safe.

This guide explains what bracing is, the main types of bracing systems used in steel and PEB structures, the key design principles and load guidelines, and a step-by-step process for designing industrial bracing systems. You’ll also see real-world applications across factories, warehouses, and modular buildings, and learn why SteelPRO PEB is a trusted global supplier of engineered bracing systems.

Whether you’re designing a new steel workshop or upgrading an existing PEB structure, understanding how different bracing systems work — and how to select the right one — is essential to achieving strength, safety, and long-term performance.

What is Bracing in Steel Structures?

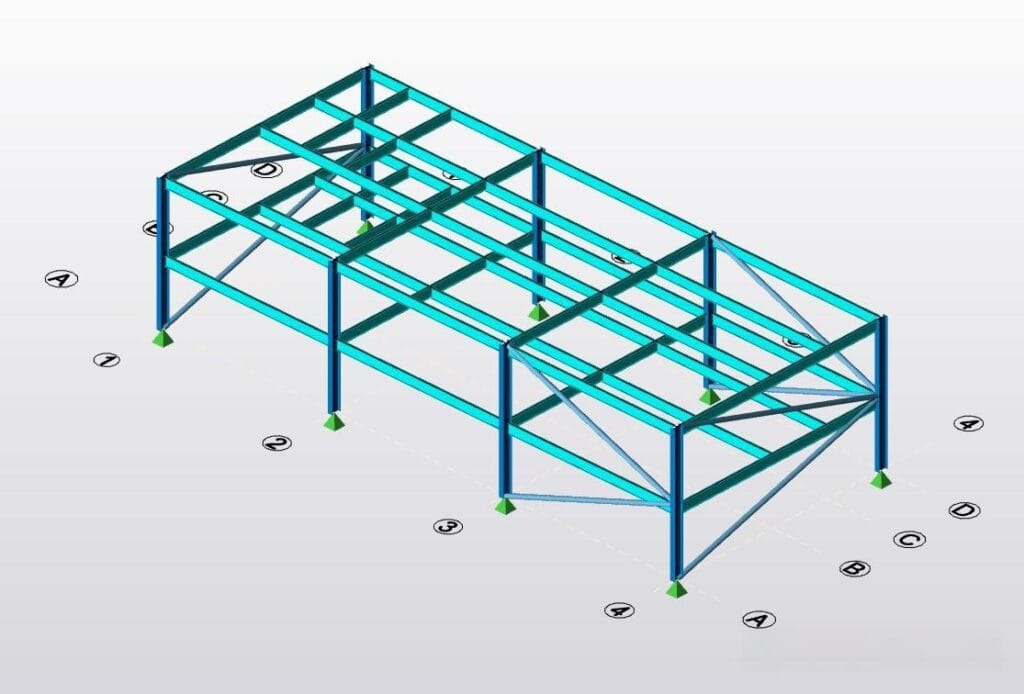

Bracing in steel structures is a primary system designed to resist lateral forces like wind and seismic loads. It consists of diagonal members that prevent deformation and ensure stability. Bracing is categorized into horizontal (lateral) and vertical types. Horizontal bracing resists lateral forces, while vertical bracing addresses vertical loads. Bracing is essential in high-rise buildings, large-span structures, and seismic zones, providing critical stability in industrial buildings, office towers, and large warehouses.

Types of Bracing Systems in Steel Structures (With PEB Applications)

When it comes to steel bracing structures, the support system isn’t one-size-fits-all. It’s part of steel structure systems tailored to meet the specific needs of the project, considering factors like architecture, load distribution, and environmental conditions.

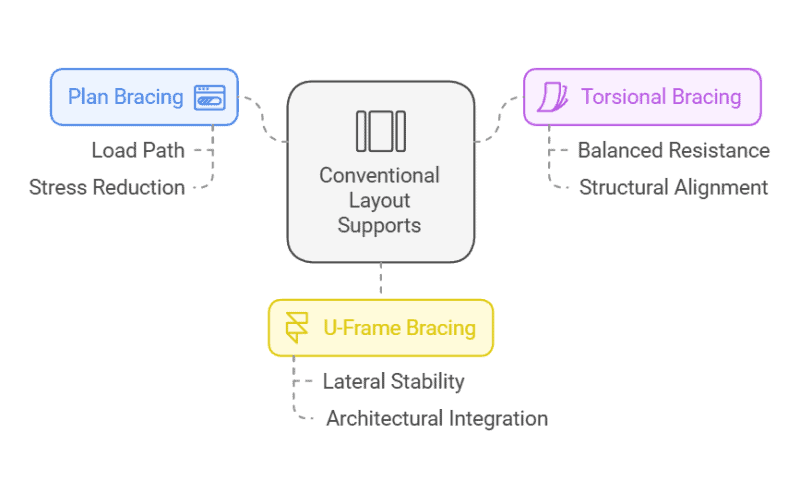

Conventional Layout Supports

These traditional supports are the backbone of many steel bracing structures, delivering the stability and load distribution needed to keep everything secure and efficient.

Plan Bracing

Plan bracing is a core system that ensures loads are evenly distributed across the structure, keeping it stable under both vertical and horizontal forces. For it to work effectively, the bracing needs to be positioned carefully to create a direct load path, reducing stress points and avoiding deformation. This approach is especially crucial for large-span structures, where poor load distribution can lead to serious structural issues.

Torsional Bracing

Torsional bracing is key to resisting twisting forces, which are common in asymmetrical or irregular structures. The bracing must be set up to offer balanced resistance, ensuring the structure stays aligned under torsional stresses. This becomes vital in buildings with complex shapes, where failure to address torsional forces can severely affect structural stability.

U-Frame Bracing

U-frame bracing is ideal for structures with open facades or large openings, where lateral stability is critical. The bracing needs to blend seamlessly with the architectural design, offering strong resistance to wind loads and other horizontal forces, all while keeping the design intact. Achieving this balance between strength and aesthetics is crucial to ensuring both structural integrity and visual appeal.

Lateral Support Systems

Lateral supports are crucial in resisting horizontal forces, making sure steel bracing structures stay stable and safe, no matter what load conditions they face. Horizontal bracing systems, including column bracing, are often incorporated alongside systems like cross bracing (X-bracing), K-bracing, and V-bracing to further reinforce structural stability.

Cross Bracing (X-Bracing)

Cross bracing, or X-bracing, uses a diagonal design to spread horizontal loads—like wind or seismic forces—across the structure. For it to work its best, the bracing should be perfectly aligned to create a clear, uninterrupted path for the load, reducing stress points and boosting overall stability. This system is especially ideal for industrial and commercial buildings, where simplicity and reliability are key.

K-Bracing

K-bracing uses a triangular design to boost structural rigidity, making it perfect for high-rise buildings. To get the most out of it, the bracing needs to be placed in a way that optimizes load transfer—this cuts down on material use while still providing strong resistance to lateral forces. Not only does this approach improve performance, but it also helps reduce construction costs, making it an efficient choice for tall, slender structures.

V-Bracing

V-bracing, with its distinctive V-shaped design, strikes a perfect balance between strength and flexibility, making it a standout choice for dynamic environments like bridges and industrial facilities. The key is to design the bracing to handle heavy loads while allowing for structural movement, ensuring it stays durable even under unpredictable conditions. This adaptability is what makes it such a versatile solution—whether you’re dealing with steady loads or the occasional shake-up, V-bracing has got you covered.

Longitudinal Support Systems

Longitudinal supports are key to keeping the structure intact along the length of a building. They ensure stability and help the structure stay resilient against both vertical and lateral forces. Vertical bracing systems are commonly used in this context to enhance resistance to vertical loads and maintain overall structural integrity.

Center Bracing

Center bracing provides steady stability along the building’s central axis, making it a game-changer for high-rise structures. For it to work best, the bracing should be perfectly aligned along the center, helping to evenly distribute the load and reduce any sway or deformation. This setup is especially useful for tall, slender buildings, where balanced support is critical to withstand wind and seismic forces. By focusing on alignment and efficient load paths, center bracing ensures reliable performance, even in the toughest conditions.

Eccentric Bracing

Eccentric bracing is designed to boost seismic resilience, making it a must-have in earthquake-prone areas. Its offset design needs to be placed strategically to absorb and dissipate energy during seismic events, keeping the structure safe and stable. This approach not only enhances safety but also ensures the building stays functional, even under extreme conditions. For projects in dynamic environments, eccentric bracing provides a strong, adaptable solution that stands the test of time.

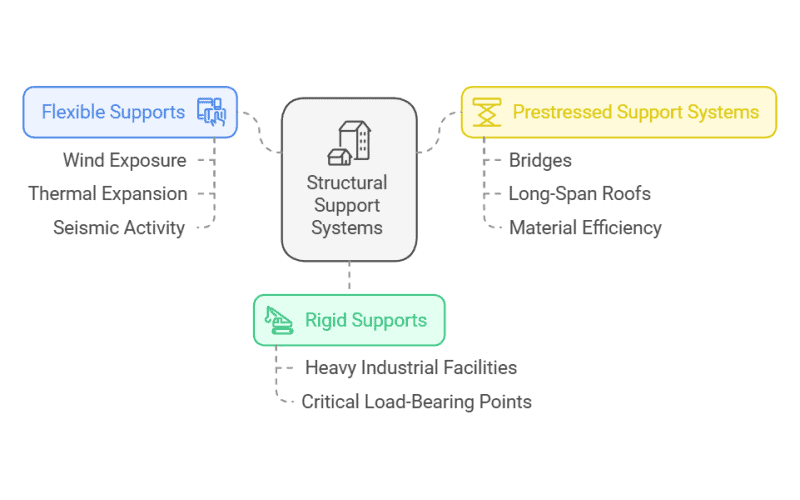

Other Support Systems

Beyond the usual lateral and conventional supports, there are other systems designed for specific structural needs, offering unique benefits tailored to the project requirements.

Rigid Supports

Rigid supports provide unbeatable stability, making them perfect for structures that need minimal movement under load, like heavy industrial facilities. To get the most out of them, rigid supports should be placed where precision and strength are non-negotiable, such as at critical load-bearing points. However, their lack of flexibility makes them less ideal for environments with dynamic or unpredictable forces, where adaptability is essential.

Flexible Supports

Flexible supports are built to handle movement, making them perfect for structures exposed to wind, thermal expansion, or seismic activity. The design should strike a balance between flexibility and enough stiffness, ensuring the structure adapts to changing conditions without sacrificing durability. While they may not offer the same rigidity as other systems, their ability to absorb and redistribute forces makes them essential in dynamic environments.

Prestressed Support Systems

Prestressed support systems work by introducing internal stresses to counterbalance external loads, boosting structural efficiency and cutting down on material usage. Preloading needs to be carefully calibrated to match expected loads, ensuring the system performs at its best in real-world conditions. This approach is especially effective for large-span projects, like bridges and long-span roofs, where it enhances load-bearing capacity and resilience while delivering significant cost savings.

For instance, at China’s Lingang International Convention and Exhibition Center, we leveraged prestressed support systems to achieve structural excellence and cost efficiency, demonstrating their value in large-scale, complex projects.

Applications of Bracing Systems in PEB and Steel Structures

Bracing systems are widely used in various steel structure projects to enhance stability and safety.

- Industrial Workshops and Warehouses: Large-span bracing systems that ensure wind and seismic resistance.

- Prefabricated & Modular Buildings: Lightweight bracing designed for rapid installation and easy transport.

- High-Rise Steel Towers: X- and K-bracing for lateral stability and vertical load management.

- Agricultural & Storage Facilities: Cost-effective bracing solutions for barns, sheds, and open storage structures.

SteelPRO PEB designs and manufactures customized bracing systems according to international standards (GB, AISC, Eurocode), ensuring both safety and efficiency for global construction projects.

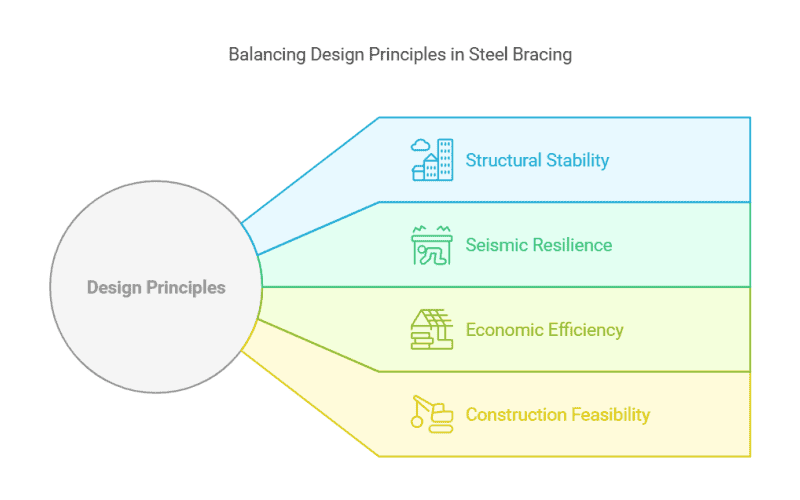

Steel Bracing Design Principles and PEB Structure Guidelines

Designing a support system for steel bracing structures is all about balancing stability, safety, and cost-effectiveness.

Structural Stability Principles

Both global and local stability are critical and must be addressed together. Global stability ensures the entire structure can resist large-scale deformations, such as leaning or swaying, while local stability focuses on preventing smaller-scale issues, like buckling or bending in individual beams or columns.

Support systems should be designed so that loads—like weight, wind, or seismic forces—travel through the structure in the shortest and most direct way possible. This reduces stress concentrations and ensures the structure remains strong and durable over time. By balancing these two aspects, the system can handle a wide range of loads, from everyday use to extreme conditions, without compromising safety or performance.

Seismic Design Principles

In earthquake-prone areas, seismic resilience is a must. Energy-dissipating bracing systems, such as buckling-restrained braces (BRBs), viscous dampers, and friction dampers, should be included to absorb and redistribute seismic forces, protecting the structure from damage.

- Buckling-Restrained Braces (BRBs): These braces are designed to buckle in a controlled way, absorbing energy without failing.

- Viscous Dampers: These act like shock absorbers, converting seismic energy into heat, which dissipates harmlessly.

- Friction Dampers: These use friction to absorb energy, sliding in a controlled manner during an earthquake.

These systems need to be carefully calibrated to balance energy absorption with the building’s functionality, ensuring it stays operational even after an earthquake. Think of them as the building’s “safety cushion,” softening the blow and keeping everything intact.

Economic Principles

Cost efficiency comes from optimizing materials and simplifying construction. Lightweight, high-strength materials like steel alloys, aluminum, and advanced composites should be prioritized. These materials cut down on weight, reducing foundation needs and transportation costs, while still ensuring strong structural safety.

Modular designs further enhance cost-effectiveness by streamlining fabrication and assembly. Prefabricated components, for example, speed up construction and lower labor costs. By combining these strategies, projects can save significantly without compromising quality or performance.

As a prefabricated steel structure builder, we can complete part of the support system assembly in our factory, saving you the hassle of on-site assembly and eliminating the extra costs of hiring an installation team.

Construction Feasibility Principles

A support system needs to be practical to build. Complex designs should be assessed for constructability early on, with feedback from construction teams to spot any potential challenges. Simplifying connections and standardizing components can cut down on construction time and costs, all while ensuring quality and precision.

Step-by-Step Bracing Design Process for Industrial Steel Buildings

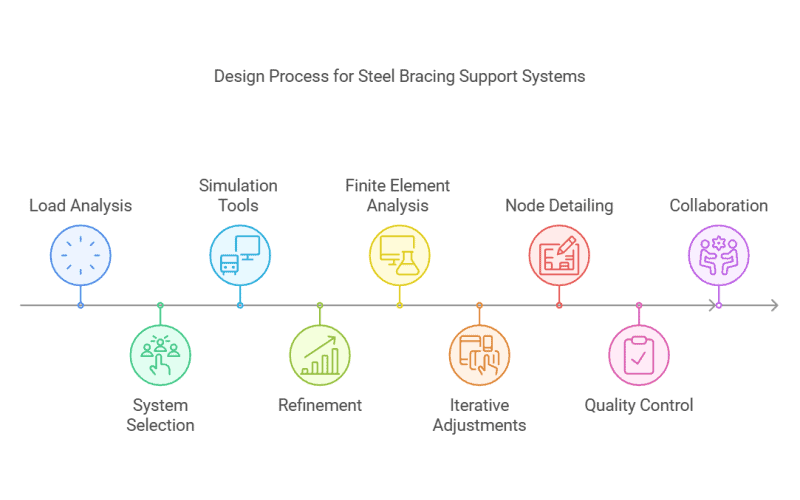

The design process for support systems is a collaborative, step-by-step journey, aimed at ensuring the best possible performance.

Preliminary Design Phase

- Load Analysis: Start by thoroughly analyzing static and dynamic loads—wind, seismic, and live loads.

- System Selection: Pick the right support system based on the load requirements and structural goals.

- Simulation Tools: Use advanced tools like computational modeling to predict how the structure will behave and validate your initial designs.

Detailed Design Phase

- Refinement: Fine-tune the design to boost performance and address any potential weak points.

- Finite Element Analysis (FEA): Run FEA to simulate the structure under different conditions, ensuring it meets both safety and performance standards.

- Iterative Adjustments: Adjust configurations based on simulation results to get the best design possible.

Construction Drawing Phase

- Node Detailing: Create detailed drawings for support nodes, ensuring accurate load transfer between components.

Quality Control: Conduct thorough checks to catch any errors that could affect structural integrity.

Collaboration: Work hand-in-hand with construction teams to make sure the design is both practical and executable.

By following this organized approach, the design process guarantees that steel bracing support systems are strong and efficient and customized to meet each project’s specific needs.

What Is a Bracing System in PEB Structure?

In PEB (Pre-Engineered Buildings), bracing systems are crucial for controlling wind and seismic loads. They connect columns, rafters, and purlins to form a rigid frame that limits lateral sway. SteelPRO designs both portal bracing and cross bracing solutions for long-span workshops and steel warehouses, ensuring overall frame stability.

How Do You Design Bracing Systems for Industrial Buildings?

Our engineers determine the bracing layout based on load analysis, span length, and building use. Using simulation tools and design codes such as GB 50017, AISC 360, and Eurocode 3, we select the optimal combination of X-, K-, or V-bracing to balance strength, cost, and constructability.

What Is the Most Effective Bracing System?

The best bracing depends on your structure type and load environment. For most industrial and PEB steel buildings, X-bracing and K-bracing offer the highest stiffness-to-weight ratio, making them ideal for resisting both wind and seismic forces.

What Are the Different Types of Wind Bracing in Steel Structures?

Wind bracing types include cross bracing, portal bracing, and moment-resisting frames. Each is applied based on the span and building height—SteelPRO provides design customization for each application.

What Is the Difference Between a Bracing System and a Grid System?

A bracing system enhances stability against horizontal loads, while a grid system defines the beam–column framework for vertical load distribution. In practical design, both systems are integrated to ensure full structural performance in PEB and industrial buildings.

Choose Us as Your Steel Structure Bracing System Supplier

SteelPRO PEB specializes in engineered bracing systems that ensure the stability and strength of steel and PEB structures. We design and manufacture every bracing component — from cross and K bracing to connection nodes — to meet precise load and seismic requirements.

Our 500-acre factory operates 24 automated lines with ISO and CE certification, delivering consistent quality across design, fabrication, and testing. Each bracing system follows GB 50017, AISC 360, and Eurocode 3 standards for guaranteed reliability.

With over 1,000 projects worldwide, we provide factory-direct, certified bracing systems tailored for industrial, commercial, and modular buildings.

Contact SteelPRO PEB for a custom bracing solution and factory quotation.