The history of steel structure development tells the story of how metal reshaped modern architecture — from early iron frameworks to the intelligent, sustainable, and high-rise steel structures that define today’s skylines. This article explores how steel evolved through key stages: its early exploration in the 18th and 19th centuries, the rise of modern skyscrapers in the early 20th century, and the post-war global expansion that transformed cities worldwide.

It also examines the technological breakthroughs — from high-strength steels and welding innovations to BIM and digital fabrication — that made these advancements possible, followed by a look at the global applications of steel in industrial, commercial, and residential buildings. Finally, it outlines the future development trends of sustainable, hybrid, and smart steel structures that are shaping the next generation of construction.

As a certified steel structure manufacturer, SteelPRO PEB continues this legacy through advanced production, green building standards, and international engineering expertise — bridging centuries of innovation with the future of global steel construction.

The Evolution of Steel Structure Buildings

1. Early Exploration (Late 18th – 19th Century)

The use of metal in construction was a groundbreaking development that set the stage for modern architecture. In the late 18th century, Britain led the charge in integrating metal, particularly cast iron, into buildings and infrastructure. At the time, cast iron was favored for its strength and fire resistance, making it a practical alternative to traditional wood and stone structures.

One of the most iconic milestones from this era was the construction of the Iron Bridge in England (1779). As the first cast iron bridge in the world, it showcased the potential of metal in construction, proving its ability to support heavy loads and span greater distances than traditional materials allowed. This innovation paved the way for future developments in iron and steel architecture.

These early innovations set the foundation for what would become the world’s first true steel structures in the late 19th century, marking the transition from the iron age to the era of modern steel construction.

The Rise of Structural Steel in the 19th Century

As industrial advancements improved metal production, the transition from cast iron to structural steel began. Engineers and architects sought materials that were stronger, more flexible, and less brittle, leading to the increasing use of wrought iron and, eventually, steel in major construction projects. This marked the beginning of a new era — the emergence of the world’s first steel buildings.

Key milestones of the 19th century include:

- 1820: First Cast Iron Building (Philadelphia, USA) – This marked the beginning of metal-framed buildings, moving beyond the use of iron solely for bridges and industrial structures. It reflected the growing confidence in metal as a structural material.

- 1828: First Steel Bridge (Vienna, Austria) – This innovation proved steel’s superior strength and flexibility compared to cast iron, laying the foundation for modern bridge engineering and demonstrating how refined steel alloys could withstand dynamic loads.

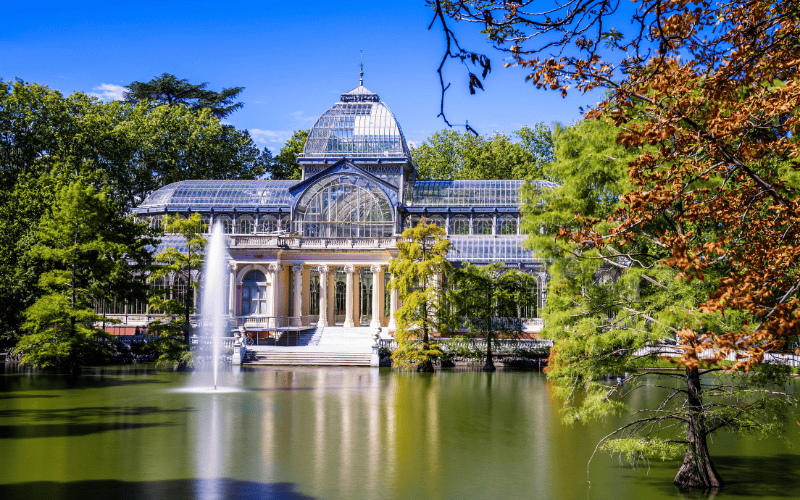

- 1851: The Crystal Palace (London, UK) – Designed for the Great Exhibition, this glass-and-iron structure revolutionized architectural design. It demonstrated the possibilities of prefabricated metal components and large-scale modular construction, influencing future engineering feats and the early concepts of pre-engineered buildings.

- 1876: The Eiffel Tower (Paris, France) – Standing at 300 meters and built with 7,000 tons of iron, the Eiffel Tower was a turning point in structural engineering, proving that metal could be used for tall, freestanding structures. It represented the culmination of iron technology before the steel revolution.

- 1889: The Rand McNally Building (Chicago, USA) – This became the world’s first all-steel framed skyscraper, a true milestone that ushered in the modern age of steel architecture. Its success demonstrated how structural steel could safely support multi-story buildings, enabling urban skylines to rise higher and stronger than ever before.

By the end of the 19th century, steel had fully replaced iron as the dominant material in large-scale architecture, thanks to its superior tensile strength, ductility, and cost-effectiveness. This transformation set the stage for the explosive growth of skyscrapers, bridges, and industrial complexes that would define the 20th century’s architectural landscape.

2. The Birth of Modern Steel Structures (Early 20th Century – Pre-WWII)

At the dawn of the 20th century, steel had firmly established itself as the foundation of modern construction. With significant advancements in steel production techniques and structural engineering, architects began pushing the limits of building height, span, and complexity. This period marked the beginning of truly modern steel structures, where strength, efficiency, and design innovation converged.

- 1909: The Berlin Turbine Factory (Germany)

Designed by Peter Behrens, this building was regarded as the first modern industrial steel structure. It showcased steel’s structural efficiency and aesthetic potential — using exposed steel frames and glass panels to achieve both strength and transparency. The factory’s minimalist, functionalist design represented a departure from traditional ornamentation and became a model for 20th-century industrial architecture. - 1931: The Empire State Building (New York, USA)

Standing at 102 stories (381 meters), this engineering marvel set a new global benchmark for skyscrapers. Built in just over a year, it became a symbol of industrial capability and the economic optimism of its era. The steel skeleton frame made it possible to build upward faster, lighter, and stronger than ever before — an innovation that defined the skyline of modern cities.

These architectural achievements represented more than just advances in building height; they reflected a transformation in how humanity conceived of architecture itself. Steel became the universal language of progress, enabling efficiency, verticality, and the mass production of architectural components.

These innovations marked the birth of the modern steel skyscraper era and laid the groundwork for the global expansion of steel construction that would follow after World War II.

3. Post-WWII Expansion of Steel Structures (Mid-20th Century – Late 20th Century)

Following the breakthroughs of the early 20th century, the post-World War II era marked a period of rapid expansion and innovation in steel construction worldwide. Economic recovery, urbanization, and industrial growth created unprecedented demand for taller, stronger, and more efficient buildings — and steel was at the heart of this transformation.

1950s–1960s: Post-War Growth and Innovation

The rebuilding of cities after World War II required materials that were durable, easy to assemble, and adaptable to modern design needs. Steel met all these demands.

- 1953: First Suspended Roof Building (Raleigh Arena, USA) – This project introduced new long-span roof systems, leveraging steel’s flexibility and lightweight properties to achieve wider, unobstructed interior spaces.

- During the 1960s, advances in engineering and material science led to a new generation of high-rise and composite structures, where steel was often combined with reinforced concrete to improve seismic performance and cost efficiency. Prefabrication techniques also became widespread, reducing construction time and enabling mass production of components — a major step toward modern prefabricated steel systems.

1970s–1990s: The Rise of Super-Tall Steel Structures

The later decades of the 20th century saw a global race for height and innovation.

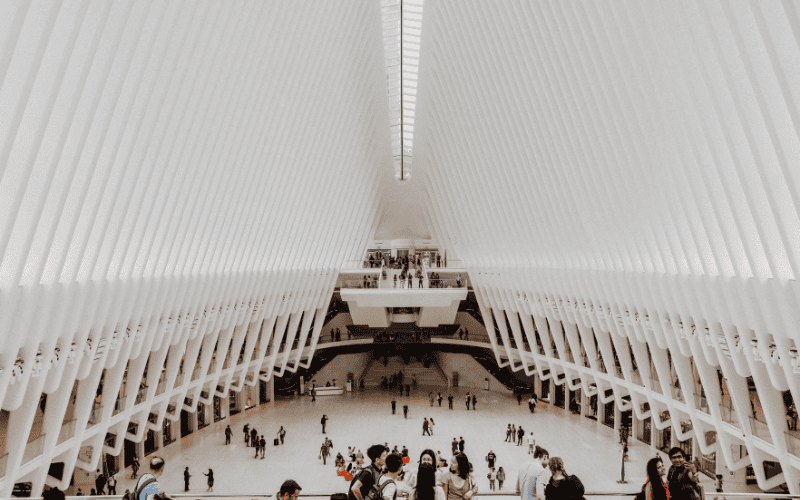

- 1970: World Trade Center (New York, USA, 410 meters) – The twin towers represented a breakthrough in tube-frame structural design, enhancing lateral stability and making record-breaking height achievable.

- 1973: Sears Tower (Chicago, USA, 442 meters) – Using a bundled-tube system, it became the tallest building in the world and a model for efficient high-rise engineering.

- During the 1980s, the influence of steel architecture spread globally. Nations such as Japan and China began embracing steel for both commercial and industrial projects, accelerating the modernization of their skylines.

- 1996: China Becomes the World’s Largest Steel Producer – This milestone not only reflected China’s industrial strength but also positioned it as the central force behind the future of global steel construction.

By the end of the 20th century, steel had evolved from a structural material into the backbone of modern civilization, supporting stadiums, airports, bridges, and high-rise buildings across continents.This transformation positioned Asia, particularly China, as the driving force behind the next generation of global steel innovation, paving the way for the 21st century’s era of sustainable and intelligent steel structures.

4. The New Era of Steel Structure Buildings in the 21st Century

As the world entered the 21st century, steel construction entered a new era defined by sustainability, digital innovation, and architectural ambition. The lessons of the previous century — efficiency, height, and strength — evolved into a broader focus on environmental responsibility, design flexibility, and smart building technologies. Across continents, modern steel structures have become symbols of progress and resilience.

1. Expansion of Lightweight Steel Housing

Lightweight steel has become a cornerstone of modern residential architecture.

- Cold-formed steel systems are now widely used for modular homes, prefabricated structures, and earthquake-resistant housing across North America, Asia, and Australia

- Its high strength-to-weight ratio, recyclability, and rapid installation make it an ideal material for sustainable construction and urban expansion.

- In China, large-scale urbanization and housing reform have accelerated the adoption of prefabricated light steel housing, especially in regions prone to seismic and climatic challenges.

This shift reflects how steel has evolved from an industrial material into an essential component of modern, eco-efficient living.

2. Growth of High-Rise and Super-Tall Steel Structures

Steel remains the material of choice for modern skylines.

- From New York and London to Dubai, Tokyo, and Shanghai, high-rise towers increasingly rely on hybrid steel–concrete systems to balance strength, seismic performance, and construction economy.

- Projects such as the Shanghai Tower (632 m) and Guangzhou Canton Tower (600 m) demonstrate the integration of advanced materials, digital modeling, and structural engineering precision.

- This generation of modern steel structures not only pushes height records but also embodies sustainability through efficient design and long lifecycle performance.

3. Sustainable and Green Steel Construction

The 21st century’s most defining trend in steel architecture is sustainability.

- Advances in low-carbon and hydrogen-based steel production are reducing global emissions and redefining how steel contributes to green building goals.

- Steel’s inherent recyclability and adaptability make it a key material for achieving net-zero carbon architecture.

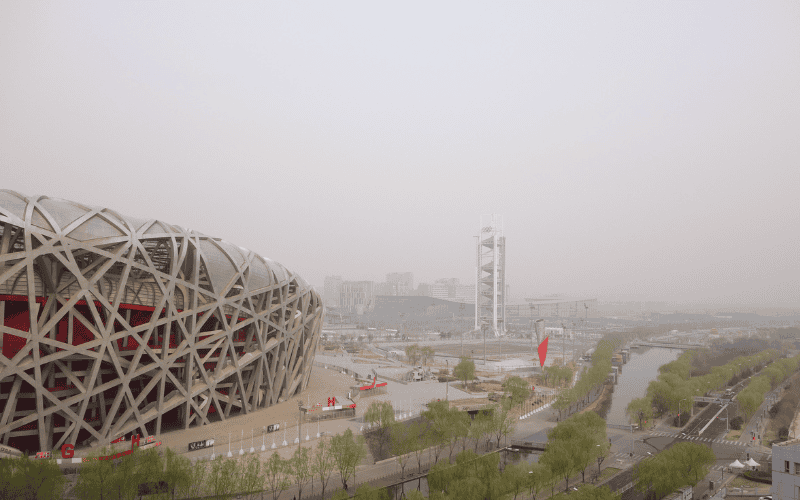

- Landmark projects such as Beijing’s Bird’s Nest, Shanghai Expo Pavilion, and Japan’s eco-skyscrapers illustrate how sustainability and aesthetics now coexist in steel construction.

Steel’s flexibility, combined with energy-efficient systems and digital monitoring, positions it as a driver of the global green transition.

4. A Global Industry in Transformation

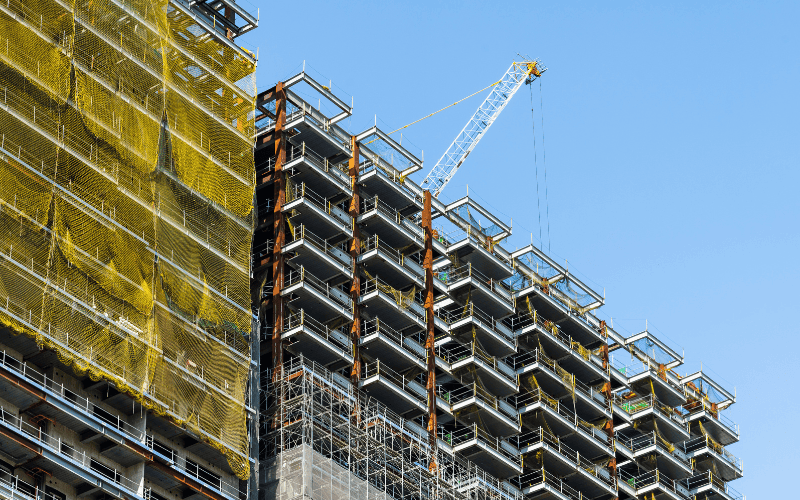

Across regions, the steel structure industry continues to evolve — integrating digital tools, modular systems, and smart fabrication technologies. Prefabrication and BIM-based design have made large-scale construction faster, safer, and more economical, fostering a new generation of intelligent steel buildings.

As part of this global transformation, manufacturers such as SteelPRO PEB have played a vital role in advancing prefabricated and eco-friendly steel structure systems — bridging the legacy of industrial steel with the innovations of modern architecture.

2. The Technological Development of Steel Structure Buildings

The evolution of steel structure buildings has been driven by significant advancements in both steel material technologies and construction techniques. These innovations have improved the strength, durability, and flexibility of steel structures, enabling them to withstand the demands of modern architecture.

Steel Material Technologies

- 1856: The Birth of Mass-Produced Steel

In 1856, the Bessemer process revolutionized steel production, making it more affordable and efficient. This process enabled the mass production of steel, laying the foundation for modern steel structures. The introduction of mass steel production meant that architects and engineers could use steel in larger quantities, facilitating the construction of taller buildings, bridges, and expansive industrial structures.

- 1930: The Introduction of Weathering Steel

Weathering steel—also known as Corten steel—was developed in 1930 and improved corrosion resistance by forming a stable, protective oxide layer when exposed to the elements. This made it ideal for outdoor applications such as bridges and industrial buildings, where rust resistance is crucial for long-term durability.

- 1980: The Development of High-Strength Steel Plates (TMCP Process)

In 1980, Japan’s NKK Company pioneered the development of high-strength steel plates through the TMCP (Thermo-Mechanical Control Processing) process. This process enhances the strength and toughness of steel while maintaining ductility, making it ideal for large-scale structures and high-rise buildings. TMCP has since become a standard in the production of structural steel worldwide, allowing engineers to build more efficient and durable steel structures.

Construction Technologies

- Advancements in Stability Calculations (19th Century)

In the 19th century, Leonhard Euler’s formula laid the groundwork for structural stability calculations. This early theoretical framework helped engineers determine how structures would behave under various loads, providing the basis for the design of more stable and efficient steel structures. In the 20th century, the plastic design method was introduced, allowing for more flexible and cost-effective designs that optimized the performance of steel structures under complex conditions.

- Computer Technology in Design (1960s Onwards)

The introduction of computers in the 1960s revolutionized structural engineering. Computer-aided design (CAD) and finite element analysis (FEA) allowed engineers to simulate and analyze the behavior of complex steel structures before construction. This innovation enabled the development of highly intricate designs, reducing the risk of errors and increasing construction efficiency. The ability to model stress distribution, load-bearing capacities, and structural interactions made steel design faster and more precise.

- Welding and Connection Technologies

- 1881: The Invention of Arc Welding

In 1881, electric arc welding was developed, which enabled the efficient joining of steel pieces. This innovation significantly reduced the labor-intensive process of riveting, making steel structures easier and faster to assemble. Welding offered greater flexibility in terms of shape and design, making it a crucial technology in the development of modern steel structures. - 1947: The Introduction of High-Strength Bolt Technology

In 1947, the establishment of standards for high-strength bolts improved the efficiency of steel connections. The use of bolted connections became widespread in the 20th century, allowing for faster construction and easier disassembly. Bolted joints also provide superior load transfer, increasing the overall strength and stability of steel structures.

- 1881: The Invention of Arc Welding

These technological milestones laid the groundwork for today’s intelligent and digital steel construction systems, integrating BIM, AI-based optimization, and automated fabrication.

Global Steel Structure Building Applications

Steel structure applications have grown significantly across the world, with the material becoming a key choice for a variety of building types due to its strength, versatility, and sustainability. Here’s a look at how steel structures are applied across different regions.

- In developed countries like the United States, Europe, and Japan, steel is extensively used in high-rise buildings, airports, sports stadiums, and bridges. Japan leads with steel structures accounting for 50% of construction projects, while in the United States, steel is used in more than 40% of buildings. The United Kingdom follows closely at 70%.

- Canada, the US, and Australia are also utilizing light steel for residential construction, with countries like Australia seeing 50% of new homes built with light steel. This trend supports sustainable building practices and energy-efficient homes. In Canada, 30% of homes are made with light steel, while in the US, the adoption is at 20% and is growing.

- China’s use of steel in construction has grown exponentially in recent years, especially as the country embraces modern architectural trends. While steel only represents 4% of total construction in China (compared to 10%-50% in developed nations), the potential for growth is massive, with high-rise buildings and iconic landmarks leading the way.

Around the world, steel has evolved from an industrial material to a symbol of modern architecture, shaping skylines through innovation and sustainability.

Future Development Trends in Steel Structure Buildings

The future of steel structure buildings is shaped by innovation, sustainability, and advanced technologies. Here are the key trends:

(1) Structural Innovation

- Space Structures: Complex designs like grid shells and membrane structures replace traditional flat designs, offering greater efficiency and aesthetic freedom.

- Light Steel for High-Rise: Steel is increasingly used for multi-story residential buildings, addressing urban density and housing demands.

(2) Green Building Development

- Eco Technologies: Integrating sustainable materials like energy-efficient glass and solar roofs with steel construction reduces environmental impact.

- Low-Carbon Production: Techniques like modular construction and high-efficiency welding minimize carbon footprints during steel manufacturing and assembly.

(3) Composite Structural Trends

- Steel-Concrete Combinations: Using steel and concrete together enhances the stability and cost-efficiency of high-rise buildings, as seen in iconic structures like the Petronas Towers and Jin Mao Tower.

(4) Digitization and Smart Technology

- BIM (Building Information Modeling): BIM optimizes design, reduces waste, and improves construction efficiency through 3D digital models.

- 3D Printing: Steel components can now be 3D printed on demand, allowing for cost reduction, custom designs, and minimal material waste.

As steel continues to evolve, the industry is entering a new phase defined by digital design, sustainability, and hybrid structures, where innovation and environmental responsibility shape the future of global construction.

Shaping Prefect Steel Structures with SteelPRO PEB

From the iron bridges of the 18th century to the supertall steel towers of today, the story of steel has always been one of innovation and resilience. As the world enters an era of intelligent, sustainable, and modular construction, this legacy continues — carried forward by those who turn engineering vision into reality.

SteelPRO PEB, a division of Xinguangzheng Group, stands as part of that continuing evolution. Established in 2013, the company has become a global provider of customized steel structure and prefabricated building solutions, integrating design, fabrication, installation, and warranty under one system. With 24 automated production lines, a 120,000-ton annual capacity, and exports spanning over 30 countries, SteelPRO PEB combines advanced technology, precision manufacturing, and green building standards to meet the world’s growing demand for sustainable steel architecture.

Driven by innovation, efficiency, and environmental responsibility, SteelPRO PEB bridges the centuries-long heritage of steel construction with the needs of modern architecture — advancing the global industry as a central entity in the evolution of steel structures.