Steel roof truss design is the foundation of every durable and cost-efficient steel structure. Whether it’s a flat roof for a warehouse, a long-span industrial building, or an architectural space demanding aesthetic precision, the right truss design determines both safety and economy.

In this guide, we’ll explore every key aspect — from material selection and component design to truss shapes, load analysis, and software-based structural calculations — helping you understand how each decision shapes performance and cost.

As an ISO- and CE-certified manufacturer, SteelPRO PEB brings engineering precision and real-world project experience to every truss system. With 24 automated production lines and global project delivery, our approach combines technical design expertise with factory-grade prefabrication quality.

Whether you’re designing a warehouse roof truss or planning an industrial structure, this article walks you through the complete process — from concept to fabrication — to help you build stronger, smarter, and more efficient steel roof trusses.

Material Selection for Steel Roof Trusses

Selecting the right materials is the foundation of any successful steel roof truss design. The selection of steel plays a critical role in determining the truss’s strength, durability, and overall effectiveness in withstanding external forces.

Grades of Steel

To balance strength, weldability, and cost:

- Q235: solid, cost-effective, versatile.

- Q345: strong, good weldability, affordable.

For heavier loads: - Q420: higher strength, better for heavy-duty applications.

Weathering steel should be considered in harsher environments—like coastal areas, humid climates, or industrial zones: - Q235NH: weathering steel, self-protecting oxide layer, low maintenance.

- A588: weathering steel, corrosion-resistant, durable.

- ASTM A242: high-strength low-alloy steel, natural protective layer.

For areas with lower corrosion risks, anti-corrosion treatments like galvanizing, epoxy coatings, or zinc-rich primers can be applied to standard steel grades:

- Q235

- Q345

- SS400: general-purpose steel, to improve rust resistance and extend their lifespan.

Material Performance Requirements

For steel roof trusses, prioritize tensile strength, yield strength, and elongation to handle both static and dynamic loads. Aim for 370 MPa tensile strength, 235 MPa yield strength, and over 20% elongation to ensure toughness.

Toughness and corrosion resistance are also key. Toughness helps absorb impact, especially in seismic zones or harsh weather. Corrosion resistance is crucial for trusses in coastal areas or industrial zones with pollution.

Weldability and machinability are important for easier fabrication. Good weldability reduces defects, while high machinability ensures precise shaping. Balancing these factors leads to strong, durable, and cost-effective trusses.

Cost and Sustainability

Striking the right balance between cost and sustainability is key. Optimizing material usage reduces waste, while incorporating eco-friendly options, such as recyclable steel (including A36, A572, and S355), which aligns with modern environmental standards.

For flat roof or long-span trusses used in warehouses and factories, Q345 or Q420 grades are preferred due to their superior load-bearing capacity and strength-to-weight performance.

Component for Steel Roof Trusses

The components of a steel roof truss must be carefully chosen to ensure seamless integration and optimal performance.

Design of Main Structural Members

In steel roof truss design, the top chord, bottom chord, and web members each play a key role, each built to handle specific loads. The top chord resists compression and needs high-strength steel to prevent buckling, while the bottom chord handles tension and requires steel with excellent tensile properties to avoid failure.

Web members play a key role in transferring shear forces and stabilizing the structure. To ensure smooth load transfer, their design should prioritize shear strength, stiffness, and efficient connections. This will help maintain stability while optimizing material use.

Key design considerations include:

- Load Calculation: Accurately assess dead, live, wind, and snow loads to ensure the structure holds up under maximum stress.

- Section Selection: Choose the right steel sections (I-beams, H-beams, or box sections) based on load and span to get the right balance of strength and stiffness.

- Connection Design: Use reliable methods like welding or bolting to ensure seamless load transfer between members.

- Stability Analysis: Check the top chord’s slenderness ratio and support conditions to prevent buckling.

- Material Selection: Opt for steel with the right strength, ductility, and corrosion resistance to ensure long-lasting performance.

- Construction Details: Pay attention to proper support and joint treatment to keep things intact over time.

For optimal performance, minimize eccentricity by aligning the member axes within the same plane. This reduces secondary stresses and improves the overall stability of the truss.

Connection Methods

Connections between members are essential for structural integrity. To ensure both strength and stability, full-perimeter welding or high-strength bolted connections should be used. These methods help distribute the load evenly and avoid localized stress concentrations, which can weaken the truss.

Gusset plates and connection plates play a vital role in reinforcing joints. For effective design:

- Gusset plates should be sized based on connection forces, with enough thickness to prevent deformation. High-strength steel is essential for handling expected stresses.

- Plates should align with the load direction, ensuring bolts or welds are placed to maximize load distribution and reduce stress concentrations. Bolt spacing should be consistent to avoid failure under shear or tension.

- Welding should be continuous for uniform strength, while pre-tensioned bolts in bolted connections minimize slippage and enhance load transfer.

- When positioning gusset and connection plates, carefully plan load paths to direct forces efficiently, reducing unnecessary bending or shear at the joints.

At SteelPRO PEB, all truss components and connections are prefabricated under ISO-certified processes, ensuring precision, quality, and long-term durability for every structure.

Truss Shape and Design Considerations

The shape of a steel roof truss plays a huge role in how well it works, how much material is used, and how it looks. Getting the design right means balancing strength with a great visual appeal.

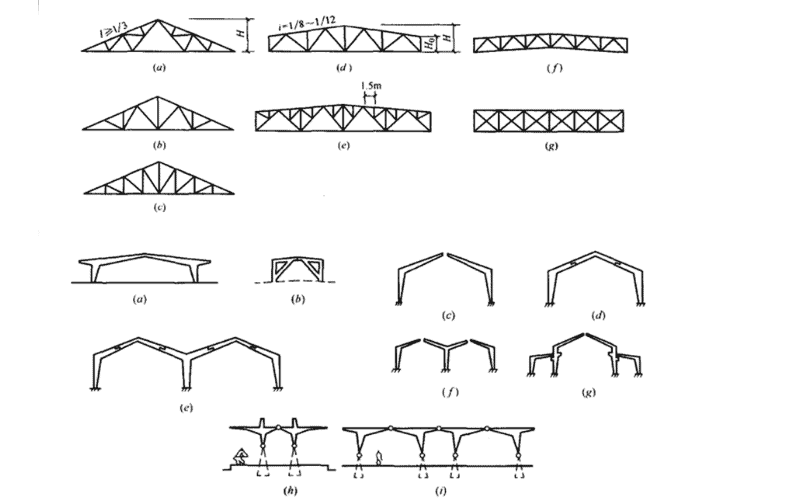

Common Truss Forms

Trusses come in shapes like triangular, trapezoidal, and parallel chord, each suited for different needs. Triangular trusses are ideal for pitched roofs, allowing snow and rain to shed effortlessly. Parallel chord trusses are ideal for flat roofs or floors, giving even load distribution. For something unique, arched or cantilevered trusses bring both strength and style.

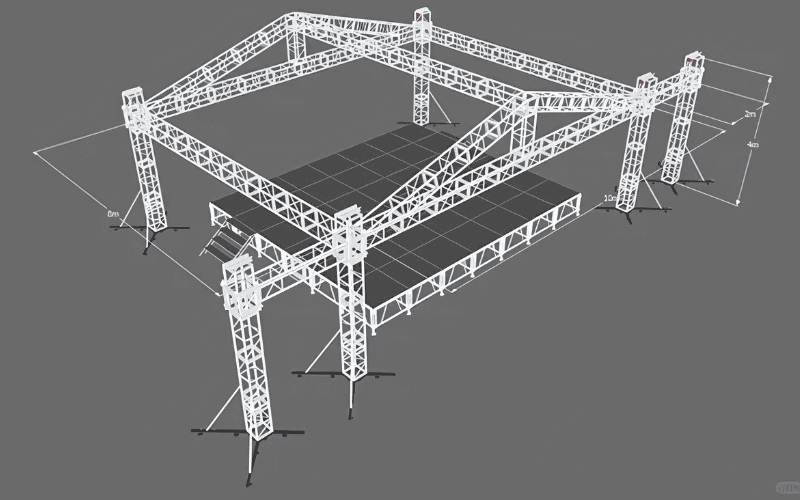

Flat roof trusses are widely used in warehouse and commercial buildings where minimal roof slope is required. They provide a clean aesthetic and efficient load transfer for large clear spans, making them an ideal choice for industrial and logistics facilities.

Geometric Parameters

The height-to-span ratio and node spacing are key to making sure loads are distributed well and material is used efficiently. For parallel chord trusses, a 1:10 to 1:12 ratio is common, balancing strength and weight. Node spacing is adjusted to ensure even load transfer, with tighter spacing in high-stress spots to avoid buckling. This design keeps the truss ready for wind, snow, and seismic forces.

Load Analysis

A solid load analysis covers dead loads (like the truss and roofing materials), live loads (like people or equipment), and environmental forces such as wind, snow, and seismic activity. In snow-heavy regions, trusses are usually designed to handle at least 1.5 kN/m² of snow load, depending on local codes. This ensures they can handle all the stresses they’ll face, including wind, snow, and seismic forces.

For warehouse trusses, a span-to-depth ratio between 1:10 and 1:12 offers an optimal balance between strength and material efficiency, ensuring both economy and long-term stability.

As a steel structure building manufacturer with decades of experience, we design steel roof trusses that can handle wind, snow, and seismic loads, ensuring long-lasting performance across various environments.

Related Reading: Metal Roof Expansion Joints: Design, Installation, and Maintenance

Structural Analysis and Calculations

To make sure your truss holds up under all stresses, accurate structural analysis is a must. This step ensures the design is safe and dependable, handling both daily loads and extreme conditions.

A typical steel roof truss design process includes concept modeling, load analysis, member sizing, and connection detailing, verified using advanced software such as STAAD.Pro and Tekla Structures. This workflow ensures that each truss is optimized for strength, economy, and performance before fabrication.

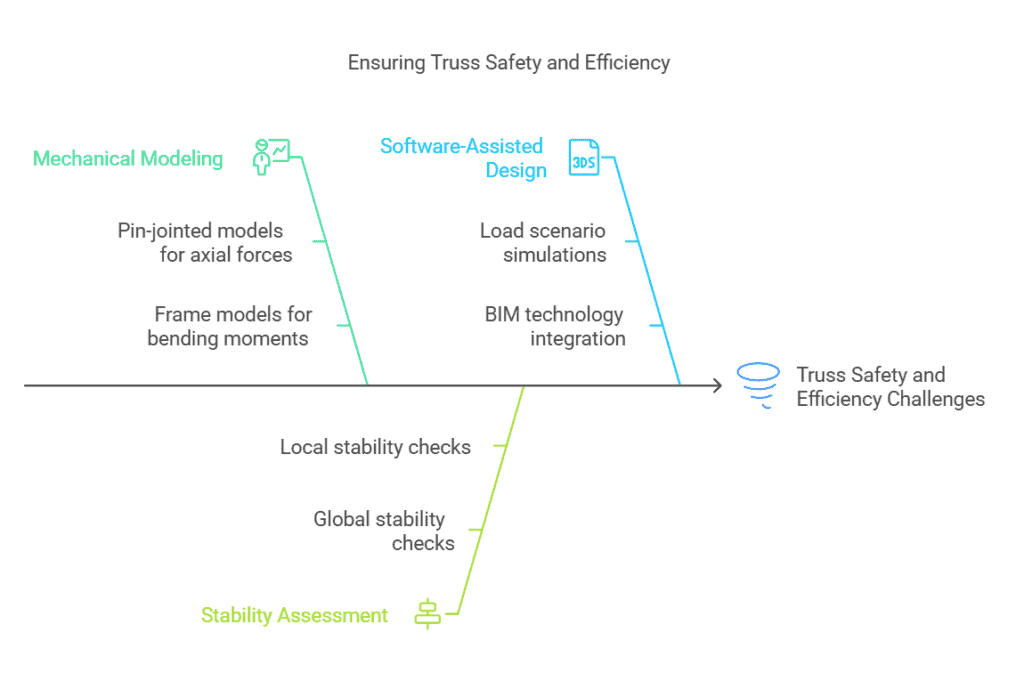

Mechanical Modeling

Mechanical models help figure out how forces affect each part of the truss. For example, using a pin-jointed model is great for figuring out axial forces (those pushing or pulling straight along the truss). If you’re dealing with more complex connections, frame models are a good choice to calculate bending moments. These models help you spot weak points, like overstressed members or joints that might need a little extra support.

Stability Assessment

Global and local stability checks are key to making sure everything stays in place. For example, global stability ensures the truss can handle things like wind, while local stability focuses on the individual parts—like making sure the top chord’s slenderness ratio doesn’t exceed 200. Adding bracing systems, like cross-bracing or diagonal struts, can boost stability and help distribute loads evenly.

Software-Assisted Design

Using tools like STAAD.Pro and Tekla Structures makes the design process faster and more accurate. For instance, STAAD.Pro can simulate different load scenarios—like a snow load of 1.5 kN/m²—to see how the truss holds up. BIM technology lets you see the design in 3D, which helps spot issues early on and improve overall coordination.

SteelPRO PEB’s engineering team utilizes these tools to deliver precise and reliable design packages for prefabricated truss systems, ensuring every structure meets international standards and project-specific performance goals.

By using these techniques, the truss will not only be safe but also efficient and ready to handle all the challenges it faces.

Choose Your Peb Steel Roof Truss From Us

Designing a steel roof truss requires precision, experience, and the right manufacturing partner. From selecting suitable materials to performing detailed structural analysis, every stage of design directly affects safety, cost, and performance. Many engineers and project owners struggle to balance these factors — especially when aiming for long-span, flat, or warehouse-style truss systems that demand both high load capacity and efficient fabrication.

That’s where SteelPRO PEB makes the difference. As an ISO and CE-certified steel structure manufacturer with over 1,000 completed projects worldwide, we integrate advanced modeling software with automated production lines to turn complex truss designs into reliable, prefabricated solutions. Our 24 production lines deliver over 120,000 tons of precision-engineered steel structures annually, ensuring consistent quality and on-time delivery.

Whether you need a custom roof truss for industrial, commercial, or warehouse applications, our engineering team can provide tailored design support, drawings, and fabrication guidance — all backed by factory-direct pricing and a 50-year structural warranty.

Contact SteelPRO PEB today to get a professional design consultation and manufacturer-direct quotation for your next steel roof truss project.