During the design, production, installation and use process, if not properly controlled, steel structures may have some quality problems, affecting the safety and service life of the structure. We will introduce common quality problems in steel structures and their preventive measures to help you better understand and deal with these challenges.

Common Disadvantages and Quality Problems of Steel Structures

Steel structures, like any building system, may face disadvantages and quality problems if not properly managed during design, production, or installation. These include issues with materials, welding, corrosion, and construction accuracy. However, with strict quality control and the expertise of a certified Steel Structures / PEB Manufacturer & Producer like SteelPRO PEB, these risks can be minimized. By combining advanced welding checks, international certifications (ISO & CE), and factory-direct supply, we ensure that steel structures remain safe, durable, and cost-efficient.

1. Material quality problems

Problems: steel strength does not meet the standard, chemical composition is not qualified, surface defects (such as cracks, rust), etc.

Reason: material procurement is not standardized, supplier quality control is not strict, or steel is not selected according to design requirements.

2. Welding quality problems

Problems: Weak welds, pores, slag inclusions, cracks, incomplete penetration or weld nodules, etc.

Reason: welding process is not standardized, welder technology is not up to standard, or welding environment (such as humidity, temperature) is not suitable.

3. Installation accuracy problems

Problems: large component installation deviation, loose bolt connection, node misalignment, etc.

Reason: inaccurate construction measurement, non-standard installation process, or construction is not carried out according to design drawings.

4. Anti-corrosion and fire prevention problems

Problems: the anti-corrosion coating on the surface of the steel structure falls off, the thickness is insufficient, or the fire-retardant coating does not meet the fire resistance requirements.

Cause: The anti-corrosion and fireproofing process is not standardized, the material quality is not up to standard, or the construction environment does not meet the standards.

5. Deformation problem

Problem: The steel structure is deformed by bending, twisting, etc. during transportation, installation or use.

Cause: Insufficient design strength of components, improper transportation or hoisting, or excessive external load.

6. Connection problem

Problem: Bolts are loose, fall off, or high-strength bolts do not meet the preload requirements.

Cause: Unqualified bolt quality, non-standard installation process, or failure to perform tightening inspection as required.

7. Fatigue problem

Problem: Fatigue cracks occur in steel structures under long-term cyclic loads.

Cause: Fatigue strength is not fully considered in the design, or the load exceeds the design range during use.

8. Design problem

Problem: Unreasonable structural design leads to stress concentration, insufficient stability or uneven load distribution.

Cause: Design calculation errors, failure to fully consider actual use conditions, or lax implementation of design specifications.

9. Environmental impact issues

Problem: Steel structures are prone to rust in humid and corrosive environments, or lose strength at high temperatures.

Cause: No effective anti-corrosion measures were taken, or steel suitable for environmental conditions was not selected.

10. Construction management issues

Problem: Lax quality control during construction leads to accumulation of quality problems.

Cause: Irregular construction management and lack of effective quality supervision and testing mechanisms.

How to ensure the quality of steel structure?

The quality of steel structure is the core of building safety and durability. To guarantee that every project attains the highest standards, we rigorously oversee every stage, from material selection to the completion of construction. The following are the key measures we take in actual work:

1. Material selection

Steel grade: We select steel grades that meet the design requirements, such as Fe 415, Fe 500, etc., to ensure that the strength and performance of the steel can meet the project requirements.

Specifications and performance: All types, specifications and performance of steel strictly comply with national standards to ensure the consistency of materials.

Surface inspection: Before the material enters the site, we will carefully check the surface of the steel to ensure that there are no defects such as cracks, slag inclusions, and delamination to avoid affecting the overall quality due to material problems.

2. Design and drawing review

Drawing review: Before construction, our technical team will conduct a detailed review of the design drawings to ensure that they meet national standards and project requirements.

Technical disclosure: Before construction, we will fully communicate with the design team and the construction team to clarify the technical requirements and ensure that every link can be executed as planned.

3. Welding and connection quality

Welding process: We strictly follow the BS EN ISO 3834 standard to ensure that every weld meets the highest quality requirements.

Welder qualifications: All welders hold valid qualification certificates to ensure the professionalism and reliability of welding operations.

Connection quality: We use high-strength bolts and ordinary bolts, and check the connection quality through hole trimming equipment to ensure that each connection point is firm and reliable.

4. Anti-corrosion and fire-proof coating

Anti-corrosion coating: We sandblast the steel surface to ensure that the coating adheres firmly and the anti-corrosion effect is optimal.

Fire-proof coating: According to the design requirements, we apply fire-proof coating in layers to ensure that the fire resistance limit of the steel structure meets the standard and provide additional safety for the building.

5. Installation and construction quality control

Installation process: From the installation of foundation anchor bolts to the hoisting of steel columns and steel beams, we strictly follow the specifications to ensure that every step is accurate and correct.

Calibration and adjustment: We use a level and theodolite to calibrate the verticality and horizontality of the steel structure to ensure the overall stability of the building.

6. Documentation and Traceability

Material Certificates: We keep detailed records of the quality certification documents for each batch of steel, bolts, coatings and other materials to ensure that every piece of material is well documented.

Inspection Reports: We provide complete inspection reports, including welding inspections, coating inspections, installation inspections, etc., to ensure that every link is strictly checked.

Before leaving the factory, we ensure that

- All materials and quality documents are complete and compliant to ensure that each component delivered is safe, reliable and durable.

- The steel surface is free of cracks, rust, and slag inclusions, and the welding quality meets the BS EN ISO 3834 standard.

- The thickness of the anti-corrosion and fire-retardant coating meets the standard, 150 microns outdoors and 125 microns indoors, to ensure long-term protection.

Why Choose a Certified Steel Structure Manufacturer?

When investing in a steel structure, choosing a certified factory supplier is critical to ensuring quality and cost-efficiency. As a Steel Structures / PEB Structures Manufacturer & Producer, SteelPRO PEB offers:

- Factory-direct supply: eliminate middlemen and reduce costs.

- Wholesale prices: competitive solutions for industrial, agricultural, and commercial projects.

- International certifications (ISO & CE): guarantee safety, welding quality, and coating standards.

- Global experience: over 1,000 completed projects across Asia, the Middle East, Africa, and Latin America.

- Full traceability system: every batch of steel comes with certificates and inspection reports.

This ensures that customers not only receive durable structures but also reliable after-sales support with long-term warranties.

How do customers check the quality of steel structures by themselves after receiving the goods?

When customers receive steel structure products, quality inspection is an important part of ensuring that the products meet the requirements and safety standards. Here are some basic steps that customers can follow to check the quality of steel structures by themselves:

1. Appearance inspection

- Surface treatment: Check whether the surface of the steel structure has rust, cracks, scratches or other obvious defects. Pay special attention to the uniformity of the coating to ensure that the anti-corrosion coating is intact and prevent the steel from being corroded by oxidation.

- Welding quality: Check the appearance of the welding part, and the weld should be smooth and uniform. The welded part should be devoid of defects such as cracks, pores, and incomplete penetration.

- Parts identification: Check whether the parts are identified and numbered according to the requirements of the drawings to ensure that they can match the design documents.

2. Size and tolerance inspection

Use a tape measure or laser rangefinder to check whether the dimensions of each steel structure component meet the design requirements. Including length, width, thickness, etc.

- Angle and verticality: Use a level and angle ruler to check the angle and verticality of the steel structure to ensure the flatness and stability of the structure.

3. Strength and durability inspection

- Weight inspection: Check whether the material of the steel structure meets the standards by weighing or comparing with the design weight. In particular, important load-bearing components must ensure that they are strong enough.

- Material inspection: Suppliers can be asked to provide material warranty or material certificate to ensure that the type and quality of the steel meet the specified standards.

4. Connection inspection

- Bolt connection: Check whether all bolts and connectors are tightened in place and there is no looseness. The type and specification of the bolts should be consistent with the design.

- Welding and riveting points: For welding or riveting parts, their quality should be checked to ensure that the connection is stable and without any defects.

5. Trial assembly and splicing

- Assembly test: A small range of trial assembly can be carried out to ensure that there are no problems with the docking and connection of steel structure components, and there are no obvious errors at the connection.

- Splicing test: Splice the main components to check whether they match, install smoothly, and whether the matching clearance between the components is reasonable.

6. Anti-corrosion and anti-rust inspection

- Coating thickness: Check the thickness of the coating through a coating thickness gauge to ensure that the coating meets the design requirements and has sufficient anti-corrosion protection.

- Anti-corrosion test: For some key parts, simple corrosion tests can be carried out, such as salt spray tests on the surface of components.

7. Material certification and inspection report

Require suppliers to provide material inspection reports, including the chemical composition and mechanical properties of steel. Confirm that the quality of steel meets relevant standards.

8. Use environment and structural adaptability inspection

According to the environment (such as humidity, large temperature difference, strong corrosion, etc.), check the adaptability of the steel structure and whether materials or protective measures suitable for the environment are used.

Attention!

When customers receive steel structure products, they must complete the inspection within a short period of time so as to find problems in time and communicate with the supplier to solve them. For important or complex structures, you can consider having a professional third-party agency conduct inspections to ensure that the product quality meets the relevant building standards and safety requirements.

What are the disadvantages of steel structures in construction?

Steel structures may face issues like corrosion, welding defects, or installation inaccuracies. However, as a certified Steel Structures / PEB Manufacturer, SteelPro PEB minimizes these risks through advanced production lines and strict ISO & CE quality management.

How to ensure welding quality check in steel structures?

Welding is inspected using non-destructive testing (X-ray, ultrasonic), visual inspection, and compliance with BS EN ISO 3834 standards, ensuring every weld is reliable and safe.

Why buy directly from a steel structure factory instead of traders?

Factory-direct supply ensures lower prices, certified materials, and traceable quality reports, while traders often cannot guarantee the same level of inspection and certification.

Can you provide design drawings and quality reports before shipment?

Yes. SteelPro PEB provides detailed design drawings, welding inspection reports, and coating thickness certificates, so customers receive complete documentation with every order.

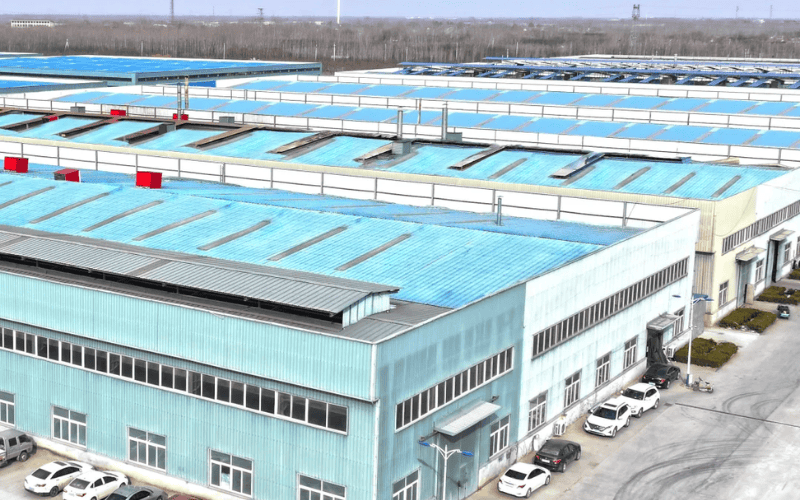

High Quality Steel Structure Supplier

Contact SteelPro PEB today for factory-direct, certified steel structures at wholesale prices. We provide custom design solutions, detailed quality inspection reports, and international shipping support — ensuring every project is delivered with safety, durability, and cost-efficiency from the manufacturer’s factory floor to your site.