When comparing steel joists and joist girders, understanding their structural roles, cost factors, and applications is essential for efficient and durable building design. In simple terms, joist girders act as primary load-bearing members that transfer concentrated loads to columns, while steel joists serve as lighter, secondary supports for roofs and floors. Knowing when to use each system—or how to combine them—is key to optimizing span length, material efficiency, and project cost.

This guide covers everything you need to know about these two essential PEB and steel structure components:

- What steel joists are and how they function in roofs and floors

- The key features and parts of a steel joist (top chord, web members, seat, and more)

- The different types of steel joists used across industrial and commercial buildings

- Cost analysis and practical strategies for optimizing steel joist design and fabrication

- The structural role and specifications of joist girders

- A detailed comparison of steel joist vs joist girder to clarify their differences

- How both systems are combined in real-world PEB structures for efficiency and long spans

- Expert insights on choosing the right system for your project

By the end, you’ll have a clear understanding of how to select and apply steel joist and joist girder systems for cost-effective, high-performance steel buildings.

What is a Steel Joist?

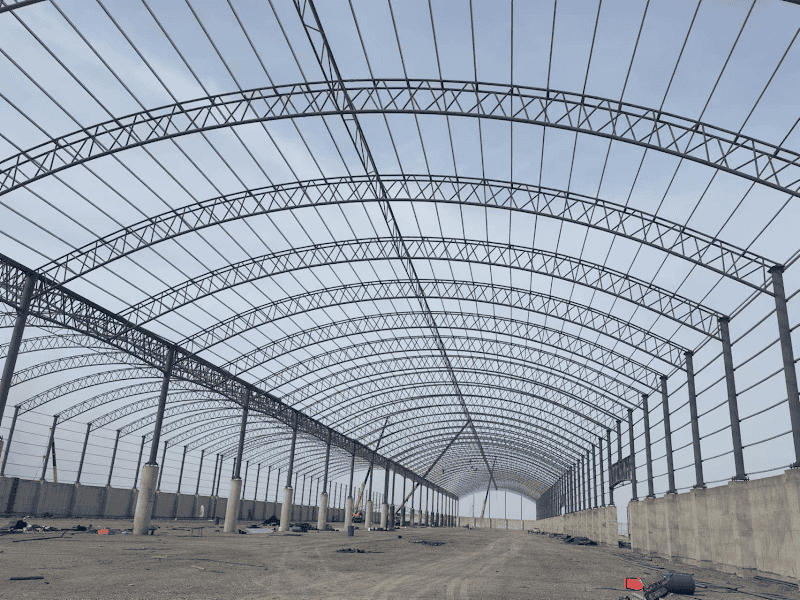

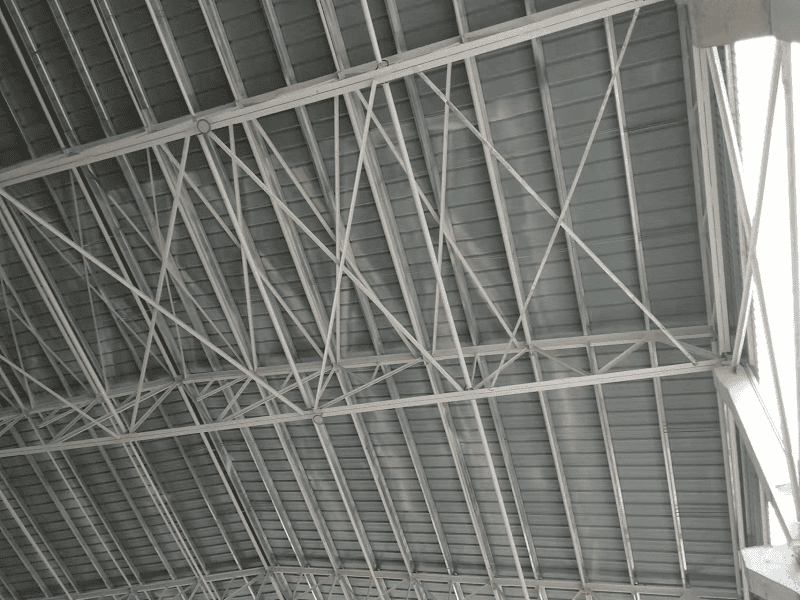

A steel joist, also known as an Open Web Steel Joist (OWSJ), is a lightweight truss structure composed of a top chord, bottom chord, and web members. It primarily supports roofs or floors and transfers loads to the building’s main structure — such as beams, girders, or columns.

The most distinctive feature of a steel joist is its open-web design, which makes it lighter yet stronger than solid beams. This structure allows for longer spans, improved material efficiency, and reduced construction costs — one reason why engineers often compare steel joists vs beams or girders when designing cost-effective PEB structures.

In a steel or PEB structure, joists function as secondary load-bearing members, working alongside joist girders to form an integrated support system. Here’s how they work:

- Joists span across joist girders or beams, distributing loads evenly to reduce structural stress.

- They provide horizontal stability, ensuring the roof or floor remains securely in place.

- Compared to solid steel beams, open web steel joists reduce overall material usage, making structures lighter and more cost-effective.

- They allow for longer spans, reducing the need for interior columns and maximizing usable space.

- Used in various structures, including warehouses, shopping malls, industrial facilities, and stadiums.

Think of a steel joist as a bridge between primary structural members. It efficiently transfers loads to the main framework while keeping the structure lightweight yet strong.

Steel joists come in various shapes, in addition to the standard Parallel Chord design:

- Single Slope – Ideal for roofs with drainage requirements.

- Double Slope – Similar to traditional pitched roofs, creating a more spacious feel.

- Arch – Commonly used in stadiums and unique architectural designs.

- Gable – Suitable for warehouses and factory roofs.

- Scissor – Used in buildings with high ceilings, such as churches and theaters.

For most buildings, standard steel joists are the most cost-effective option, while special shapes are used for specific architectural or drainage needs.

Key Features of Steel Joists:

- High Strength & Stability: Despite being lightweight, steel joists can support significant loads.

- Lightweight Design: The open-web structure reduces material usage and decreases overall building weight.

- Span Capability: Able to span longer distances, reducing the need for interior columns and maximizing open space.

- Efficient Installation: Prefabricated for quick and easy on-site assembly.

- Versatile Applications: Suitable for both roof and floor structures in various building types.

- Cost-Effective: Lower material and labor costs due to reduced weight and faster installation.

- Durability: Steel is resistant to pests, fire, and weather, ensuring long-term durability.

- Design Flexibility: Customizable in size and shape for specific design needs.

- Sustainability: Steel is highly recyclable, supporting eco-friendly construction.

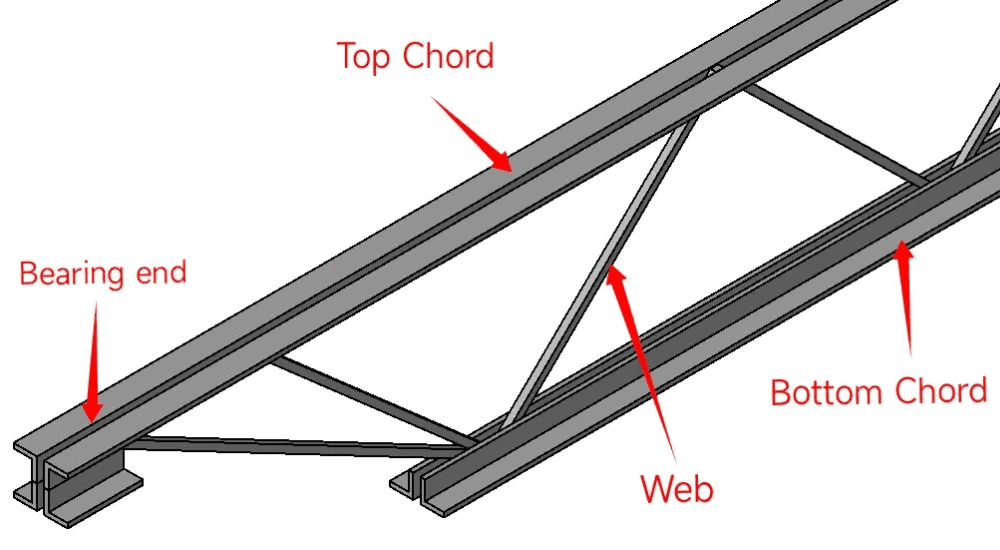

Steel Joist Components

Steel joists are engineered with a truss-like open web design, allowing them to be lightweight yet strong. Each component plays a crucial role in load distribution and structural integrity. These component terms — like joist top chord, bottom chord, and steel joist seat — are often referenced by engineers searching for detailed technical specifications. These component terms — like joist top chord, bottom chord, and steel joist seat — are often referenced by engineers searching for detailed technical specifications.

Top Chord

- The uppermost structural member of the joist.

- It carries compression forces and helps distribute roof or floor loads.

- Typically connects to bridging members or roofing materials.

Bottom Chord

- The lowermost structural element in a joist.

- Primarily resists tensile forces, helping maintain structural stability.

- Often used as an attachment point for ceiling components or utilities.

Web Members

- Diagonal and vertical steel members that connect the top and bottom chords.

- Responsible for shear force distribution, transferring loads efficiently.

- Can be triangular, V-shaped, or zigzagged, depending on design.

End Bearing

- The supporting ends of the joist that rest on joist girders, beams, or walls.

- Transfers the load from the joist to the main structure.

- Usually bolted or welded for secure attachment.

Bridging [Not visible in the provided image]

- Small horizontal or diagonal members connecting multiple joists.

- Prevents lateral movement and improves overall stability.

- Two types: horizontal bridging (runs parallel) and diagonal bridging (forms an X-shape).

- Typically installed mid-span or at regular intervals to maintain alignment and load distribution.

Bearing Seat [Not visible in the provided image]

- The area where the joist makes contact with the supporting girder or beam.

- Designed to distribute the joist’s load across a wider surface, reducing stress concentration.

Types of Steel Joists

Steel joists are classified into four main series: K-Series, LH-Series, DLH-Series, and CJ-Series, each designed for different spans, load capacities, and applications. Additionally, within the K-Series, there is a KCS Joist, specifically designed to handle concentrated loads. Below is a breakdown of their differences and typical uses:

| Type | Full Name | Span Range | Common Applications | Key Features |

| K-Series Joists (Standard) | Standard Open Web steel joist | Short Span (8-60 ft.) | Offices, malls, schools, small warehouses | The most commonly used steel joist, lightweight and cost-effective for smaller spans. |

| KCS Joists (Enhanced) | K-Series Constant Shear Joist | Short Span (10-60 ft.) | Roof equipment support, mechanical rooms, localized floor loads | Designed for concentrated loads such as HVAC units and piping, stronger than standard K-Series. |

| LH-Series Joists (Long Span) | Long Span Open Web Steel Joist | Long Span (20-96 ft.) | Industrial buildings, large warehouses, shopping centers | Stronger than K-Series, ideal for mid-to-large span structures. |

| DLH-Series Joists (Deep Long Span) | Deep Long Span Open Web Steel Joist | Long Span (60-240 ft.) | Stadiums, aircraft hangars, exhibition halls | Designed for ultra-long spans, reducing interior columns and creating open spaces. |

| CJ-Series Joists (Composite) | Composite Open Web Stee-l Joist | Medium to Long Span (20-120 ft.) | Parking garages, office buildings, large floor structures | Works with concrete slabs to increase floor load capacity while minimizing steel usage. |

Steel Roof Joist: Types and Applications

Steel joists play a crucial role in roof construction, offering lightweight, high-strength support while allowing for long spans and open interior spaces. Different roof joist designs are used depending on structural needs, drainage, and architectural style.

Common Types of Steel Roof Joists

| Joist Type | Description | Common Applications |

| Single Slope Joist | One side is higher than the other, designed for roof drainage. | Warehouses, industrial buildings, structures requiring effective water runoff. |

| Double Slope Joist | Similar to a traditional pitched roof, providing a symmetrical slope. | Factories, workshops, commercial buildings needing additional interior height. |

| Arch Joist | Curved design, reducing the need for interior columns and enhancing aesthetics. | Stadiums, sports arenas, architectural structures. |

| Gable Joist | A symmetrical, peaked roof joist for efficient load distribution. | Factories, warehouses, large-scale commercial buildings. |

| Scissor Joist | Forms an inverted V-shape, creating higher interior ceilings. | Churches, theaters, auditoriums, large event spaces. |

For most buildings, standard parallel chord joists are the most cost-effective option, while special shapes are used for specific architectural or drainage needs.

Why Use Steel Joists for Roofs?

Compared to other roof support systems, steel joists provide several advantages:

| Feature | Steel Roof Joist | Solid Steel Beam (H-Beam/I-Beam) | Wood Roof Truss |

| Weight | Lightweight, reduces structural load | Heavy, increases foundation load | Light, but less durable |

| Span Capability | Long spans (up to 240 ft.) | Limited span unless using large beams | Moderate spans, often shorter |

| Installation Speed | Prefabricated for quick assembly | Requires heavy equipment and on-site welding | Requires framing and careful on-site construction |

| Cost | Cost-effective for large projects | Expensive due to material and labor costs | Cheap but high maintenance |

| Durability | Resistant to fire, pests, and weather | High strength, but needs coatings for corrosion resistance | Prone to rot, fire, and termites |

Key Takeaway: Steel joists offer an optimal balance between strength, weight reduction, and cost efficiency compared to solid beams or wood trusses, making them ideal for industrial, commercial, and long-span structures.

Cost of Steel Joists: Factors, Comparison & Optimization

When estimating the steel joist cost for a project, several technical and logistical variables come into play — from steel grade and span length to fabrication methods and coating requirements. Understanding these elements helps engineers and buyers optimize budgets without compromising structural performance.

Key Cost Factors of Open Web Steel Joists

Several parameters affect the final price of steel joists per ton or per linear foot.

- Material Type and Steel Prices: Fluctuations in raw steel markets directly influence joist pricing. High-strength grades may cost more per ton but allow for lighter and more efficient designs, which can reduce total material use.

- Span and Load Capacity: Longer spans and heavier loads require deeper chords or customized reinforcement, which increases fabrication costs. Structural optimization during the design phase helps minimize these expenses.

- Fabrication and Customization: Standard K-Series joists are mass-produced and cost-effective, while special shapes such as scissor or arched joists require additional engineering and processing time, raising costs.

- Surface Coating and Corrosion Protection: Protective coatings such as galvanization or fireproof paint improve durability in humid or coastal environments, though they add to overall cost.

- Transportation and Handling: Long-span DLH joists may require special trucks, cranes, or handling systems. This can add logistical costs that vary depending on project location and access conditions.

- Installation Efficiency: Prefabricated joists reduce on-site labor, improve installation speed, and lower total project costs through simplified assembly.

Steel Joists vs. Alternative Support Systems

A common engineering question is how the cost of a steel joist compares to beams or other structural supports. The difference depends on span length, material type, and construction scale.

| Structural Component | Relative Cost | Key Notes |

| Open Web Steel Joist | Moderate | Lightweight, pre-engineered, ideal for long spans |

| Hot-Rolled Steel Beam (H/I Beam) | High | Heavier and more expensive to install |

| Cold-Formed Joist | Low | Limited span and load capacity |

| Reinforced Concrete Beam | Medium to High | Heavy, labor-intensive, suitable for high-load structures |

For most industrial and commercial projects, open web steel joists provide the best balance between load efficiency, cost, and installation speed, particularly when combined with joist girders.

How to Optimize Steel Joist Costs

To achieve structural performance at minimal expense, consider these approaches:

- Use standard joist sizes such as K-Series to reduce customization costs.

- Optimize span lengths to avoid overdesign that requires deep or custom joists.

- Combine joists and joist girders strategically for efficient load distribution.

- Select prefabricated joists to minimize site labor and waste.

- Compare multiple suppliers and consider bulk ordering to lower per-unit cost.

Factory Supply and Cost Control

Working directly with a certified steel structure manufacturer helps reduce material waste and ensures precision in production.

For example, SteelPRO PEB operates 24 automated production lines with an annual capacity of 120,000 tons, ensuring consistent quality and cost control from raw steel processing to final joist fabrication.

All products meet ISO and CE certification standards and are offered with factory-direct pricing and full traceability. This manufacturing efficiency supports cost optimization for projects worldwide.

What is a Steel Joist Girder?

A joist girder is a stronger and larger steel truss girder compared to a steel joist. It is primarily used to support multiple steel joists and transfer loads to columns or other primary structural members. Joist girders have a higher load-bearing capacity and are suitable for longer spans in large-scale structures.

| Type | Span Range | Common Applications |

| Joist Girder | 20-120 ft. | Industrial buildings, large warehouses, shopping centers, stadiums |

Key Features of Joist Girders

- High Load Capacity: Supports multiple steel joists and handles heavier loads.

- Structural Stability: Can be part of wind and seismic-resistant designs.

- Fewer Interior Columns: Ideal for large-span buildings, optimizing open space.

- Customizable Design: Tailored to meet specific span, load, and height requirements.

- Efficient Material Use: Maximizes strength with minimal material for cost-effective construction.

- Durability: Offers long-term durability and resistance to environmental factors when properly treated.

- Prefabricated Components: Often prefabricated for quicker on-site assembly.

Standard Specifications:

- Joist Girders typically have an end-bearing depth of 7.5 inches.

- They are commonly connected to columns using two 3/4-inch A325 bolts for secure fastening.

Steel Joist vs. Joist Girder: Key Differences

Understanding the difference between a steel joist and a joist girder is essential for structural design, cost estimation, and load distribution analysis. Engineers often search for comparisons such as girder vs joist or beam vs girder vs joist when selecting the optimal system for a project.

Here is a concise technical summary of the key distinctions among these elements.

| Comparison Aspect | Steel Joist (Secondary Member) | Joist Girder (Primary Member) |

| Function | Supports floors or roofs and transfers uniform loads to main beams or girders. | Supports multiple joists and transfers concentrated loads to columns or main frames. |

| Load Type | Uniform distributed loads (e.g., roof decking, floor slabs). | Concentrated loads from attached steel joists. |

| Load Capacity | Suitable for light to medium loads. | Designed for heavy, large-span load-bearing requirements. |

| Span Range | Short to medium spans (8–240 ft), depending on series (K, LH, DLH). | Long spans (30–120 ft), ideal for large buildings. |

| Structural Design | Lightweight open-web truss; reduces material weight and cost. | Deeper truss with higher load-bearing capacity; often bolted to columns. |

| Connection Method | Welded or bolted to joist girders or main beams. | Typically secured to columns using A325 high-strength bolts. |

| Installation Order | Installed after joist girders, acting as secondary support. | Installed first, forming the primary load-bearing framework. |

| Applications | Warehouses, commercial roofs, offices, schools. | Stadiums, aircraft hangars, distribution centers, large industrial spaces. |

| Cost Efficiency | Lower cost and faster installation for moderate spans. | Higher cost but reduces interior columns and increases open space efficiency. |

How Are Steel Joists and Joist Girders Used Together?

In modern steel structures, steel joists and joist girders are often designed to work in combination, forming a highly efficient load-bearing system. Joist girders act as the primary framing members, transferring major loads to columns, while steel joists serve as secondary members, supporting roof decks or floor slabs.

This integrated system is particularly common in PEB (Pre-Engineered Building) design, where long-span efficiency and material economy are critical.

Standard Combination: Steel Joist and Joist Girder

The standard configuration connects joist girders directly to steel or concrete columns. Steel joists are then placed perpendicular across the girders, supporting the roof or floor system. This layout enables uniform load transfer, fewer columns, and open interior space.

Typical applications include industrial facilities, logistics centers, and large-span warehouses where long clear spans are required. In projects across Southeast Asia and the Middle East, this joist–girder combination is widely used in PEB factories and commercial steel buildings for its balance of cost and performance.

Using Steel Joists Alone (Without Joist Girders)

In smaller structures, steel joists can connect directly to steel or reinforced concrete beams without joist girders. This approach is effective when the main framework already provides sufficient load-bearing capacity. It simplifies construction and reduces cost for low-rise buildings or multi-story floor systems.

For example, multi-story office buildings and commercial facilities often adopt this system, where steel joists directly support concrete slabs or metal decks without additional girder framing.

Using Joist Girders Alone (Without Steel Joists)

In some heavy-duty industrial or infrastructure projects, joist girders may be used independently to support roof or floor structures without steel joists. This configuration is less common but can be suitable for specialized applications such as bridges, power plants, or large-span industrial plants, where high-load concentration demands a stronger primary member.

Although feasible, joist girders are generally more effective when paired with steel joists to distribute loads evenly and enhance the overall stability of the structure.The choice of configuration depends on span length, load type, and architectural design. For most industrial, warehouse, and PEB structures, the standard combination of joist girders with steel joists remains the most efficient and cost-effective solution. It provides open space flexibility and ensures reliable load transfer across the structural system.

Conclusion: Why Choose Steel Joists and Joist Girders?

Choosing the right structural system—whether steel joists, joist girders, or a combination of both—directly impacts a building’s cost, efficiency, and long-term performance. These two components complement each other within PEB and modern steel structure systems, offering both strength and design flexibility.

From a structural perspective, joist girders act as the primary load-bearing elements, transferring concentrated loads to columns, while steel joists provide lightweight and efficient support for roofs or floors. This balance between load capacity and material economy makes them ideal for applications ranging from industrial facilities and warehouses to stadiums and multi-story commercial buildings.

The main advantages include:

- High strength-to-weight ratio for long-span design

- Reduced material usage and faster on-site installation

- Adaptability to different project types, including PEB systems

- Lower lifetime cost through durability and low maintenance requirements

When comparing the difference between a girder and a joist, the choice depends on span requirements, load type, and design intent. Engineers typically combine both to achieve optimal structural performance while maintaining architectural freedom.

At SteelPRO PEB, every joist and girder is engineered and fabricated in compliance with ISO and CE standards, using automated production lines for consistent quality and load accuracy. We specialize in custom-engineered joist and girder systems for PEB structures—covering design, manufacturing, and optimization of load-bearing assemblies.

If you are planning a project that requires customized steel joist and girder systems, our engineers can help you determine the optimal configuration for your roof or floor structure—balancing load design, span efficiency, and fabrication cost.

Contact SteelPRO PEB’s technical team to discuss your project’s joist and girder requirements and receive a tailored structural proposal based on actual span and load criteria.