Steel structure buildings are known for their incredible strength, durability, and versatility. But what truly keeps these structures standing strong? The answer lies in their connections. Often unseen, steel connections are vital in ensuring stability, safety, and functionality. Whether a towering skyscraper or a sprawling industrial facility, the right connections make all the difference.

At SteelPRO PEB, a global steel structures and PEB manufacturer, we provide factory-direct, ISO & CE certified bolted and welded connections designed for industrial, commercial, and prefabricated steel buildings. With advanced CNC fabrication and robotic welding, our connections ensure durability, safety, and efficiency.

In this article, we’ll look closer at the types of steel connections, where they’re used, and how to design and implement them for the best results. Let’s dive in!

Types of Steel Connections

Connections in steel structures are essential in addressing various structural needs, and there are typically 5 main types. Each offers distinct advantages depending on factors like strength, flexibility, and installation ease. As a certified PEB structures producer, SteelPRO PEB provides bolted, welded, riveted, hybrid, and fixed connections tailored for warehouses, factories, and commercial steel buildings.

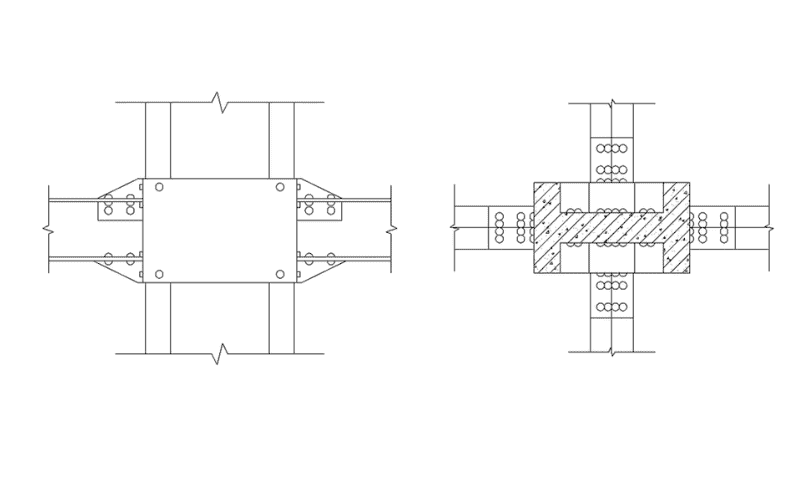

Bolted Connections

Bolted connections are established by fastening structural members together using bolts and nuts, allowing for secure yet flexible joints in steel structures.

These connections are widely used for their ease of installation and adjustability. They are cost-effective and versatile, making them suitable for a variety of applications. High-strength bolted connections, for example, are often used in seismic zones for their reliability.

Depending on the internal forces they’re designed to transfer, bolted connections can be classified into the following types:

- Force Combination:

- Axial + Shear: Typical in beam-to-column joints where both vertical loads and horizontal forces act simultaneously.

- Moment + Shear: Common in rigid frame joints where rotational stiffness is required.

- By Force Type:

- Axial Force Connections: Used in bracing systems to carry tension or compression.

- Shear Connections: Designed to transfer vertical or horizontal shear loads between members.

- Moment Connections: Resist bending moments and are used where frame rigidity is needed.

- By Load Transfer Mechanism:

- Bearing-Type Connections: Load is transferred through bolt bearing on the hole surface—simple and widely used.

- Friction-Type (Slip-Critical) Connections: Rely on bolt tension and surface friction to prevent slippage—ideal for dynamic or seismic loads.

These categories help engineers match the right connection to each structural need, ensuring safety and efficiency from the ground up.

All bolted connections supplied by SteelPRO PEB are manufactured in-house with CNC drilling and ISO-certified processes, ensuring high precision and global compliance.

Related Reading: Steel Structure Bolts: Types, Applications, Installation and Others

Welded Connections

Welded connections are formed by fusing steel components together using heat, creating a continuous joint with no mechanical fasteners. This results in a rigid, permanent bond that transfers loads smoothly between connected members.

Welded connections offer exceptional strength and rigidity, creating a seamless bond between structural members. They’re commonly used in applications where aesthetics and load-bearing capacity are equally important. However, they require skilled labor and precise execution.

Depending on the function and stress behavior, welded connections can be classified into:

- By Weld Type:

- Fillet Welds: Used in lap joints, T-joints, and corner joints—easy to apply and ideal for shear transfer.

- Groove Welds: Found in butt joints and used where full-strength axial or moment transfer is required.

- Fillet Welds: Used in lap joints, T-joints, and corner joints—easy to apply and ideal for shear transfer.

- By Load Transfer:

- Shear-Resisting Welds: Found in beam-to-column joints where horizontal forces need to be transferred efficiently.

- Moment-Resisting Welds: Provide rotational restraint in rigid frames—critical for high-rise and seismic applications.

- Shear-Resisting Welds: Found in beam-to-column joints where horizontal forces need to be transferred efficiently.

- By Fabrication Method:

- Shop Welds: Done in controlled environments for precision and quality assurance.

- Field Welds: Performed on-site—offer flexibility but require tighter supervision and experienced welders.

- Shop Welds: Done in controlled environments for precision and quality assurance.

These categories ensure welded connections are tailored to meet specific load paths, structural demands, and site conditions, helping engineers design safer, more efficient buildings.

At SteelPRO PEB, welded connections are produced using robotic welding and strict ISO quality checks, guaranteeing long-term durability and seamless strength.

Riveted Connections

Riveted connections are created by inserting a hot metal rivet through aligned holes in steel members and then hammering or pressing the tail to form a second head, producing a permanent mechanical joint upon cooling.

While riveted connections are less common today, they were once the standard in steel construction. They’re still used in specific scenarios, such as heritage restoration projects, where their historical significance is valued.

Hybrid Connections

Hybrid connections combine the best of both worlds—bolting and welding. This approach is often used in complex structures where flexibility and strength are equally critical.

Pinned and Fixed Connections

Pinned connections allow rotation, making them ideal for trusses and arches. Fixed connections, on the other hand, prevent rotation and are used in rigid frames to ensure stability under heavy loads.

The following is the historical timeline of steel connection methods:

Practical Roles of Steel Connections in Prefabricated & PEB Structures

Steel connections keep structures strong, stable, and safe. While we’ve covered types, let’s now explore their real-world applications. Beyond load transfer, they boost construction speed, safety, and flexibility. Here’s how they work:

Supporting Vertical and Lateral Load Distribution

Steel connections help distribute vertical and lateral loads throughout a structure, making sure forces move smoothly from one part to another. For example, in multi-story buildings, loads from the upper floors are transferred down to the foundation through well-designed connections. This ensures the structure can handle everything from daily use to extreme weather, like strong winds or earthquakes—keeping the building safe and sound.

Enabling Open, Flexible Layouts

Ever wondered how those wide open spaces in commercial buildings or warehouses are made possible? It’s thanks to steel connections! By transferring loads efficiently, connections like beam-to-beam designs let architects create large, unobstructed areas without worrying about sacrificing safety. These designs offer the flexibility businesses need to adapt to different uses, all while keeping things structurally solid.

Ensuring Stability and Safety in High-Rise Structures

In tall buildings, steel connections are crucial for maintaining stability. Column base connections, for example, anchor columns to the foundation, ensuring the building stays grounded and secure. This is particularly crucial in high-rise structures, where the building must remain resilient against seismic forces or strong winds. Simply put, these connections are what keep the skyscrapers from swaying too much in a storm.

Design Considerations for Steel Connections

Steel connection design requires balancing performance, safety, and efficiency. Key factors like load handling, material compatibility, and long-term durability are critical. Here are the essential considerations for successful connection design:

Load Transfer Mechanisms

Understanding how forces like axial loads, shear, and moments are transferred is essential for designing effective connections. These forces must move efficiently between structural elements, ensuring stability under both static and dynamic loads. An improperly designed connection can lead to stress concentrations, causing potential failure.

- Axial Loads: Responsible for pushing or pulling on structural members.

- Shear Forces: Need to be transferred safely to prevent slippage or failure.

- Moments: Must be handled to avoid bending or twisting of components.

For example, in beam-to-column connections, both vertical loads and lateral forces from wind or seismic events must be effectively managed without compromising the structure’s integrity.

Material Compatibility

The materials used in connections must be compatible with the steel structural members to ensure long-term durability. Incompatible materials can lead to corrosion, reduced strength, or thermal expansion mismatches. Choosing the right material is especially important in challenging environments.

- Corrosion Resistance: Important in coastal or industrial environments.

- Thermal Expansion: Mismatches between materials can create stresses over time.

- Strength and Durability: Materials must withstand daily wear and environmental conditions.

For instance, in coastal regions, selecting corrosion-resistant alloys or applying protective coatings is vital for maintaining the structural health of the connections.

Fabrication and Installation

Precision in the fabrication process and ease of installation are crucial to the success of steel connections. Errors during fabrication or challenges during installation can lead to costly delays and compromised structural performance. Connections must be fabricated to tight tolerances and installed with careful alignment to avoid issues like misfitting or weakening the connection.

For instance, poorly aligned beam connections can create stresses that exceed the design limits, leading to premature failure. Streamlining the installation process while ensuring quality control can result in substantial time and resource savings.

Designing steel connections requires balancing performance, safety, and efficiency. At SteelPRO PEB, we specialize in high-strength bolted connections for seismic resilience and precision-welded joints for seamless strength. Our tailored solutions ensure durability and reliability, even in the harshest conditions.

Durability and Maintenance

The durability of steel connections depends largely on factors like corrosion resistance and ease of maintenance. Steel structures are subjected to various environmental factors, including moisture, temperature fluctuations, and pollutants, all of which can deteriorate connection performance over time.

Therefore, using corrosion-resistant materials and ensuring access for regular inspections are key to extending the service life of the connections.

Additionally, designing connections for ease of maintenance—allowing for quick repairs or replacements—can reduce long-term operational costs and prevent unexpected failures, enhancing the building’s overall sustainability.

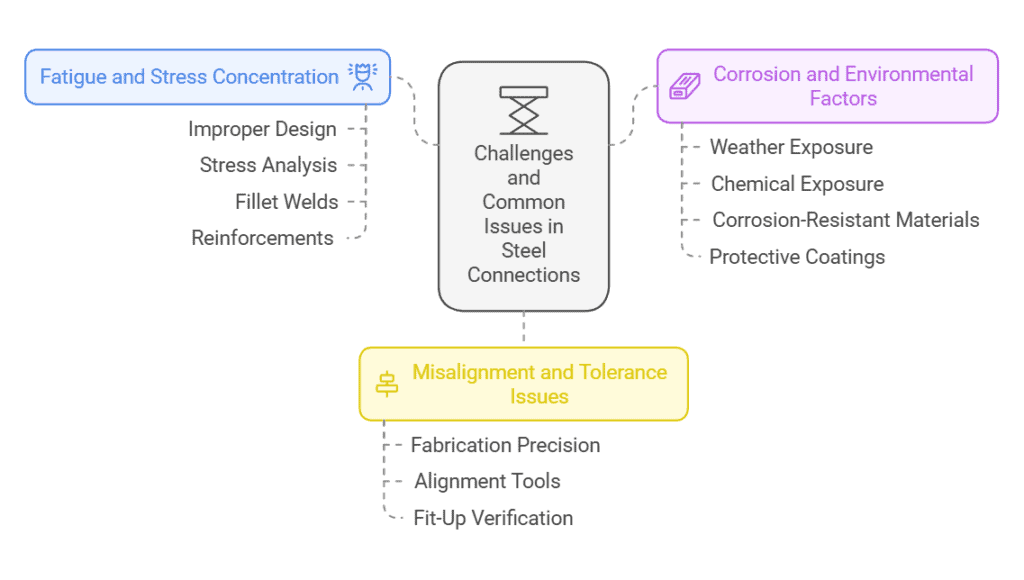

Challenges and Common Issues

While steel connections are crucial for structural stability, several challenges can arise during design, fabrication, or installation. Addressing these issues promptly can help prevent costly failures and ensure the longevity of the structure.

Fatigue and Stress Concentration

Improperly designed connections can lead to fatigue and stress concentration, causing failures over time, especially under repetitive loading conditions.

- Solution: Conduct thorough stress analysis during the design phase to ensure that forces are evenly distributed across the structure. Consider fillet welds and reinforcements in areas of high stress to prevent local overloads.

Corrosion and Environmental Factors

Exposure to weather, chemicals, and moisture can weaken the integrity of steel connections, leading to premature failure.

- Solution: Choose corrosion-resistant materials and apply protective coatings to enhance durability. Regular maintenance and inspection schedules can also identify early signs of corrosion and address them before they become major issues.

Misalignment and Tolerance Issues

Misalignment during fabrication or installation can lead to structural weaknesses, compromising the performance of steel connections.

- Solution: Ensure precise fabrication to tight tolerances. During installation, use alignment tools and verify fit-ups before welding or bolting connections in place.

Innovations in Steel Connections

Steel connection design is evolving through advancements in materials, technology, and construction, improving performance and sustainability. Here’s how these innovations are influencing the future:

Advanced Materials

Using high-strength steels and corrosion-resistant alloys enhances connection design, making them stronger, lighter, and more durable. These materials allow for higher load capacities and better resistance to harsh environments, reducing long-term maintenance costs. For instance, weathering steel minimizes corrosion, making it perfect for outdoor and coastal structures.

Smart Connections

Smart connections equipped with sensors are revolutionizing structural monitoring. These sensors can detect early signs of wear or failure by tracking real-time data, such as strain and temperature, allowing for proactive maintenance. This innovation extends the lifespan of structures and reduces the need for expensive repairs by catching issues before they escalate.

Modular and Prefabricated Connections

Streamline construction by reducing on-site errors and accelerating project timelines. By fabricating connections off-site, it’s possible to ensure higher precision, better quality control, and faster assembly, resulting in quicker and more cost-efficient builds.

What are the advantages of bolted connections over welded connections?

Bolted connections are faster to install, cost-effective, and easier to inspect and maintain compared to welded joints. At SteelPRO PEB, we manufacture high-strength bolted connections using CNC drilling and ISO-certified processes to ensure precision and reliability.

How are column-to-column connections designed in steel structures?

Column-to-column connections must handle both vertical loads and lateral forces. Our engineering team designs these joints with advanced analysis tools and fabricates them in-house, ensuring structural safety and compliance with international standards.

Which steel connections are best for commercial construction projects?

For warehouses, factories, and commercial facilities, bolted and hybrid connections are most commonly recommended due to their efficiency and adaptability. SteelPRO PEB provides factory-direct connectors, enabling faster project delivery and wholesale pricing.

Do you provide prefabricated steel connectors with international certification?

Yes. All our steel connections are produced in our 500-acre factory, fully compliant with ISO and CE certifications. We supply prefabricated steel connectors worldwide, ensuring durability, safety, and factory-direct cost advantages.

Finding Your Trusted Steel Structure Manufacturer

Steel connections are more than just technical components—they’re the foundation of structural integrity. From bolted and welded connections to hybrid and pinned designs, each type uniquely ensures steel structures’ stability and durability.

At SteelPRO PEB, we go beyond theory—we deliver factory-direct, ISO & CE certified steel connections for prefabricated and PEB structures worldwide. With 24 advanced production lines, 120,000 tons annual capacity, and projects in 30+ countries, our expertise ensures your buildings achieve maximum safety, efficiency, and durability.

Whether it’s a high-rise, industrial facility, warehouse, or bridge, our CNC-fabricated bolted joints and precision robotic welds provide the reliability your project demands.

Contact SteelPRO PEB today for a wholesale manufacturer quote and factory-direct supply of certified steel connections.