Building a metal home offers unmatched strength, energy efficiency, and design flexibility — but how exactly is a steel house constructed from start to finish?

This guide explains the entire metal house construction process, from pre-construction preparation and planning to factory manufacturing, on-site installation, and long-term maintenance. You’ll learn how to choose the right materials and structure type, how professional prefabrication reduces errors and build time, and what to consider during site preparation and installation. We’ll also cover key factors such as foundation design, climate adaptation, insulation, corrosion protection, and practical maintenance tips to extend your home’s lifespan.

All processes described are based on the expertise of SteelPRO PEB, an ISO- and CE-certified manufacturer and factory producer of steel structures, ensuring every step—from design to delivery—is backed by engineering precision and real-world experience.

Pre-construction preparation

Before you start building your metal home, several key factors must be carefully evaluated in advance. These include your purpose, budget, land conditions, and the materials to be used. Proper preparation ensures your construction process runs smoothly and your finished home is durable and safe.

Purpose of the Metal House

Before you decide to build a metal home, you should clarify your needs, budget, and lifestyle expectations.

Ask yourself:

- What is my budget?

- Do I need a custom design?

- Is the metal material suitable for my local climate?

- How quickly do I need to complete the house?

- Do I need flexibility for future expansion?

- What are the maintenance requirements?

- What functional systems (electricity, plumbing, ventilation) will I need?

- Does the plan comply with local building codes?

- What level of energy efficiency do I want?

- Is my land suitable for construction?

By answering these questions, you can better plan your metal home and avoid issues during construction.

Material Selection and Structural Type

Choosing the right structural type and metal material is a critical part of pre-construction preparation.

There are several main options for metal home structures:

- Light Steel Frame: Ideal for residential or small commercial houses. Lightweight yet strong, suitable for fast assembly.

- H-Beam or Portal Frame: Common for larger or multi-span buildings, offering excellent load-bearing capacity and wind resistance.

- Sandwich Panels: Used for walls and roofs, providing insulation, soundproofing, and waterproofing.

- Galvanized or Zinc-Aluminum Coated Steel: Recommended for humid or coastal regions due to enhanced corrosion resistance.

At SteelPRO PEB, all metal materials are produced under ISO and CE certifications, ensuring compliance with global safety and durability standards. Our engineers can recommend the most suitable structure based on your site environment and project scale.

Site Preparation

Choosing the right land and ensuring a stable foundation are essential. After determining the site, we recommend a professional soil and foundation assessment to ensure it meets the structural requirements for a metal house. Our technical team can provide detailed land preparation and foundation construction guidance.

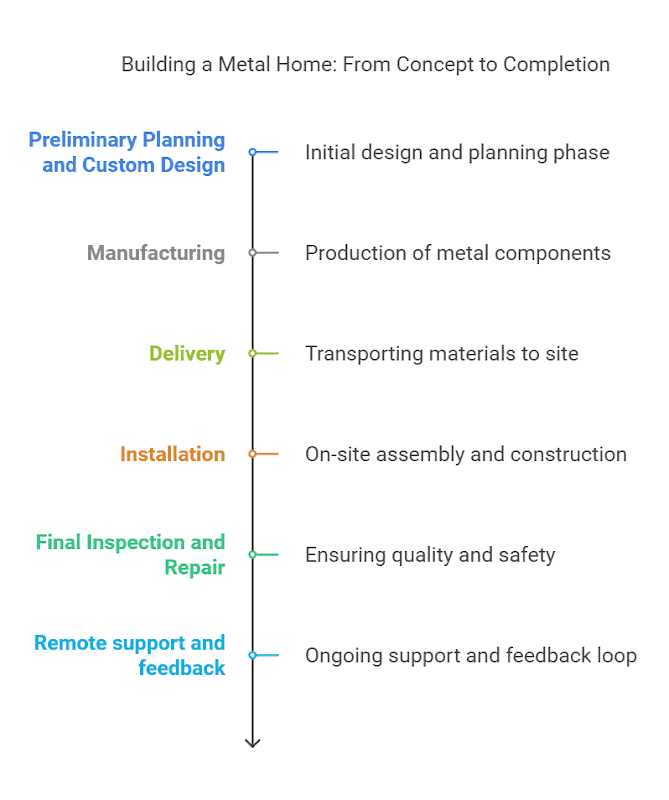

Step 1: Preliminary Planning and Custom Design

Planning is one of the most critical stages when building a metal home. A well-structured plan helps you manage your budget, ensure safety, and achieve the expected functionality and appearance. Before fabrication begins, clear communication and technical planning set the foundation for smooth construction.

Understanding Your Needs

The first step is to define your functional requirements and living preferences. Through one-on-one communication, our team helps identify your ideal layout, space division, and architectural features. Whether you need a simple single-room home or a multi-bedroom residence, this phase determines your project’s direction.

| Building Type | Typical Dimensions |

| Small Single Room | 6m × 6m |

| Two-Bedroom House | 8m × 12m |

| Three-Bedroom House | 10m × 15m |

| Garage / Workshop | 6m × 9m |

| Small Office | 10m × 20m |

| Warehouse / Workshop | 15m × 30m |

| Agricultural Barn | 20m × 40m |

During the planning phase, you can estimate the approximate construction cost and foundation requirements according to building size and type.

Technical & Structural Planning

Before entering the manufacturing stage, the structural stability of your design must be verified.

This includes:

- Load-bearing design review: Ensuring beams, columns, and joints can handle local wind and snow loads.

- Foundation alignment verification: Checking foundation layout and anchor bolt positioning before installation.

- Seismic and corrosion resistance planning: Selecting appropriate steel grades and anti-corrosion coatings based on the local environment.

All design drawings and technical details will be cross-reviewed by our engineering team to guarantee that the structure meets international standards for safety and durability.

Custom Features

After confirming the layout and structural plan, you can choose from various customization options such as roof type, wall materials, door and window placement, or insulation systems. Customization focuses on practicality — ensuring your home is functional, safe, and cost-efficient.

At SteelPRO PEB, our engineers conduct detailed technical audits before manufacturing to confirm the structure’s precision and compliance with international building codes.

Step 2: Manufacturing

Once the design plan is confirmed, the next stage is manufacturing, where your metal home’s components are produced with precision and quality control. This stage determines how efficiently the installation will proceed, so every detail must meet strict standards.

Factory Prefabrication Process

Most metal home components are prefabricated in the factory, including steel frames, columns, beams, wall panels, and roofing sheets. Prefabrication ensures:

- High precision: Each piece is cut, drilled, and welded according to the finalized design drawings.

- Faster assembly: On-site construction time is significantly reduced because the components fit perfectly.

- Lower labor cost: Less manual welding and adjustment on site.

- Fewer errors: Factory-controlled conditions guarantee accurate dimensions and consistent quality.

At SteelPRO PEB, all components are produced in our ISO- and CE-certified factory, equipped with CNC cutting, laser welding, and automatic shot blasting lines. Our production capacity of 120,000 tons per year ensures both small-scale residential and large commercial projects are delivered efficiently and consistently.

Precision Manufacturing and Quality Assurance

Every metal part is fabricated under a unified quality management system.

- Steel cutting & forming: Using CNC and plasma cutting machines to ensure accuracy.

- Welding: Automatic and manual welding combine for maximum strength.

- Surface treatment: Shot blasting and galvanizing remove impurities and enhance corrosion resistance.

- Coating inspection: Anti-corrosion paint and coatings are applied under controlled conditions to extend service life.

Each batch undergoes strict inspection before packaging — including dimensional testing, weld integrity, coating adhesion, and structural verification — ensuring that all parts are ready for seamless on-site installation.

Prefabrication Advantages

| Benefit | Impact |

| Faster project completion | 30–50% less construction time |

| Higher installation accuracy | Prefitted joints and pre-drilled holes |

| Lower environmental impact | Reduced on-site waste |

| Long-term durability | Anti-rust coating and quality steel |

With SteelPRO PEB’s advanced prefabrication process, you can ensure precision, reduce project risks, and achieve a faster build timeline — all while maintaining international quality standards.

Step 3: Delivery

After all components are manufactured and quality-checked, the next phase is delivery — ensuring that every part of your metal home reaches the site safely, accurately, and on time. Proper delivery preparation is crucial because even minor transportation damage can delay installation or compromise structural performance.

Efficient & Protected Logistics

Our logistics process begins immediately after factory inspection. Each steel component, panel, and accessory is carefully packaged, labeled, and wrapped with anti-rust film and corner protection to prevent moisture, scratches, or deformation during long-distance transportation. For overseas shipments, we use steel frame crates and waterproof wrapping to ensure safety during sea transport.

SteelPRO PEB collaborates with certified logistics partners to provide secure, GPS-tracked transportation solutions for both domestic and international projects.

Component Identification & Loading Process

Before loading, every piece is:

- Numbered and coded according to the assembly sequence.

- Listed in a packing checklist to ensure complete delivery.

- Loaded in order of installation, so components can be unloaded directly in the correct sequence at the job site.

This systematic approach minimizes handling errors and accelerates on-site installation.

Delivery Coordination

Once shipping arrangements are confirmed, our team provides you with:

- A full packing list and component map for easy verification on arrival.

- Customs and import documentation (for international deliveries).

- Delivery schedule tracking with real-time status updates.

If your project involves multiple buildings or phases, we can arrange batch delivery — sending components in stages to match your construction timeline and reduce on-site storage needs.

Smooth Transition to Installation

When the metal home kit arrives, each part is ready for assembly. Components are pre-drilled, pre-fitted, and delivered with installation manuals and technical drawings to guide efficient setup. Each SteelPRO PEB kit is designed for quick identification and simplified on-site work, reducing installation time and cost while ensuring structural accuracy.

Step 4: Installation

After manufacturing and delivery, the final stage of building your metal home is installation. This process can be completed through self-installation, contractor installation, or remote-assisted installation provided by the manufacturer. Whichever method you choose, following a systematic approach and precise alignment will ensure safety, durability, and long-term performance.

1. Preparation

Before starting installation, make sure the foundation and site are fully ready.

Pre-checks:

- Foundation verification: Confirm the foundation is solid, level, and fully cured.

- Tool & equipment setup: Prepare essential tools — cranes, electric screwdrivers, bolts, torque wrenches, safety harnesses, and protective gear.

- Component inspection: Verify all prefabricated components match the packing list and design drawings.

- Safety inspection: Ensure workers are equipped with helmets, gloves, and insulated boots; set up temporary fencing if needed.

Always check foundation bolt alignment and height before placing the base frame. This prevents later misalignment.

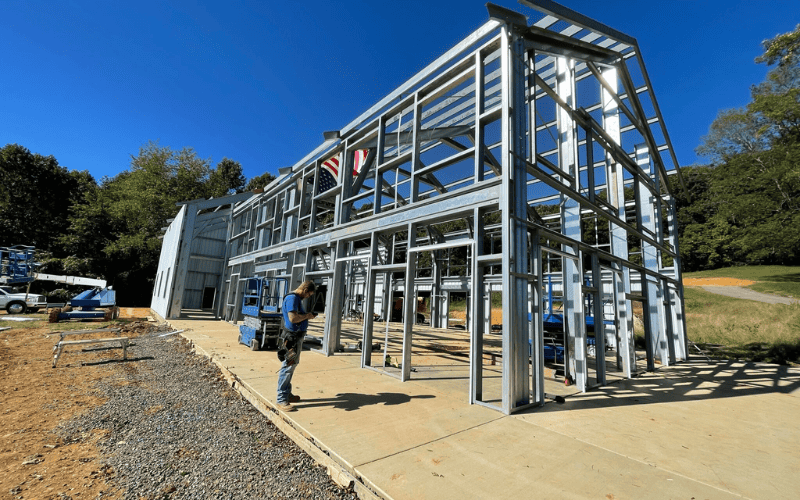

2. Frame Construction

The frame forms the skeleton of your metal home. Accuracy in this step determines the structural integrity of the entire building.

Process:

- Base frame assembly: Lay out base beams and secure them with anchor bolts.

- Column installation: Erect vertical columns, checking plumb alignment with a level.

- Beam connection: Attach beams to columns using high-strength bolts; tighten gradually in a cross pattern to ensure uniform stress.

- Structural bracing: Add diagonal bracing to enhance stability, especially in windy or seismic zones.

All SteelPRO PEB frames are pre-drilled and numbered, simplifying alignment and ensuring precise on-site assembly.

3. Roof Installation

The roof not only protects the structure but also contributes to insulation and energy efficiency.

Process:

- Install roof purlins and brackets according to the structural drawing.

- Lay roof panels from one side to the other, slightly overlapping each panel for proper drainage.

- Fasten panels with self-tapping screws, ensuring each joint is sealed with waterproof tape or silicone.

- Inspect the roof ridge and flashing to prevent water leakage and ensure tightness.

Apply sealing materials at screw points to enhance water resistance and prevent long-term corrosion.

4. Wall Installation

Once the frame and roof are in place, you can begin wall panel installation.

Steps:

- Position wall frames and secure them to the base and roof connections.

- Fix wall panels vertically or horizontally as per design. Ensure the joints are tight and uniform.

- Add structural reinforcement at corners and door/window openings to strengthen load capacity.

- Seal panel joints with weatherproof silicone or insulation tape for thermal efficiency.

Using sandwich panels with insulation cores (PU or rock wool) can significantly improve thermal performance in both hot and cold climates.

5. Door and Window Installation

Doors and windows must be installed precisely to ensure proper sealing, insulation, and long-term usability. Each frame should be aligned carefully before fixing the panels.

Steps:

- Install door and window frames — Check for levelness and perpendicularity; use spacers where needed to ensure uniform gaps.

- Fix panels or glass sections — Secure with screws or bolts according to material type (metal, aluminum, or PVC).

- Apply sealant — Use weatherproof silicone or rubber gaskets around the perimeter to prevent water infiltration.

- Final check — Open and close each door and window to confirm smooth operation and no gaps.

Use polyurethane foam or rubber insulation between frames and walls to improve soundproofing and prevent heat loss.

6. Internal System Installation (Electrical and Plumbing)

Internal systems must be installed in coordination with the steel frame to avoid interference and ensure safety.

Key Points:

- Electrical wiring: Plan wiring routes before wall cladding. Use conduits and pre-drilled holes in beams or columns to avoid cutting or welding on-site.

- Plumbing layout: Install supply and drainage pipes along the planned routes, keeping a minimum clearance from steel joints.

- HVAC and insulation: Mount brackets before wall finishing, and seal all pipe penetrations with waterproof sleeves.

Never modify the structural members during electrical or plumbing installation. All SteelPRO PEB designs include predefined access points for wiring and piping to simplify internal system layout.

7. Final Inspection and Adjustment

When installation is complete, conduct a comprehensive inspection to confirm that every part meets the design requirements.

Checklist:

- Verify all bolts are tightened to the specified torque.

- Check alignment of roof panels, walls, and door/window frames.

- Test all electrical and plumbing systems for functionality and leaks.

- Inspect coating, sealant, and insulation for damage or gaps.

- Perform a load check if applicable for large-span or multi-storey structures.

After verification, clean the site and remove all temporary supports and debris.

Following the manufacturer’s bolt torque and sequence specifications ensures consistent tension and prevents frame distortion.

8. Remote Support and Feedback

If you encounter any issues during installation, our technical support team provides real-time remote assistance via:

- Video calls or online conferencing

- Detailed digital manuals and drawing sets

- Troubleshooting guides for structural alignment or system integration

SteelPRO PEB engineers are available to train your on-site crew or contractors before installation begins, ensuring that every project follows correct assembly standards and safety protocols.

This remote support service helps reduce installation errors, ensures compliance with engineering standards, and speeds up project delivery.

Tips & Best Practices

- Always follow the installation sequence — skipping steps can lead to structural misalignment.

- Tighten bolts in a cross pattern to maintain frame balance.

- Conduct weekly inspections during installation to catch issues early.

- Ensure grounding for all electrical systems.

- Keep construction logs and inspection reports for future maintenance reference.

Regular monitoring and adherence to safety procedures are essential for a stable, long-lasting metal home.

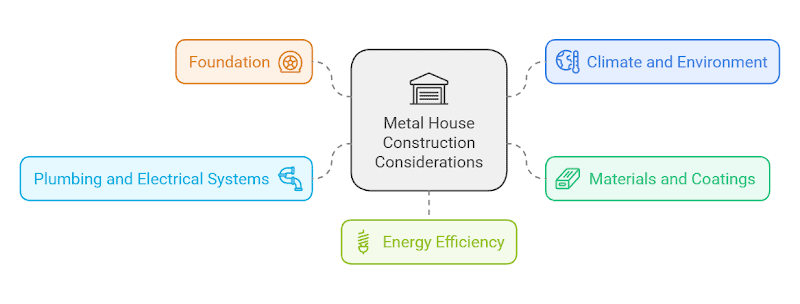

Considerations for building a metal house

Building a metal home requires careful attention to details that directly affect structural safety, comfort, and long-term performance. While the design and installation processes are relatively straightforward, several technical and environmental factors deserve special focus.

1. Foundation Stability

A solid foundation ensures the entire structure remains stable and safe. Before construction, perform a soil load-bearing capacity test and verify that the foundation surface is level. Minor deviations in elevation or anchor bolt placement can cause misalignment during frame installation.

For soft soil or high groundwater areas, consider using reinforced concrete pads or deep footings to prevent settlement and moisture issues.

2. Climate and Environmental Conditions

Different climates require specific structural and material adaptations:

- High-humidity areas: Use galvanized or aluminum-zinc-coated steel for corrosion resistance.

- Cold regions: Add insulation panels (PU or rock wool) and anti-condensation coatings.

- High-wind zones: Strengthen column spacing and roof bracing according to local wind load standards.

Proper environmental adaptation not only improves safety but also extends the building’s service life.

3. Material and Coating Selection

Select steel grades and protective coatings that match your regional conditions and maintenance capabilities. While standard painted steel works well in most environments, galvanized, hot-dip, or aluminum-magnesium alloy coatings are ideal for coastal or industrial areas. Inspect coatings annually to ensure continued protection against rust and fading.

4. Plumbing, Electrical, and Drainage Planning

Plan these systems before wall and roof closure.

- Reserve wiring conduits and pipe openings during design.

- Include sufficient slope in roof drainage systems to avoid water pooling.

- Add insulation around pipes that run through external walls or roofs to prevent condensation.

5. Energy Efficiency and Ventilation

A metal home can be highly energy-efficient if proper insulation and ventilation systems are applied. Use double-layer roof systems and ventilated wall gaps to balance indoor temperature and reduce thermal bridging. Installing ridge vents, wall louvers, or exhaust fans helps regulate humidity and airflow.

Common Construction Challenges & Solutions

| Challenge | Cause | Solution |

| Foundation unevenness | Inaccurate excavation or poor curing | Re-level using leveling grout or shim plates before installing the base frame. |

| Roof leakage | Improper overlap or sealing | Apply waterproof tape under joints and check torque on roof fasteners. |

| Panel deformation | Over-tightened bolts or uneven support | Use torque-controlled tools; avoid excessive tightening. |

| Thermal bridging | Continuous steel contact between interior/exterior | Add insulation breaks or thermal spacers. |

| Corrosion spots | Scratched coating during handling | Touch up with approved anti-rust paint immediately. |

These issues are common in first-time installations and can be prevented through proper inspection, alignment checks, and qualified supervision.

Professional Support

Even with a solid plan, unexpected field conditions may require expert advice. That’s why SteelPRO PEB’s engineering team provides on-demand consultation for foundation reinforcement, structure optimization, and load recalculation. Our experience in global steel structure projects ensures your metal home meets both international standards and local site conditions.

Working with an experienced manufacturer ensures every detail—from material selection to installation tolerance—is professionally handled.

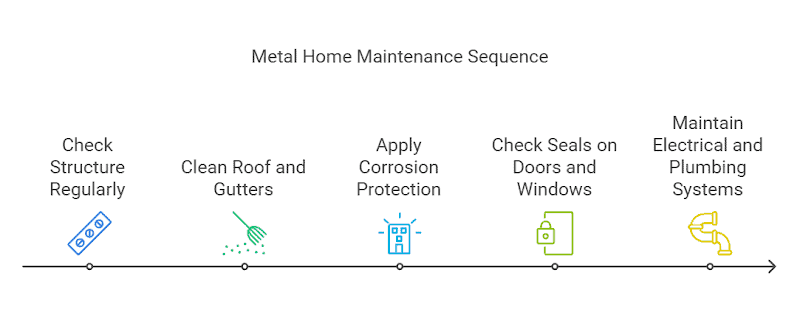

How to maintain a metal house

Metal homes are relatively simple to maintain, but regular maintenance can help ensure they stay in good shape for the long term. Here are some tips:

1. Structural and Joint Inspection

Perform a comprehensive inspection of the structure at least once a year. Focus on areas that experience high stress or exposure to weather, such as roof joints, wall connections, and beam intersections.

Check for:

- Loose bolts or fasteners

- Minor frame deformation

- Corrosion at exposed metal surfaces

- Cracked sealant or coating peeling

Use a torque wrench to verify bolt tightness and apply anti-rust lubricant to joints if needed.

2. Cleaning the Roof and Gutters

Debris such as leaves, dust, and bird droppings can trap moisture and accelerate corrosion.

- Clean the roof and gutters at least twice a year (ideally before and after the rainy season).

- Check for clogged drainage pipes or standing water on flat roof sections.

- Avoid using abrasive cleaning tools that may scratch the protective coating.

Use soft brushes or low-pressure water jets for safe cleaning.

3. Corrosion Protection and Surface Coatings

The protective coating on your metal home prevents oxidation and extends the structure’s lifespan.

Inspect the coating regularly and take corrective action immediately if damage is found.

Maintenance recommendations:

- For standard galvanized steel, check for scratches or rust spots every 12 months.

- For zinc-aluminum-magnesium coatings, inspection every 2–3 years is sufficient.

- For painted or powder-coated surfaces, repaint or touch up every 5–7 years, depending on exposure.

When repairing, always use a compatible primer and topcoat — mismatched paint can cause blistering and faster corrosion.

4. Doors, Windows, and Sealing Systems

Check seals, gaskets, and insulation strips around doors and windows at least once a year.

Aged or cracked seals can lead to moisture penetration, heat loss, and noise leakage.

- Replace damaged rubber seals promptly

- Lubricate hinges and locks to prevent corrosion or jamming.

- Reapply waterproof sealant on window perimeters if peeling is observed.

5. Internal System Maintenance

Regularly inspect internal systems such as electrical wiring and plumbing:

- Test circuit breakers, sockets, and lights after heavy storms or long idle periods.

- Inspect water pipes for leaks or condensation.

- Clean ventilation ducts and filters to maintain healthy airflow and prevent mold.

Avoid drilling or modifying structural elements when making repairs to internal systems.

6. Maintenance Frequency: DIY vs Professional Care

| Maintenance Task | Recommended Frequency | Who Should Do It |

| Roof & gutter cleaning | 2 times per year | Homeowner (DIY) |

| Coating inspection | Annually | Professional inspector |

| Bolt tightening & frame check | Annually | Professional or trained crew |

| Sealant & waterproofing | Every 2 years | Homeowner / Contractor |

| Repainting or recoating | Every 5–7 years | Certified coating specialist |

A simple maintenance logbook can help track these actions and ensure your structure remains compliant with warranty conditions.

7. Long-Term Protection and Support

Proper maintenance dramatically extends the lifespan of your metal home — often exceeding 50 years with regular care. For major inspections or refurbishment, SteelPRO PEB provides professional technical support, including:

- Coating inspection and corrosion analysis

- Structural integrity testing

- Replacement of aged fasteners or components

Our engineering team offers on-demand consultation to help you keep your steel home performing at its best under any environmental condition.

Related Reading: Steel Structure Building Maintenance: What You Need to Know

Where to Get Reliable Metal Home Construction Support

Building a metal home is more than just assembling steel components. It requires precise coordination between design, factory manufacturing, and on-site installation. For many homeowners, the biggest challenge isn’t the plan itself, but finding a trusted partner who can guarantee structural quality, accurate prefabrication, and post-installation support.

That’s where SteelPRO PEB, a certified steel structure manufacturer, provides real value. Unlike trading companies, we handle the entire process — from engineering design and component fabrication in our ISO- and CE-certified factory, to packaging, delivery, and remote installation guidance. This factory-direct model eliminates middlemen, ensuring that each project receives both cost transparency and technical consistency.

Whether you’re building a small residential home or a multi-unit steel housing project, our team focuses on one goal: to make your construction process faster, safer, and easier — backed by professional manufacturing strength and real engineering experience.

Build confidently with a factory that understands every bolt, beam, and joint of your metal home.

How long does it take to build a metal home?

The construction timeline depends on the design complexity, size, and site preparation. Typically, a prefabricated metal home can be completed within 3 to 6 months — from design to full installation. Factory fabrication significantly shortens on-site work, allowing faster, cleaner, and more predictable project delivery.

Can custom features such as windows or balconies be added?

Yes. Metal homes are highly flexible in design. You can customize roof styles, wall materials, window sizes, or even add balconies and porches. All modifications are engineered in the factory stage to ensure stability, waterproofing, and aesthetic harmony.

What kind of foundation does a metal home need?

A reinforced concrete foundation is recommended for most projects. The exact type—slab, strip, or pier—depends on soil condition, local regulations, and building size. Our engineering team reviews foundation data to ensure structural safety and proper anchor alignment before installation.

How to ensure the energy efficiency of a metal home?

Energy efficiency is achieved through the right materials and structural design:

- Use insulated sandwich panels for walls and roofs.

- Add ventilated roof gaps and ridge vents for airflow.

- Choose low-emissivity windows and tight seals to reduce heat transfer.

- Proper insulation minimizes cooling and heating costs all year round.

SteelPRO PEB provides material selection guidance to help you meet energy standards while maintaining cost efficiency.

Do I need professionals to install a metal home?

While smaller kits can be assembled with basic tools, professional installation is strongly recommended for long-term safety. Certified installers ensure correct torque on bolts, proper sealing, and alignment — all critical to structural performance and warranty validity. SteelPRO PEB offers remote and on-site installation guidance, ensuring your metal home is built precisely to design specifications.