Typically, construction can range from just a few days for small sheds to several months for large industrial facilities, depending on design complexity, project type, and preparation.

This guide breaks down the entire metal building construction process, explores key factors that influence timelines, such as building size, crew experience, and supply chain reliability, and shares proven ways to speed up construction through prefabrication and better scheduling. You’ll also find estimated timeframes for different building types, from modular warehouses to steel barndominiums, followed by practical takeaways to help plan your project efficiently.

Written with insights from SteelPRO PEB, a certified steel structure manufacturer, this article reflects real-world data and global best practices to help you set realistic expectations and ensure a smooth, on-time build.

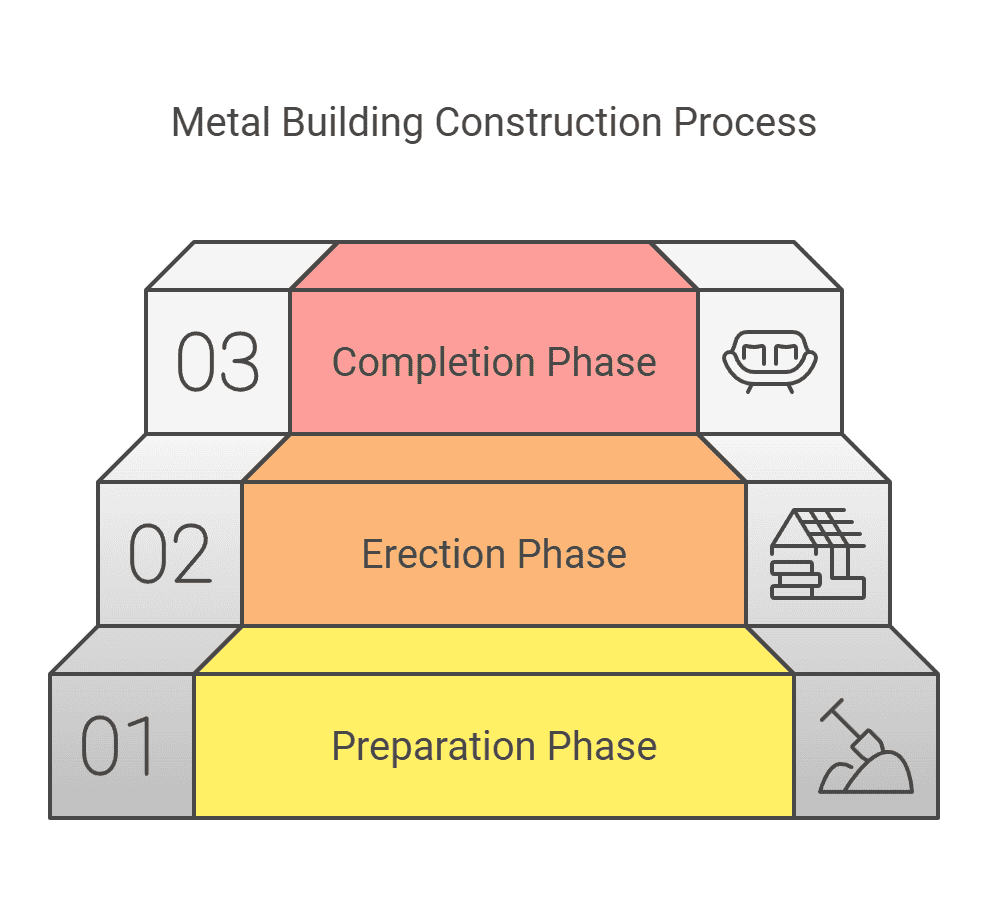

The Metal Building Construction Process

Understanding the general construction process of a metal building can help you set realistic expectations for your project timeline. If you’re already familiar with this part, feel free to skip ahead to other sections of the article. The construction of a metal building typically follows three main stages:

1. Preparation Phase

- Site Preparation: Land is cleared, leveled, and prepped for construction.

- Foundation Work: Concrete foundation is poured and cured.

- Material Delivery: Materials are delivered to the site, with timing depending on availability and shipping.

This phase generally accounts for about 15% of the total construction time for most standard projects.

2. Erection Phase

- Framing and Structure Setup: The steel columns, beams, and supports are assembled.

- Exterior Installation: Metal panels for the walls and roof are installed.

For standard single-span steel warehouses or workshops, the erection phase typically takes 40–60% of total time, depending on crew experience, site readiness, and weather. Pre-engineered components fabricated off-site can significantly reduce erection time once delivered and inspected.

3. Completion Phase

- Interior Work and Finishing: This includes installing doors, windows, and internal systems like electricity and plumbing.

This phase generally accounts for about 45% of the total construction time, though complex projects (e.g., multi-story or customized commercial steel buildings) may extend this stage.

Disclaimer: These time allocations are general estimates, not fixed standards. Actual construction timelines can vary significantly based on customization, building type, and fabrication efficiency. Consulting with an experienced steel structure manufacturer can help you obtain a more accurate project-specific schedule.

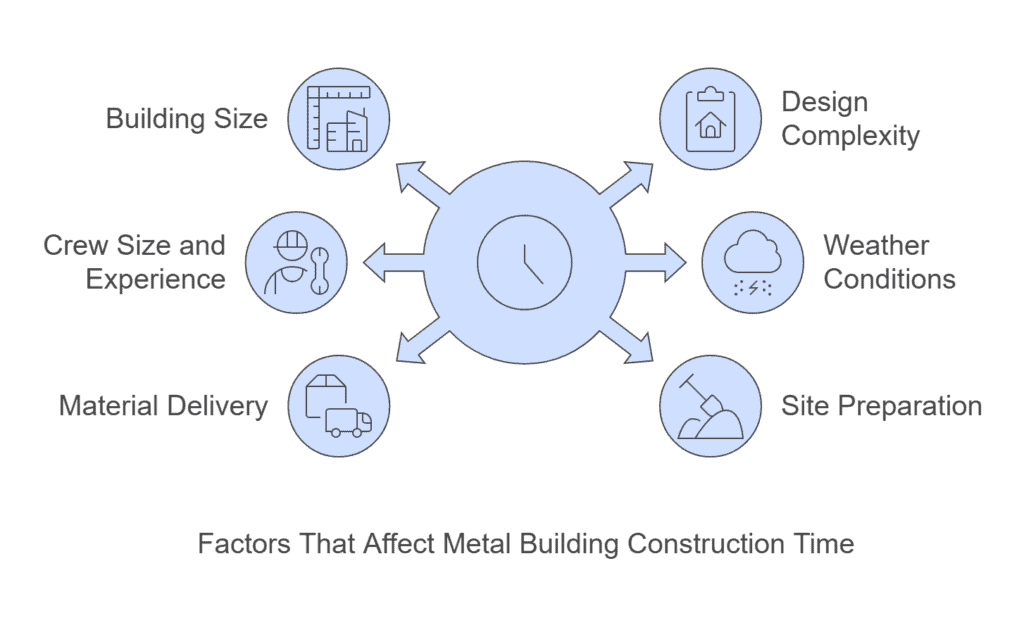

Factors That Affect How Long It Takes to Build a Metal Building

Several key factors determine how long it takes to complete a metal building project. While timelines vary, understanding each element can help you plan better and reduce avoidable delays.

1. Building Size

The size of the building remains one of the most significant factors in determining construction time.

- Small Buildings: A simple garage or storage shed (e.g., 20×30 ft) could take a few days to a week.

- Medium Buildings: A modular warehouse or small workshop (e.g., 40×60 ft) could take 2–4 weeks, depending on prefabrication level.

- Large Buildings: For commercial facilities or industrial warehouses (e.g., 100×200 ft), construction could take 1–3 months.

Larger projects require more materials, labor, and logistics coordination. Choosing pre-engineered kits from a certified steel structure producer can shorten the total schedule.

2. Design Complexity

The complexity of your design directly impacts how long construction takes.

- Simple Designs: A rectangular, single-story metal building with standard roof height typically goes up in a few days to two weeks.

- Complex Designs: Barndominiums or multi-story steel buildings often require additional time for custom fabrication and assembly.

Projects using modular or pre-engineered components can simplify this stage and reduce overall lead time.

3. Crew Size and Experience

The number and expertise of your construction crew significantly influence project speed.

- A small, less experienced team may be suitable for basic sheds or garages.

- A professional crew of 8–10 trained workers can cut the erection phase by 30–40% compared to small local teams.

Partnering with an experienced steel contractor familiar with pre-engineered systems improves accuracy and installation efficiency.

4. Weather and Climate Conditions

Weather is an unpredictable but crucial factor.

- Rain, snow, or strong winds can halt construction, especially during the foundation and erection phases.

- In colder climates, frozen soil or curing issues can add days or weeks.

Plan your schedule to avoid extreme seasons whenever possible. For modular and pre-assembled structures, construction time can often be reduced since most work is completed indoors before delivery.

5. Material Delivery and Supply Chain Issues

Timely delivery of materials is essential for keeping projects on schedule.

- Late arrival of steel frames, roofing panels, or bolts can create idle time for crews.

- International shipping or custom fabrication can also extend lead times.

Working with a certified steel manufacturer that integrates fabrication, logistics, and quality control helps avoid supply chain delays and ensures consistent delivery.

6. Site and Foundation Preparation

Site readiness strongly affects how quickly construction can begin.

- Sites with poor drainage or uneven terrain often require rework or additional grading.

- A well-prepared foundation allows immediate steel erection once materials arrive.

Proper soil testing and site inspection before fabrication can prevent unexpected downtime later.

7. Project Type and Prefabrication Level

The level of prefabrication and the project type can drastically influence construction speed.

- Pre-engineered modular warehouses, steel carports, or temporary structures often take 40–60% less time to assemble than conventional builds.

- Highly customized industrial buildings, by contrast, may require on-site adjustments that extend the schedule.

Opting for a higher prefabrication ratio—where structural components are factory-produced—leads to faster on-site assembly and fewer weather-related interruptions.

Timely project completion is one of the biggest priorities for any metal building owner. While many factors are beyond control—like weather or shipping—there are proven strategies to shorten the construction schedule and reduce downtime.

Plan Early and Confirm Details

Address potential challenges early — from site selection and permits to foundation design and utility planning. Completing these preparations before fabrication ensures a smooth start once materials arrive. Double-check anchor bolt plans, foundation drawings, and component compatibility before production begins. This helps avoid costly rework during erection.

Choose an Experienced Construction Team

An experienced team familiar with PEB (Pre-Engineered Building) systems can assemble components faster and with higher precision. Skilled crews can also adjust for minor site deviations without halting progress. A crew trained specifically for pre-engineered steel erection can typically reduce total project time by 20–30%.

Use Prefabricated or Modular Building Systems

Prefabrication is one of the most effective ways to accelerate metal building construction. By producing columns, beams, and roof panels in a controlled factory environment, on-site assembly time is drastically shortened. Modular warehouses, carports, and workshops often take 40–60% less time to complete compared to traditional steel structures assembled entirely on-site.

Optimize Material Delivery and Scheduling

Coordinate material delivery to match your construction timeline. Avoid having components idle on-site, but also ensure deliveries arrive just before erection to prevent waiting gaps. Many professional suppliers offer synchronized logistics — planning shipments in stages so that framing, wall, and roof materials arrive exactly when needed.

Schedule Construction During Favorable Seasons

Whenever possible, plan your project during dry or mild weather months. This minimizes downtime caused by heavy rain, snow, or extreme heat, especially during the foundation and exterior phases.

Ensure Continuous Communication Between Teams

Delays often occur when designers, manufacturers, and installers are not aligned. Regular communication helps ensure all parties stay synchronized, particularly when custom adjustments are needed during construction.

Working with an experienced steel structure manufacturer or PEB producer that integrates design, fabrication, and logistics ensures every stage — from material readiness to on-site erection — flows efficiently and reduces unnecessary waiting time.

Estimated Construction Time for Different Types of Metal Buildings

Here’s a general overview of how long different types of metal buildings take to complete, assuming standard site conditions and prefabricated components.

| Building Type | Typical Size (ft) | Construction Time | Notes |

| Small Metal Shed / Garage | 20×30 | 3–7 days | Ideal for storage or small workshops; quick assembly using prefab kits. |

| Modular Warehouse | 40×60 | 2–4 weeks | Prefabricated sections reduce on-site welding and assembly time. |

| Commercial Steel Workshop | 80×150–100×200 | 4–8 weeks | Time varies based on design complexity and interior fit-out needs. |

| Steel Barndominium / Multi-Story Building | Custom | 8–12 weeks | Includes framing, insulation, and interior work; more complex scheduling. |

| Prefabricated Carport / Storage Unit | Standard kit | 1–2 weeks | Factory-made frames allow very fast installation. |

These timeframes assume a well-prepared foundation and timely material delivery. Weather, design changes, or late shipments can extend total project duration.

If you’re comparing project timelines, note that prefabricated and modular steel buildings generally complete 40–60% faster than conventional structures due to reduced on-site fabrication.

For accurate scheduling, always confirm with your building manufacturer — they can estimate based on your building size, customization level, and site conditions.

Key Takeaways

Building a metal structure involves a series of planned stages — from preparation and foundation work to steel erection and finishing. How long each stage takes depends on building size, complexity, crew experience, weather, and supply chain reliability.

Here’s a concise summary of what to keep in mind when planning your project:

- Small buildings (e.g., garages or sheds) can often be completed within a week.

- Medium projects, like modular warehouses or workshops, generally take 2–4 weeks, depending on prefabrication level.

- Large or customized facilities may require 1–3 months, especially when interior finishing is included.

- Early planning and experienced teams significantly reduce construction time.

- Prefabricated and modular steel structures consistently deliver faster timelines due to minimized on-site work.

The more fabrication work completed in the factory, the less time required on-site — improving both efficiency and schedule reliability.

To accurately estimate your timeline, consider consulting a professional PEB (Pre-Engineered Building) manufacturer. They can assess your project type, material readiness, and local site conditions, helping you set realistic expectations and minimize potential delays.