Light steel framing is a modern construction system that combines strength, precision, and sustainability. For builders, architects, and homeowners asking “Is light steel framing the right choice for my project?” — the answer depends on understanding its real advantages, disadvantages, and practical factors.

In this guide, we explore the key pros of light steel framing — including its lightweight design, durability, construction speed, energy efficiency, and cost-effectiveness — as well as the common misconceptions surrounding steel frames, such as cost, rust, and noise. We’ll also examine the potential challenges like thermal conductivity, initial investment, and reliance on supplementary materials, and provide decision factors to help you assess budget, project scale, and sustainability goals.

With insights from SteelPRO PEB, a certified PEB & Steel Structures Manufacturer, this article offers a balanced, experience-based view to help you make confident, data-driven construction decisions backed by engineering expertise and international quality standards.

The Pros of Light Steel Framing

1. Lightweight and Strong

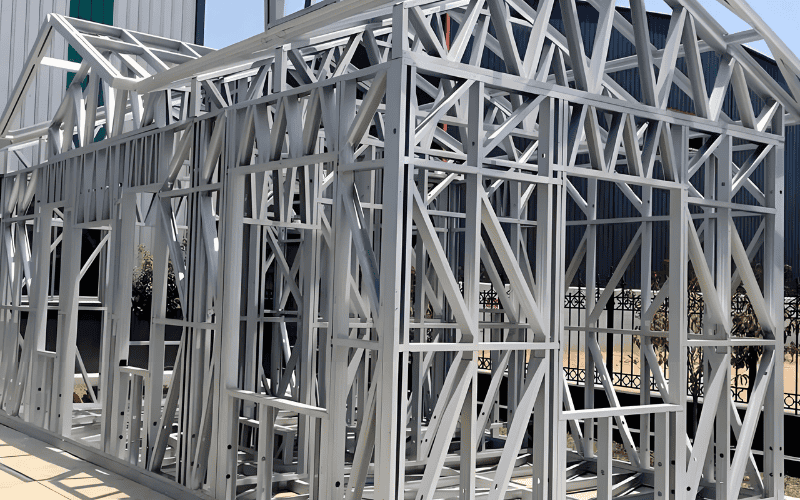

Light steel framing is approximately 30% lighter than timber, yet significantly stronger. This combination means easier transportation, quicker installation, and less labor on-site. For owners, it translates into lower costs and faster project completion.

2. Fast and Precise Construction

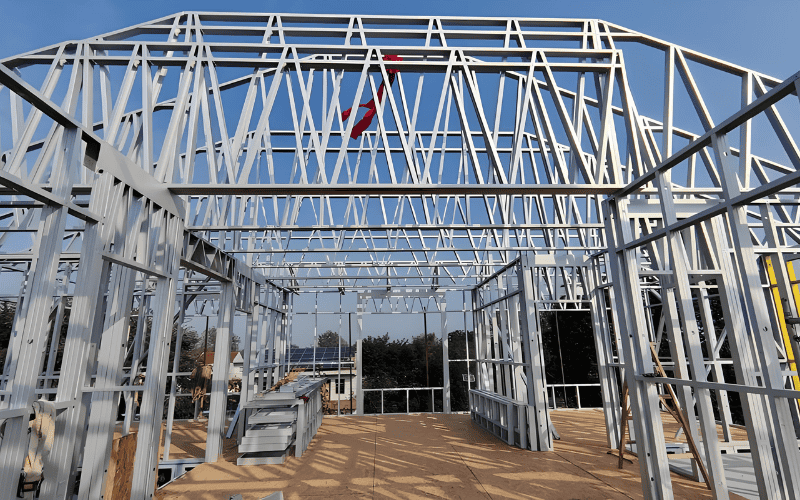

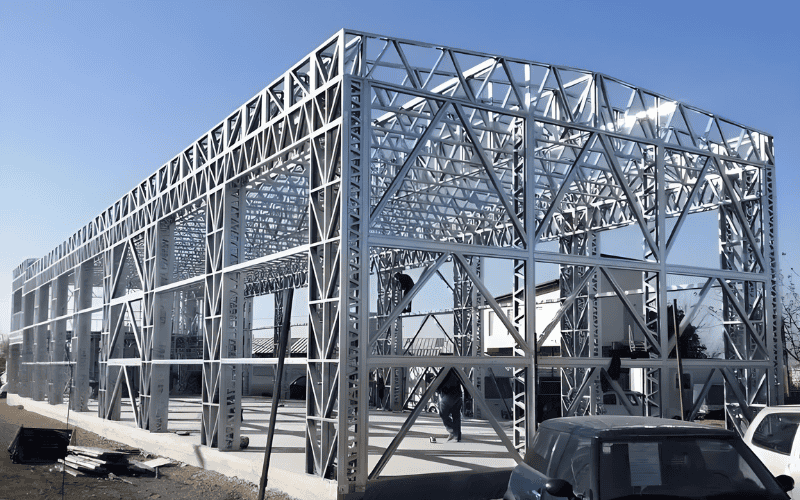

Thanks to its modular, prefabricated design, light steel framing ensures fast, efficient construction with minimal errors. Factory-made components reduce delays and provide better control over timelines and budgets, making it a great choice for projects that demand speed and reliability. It’s even ideal for temporary structures like modular housing or site offices.

3. Durable and Low Maintenance

Steel resists fire, moisture, pests, and decay, offering long-lasting protection with minimal upkeep. Treated with protective coatings, it performs exceptionally well in humid or coastal areas, cutting down on repair costs. Plus, its durability means it can be reused or recycled, providing both environmental and economic benefits at the end of its lifecycle.

4. Flexible and Space-Efficient Design

Light steel framing supports open layouts and adaptable designs, perfect for modern homes or high-rise buildings. Its slim yet strong walls maximize usable interior space, which is especially valuable in urban projects. Additionally, its flexibility allows for easy future expansions, like adding new floors or extending wings, with minimal disruption.

5. Eco-Friendly and Sustainable Material

Steel is 100% recyclable, and many light steel framing projects use up to 85% recycled materials. This significantly reduces waste during production and construction, making it a top choice for eco-conscious builders. Its ability to be repurposed or recycled at the end of its lifecycle also adds long-term economic and environmental benefits.

6. Resilient in Extreme Conditions

Light steel framing is designed to withstand earthquakes, hurricanes, and other harsh conditions. Its flexibility absorbs shocks during seismic events, making it a reliable choice in regions like Japan or New Zealand. Strong connection systems also ensure stability in high winds, while its ability to support long spans without extra support makes it perfect for large commercial buildings, industrial spaces, and even bridges.

7. Compatible with Modern Building Technology

Light steel framing works seamlessly with tools like Building Information Modeling (BIM), allowing for precise designs and reduced on-site conflicts. This integration streamlines project execution and ensures high-quality results.

8. Water-Tight and Air-Tight Performance

The non-porous nature of steel makes it ideal for structures requiring water-tight or air-tight properties. Whether it’s pipelines, reservoirs, or energy-efficient buildings, light steel framing ensures superior sealing and lasting performance.

9. Cost-Effective Over Time

While light steel framing may have higher upfront costs than timber, its durability, precision, and minimal maintenance requirements offer a much lower lifetime cost. Over time, the savings on repairs, replacements, and delays make it a cost-effective solution — especially when combined with efficient prefabrication and factory-direct supply chains.

Misconceptions About Light Steel Framing

Before diving into the actual disadvantages, let’s address some common myths. You might be surprised to learn that some of the ‘downsides’ of light steel framing aren’t true—or at least not as problematic as they seem.

Steel is too expensive

While initial costs may be higher, steel’s long-term durability, pest resistance, and lower maintenance needs often save money in the long run. Studies show steel-framed buildings can cut maintenance costs by 20%–30% over their lifespan compared to wood-framed structures.

When sourced directly from manufacturers, the overall cost of light steel framing can be reduced by 10–15% through bulk fabrication and efficient logistics, making it a cost-effective solution for both residential and commercial projects.

Steel frames will rust

Modern steel frames come with advanced rust-preventive measures, like galvanization or zinc-aluminum coatings, making them highly resistant to corrosion. Regular inspections and proper design further ensure long-term durability.

Certified manufacturers like SteelPRO PEB use zinc-aluminum coatings and controlled factory environments to prevent corrosion and ensure long-term structural reliability, especially for coastal or humid climates.

Steel frames make buildings less stable

Engineered for strength, light steel framing is highly stable even in seismic-prone areas. Its ductility helps absorb shocks during earthquakes, reducing the risk of structural failure. In fact, it’s a top choice in earthquake-resistant construction across Asia and Europe.

Light steel framing is only for industrial buildings

Not true. Light steel framing is widely used in homes, offices, schools, and modular housing projects. Its flexibility, sustainability, and fast installation make it a versatile choice for nearly all types of buildings.

Steel framing interferes with signals

Steel framing does not block Wi-Fi or mobile signals. Signal issues are usually caused by dense walls or reflective surfaces, not by the steel structure itself. Proper architectural planning ensures strong and stable connectivity throughout the building.

Steel framing is noisy

Noise concerns arise mostly during construction or due to poor installation. With proper insulation and design, steel-framed buildings are no noisier than wood or concrete ones, ensuring a comfortable living or working environment.

Related Reading:

Is Steel Good for Soundproofing? This Might Not Be What You Think

The Cons of Light Steel Framing

1. High Thermal Conductivity

Steel transfers heat easily, which can make buildings warmer in summer and cooler in winter. Without proper insulation, energy costs may rise.

Modern pre-engineered steel buildings now integrate insulated sandwich panels and thermal breaks to effectively reduce heat transfer, improving energy efficiency and indoor comfort in all climates.

2. Initial Costs

Light steel framing typically costs 20%–30% more upfront compared to timber, especially for smaller projects. However, its durability and low maintenance can save money over time.

Working with a certified steel structure producer can reduce custom fabrication expenses and ensure better cost predictability through efficient factory production and logistics management.

3. Limited On-Site Adjustments

Prefabricated steel components are precise but difficult to modify on-site. Last-minute changes may cause delays or additional costs.

Conduct detailed pre-construction planning and ensure accurate design measurements to avoid modification issues.

4. Dependence on Supplementary Materials

Steel frames require additional materials such as drywall, insulation, and sheathing to complete the structure. This can increase project complexity.

Using integrated wall systems and factory-assembled panels can simplify construction and shorten installation time while improving insulation performance.

5. Environmental Impact of Production

Steel manufacturing consumes significant energy, raising concerns about its carbon footprint. However, steel’s recyclability and long lifespan help balance this impact over time.

Opting for suppliers that use recycled steel and maintain ISO/CE-certified processes further enhances sustainability and reduces the environmental load per project.

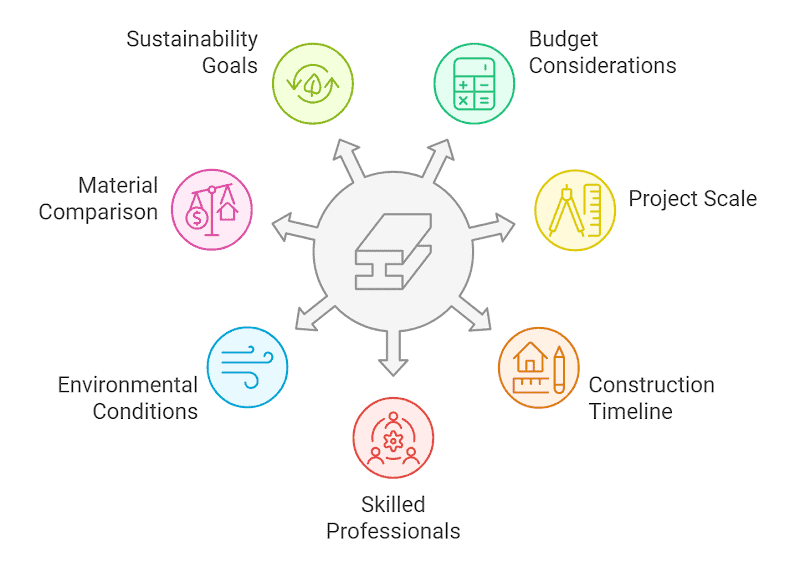

Factors to Consider Before Choosing Light Steel Framing

Budget

Light steel framing often has higher upfront costs compared to wood or concrete. However, its durability, pest resistance, and low maintenance can offset these expenses over time. Factory-fabricated steel components can also reduce overall project time and maintenance costs, improving cost-efficiency throughout the building’s lifecycle.

How to Assess:

- Calculate total material, labor, and supplementary material costs (e.g., insulation, drywall).

- Compare potential long-term savings from reduced repairs and energy efficiency.

- Ask: Am I investing for short-term use or long-term value?

Project Scale and Complexity

Light steel framing is ideal for projects requiring precision, large spans, or modular construction. For small or highly customized projects, however, prefabrication may feel restrictive.

How to Assess:

- For large-scale projects: consider the benefits of prefabrication, cost control, and faster timelines.

- For small projects: evaluate whether the design flexibility aligns with your goals.

- Ask: Does my project require the strength, accuracy, or scalability that steel framing offers?

Construction Timeline

Light steel framing can reduce construction time by 30%–50% compared to traditional methods, making it highly suitable for time-sensitive or commercial projects.

How to Assess:

- Determine if rapid completion aligns with your project goals.

- Evaluate whether prefabrication and modular installation fit your schedule and workforce availability.

- Ask: Will saving time on-site lower total costs or operational disruptions for my project?

Access to Skilled Professionals

Light steel framing requires precision during design, prefabrication, and installation. Inexperienced teams may lead to costly errors or schedule delays.

How to Assess:

- Choose contractors experienced with light gauge steel construction and modular assembly.

- Confirm that the team has access to the right tools, lifting equipment, and technical guidance.

- Ask: Do I have access to professionals who can manage the accuracy required for steel framing?

Environmental Conditions

Steel performs exceptionally well in fire-prone, pest-infested, or high-humidity environments but needs proper insulation in areas with extreme temperatures.

How to Assess:

- Review local climate conditions, such as humidity, temperature variations, or coastal exposure.

- Select steel framing systems with galvanized coatings or corrosion-resistant finishes.

- Ask: Does my project location benefit from steel’s durability and resistance?

Comparing Materials and Sustainability Goals

Light steel framing offers unique advantages, but each material has its trade-offs. Compared to wood, steel is more durable and termite-resistant; compared to concrete, it is lighter and faster to assemble. From a sustainability perspective, steel’s recyclability and long lifespan significantly reduce environmental waste. Working with ISO/CE-certified suppliers ensures responsible sourcing and lower environmental impact.

How to Assess:

- Compare key factors such as cost, durability, energy efficiency, and recyclability for your project.

- Evaluate whether the supplier uses recycled materials and sustainable production methods.

Ask: Does this choice align with my project’s environmental and performance goals?

How much does light steel frame construction cost per square meter?

The cost of light steel frame construction depends on project size, design complexity, and material specifications. On average, it ranges from USD 250–450 per square meter for residential projects. Factory-prefabricated systems and direct sourcing from certified manufacturers like SteelPRO PEB can reduce total costs by up to 15% through efficient production and logistics.

Is light steel framing suitable for two-storey homes?

Yes. Light steel framing is commonly used for two-storey residential buildings due to its strength-to-weight ratio, precision, and fast installation. It also allows flexible layouts and future expansion, making it ideal for both family homes and modular housing projects.

Does steel framing require more maintenance?

No. Steel structures are low-maintenance compared to wood or concrete. They are resistant to termites, rot, and mold, and require only periodic inspections for protective coatings. Modern galvanized steel and zinc-aluminum finishes can last decades with minimal upkeep.

Are light steel frames environmentally friendly?

Yes. Steel is 100% recyclable, and light steel framing systems can use up to 85% recycled content. This minimizes waste and supports green building standards such as ISO and CE certifications. In addition, prefabrication reduces on-site waste and environmental impact.

Get Factory-Direct Light Steel Framing Solutions

Choosing light steel framing isn’t just about speed or durability—it’s about making smarter, long-term construction decisions. For builders and property owners, the key advantages—lightweight strength, cost control, energy efficiency, and recyclability—make it one of the most future-ready structural systems available today.

However, these benefits truly materialize only when frames are produced with precision engineering and certified materials. That’s where SteelPRO PEB, a leading ISO & CE–certified steel structures manufacturer, plays a critical role. With over a decade of global project experience and advanced prefabrication technology, SteelPRO PEB ensures that every structure meets both performance and sustainability standards.

Whether you’re planning a residential build, modular housing project, or industrial facility, factory-engineered light steel systems can help you achieve lower lifecycle costs, shorter construction times, and lasting quality.

Contact SteelPRO PEB today to discuss your project and get a factory-direct, performance-driven solution.