Cantilever solar carports are engineered steel structures that maximize parking space while supporting high-efficiency solar panels. If you’re exploring how to design, build, or customize one for your site, this guide gives you a complete overview—from structural design principles and key components to modular options and real-world applications.

You’ll learn why the cantilever structure outperforms traditional carports, what essential parts define its strength, and how engineers plan spans, foundations, and load capacities for safety and durability. We’ll also walk through the construction and installation process, explore customization for residential, commercial, and EV charging projects, and show how to start your project efficiently with a trusted steel structure provider.

As a certified PEB and steel structure manufacturer, SteelPro Group combines advanced modeling, factory-grade production, and international engineering standards to deliver reliable, factory-direct solutions. Whether you’re an EPC contractor or a project owner, this guide helps you move confidently from concept to construction.

What to Expect in This Blog:

What Is a Cantilever Solar Carport?

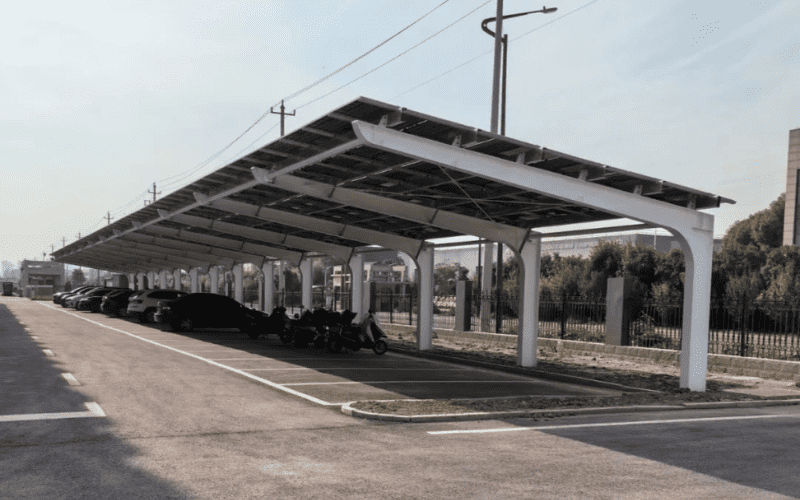

A cantilever solar carport is a type of solar mounting structure that uses single-sided columns to support a wide, overhanging canopy. Unlike traditional carports with posts on both sides, this structure keeps one side completely open. It’s especially useful in parking lots where space or underground layout limits where columns can be placed.

If you’re working on a solar carport project, you’ve probably seen the cantilever style used in commercial or industrial settings—places like shopping centers, office buildings, or EV charging stations. The clean look and open layout make it easier for vehicles to park and move, while still supporting a full solar array overhead.

The key feature here is the cantilevered beam, which transfers the load to one side only. This requires careful structural design, but when done right, it offers a great balance of function and form. Compared with traditional double-post carports, a PEB steel cantilever system minimizes ground interference while offering scalable strength and long-term corrosion protection — making it ideal for factory-direct and large-scale solar installations.

In short, if you’re looking for a solution that maximizes space, improves accessibility, and supports solar power, the cantilever solar carport is worth serious consideration.

Why Choose a Cantilever Structure Over Traditional Designs?

Have you ever struggled with placing columns in a tight parking lot? If so, you’re not alone. Traditional double-post carports often get in the way—cutting into parking spaces or conflicting with underground pipes and cables. A cantilever structure solves that by moving all the supports to one side, leaving the rest open and usable.

In commercial projects, space is money. Fewer columns mean more flexible parking layouts, smoother traffic flow, and easier maintenance. It also makes EV charger installation or future expansion much simpler. You can even accommodate wider vehicles without redesigning the whole layout.

Another reason? Clean design. Cantilever carports offer a sleek, modern appearance that many property owners prefer. When you’re building something visible—like in front of a shopping mall or corporate HQ—looks do matter. And with fewer columns, the structure feels less crowded and more open.

You may also be working on a site with underground utilities. Water pipes, drainage lines, or power cables often make it impossible to place columns where you want. Cantilever structures reduce the need for excavation and avoid costly foundation conflicts.

In short, the cantilever design gives you:

- More usable space

- Greater flexibility in layout

- Better appearance

- Fewer site conflicts

If your site has space constraints, aesthetic goals, or underground complexity, a cantilever structure isn’t just an option—it’s often the best solution.

What Are the Key Structural Components?

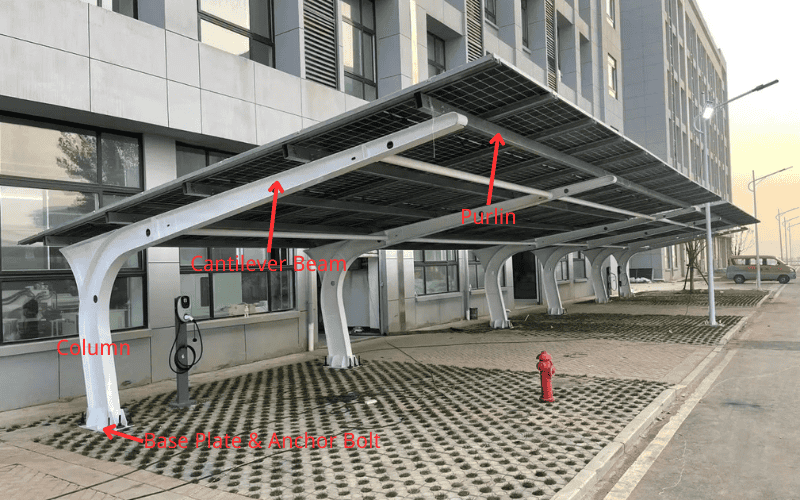

To build a cantilever solar carport, you need more than just steel and bolts. Every part of the structure plays a role in how well your project performs—both structurally and financially. Here’s a quick breakdown of the main components and why they matter:

1. Cantilever Beam

This is the core element—the horizontal arm that extends from the column and holds the entire canopy. It needs to carry the full load of the solar modules, wind, and sometimes snow, all on one side.

Why it matters: Beam size and thickness affect your span length, cost, and local code compliance. Our factory-grade beams are fabricated using high-tensile PEB steel sections for maximum span stability and compliance with international standards.

2. Column (Support Post)

Usually placed on one side of each parking bay, columns transfer all the vertical and lateral loads to the foundation.

Why it matters: Fewer columns = faster installation, but higher load per post. Steel grade and section size are key.

3. Base Plate and Anchor Bolts

These connect the column to the foundation and handle shear and uplift forces.

Why it matters: A weak connection here can compromise the whole structure. Proper sizing is critical, especially in high-wind zones.

4. Foundation (Concrete Footing)

This supports the entire system and must be designed for local soil conditions and loads.

Why it matters: Foundation type affects cost, construction time, and equipment needs. Over-designing wastes money, under-designing creates risk. Foundation design can be standardized or customized based on soil type, load requirement, and project budget, ensuring quick on-site installation and reduced civil work.

5. Purlins and Rails

These horizontal members span across the beams and hold the solar panels in place.

Why it matters: They determine panel orientation, tilt angle, and ease of installation. Aluminum or steel options may be used.

6. Optional Elements

Depending on your project, you might include:

- Gutter systems for drainage

- Cable trays for neat wiring

- EV charger mounting brackets

Understanding these components helps you communicate better with engineers, avoid design oversights, and stay on budget.

How Is a Cantilever Carport Designed?

Designing a cantilever solar carport isn’t just about drawing beams on paper. It’s a process that balances structural safety, local code requirements, cost, and functionality. While your structure provider will handle the technical details, understanding the key design factors will help you lead the project more effectively.

Here are the main parameters that shape a cantilever carport design:

1. Span Length (Beam Reach)

This refers to how far the canopy extends from the column. Longer spans give more parking space per bay but require stronger (and more expensive) beams.

Your role: Let your supplier know how many parking spaces per row, and any space constraints.

2. Column Height and Clearance

You need enough clearance for vehicle movement—typically between 2.3m and 3.5m. For commercial projects, higher clearance may be needed for vans or trucks.

Tip: Don’t forget to account for panel tilt when calculating total height.

3. Wind and Snow Load Requirements

Design loads vary by location and must comply with local building codes. These loads directly impact steel sizing, foundation depth, and connection details.

Your role: Provide the project location. The engineering team will handle the calculations.

4. Foundation Conditions

Soil type, underground utilities, and surface materials all influence what type of foundation is feasible.

Result: The wrong foundation choice can delay construction or increase cost.

5. PV Module Layout and Tilt Angle

Your solar layout (portrait or landscape, one or two rows) affects the width and angle of the canopy. The tilt angle also impacts energy output.

Your role: Decide based on site orientation and energy goals. The structure must support your chosen layout.

6. Aesthetic or Functional Customizations

Need branding, EV charger supports, or integrated lighting? These should be included early in the design stage to avoid later modifications.

In summary, you don’t have to calculate every number—but you do need to communicate project goals clearly. A reliable structure provider will turn your site data into a safe, optimized design that fits both budget and code.

SteelPRO PEB’s in-house structural engineers use advanced PEB modeling software to optimize beam-to-column ratios, load distribution, and material weight, delivering a cost-effective design certified for local wind and snow loads.

What Does the Construction Process Look Like?

Once the design is finalized, the focus shifts to construction. A cantilever solar carport is relatively straightforward to install—but only if you prepare properly. Here’s how the process typically unfolds on-site:

1. Site Preparation and Marking

Before anything arrives, the installation area needs to be cleared, leveled, and marked. If you’re building on asphalt or existing concrete, coring or trenching may be required.

Tip: Early coordination with utility and civil teams helps avoid underground surprises.

2. Foundation Work

Concrete footings are poured based on structural drawings. Anchor bolts or embedded parts are positioned precisely, as they’ll determine column alignment.

Critical step: Poor foundation accuracy leads to installation delays and rework. Surveying matters here.

3. Column and Beam Installation

Once the concrete cures, columns are erected, and cantilever beams are mounted. This may require cranes or lifts, depending on beam size and height.

Good to know: With fewer columns than traditional systems, this step is typically fast—sometimes 2–3 bays per day.

4. Purlins, Rails, and Panel Mounting

After the main frame is up, purlins and rails are added. Solar panels can then be mounted according to your layout.

Watch out for: Proper torque settings, earthing, and consistent alignment—especially in visible parking areas.

5. Electrical Work and Final Touches

Wiring, inverters, cable trays, and optional components (like lighting or EV chargers) are installed last. Final inspections are performed before grid connection or commissioning.

Installation Timeframe

A mid-sized project (20–30 car bays) typically takes 2–4 weeks from start to finish, assuming foundation work and material delivery are well coordinated.

A smooth installation depends on preparation and communication. If your team handles on-site work, a detailed construction manual from the structure provider is essential. If not, many manufacturers (like us) can support you with layout drawings, lifting points, and step-by-step guides.

Can It Be Modular or Customized for My Project?

Yes—and it often needs to be. While cantilever carports follow common structural principles, no two sites are exactly alike. That’s why most systems are designed with both modularity and flexibility in mind.

If your site has a specific number of parking bays, you don’t need to squeeze into a “standard” layout. Modular units—typically in 2-car or 3-car sections—can be combined or extended as needed. Want 7 continuous bays with just 4 columns? That’s a design we can do.

Need to adjust the height or tilt angle? That’s possible too. Column height can be adapted to allow for vans or delivery vehicles. Tilt angles can be modified to optimize solar gain based on your latitude and roof orientation.

What if your ground isn’t flat? Uneven terrain, surface slopes, or obstacles like curbs and drainage lines are all common. These can be addressed during the foundation and column design stage. It’s not one-size-fits-all—we engineer for your site.

Other custom options include:

- Different foundation types for asphalt, gravel, or concrete

- Integrated brackets for EV chargers, lighting, or signage

- Optional rain gutters or water management systems

- Specific coatings or finishes based on corrosion requirements

Customization doesn’t mean starting from scratch. It means adapting a proven structure system to your project’s exact needs—with clear parameters, fast design cycles, and structural reliability.

If you’re unsure whether your site is a good fit, just share a basic site plan and project brief. From there, we can propose a tailored layout that matches your goals—and fits your timeline.

We support OEM customization, modular production, and wholesale supply to EPC contractors and solar developers worldwide — all under factory certification standards.

What Project Scenarios Are Best Suited for This Type?

Cantilever solar carports are used across a wide range of project types—but they shine brightest in environments where space, access, or appearance really matter. If your site fits one of the following categories, this structure could be your best option:

Corporate and Office Campuses

These sites often have limited parking space and strict architectural standards. A cantilever design keeps the layout clean, open, and easy to navigate—while delivering solar energy and a modern appearance that aligns with corporate sustainability goals.

Shopping Malls and Retail Centers

High vehicle turnover means traffic flow is critical. With no posts blocking the front of the bays, parking is smoother and safer. Add to that integrated lighting or branding elements, and the carport becomes a visual asset—not just infrastructure.

EV Charging Stations

When charging spots are tight and future expansion is expected, the flexibility of a single-side support structure helps. It also allows for easier integration of cable trays, chargers, and control cabinets—without cluttering the layout.

Industrial and Logistics Parks

Trucks, forklifts, and service vehicles need wide maneuvering areas. Cantilever carports keep the ground space open while still generating solar power for facility operations or fleet charging.

Public Sector Projects (Schools, Hospitals, Government Buildings)

These often come with limited budgets but long-term usage needs. The durable, low-maintenance nature of a cantilever system makes it ideal for public installations—especially when aesthetics and space use are both priorities.

If your project requires clean layouts, open access, or visual consistency, there’s a good chance this structure is a strong match.

How to Start a Project with a Steel Structure Provider?

Once you’ve decided a cantilever solar carport might be the right fit, the next step is simple: start the conversation. A good steel structure partner won’t just ask for a PO—they’ll help you think through the details, avoid mistakes, and move fast.

What You Should Prepare

To begin, you don’t need full drawings—just the basics:

- A rough site plan or layout sketch

- Number of parking bays or target vehicle count

- Project location (for wind/snow load calculation)

- Any special requirements (height, tilt angle, EV charger mounts, etc.)

If you have early-stage electrical or civil inputs, that’s helpful too—but not mandatory.

What We Provide

Based on your input, we can deliver:

- A preliminary structure layout tailored to your site

- Span and column recommendations to optimize space

- Basic CAD drawings or 3D visualizations for your review or client presentation

- Load calculations and material specifications for quotation or bidding

Need to present to your client or internal team? We’ll support you with visuals, tech sheets, and even technical Q&A if needed.

Not Sure About Certain Details?

No problem. Many of our clients reach out before their plans are finalized. We can help you explore options, clarify uncertainties, or even support your proposal development phase. Think of us as your extended engineering team.

Ready to Build Smarter? Here’s Your Next Move.

By now, it should be clear: a cantilever solar carport isn’t just a structure—it’s a space-smart, future-ready solution that brings real engineering and commercial value to your project. You’ve seen how it works, what makes it different, and where it fits best. And more importantly, you now know what to expect—and how to move forward with confidence.

If you’re designing a solar-ready parking facility, building for long-term ROI, or simply looking to remove complexity from your layout, this structure gives you the edge:

clean lines, open space, and fewer design compromises.

At SteelPRO PEB, we don’t just manufacture steel—we engineer certainty. Every cantilever system we design reflects years of structural experience, practical insight, and real-world adaptability. When you work with us, you’re not just buying a product—you’re partnering with a team that understands what your project is really up against.

Contact SteelPro Group – Certified Steel & PEB Structure Manufacturer

Share your site plan or layout, and we’ll provide a factory-direct quotation with optimized structural drawings and load reports.