They carry 90% of the world’s traded goods, yet most professionals fundamentally misunderstand shipping container dimensions. That “standard” 20ft unit you’re picturing? Its actual measurements might vary by up to 5 inches – enough to derail construction plans or leave cargo stranded at ports. From intermodal logistics to cutting-edge architecture, these steel giants hide dimensional nuances that separate operational success from costly miscalculations.

This isn’t just about length and width. We’re decoding the hidden geometry that determines: how height variations impact global rail compatibility, why 40ft containers aren’t simply double-length 20ft units, and what “tare weight” really means for your shipping costs. Whether you’re stacking containers for urban farming projects or calculating cube utilization for transpacific routes, our dimensional breakdown transforms these industrial workhorses from mysterious metal boxes into precision-engineered assets. The global economy literally runs on these measurements – shouldn’t you master them?

Types of Shipping Containers: Understanding the Variations in Size and Purpose

When it pertains to shipping containers, there isn’t a universal size that suits all. Various kinds of containers cater to diverse needs, and that implies their measurements differ. Let’s take a look at some of the most common container types and what makes them unique.

Dry Storage Container

Dry storage containers are the preferred option for general cargo shipment. These sealed metal workhorses maintain structural integrity through ocean storms and desert heat, making them perfect for electronics, furniture, and industrial parts. Their weatherproof design keeps goods safe and dry, while high-cube versions offer extra height for more storage space. Reliable, versatile, and ready for almost any dry cargo, they’re essential in logistics and storage.

Refrigerated Container (Reefer)

Refrigerated containers, or reefers, are engineered to convey temperature-delicate merchandise such as edibles, medicinals, and chemicals. They maintain temperatures from -30°C to +30°C (-22°F to +86°F), making them perfect for goods like life-saving vaccines, fresh fruits from Chilean orchards, or chocolate on tropical detours. While their refrigeration systems make them slightly bulkier than dry containers, their ability to keep items at a precise temperature is essential for shipments like Brazilian coffee beans arriving fresh in Milan. Reefers are vital when you need reliable temperature control throughout the journey.

For those repurposing containers into food-related spaces, understanding how to optimize interior layouts is key. Explore practical tips in our guide to shipping container kitchen design.

Flat Rack Container

Flat rack containers with collapsible sides, or flat racks, are ideal for conveying oversized or oddly shaped freight. With an open design and no sides or roof, they’re ideal for items like turbine blades or steel beams that wouldn’t fit in a standard container. While exposed to the elements, they save on costs by avoiding disassembly. These containers are great for heavy machinery, industrial components, or construction materials, especially when flexibility is key.

Tank Container

Tank containers are engineered for the secure conveyance of liquids, gases, and chemicals. Made from food-grade stainless steel, they prevent sloshing and maintain the purity of cargo like olive oil, pharmaceuticals, or even liquid chocolate. The cylindrical shape ensures stability, while protective coatings safeguard both delicate and corrosive materials, making them ideal for industries like fuel or food production.

Open Top Container

Open top containers are ideal when you require loading freight from overhead utilizing cranes. Ideal for marble slabs or assembled sculptures, they are available in 20ft and 40ft sizes. While the open design exposes goods to weather, the removable tarpaulin roof offers some protection. These containers excel in controlled environments where vertical loading reduces risk.

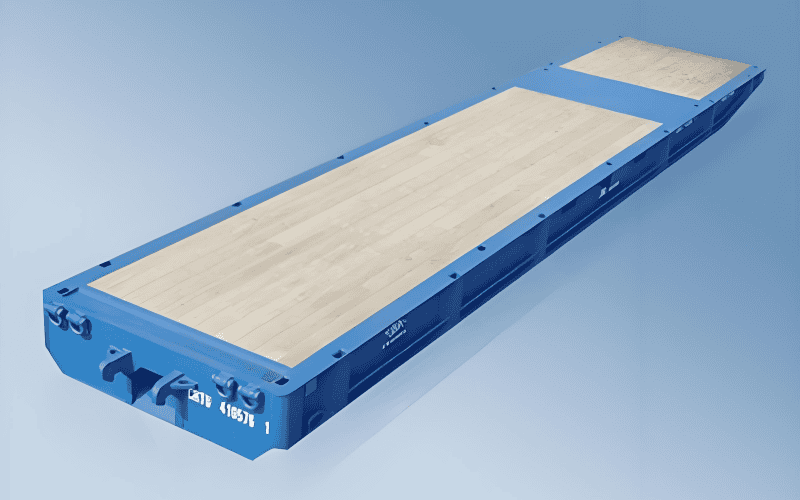

Platform Container

Platform containers are versatile flatbed containers. They’re used for transporting heavy, large, or irregular cargo like military tanks or wind turbine parts. Without sides or a roof, they offer flexibility, though extra care is needed to secure and protect the cargo. They’re great for custom shipments, such as moving prefabricated units to disaster zones or transporting oversized machinery.

Standard Shipping Container External Dimensions

Now that we’ve covered the different container types and their purposes, let’s look at their standard external dimensions. These sizes apply to the containers we’ve just discussed, helping you understand the usable space available for your needs, whether it’s for logistics, container-based structures, or just general curiosity.

Shipping containers generally come in 8ft, 10ft, 20ft, 40ft, and 45ft sizes, with the dimensions of each varying slightly based on factors like height and specific container features. Having knowledge of these dimensions aids in selecting the appropriate container for your venture, whether it pertains to storage, conveyance, or construction.

Below are the typical external dimensions of standard containers, which may vary slightly depending on the specific model:

| Container Size | Length (ft) | Length (m) | Width (ft) | Width (m) | Height (ft) | Height (m) | Max Payload (lbs) | Max Payload (kg) | Tare Weight (lbs) | Tare Weight (kg) | Max Gross Weight (lbs) | Max Gross Weight (kg) | Approx. Volume (cu ft) | Approx. Volume (cu m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8ft Container | 8 | 2.44 | 8 | 2 | 8 | 2 | 5,500 | 2,495 | 1,100 | 499 | 6,600 | 2,997 | 150 | 4.25 |

| 10ft Container | 10 | 3.05 | 8 | 2 | 8 | 2 | 6,500 | 2,950 | 1,200 | 544 | 7,700 | 3,493 | 185 | 5.23 |

| 20ft Container | 20 | 6.1 | 8 | 2 | 8 | 2 | 24,000 | 10,886 | 2,200 | 998 | 26,200 | 11,874 | 1,150 | 32.5 |

| 40ft Container | 40 | 12.19 | 8 | 2 | 8 | 2 | 48,000 | 21,772 | 3,700 | 1,678 | 51,700 | 23,454 | 2,380 | 67.4 |

| 45ft Container | 45 | 13.72 | 8 | 2 | 9 | 3 | 54,000 | 24,494 | 4,000 | 1,814 | 58,000 | 26,308 | 2,700 | 76.4 |

Note: The height of containers may vary slightly for high-cube containers, which offer an extra foot of height (9ft) compared to the standard 8ft.

Standard Shipping Container Internal Dimensions

While the external dimensions give you a sense of the overall container size, it’s the internal dimensions that really determine how much cargo or materials you can store and transport. Whether you’re packing cargo or designing a container-based structure, understanding the internal space is crucial to maximizing efficiency and ensuring a good fit for your needs. Keep in mind that the internal space is where everything happens—from stacking goods to securing materials—so knowing the exact measurements inside is key to getting the most out of your container.

Below are the typical internal dimensions for standard shipping containers, along with other important specifications you should consider for storage and cargo handling:

| Container Size | Length (ft) | Length (m) | Width (ft) | Width (m) | Height (ft) | Height (m) | Max Payload (lbs) | Max Payload (kg) | Tare Weight (lbs) | Tare Weight (kg) | Max Gross Weight (lbs) | Max Gross Weight (kg) | Approx. Volume (cu ft) | Approx. Volume (cu m) | End Door Aperture Width (ft) | End Door Aperture Width (m) | End Door Aperture Height (ft) | End Door Aperture Height (m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8ft Container | 7.5 | 2.29 | 7.5 | 2 | 7 | 2 | 4,500 | 2,041 | 1,100 | 499 | 5,600 | 2,540 | 125 | 3.54 | 6.5 | 1.98 | 7.5 | 2.29 |

| 10ft Container | 9.5 | 2.9 | 7.5 | 2 | 7 | 2 | 5,500 | 2,495 | 1,200 | 544 | 6,700 | 3,039 | 160 | 4.53 | 6.5 | 1.98 | 7.5 | 2.29 |

| 20ft Container | 19.5 | 5.94 | 7.5 | 2 | 7 | 2 | 20,500 | 9,290 | 2,200 | 998 | 22,700 | 10,290 | 1,000 | 28.3 | 7.5 | 2.29 | 7.5 | 2.29 |

| 40ft Container | 39.5 | 12.04 | 7.5 | 2 | 7 | 2 | 42,000 | 19,050 | 3,700 | 1,678 | 45,700 | 20,750 | 2,380 | 67.4 | 7.5 | 2.29 | 7.5 | 2.29 |

| 45ft Container | 44.5 | 13.53 | 7.5 | 2 | 8 | 2 | 48,000 | 21,772 | 4,000 | 1,814 | 52,000 | 23,587 | 2,600 | 73.5 | 7.5 | 2.29 | 8 |

End Door Aperture Width and Height are particularly important for loading/unloading large or bulky items, as these dimensions dictate the types of machinery or forklifts you can use.

Why Container Size Matters for Prefabricated Steel Structure Projects

Understanding container size is crucial for steel structures buildings, not just shipping or storage. Shipping containers are often repurposed for buildings, homes, and offices. Here’s why knowing their dimensions matters:

- Space Efficiency: Internal dimensions determine how much usable space you have. Whether it’s a modular home or multi-story building, the size impacts layout and design.

- Foundation Planning: Accurate size and weight ensure a solid foundation. A 40ft container may need a stronger base than a smaller one.

- Structural Integrity: Container dimensions affect load-bearing calculations. The augmented height of a high-cube container may alter the manner in which framing and roofing are conceived.

- Cost Efficiency: Choosing the right container size can reduce transportation and foundation costs.

- Design Flexibility: With sizes ranging from 8ft to 45ft, you have flexibility to create the structure you need, from homes to community centers.

Knowing container dimensions helps ensure smooth, safe, and cost-effective projects.

The Big Picture of Shipping Container Sizes from a Container Builder’s Perspective

So, how big is a shipping container? It’s more than just the size you might expect! Understanding the size variations and how they impact everything from storage to construction is key to avoiding costly mistakes down the line. Whether you’re using containers for logistics or modular building projects, the right size is critical.

As a container building manufacturer, we specialize in crafting high-quality, brand-new container structures. Whether you’re looking for a modular construction or a customized container office, we work with containers of various sizes to create efficient, durable, and cost-effective solutions. Our expertise ensures that we not only deliver top-tier products but also handle the logistics of transporting containers for projects of any scale. From container homes to multi-functional spaces, we can guide you through every step—design, construction, and delivery. Let us help you build with precision and reliability, using the perfect container for your next project.