Looking for the best 20ft container kitchen layout that actually works in real-world conditions? Whether you’re building a mobile café, a prep kitchen for events, or a small commercial food unit, the right layout determines how efficiently your space performs.

This guide breaks down everything you need to know — from what a 20ft container kitchen is and why it’s so popular, to real layout ideas, cost breakdowns, and practical design tips that save both time and budget. You’ll also learn why working with a professional container manufacturer makes all the difference when turning your layout plan into a certified, factory-built kitchen ready for connection.

As an experienced steel and modular structures producer, SteelPRO PEB brings decades of engineering and manufacturing expertise to every container kitchen we build — ensuring safety, efficiency, and compliance from design to delivery.

What is a 20ft Container Kitchen?

A 20ft container kitchen, also known as a 20ft shipping container kitchen or portable kitchen unit, is a compact cooking space built inside a standard 20-foot shipping container. With dimensions of approximately 5.9m × 2.3m × 2.3m, it offers enough room to fit essential commercial kitchen equipment while remaining easy to transport, install, and relocate.

Think of it as a ready-to-use modular kitchen that serves as a mobile commercial workspace for food trucks, cafés, and catering stations. It combines efficiency and mobility, allowing users to set up cooking operations quickly in different environments.

Each kitchen unit can be customized with ventilation, insulation, stainless-steel interiors, and utility connections — ensuring both safety and hygiene compliance.

A standard 20ft container kitchen provides the flexibility for linear (galley) or L-shaped layouts, maximizing workflow efficiency within limited space.

Why Choose a 20ft Container Kitchen?

The 20ft container kitchen stands out for its perfect balance between mobility and usability. It can be easily transported and installed globally, making it suitable for both permanent and temporary food operations. This flexibility helps operators reduce setup costs and respond quickly to changing business needs.

Here’s why this size works so well:

- Long enough for linear or L-shaped layouts that include essential appliances like a grill, sink, and fridge

- Compact enough to fit in urban lots, festival grounds, or roadside locations

- Built with ISO-certified steel frames and insulated wall panels, ensuring durability, temperature control, and hygiene compliance

- Factory-prefabricated by SteelPRO PEB, guaranteeing precision fabrication, corrosion protection, and global certification

- Smart layout potential with foldable counters, vertical storage, and modular equipment setups

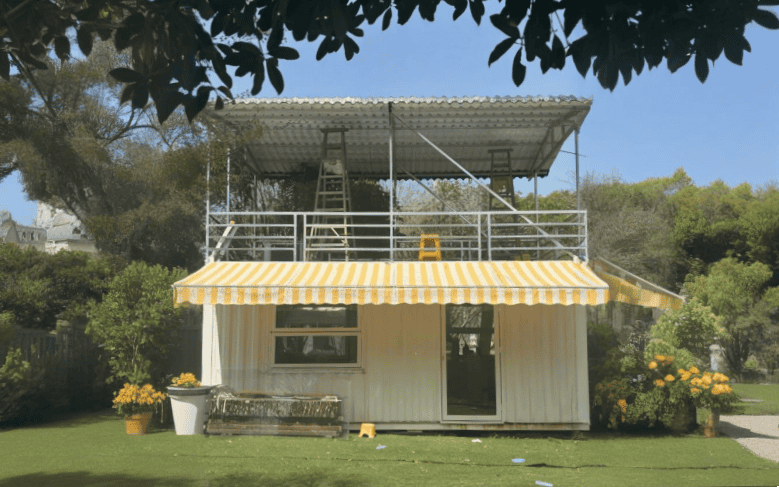

Whether you’re serving burgers at events or running a small café by the beach, a 20ft modular kitchen offers the right amount of space to work efficiently and affordably—built to last by a trusted manufacturer.

Popular 20ft Container Kitchen Layout Ideas

Choosing the right layout can make or break your workflow inside a 20ft kitchen. Below are practical layout ideas based on real-world builds completed by SteelPRO PEB’s modular housing division, designed to help you make the most of every inch while maintaining efficient cooking flow and safety compliance. Each configuration is optimized for space, function, and mobility.

Straight-Line Galley Layout for Compact Cooking Efficiency

If you’re running a solo operation or a tight prep station, this layout keeps things simple and efficient. All equipment is arranged along one wall—think cooktop, sink, fridge, and prep table in a straight line. It minimizes foot traffic, so you’re not wasting time turning around or stepping over cables.

This style works best when paired with:

- A serving window on the opposite wall for fast customer interaction

- Open counter spaces for flexible prep and plating

- Wall-mounted shelves to maximize vertical storage

It’s one of the easiest setups to install and maintain, especially if you’re just starting out and need a lean, functional workspace.

L-Shaped Layout for Better Workflow Separation

This layout gives you more structure and flow. One wall handles cooking, while the adjacent wall handles cleaning or prep, creating a clear separation between hot and cold zones. It’s especially helpful when two people are working in the same container—they can operate without stepping into each other’s space.

Some smart layout features include:

- Corner sinks or under-counter refrigerators to free up counter space

- Strategic appliance placement to avoid clashing doors or heat buildup

- Overhead shelving in the corner to store utensils or supplies

We often suggest this setup for small catering teams or businesses that prep and serve on-site with tight turnaround times.

Open-End Walk-Through Layout for Fast Service

Need to move fast during busy hours? This layout opens up both ends of the container, allowing for a straight pass-through design. It’s perfect for high-volume vendors who serve customers on one side while restocking or prepping from the other.

Here’s how it’s typically arranged:

- Cooking equipment on one wall, with an exhaust hood overhead

- Serving counter or pass-through window on the other side

- Clear aisle through the center, wide enough for two-person movement

We’ve seen this layout thrive at food festivals, construction sites, and other locations where speed and flow are everything.

Split-Zone Layout for Multi-Use Flexibility

This option divides the 20ft unit into two separate functional zones—usually a kitchen and a storage or office space. It’s a great fit for clients who need more than just a cooking station, like event caterers or delivery hubs.

What makes it work:

- Interior partition walls, often pre-framed or bolted in for stability

- Dedicated entry points for each zone, or sliding partitions to save space

- Shelving systems or prep tables that double as storage dividers

We’ve helped clients design split-zone layouts using modular shelves and bolted partitions that separate functions cleanly, while still keeping air circulation and equipment access in check. It’s all about working smart inside a small box.

This layout is often factory-built for catering operators who need combined storage and service zones, offering both efficiency and long-term durability in commercial use.

Cost of a 20ft Container Kitchen Layout

Budget is always one of the first questions we get—and for good reason. Building a 20ft container kitchen isn’t just about the container; it’s about how you turn that steel box into a safe, functional, and code-compliant kitchen. Below is a clear breakdown of where your investment typically goes, and how to stretch your budget without cutting corners.

General Cost Breakdown for a Modular Container Kitchen

Pricing can vary depending on region, materials, appliance selection, and compliance requirements. But to give you a realistic range, here’s what to expect from a modular construction perspective:

- Container base unit (steel frame): $3,000–$7,000

A new or lightly used 20ft container in good structural condition is the starting point. If additional steel framing or custom cut-outs are needed, this can bump up the base cost. - Interior fit-out (walls, flooring, insulation, plumbing): $8,000–$20,000

Includes installation of kitchen-grade stainless steel surfaces, insulated panels, waterproof flooring, interior wall finish, and basic plumbing for sinks and drainage. - Electrical, gas, and fire suppression systems: $5,000–$15,000

These systems must be commercial-grade and often require certification. This range covers wiring, outlets, lighting, gas line installation, and ventilation or hood systems, plus fire suppression if needed for cooking equipment. - Kitchen equipment (cooktops, sinks, fridges, exhaust fans): $4,000–$12,000

This depends entirely on the level of equipment—basic electric cookers and prep fridges cost far less than high-output commercial ranges, fryers, or under-counter combos. - Optional features (serving window, AC, water tanks, shelving): $1,500–$6,000

These extras can significantly improve comfort and usability. For example, installing a commercial pass-through window or built-in water storage tanks for mobile setups.

Overall, a fully outfitted 20ft container kitchen typically falls between $22,000 and $60,000 for a factory-built 20ft modular kitchen ready for site connection.

As a container kitchen manufacturer, SteelPRO PEB controls cost directly from production — from steel frame fabrication to utility pre-installation — eliminating middleman markup. This allows us to provide consistent quality, faster turnaround, and better pricing compared to local assembly-based solutions.

Cost-Saving Tips from our expect’s Perspective

Over the years, we’ve worked with a wide range of clients trying to balance quality and budget. Here are a few practical tips that can help keep costs down without compromising safety or performance:

- Use pre-cut steel framing to speed up the interior assembly process. It reduces labor time and helps keep the structure precise and consistent.

- Opt for prefabricated utility wall panels that already include built-in insulation and pre-set conduit paths. This simplifies both the electrical and plumbing installations.

- Choose compact commercial-grade appliances that are built for small kitchens but still meet health and safety codes.

Pro tip: We often recommend prefabricated wall panels with integrated conduit channels, which allow electricians to run wiring more quickly—saving days of work without sacrificing layout flexibility.

With smart planning and modular thinking, you can build a cost-effective container kitchen that’s ready to perform without overspending on features you don’t need. Everything mentioned above is part of what we offer—our in-house factory handles both structural fabrication and full interior outfitting under one roof.

Practical Tips for Designing Your 20ft Container Kitchen Layout

A well-planned layout isn’t just about fitting equipment—it’s about creating a space that works smoothly every day. Below are practical, experience-based tips drawn from real container kitchen projects to help you design smarter and build with fewer complications.

Start with Zoning and Approval

The first step should always be defining your kitchen zones—prep, cook, clean, and serve—and submitting your layout for any required health or fire safety approvals. Planning ahead helps avoid costly changes later and keeps your project on track.

Plan Utilities Before You Build

Think through water lines, drainage, electrical outlets, and gas hookups early. Once your walls are sealed, modifications become expensive. Make sure your fire suppression system fits the space and remains easy to access for maintenance. Pre-planning your utility runs also ensures compliance with commercial kitchen standards.

Ventilation and Hygiene Matter

Steel containers heat up fast, so prioritize roof-mounted exhaust fans when wall space is tight. Line walls with stainless steel panels—they’re easy to clean and meet hygiene standards. Install a sloped floor with a central drain for effortless cleanup after daily operations.

Optimize Workflow and Space Planning

Use the kitchen triangle rule: cooking, cleaning, and serving zones should flow naturally. Keep safe clearance between burners, walls, and other appliances. Leverage under-counter storage and wall-mounted shelving to free up counter space. Hang utensils and tools to save drawer space, and make full use of vertical height for storage or mounted equipment.

This integrated approach to workflow and space design ensures smooth daily operations while keeping the compact 20ft layout efficient.All our 20ft modular kitchens are pre-configured for efficient workflow and hygiene compliance at the factory level, ensuring every installation meets both safety and usability standards right out of production.

Why Work with a Container Home Manufacturer for Your Kitchen Build

When your 20ft kitchen layout moves from concept to construction, the real challenge begins—balancing design precision, safety compliance, and on-site assembly costs. That’s where working with a professional container manufacturer truly pays off.

At SteelPRO PEB, every kitchen is factory-engineered, not just assembled. Our modular process integrates steel frame fabrication, insulation, utility pre-installation, and finish work under one roof—reducing delays, minimizing onsite errors, and cutting total project costs. For food operators, this means your container kitchen arrives on-site ready for connection, already fitted for ventilation, hygiene, and workflow efficiency.

If you’re planning a larger setup, explore our Shipping Container Restaurant solutions—built on the same certified modular system. For design inspiration and practical layout tips, visit our detailed Shipping Container Kitchen Design guide.

SteelPRO PEB’s 150,000 m² facility and 24 automated production lines ensure precision and consistency for every build. Ready to move from layout to launch? Contact us for a factory-direct quote and turn your kitchen plan into a certified modular workspace built to perform.