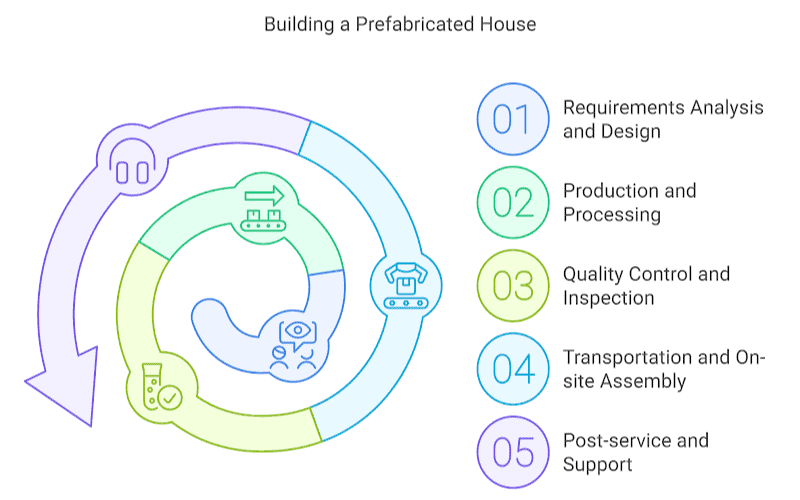

The construction process of a prefabricated house is a systematic and efficient way to move many links in traditional construction from the site to the factory, which greatly improves construction efficiency, reduces costs, and can also be better controlled in terms of quality. Next, we will take you step by step through each key link from design to assembly, showing how to ensure the perfect delivery of each project through precise design and efficient production.

1. Requirements analysis and design stage

The construction of a prefabricated house is not done overnight, but is a carefully designed and carefully planned process. From the initial demand communication to the final design confirmation, each step is vital. In order to ensure that the final prefabricated house fully meets the needs of the customer, we have in-depth communication and cooperation with the customer.

Customer demand collection: understanding your needs is the key

Whether it is office space, residence, or other types of functional buildings, the first step is to fully understand the specific needs of the customer.

For example, we will discuss with the customer: What is the purpose of the house? Are there any special space or structural requirements? What is the size of the house? How much space is needed? These questions help us to deeply understand the actual needs of the customer and lay a solid foundation for the subsequent design stage.

Personalized custom design: flexible adaptation to market needs

Different markets and different customer groups have different needs for prefabricated houses. At this stage, we provide fully customized design options.

We can provide folding container houses of different sizes, structures, floors and functional configurations according to the customer’s budget and needs. For some customers with special needs, we can provide solutions such as steel structure platforms to ensure that every function can be perfectly realized.

Different prefabricated house configuration options

- Single-story and multi-story structures: The single-story design is usually suitable for small residences or offices, while the multi-story structure is suitable for larger residential buildings or commercial spaces. Regardless of the design, our manufacturing and assembly methods can effectively support and ensure the stability and safety of the structure.

- Different capacities (1-10 people or more): For small residences or offices, a configuration of 1-3 people is usually sufficient, while for larger teams or families, more bedrooms, public spaces, etc. can be provided to ensure the comfort of the living and working environment.

- Universal and high-box: The universal type is suitable for a variety of environments and uses, while the high-box design is more sturdy and can adapt to extreme weather conditions or places with special height requirements.

Design software support: accurate modeling ensures accurate delivery

In order to ensure that the design is highly consistent with customer needs, we use advanced design software (such as CAD and BIM) for accurate modeling. With these efficient design tools, we can solve potential structural problems in the design stage and ensure that every detail is carefully optimized.

This not only reduces the errors in on-site construction, but also provides accurate construction drawings before delivery, avoiding many uncertainties in on-site construction. During the design process, we will ensure that each design scheme complies with relevant building specifications and safety standards, and can effectively withstand different loads and climatic conditions.

2. Production and processing stage

During the production stage of prefabricated houses, all work is concentrated in the factory. This stage is not only a display of technical strength, but also a key link to ensure the quality of the house.

Factory manufacturing: high-precision production ensures high-quality delivery

Once the design is confirmed, we enter the production stage. All house modules, including walls, floors, roofs, etc., will be precisely manufactured in our factory. In this process, the steel, plates and other building materials used will be strictly screened to ensure that the quality meets the standards.

Especially in the production process of steel structure platforms and folding container houses, we use high-standard processing technology to ensure the stability and durability of each module. Our factory is equipped with modern equipment and technology, which can efficiently and accurately produce house components of various sizes and configurations.

Quality control: strict control at every link

Every link in the production process is supervised and tested by a professional quality control team. Through rigorous quality inspections, we ensure that each module meets the design and technical requirements before leaving the factory.

These quality control measures help us ensure the standardization and consistency of all components, reduce possible errors during on-site assembly, and provide customers with a more reliable delivery time and user experience.

Modular production: simplify on-site assembly and improve efficiency

Compared to traditional construction methods, one of the most significant benefits of prefabricated houses lies in their modular design. After the bulk of the construction work is carried out in the factory, the modules are transported to the construction site for assembly.

This approach drastically cuts down the time and complexity involved in on-site construction. On-site workers merely need to connect and install each prefabricated module. The entire process is straightforward and efficient. This not only curbs the construction duration but also minimizes unforeseen challenges on-site, such as disruptions caused by inclement weather.

3. Quality Control and Inspection

Strict quality control: ensure that every part meets high standards

In the manufacturing process of prefabricated houses, all raw materials undergo rigorous screening to guarantee that their quality aligns with the stringent standards of the construction industry. From steel to wood, from floors to walls, each component will be carefully inspected before leaving the factory to ensure that they meet the construction requirements such as durability and earthquake resistance.

At the same time, we use precise manufacturing technology to ensure that the dimensions and specifications of all components meet the standards and will not affect the stability and safety of the overall structure due to deviations.

Third-party verification: ensure compliance with international building codes

In order to ensure that our products can be smoothly delivered worldwide and meet local building standards, we work with a number of certification agencies to conduct necessary quality certifications. These certifications not only ensure that the prefabricated houses we provide meet various local building codes, but also increase our customers’ trust in us.

Through this strict quality control and third-party certification, we are able to provide customers with a prefabricated house that meets the highest quality requirements and can be smoothly delivered in different markets.

4. Transportation and on-site assembly

In the construction process of prefabricated houses, transportation and on-site assembly are crucial links. Through remote support, we help customers ensure the accuracy and efficiency of the assembly process, thereby reducing any potential construction problems.

Efficient transportation: ensuring timely and safe delivery

After the modules of the prefabricated house are produced in the factory, our professional transportation team will be responsible for delivering them safely and on time to the customer’s designated location.

To avoid any delays, we will plan the transportation route in advance to ensure that uncontrollable factors such as traffic congestion and bad weather are avoided throughout the transportation process. With precise logistics management, customers can rest assured that our prefabricated house modules will be delivered to the site on time and safely.

Remote guidance: ensuring smooth assembly

Once the modules arrive on site, our work is not over. We provide detailed remote guidance to ensure that every step of the assembly process goes smoothly according to the predetermined plan.

Our technical team will work closely with you and your installation team through video, phone or other online platforms to ensure that each module is installed correctly and the interfaces are seamlessly connected. In this way, customers can still enjoy an efficient and worry-free assembly experience, and finally complete a solid, safe, and design-compliant prefabricated house.

5. Post-service and support for prefabricated houses

Even after the prefabricated house is completed and delivered for use, we still provide comprehensive post-service and support to ensure that problems encountered by customers during use can be solved in a timely manner and the house can be maintained in the best condition for a long time.

After-sales service after installation

Maintenance and care: The components of prefabricated houses undergo rigorous quality inspection and processing, but proper maintenance cannot be ignored during use. We offer customers routine maintenance services to ensure that all house functions operate smoothly. Whether it is wall inspection, floor repair, or maintenance of electrical systems, we can provide timely support.

Modification and expansion: As needs change, prefabricated houses can be modified and expanded according to customer requirements. For example, as the number of family members increases, customers may need additional bedrooms or bathrooms, or convert certain spaces into offices. We provide flexible modification services to help customers expand and change functions without affecting structural safety.

Customer support: Ensure continuous needs in long-term use

In order to ensure the long-term value of each project, we not only focus on quality at the time of delivery, but also strive to help customers upgrade and transform according to changing needs. Whether it is adjusting the internal layout, upgrading facilities, or changing the exterior style, our support team will provide the most suitable solution according to customer needs to ensure that prefabricated houses can always adapt to customer usage needs.

Prefabricated House Supplier

As the global construction industry continues to increase its demand for efficient, environmentally friendly and economical solutions, prefabricated houses will continue to occupy an increasingly important position in the construction field. Our SteelPRO PEB’s advantages in construction speed, cost-effectiveness, sustainability and quality control have been recognized by more and more companies and developers.

Through continuous innovation and optimization of technology, we provide customers with higher quality, more flexible and more customized prefab house solutions, such as T Type Prefab House. Whether it is residential, commercial or temporary construction, we can provide perfect prefabricated houses to help customers realize construction projects quickly and efficiently.