Building a church is a journey filled with both inspiration and challenges. From selecting the right materials to ensuring the design reflects the community’s vision, every step demands thoughtful planning and expertise. For those considering a steel-structured church, the process may feel overwhelming—questions about durability, cost, and installation often arise.

This guide aims to provide clear insights into the essential steps of constructing a metal church building, from early preparations to final installation. Whether you’re starting from scratch or looking to upgrade an existing structure, understanding the process can save time, reduce costs, and bring your vision to life with confidence.

Ready to explore how steel can transform your church into a strong, timeless, and welcoming space? Let’s begin!

Build Your Team

Big projects like this need everyone working together. To make the dream a reality, the entire church community needs to support and contribute.

Create a core team to lead the project and keep things on track. It helps to include members with different skills and backgrounds—they’ll make solving challenges a whole lot easier.

Confirm Your Budget

From the overall style, size, and capacity to details like interior materials and special areas (such as a confessional or sacristy), the more specific your plan, the better. Clear budgeting helps ensure your vision aligns with your resources.

Church construction projects often come with long timelines and unexpected costs. Whether it’s additional foundation work due to geological conditions or price fluctuations in building materials, setting aside 10%–20% as a contingency fund can help avoid delays caused by financial shortages.

When you have prepared all the lists, please submit your requirements directly to us and we will immediately calculate your quotation. As a manufacturer specializing in steel structure construction, we promise transparent pricing and competitiveness in the industry!

Secure Land Ownership

If you’re renovating an old church, the process is simpler, often requiring only basic approvals such as zoning confirmation, building permits, and safety inspections.

More comprehensive preparations are needed when planning to build on a fresh site for a new church. This includes:

- Conducting land surveys to assess topography and soil conditions.

- Confirming zoning compatibility with local regulations.

- Securing a land use permit or religious land designation.

- Drafting an initial site plan to outline the building layout and utility connections.

- Addressing environmental impact assessments if required.

For a new community church, we recommend focusing on underutilized urban public service land or opportunities to repurpose old factories.

If you’re planning a large religious center, suburban undeveloped plots are often more suitable, as they match zoning needs and reduce acquisition challenges.

We can help you navigate relevant laws and regulations, understand approval processes, and explore how our recyclable steel structures can simplify and accelerate the project.

Work with a Manufacturer to Finalize Your Design

Once you’ve secured land ownership, it’s time to collaborate with a manufacturer to design your church.

We recommend prefabricated steel structures for their durability and longevity. With optimal materials like weathering steel, profiled steel sheets, or galvanized steel, and proper protective measures, the structure can last over 50 years.

If you have plans for interior features, we can incorporate them into the design. For instance, we can reserve hidden slots for built-in speakers along the side walls, rear walls, and load-bearing columns at regular intervals.

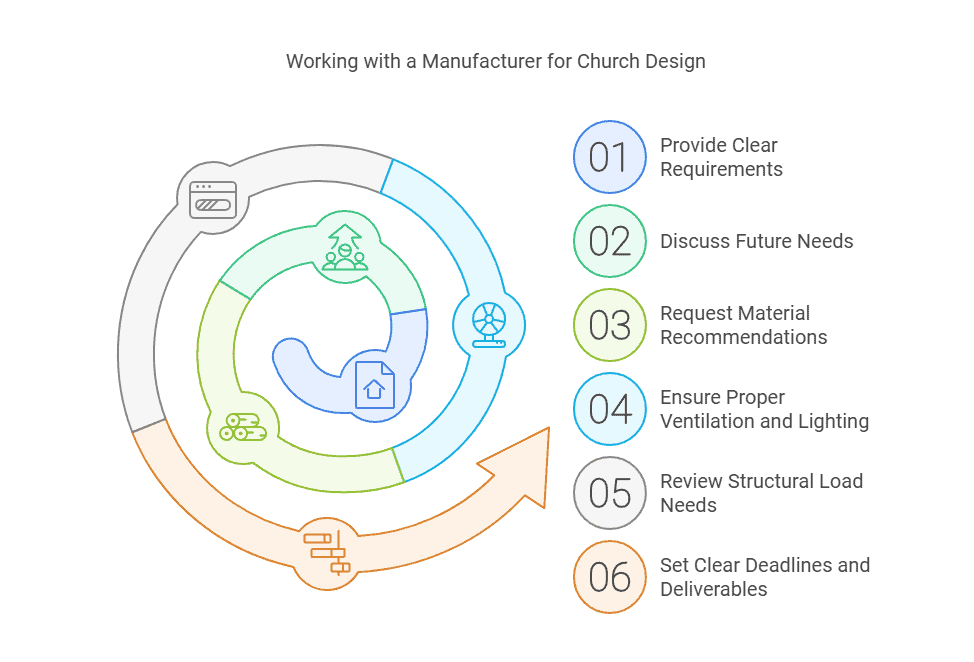

Tips for Working with a Manufacturer

We advise against using wood or highly reflective metals for church construction, as these materials may have shorter lifespans or create undesirable acoustics and lighting effects in worship spaces.

Installation

Once your prefabricated steel church components arrive, it’s time to get started on the installation!

Most manufacturers don’t handle on-site assembly, so you’ll need to have the foundation ready beforehand. Don’t worry—we provide anchor bolts, assembly guides, and connection components to ensure everything fits perfectly. You can hire a local team of 4–8 people, such as:

- 2 steel structure installers

- 1 welder

- 1 electrician

The great news? Our prefabricated components are partially assembled and welded at the factory, so putting everything together on-site is straightforward. In just 3–6 months, your church can be ready—much faster than the 10–12 months needed for traditional concrete churches. It’s efficient, simple, and saves you time!

Choose Us as Your Metal Church Building Manufacturer

- 20+ Years of Experience: We deliver preliminary church design sketches quickly and provide 3D dynamic simulations to ensure your church remains durable for at least 50 years.

- Fast Production & Delivery: All components are processed within 20–30 days and shipped to you using the fastest transport options available.

- Modern Design Aesthetic: Our contemporary designs make your church stand out, becoming a unique spiritual landmark in your city or town.

Our Customizable Church Building Features

- Exterior Facade: Tailored to your desired style.

- Flexible Wall Configurations: Adjusted to suit your needs.

- Framed Openings: For doors, windows, or other structures.

- Lean-to Structures: Perfect for auxiliary spaces.

- Noise-Reducing Wall Panels: Enhancing the worship experience.

To learn more, visit our prefab steel church building for detailed information and examples of our work.

Customizable Interior Spaces

We can help you design the interior layout of your church to meet your unique needs, including:

- Kitchen Areas: Designed for events and gatherings.

- Sunday School Rooms: Dedicated spaces for educational activities.

- Offices: Functional layouts for administrative tasks.

- Storage Areas: Organized zones for equipment and supplies.

- Waiting Areas: Welcoming spaces for visitors.

- Wedding Reception Areas: Layouts tailored for hosting special celebrations.

Our expertise ensures your church’s interior is both functional and thoughtfully designed.

Related Reading: Why Prefab Church Buildings Are Popular