Steel structure buildings are stealing the spotlight in modern construction, and it’s no surprise—they’re strong, quick to build, and eco-friendly. Market research shows the structural steel market is set to grow from $109.0 billion in 2024 to $115.8 billion in 2025[1], with a compound annual growth rate (CAGR) of 6.2%. This booming growth reflects the global shift toward energy-efficient, sustainable materials and stricter efforts to cut construction waste and carbon emissions. In this article, we’ll dive into what makes steel structures so special—covering their definition, construction process, installation steps, and quality control—and see how smart planning turns them into cost-effective marvels.

What is Steel Structure?

Steel structures are building frameworks made from steel materials, primarily using sections like beams, columns, and plates, joined together with welding or bolted connections. They’re celebrated for their high strength-to-weight ratio, seismic resistance, and recyclability, making them a popular choice for everything from industrial facilities to sports arenas. Plus, their inherent rigidity boosts stability, keeping deformation under control even under heavy loads. With such versatility and durability, it’s easy to see why steel structures are a favorite in modern construction projects.

Steel Structure Construction Process

A single misstep in the steel structure construction process can lead to costly delays, safety risks, or structural failures—understanding each phase ensures your project stays on track and delivers lasting value.

Project Planning and Design

A well-executed steel structure project begins with thorough planning and precise design, ensuring every detail aligns with both functional requirements and client expectations.

Site Survey

The initial step involves a comprehensive site survey to assess terrain, geological conditions, and environmental factors. Sites with soft soils, high water tables, or uneven terrain often require additional groundwork to ensure stability, while rocky or unstable geological formations may necessitate specialized foundation solutions. Identifying these challenges early helps define the construction scope and avoid costly adjustments later.

Structural Design

The structural design phase includes load calculations, component selection, and connection design, all optimized for safety and efficiency. Our team utilizes advanced software such as Tekla Structures and STAAD.Pro to ensure precision in modeling and analysis. Regular client consultations are conducted to align the design with expectations, and multiple design options are provided to meet diverse needs.

Our design team holds regular video conferences during the design phase to ensure the building’s direction fully meets your expectations, offering a variety of design options for selection.

Foundation Construction

A solid foundation is the unsung hero of any steel structure, making sure it stands tall and steady against all kinds of forces over the years.

Excavation

Excavation follows strict standards like ISO 21873 and ACI 318 to ensure the pit is just the right size and depth—usually between 1.5 to 3 meters, depending on the soil and load requirements. For example, think of preparing the ground for a heavy-duty crane; you need the right depth and stability to prevent any sinking or tipping. Proper slope stabilization and dewatering are also crucial to keep the site safe and dry.

Foundation Reinforcement

Steel bars are bound into a sturdy grid, then high-strength concrete (C25/30 or higher) is poured to create a rock-solid base. Bars are spaced 150-200 mm apart to evenly handle the load. Imagine laying the groundwork for a steel bridge—every bar and bolt must be in the perfect spot to handle the weight and motion.

Since steel structure projects often don’t cover foundation work, it’s essential to pour and cure the concrete before the steel arrives. We provide precision-engineered anchor bolts for seamless installation. Pro tip: Use a laser level to double-check bolt alignment before the concrete sets—it’ll save you headaches later!

Steel Structure Fabrication

Creating durable steel structures starts with high-quality fabrication, where raw materials are transformed into precision-engineered components designed for seamless assembly and lasting performance.

Manufacturing Process

Modern prefabrication facilities use CNC plasma cutters, automated saws, and robotic welding systems for precise cutting, drilling, and welding. Beams are often pre-drilled with exact hole patterns, simplifying on-site installation. Columns feature integrated connection plates, speeding up assembly. These techniques ensure consistent quality, faster production, and less waste, making steel structures a smarter choice over traditional methods.

Component Fabrication

The process produces essential structural elements like columns, beams, braces, trusses, and connection plates, as well as secondary framing members such as wall girts and roof purlins. Each component is manufactured to precise specifications, ensuring reliability and a perfect fit during assembly. This degree of accuracy not only enhances the structure’s strength but also shortens construction time, providing a cost-efficient and effective solution for contemporary building projects.

Our in-house steel factory guarantees high-quality raw materials and uniform component specifications. By eliminating middlemen, we offer more competitive pricing without compromising on quality.

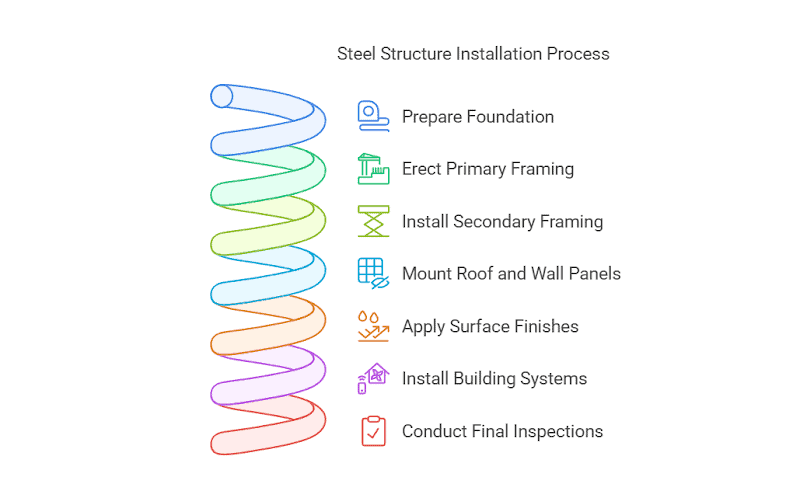

Steel Structure Installation

Efficient installation is the backbone of a successful steel structure project, ensuring everything comes together safely, accurately, and on time. Here’s a step-by-step guide to the process, packed with practical tips to make it as smooth as possible:

1. Prepare the Foundation

Before anything else, double-check that the foundation is fully cured and the anchor bolts are perfectly aligned. A laser level is essential here—misaligned bolts can cause major issues down the line, so taking the time to get it right is crucial.

2. Erect Primary Framing

Start by lifting the columns into place with a crane, aligning them with the anchor bolts. Temporary bracing or guy wires can help keep the columns plumb while you tighten the bolts to the specified torque.

Next, move on to the beams and braces. Beams are raised into place and secured to the columns using high-strength bolts or welding. Bolts should be tightened in a staggered pattern to avoid warping, while welds need to be clean and strong for maximum durability. Diagonal braces are then installed between columns and beams to enhance stability.

Tip: Always follow the tightening sequence in the design drawings—it’s a small detail that makes a big difference.

3. Install Secondary Framing

Once the primary frame is up, it’s time to add the wall girts and roof purlins. These horizontal supports are crucial for attaching the wall and roof panels. Use self-tapping screws or bolts to secure them, and a chalk line can help keep everything level and evenly spaced.

4. Mount Roof and Wall Panels

Start with the roof panels, working from one corner and overlapping them as you go. Secure the panels to the purlins with self-tapping screws, and don’t forget to add insulation for better energy efficiency.

For the wall panels, start at one corner and continue around the building. Attach the panels vertically to the girts, overlapping them as needed, and add insulation and vapor barriers to keep the interior comfortable and dry.

Tip: A rubber mallet is handy for adjusting panel alignment without leaving marks.

5. Apply Surface Finishes

Once the structure is up, it’s time to protect it. Clean the steel surfaces thoroughly, then apply anti-corrosion primers and fire-resistant coatings. Finish with a layer of protective paint for added durability and a polished look. Allow each coat to dry fully before proceeding to the next one.

6. Install Building Systems

With the structure complete, it’s time to add the essentials—electrical wiring, plumbing, and HVAC systems. These are run through pre-designed openings in the structure, ensuring everything fits neatly and functions perfectly.

Tip: Early coordination with system installers can prevent clashes and save time down the line.

7. Conduct Final Inspections

A comprehensive inspection is essential before finalizing the project. Check all connections, finishes, and systems to ensure they comply with design and safety standards. A detailed checklist can help make sure nothing is overlooked.

By following these steps and tips, the installation process becomes a seamless operation, delivering a safe, durable, and fully functional steel structure. If you are interested in installing steel warehouses, feel free to explore our Steel Warehouse Buildings Installation.

We also stand behind our steel structures with industry-leading warranties:

- 50 years on the structural framework.

- 25 years on the roof and wall systems.

- 3-day response guarantee for problem resolution.

Our commitment to quality and customer satisfaction ensures your project is built to last, with peace of mind for decades to come.

Safety Considerations

- Properly designate safety zones on the construction site to restrict unauthorized entry.

- Make sure all workers are equipped with protective gear, such as helmets, safety harnesses, and steel-toed boots.

- Restrict access to lifting areas during crane operations to avoid accidents.

- Install fire prevention equipment and ensure adequate ventilation in welding areas to minimize risks.

- Perform routine inspections and maintenance on construction equipment to keep it in peak working condition.

- Implement fall protection systems, like safety nets or guardrails, when working at elevated heights.

- Adhere to load capacity guidelines for cranes and lifting equipment to avoid overloading and ensure safety.

Related Reading: Fire prevention for steel structure

Trust Us for a Precise Steel Structure Construction Process

The construction of steel structures is a meticulous process that combines advanced engineering, high-quality materials, and precise execution at every stage. From the initial design to the final inspection, each step is carefully managed to deliver a safe, durable, and aesthetically pleasing building that stands the test of time.

With decades of industry experience, we provide unparalleled expertise in every project. Our in-house design team leverages advanced software such as Tekla Structures and STAAD.Pro to craft optimized, efficient designs that are customized to your requirements. We adhere to international standards such as AISC, Eurocode 3, and ISO 9001, ensuring every structure meets the highest quality and safety benchmarks.

Our commitment to excellence extends beyond construction. We offer comprehensive warranties, including a 50-year structural warranty, a 25-year roof and wall warranty, and a 3-day problem-solving guarantee, giving you peace of mind for decades to come.

Whether you’re planning an industrial facility, a commercial building, or a custom project, we’re here to help you bring your vision to life. Let’s build the future together with steel.

Faq About Steel Structure Construction Process

How Do You Ensure The Steel Components Are Protected From Corrosion During The Construction Process?

We apply anti-corrosion primers immediately after fabrication and store components in covered, ventilated areas to prevent moisture damage.

What Measures Are Taken To Prevent Delays During The Steel Structure Installation Phase?

We conduct pre-installation inspections, ensure timely delivery of components, and use detailed installation plans to avoid disruptions.

Can The Design Accommodate Future Expansions Or Modifications To The Steel Structure?

Our modular designs enable easy expansions or modifications without affecting the structural integrity.

How Do You Manage Quality Control During The Manufacturing And Installation Of Steel Components?

We use advanced inspection tools to check dimensions, welding quality, and alignment, ensuring strict adherence to design standards.

What Additional Safety Protocols Are Implemented During The Lifting And Assembly Of Steel Components?

We enforce strict crane operation procedures, use temporary bracing for stability, and ensure workers are equipped with proper safety gear.

[1] The Business Research Company. (2024). [Structural Steel Global Market Report]. [Press Release]