In modern construction, finding solutions that are both strong and flexible is key. Cable bracing is one such solution that has gained popularity among architects, engineers, and builders. By using high-strength steel cables, it provides lateral stability to buildings, effectively handling forces like wind and earthquakes. Compared to traditional systems like X-bracing or K-bracing, cable bracing is lighter, quicker to install, and more visually appealing.

But what exactly makes cable bracing stand out? Is it truly a cost-effective and efficient choice? In this article, we’ll explore how cable bracing works, its advantages over traditional systems, and key design considerations. By the end, you’ll understand why cable bracing is becoming the preferred solution for building structures that are not only sturdy but also lightweight and aesthetically pleasing.

What You’ll Discover in This Blog:

What is Cable Bracing?

At its core, cable bracing is a structural system that uses tensioned steel cables to provide lateral stability to steel buildings. Think of it as the building’s “high-performance rubber band”—flexible yet incredibly strong, capable of absorbing and redistributing forces to keep the structure steady under pressure.

How Does It Work?

Cable bracing typically consists of three main components:

- Steel Cables: High-strength cables, often made from materials like galvanized steel or stainless steel, are the backbone of the system. These cables are designed to handle significant tension forces.

- Anchors and Connectors: These secure the cables to the building’s primary steel frame, ensuring a stable and reliable connection.

- Tensioning Devices: These are used to adjust the tension in the cables, ensuring they provide the right amount of support without overloading the structure.

When lateral forces (like wind or seismic activity) act on the building, the cables stretch slightly to absorb the energy, then pull the structure back into alignment once the force subsides. This dynamic behavior makes cable bracing particularly effective in environments where flexibility and resilience are critical.

Related Reading:

Steel Structure Bracing System: Types, Design Principles

Key Advantages of Cable Bracing

Cable bracing isn’t just a modern alternative to traditional bracing systems—it’s a superior solution for many steel building projects. Here’s why it’s gaining popularity among architects, engineers, and builders:

1. Lightweight Design

One of the most significant advantages of cable bracing is its lightweight nature. Unlike rigid steel braces, which add substantial weight to the structure, cable bracing uses high-strength steel cables that are both strong and incredibly light. This reduces the overall load on the building’s foundation, leading to cost savings in materials and construction.

2. Superior Resistance to Lateral Forces

Cable bracing excels at handling lateral forces such as wind and seismic activity. The cables are designed to stretch slightly under pressure, absorbing and redistributing the energy. This flexibility allows the structure to “give” during extreme conditions, then return to its original position once the force subsides. This makes it an ideal choice for buildings in hurricane-prone or earthquake-prone regions.

Related Reading:

Essential Resistances for Steel Structures: From Weather to Fire and Earthquake Protection

# Wind Bracing in Metal Buildings

Wind bracing helps metal buildings resist strong winds by preventing sideways movement. There are different ways to do this, including cross bracing (X-bracing), rigid frames, and cable bracing.

✔ Traditional wind bracing uses steel beams in an “X” or “K” shape to add stiffness.

✔ Cable bracing offers a lighter, more flexible alternative. Instead of staying rigid, cables absorb wind pressure and return the structure to its normal position.

For large metal buildings, especially warehouses and hangars, cable bracing is a cost-effective way to improve wind resistance without adding extra weight.

3. Faster and Easier Installation

Thanks to its lightweight components and pre-tensioning technology, cable bracing can be installed faster and with less labor compared to traditional bracing systems. This not only speeds up construction timelines but also reduces labor costs, making it a cost-effective option for tight schedules and budgets.

4. Unobstructed Space and Aesthetic Appeal

Traditional bracing systems, such as X-bracing (cross bracing) or K-bracing, can obstruct views and limit usable space. Cable bracing, on the other hand, is minimalist and visually unobtrusive. Its sleek design allows for open, column-free interiors, making it perfect for commercial spaces, sports arenas, and architectural masterpieces where aesthetics matter.

# What is Metal Building Cross Bracing?

Metal building cross bracing is a way to strengthen steel structures. It uses steel beams in an “X” shape between columns to keep buildings stable during wind or earthquakes.

While cross bracing is strong, it can block windows, doors, or open areas. If a building needs both strength and open space, cable bracing is a better option. It keeps the structure stable without taking up extra room.

5. Cost-Effectiveness

Cable bracing offers long-term cost savings in multiple ways:

- Lower material costs: Less steel is required compared to rigid bracing systems.

- Reduced foundation costs: The lightweight design decreases the load on the foundation.

- Minimal maintenance: High-quality cables are durable and resistant to corrosion, reducing the need for frequent upkeep.

6. Versatility Across Applications

From industrial warehouses to commercial buildings and even temporary structures, cable bracing is adaptable to a wide range of projects. Its ability to handle large spans and dynamic loads makes it a go-to solution for modern construction challenges.

Cable Bracing vs. Traditional Bracing

To better understand the value of cable bracing, let’s compare it to traditional rigid bracing systems, such as X-bracing or K-bracing:

| Feature | Cable Bracing | Traditional Rigid Bracing |

| Weight | Lightweight | Heavy |

| Flexibility | High (absorbs dynamic forces) | Low (rigid, less adaptable) |

| Installation | Faster, less labor-intensive | Slower, more complex |

| Aesthetic Appeal | Minimal visual obstruction | Can obstruct views and space |

| Cost | Lower material and labor costs | Higher material and labor costs |

Cable bracing shines in scenarios where weight savings, speed of construction, and design flexibility are priorities. Its ability to combine strength with elegance makes it a favorite among architects and engineers alike.

Applications of Cable Bracing

- Industrial Buildings: Helps resist wind with a lightweight structure, reducing the need for strong foundations and cutting costs.

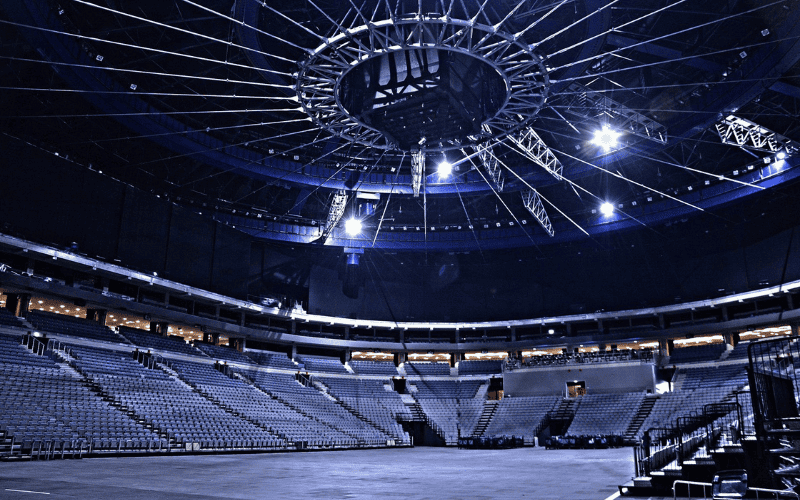

- Commercial Buildings: Supports large, open spaces like malls and sports arenas, improving flexibility and safety.

- Special Structures: Great for temporary buildings or towers, offering quick and lightweight reinforcement.

- Sports Venues: Used in stadiums and arenas to support large roofs without blocking views.

- Bridges: Ideal for suspension bridges, where it helps carry heavy loads while keeping the structure light.

- High-rise Buildings: Supports large roofs or facades, improving stability and safety against wind or earthquakes.

- Outdoor Structures: Used in gardens or viewing platforms, providing strong support while keeping the view clear.

Key Considerations in Cable Bracing Design

When designing a cable bracing system, several key technical factors need to be considered to ensure its effectiveness, safety, and long-term stability. Here are some critical points to focus on during the design process:

1. Types of Loads

The cable bracing system must be designed to handle various loads that a building may experience, especially live loads (such as wind and seismic forces) and dead loads (such as the building’s own weight).

- Dead Loads: This mainly refers to the building’s own weight. While cable systems are lighter, the pressure from the building’s weight still needs to be considered.

- Live Loads: External factors like wind and seismic forces can cause sudden and intense vibrations in the building, which in turn create fluctuating tension in the cables. Therefore, the design must account for the real-time effects of these loads and calculate the tension in the cables accordingly.

During design, load analysis software can simulate different conditions, such as wind speeds and earthquake epicenter distances, to ensure the cable bracing remains stable under extreme conditions.

Related Reading:

Seismic Resistance Steel Structures: The Smart Solution for Earthquake-Prone Areas and Beyond

2. Pre-Tension Control

One of the core advantages of cable bracing is the pre-tensioning design, where cables are pre-stretched to help distribute pressure more effectively when external forces are applied. However, too much or too little tension can cause structural issues:

- Too Much Tension: Can lead to excessive deformation of the cables, potentially damaging connection points or anchorages.

- Too Little Tension: May result in insufficient support, unable to effectively resist wind or seismic forces. Thus, it’s crucial to precisely calculate the tension for each cable and adjust it using specialized tension measuring equipment to ensure optimal balance. Designers typically consider load variations in different environments and set tension ranges that can be adjusted during operation.

3. Material Selection

Cable bracing is typically made from high-strength steel, but the specific requirements may vary by project. The following factors must be carefully considered during design:

- Tensile Strength: The steel cables must have sufficient tensile strength to withstand the expected loads. Common materials include galvanized steel strands and stainless steel strands, with galvanized steel being widely used due to its cost-effectiveness.

- Corrosion Resistance: Steel cables are exposed to outdoor environments and are vulnerable to damage from rain, wind, and humidity. Protective measures, such as galvanizing (hot-dip galvanization) and coating, are necessary to extend the cables’ lifespan, especially in harsh environments like coastal areas.

- Wear Resistance: Since the cable system undergoes frequent tensioning and loosening, the cables’ surface must be resistant to wear to prevent damage from friction.

Related Reading:

A Quick Guide to Steel Types in Steel Buildings

4. Compliance

When designing cable bracing systems, it’s essential to adhere to relevant international building codes and standards, such as the American Institute of Steel Construction (AISC) standards in the U.S. and European Norms (EN). These standards provide detailed guidance for steel structure design and construction, ensuring the applicability and safety of cable bracing systems worldwide.

Can You Use Steel Cables Instead of Beams for Bracing?

Yes, steel cables can replace steel beams for bracing in many buildings. They are lighter, more flexible, and easier to install than traditional steel beams. However, whether cables or beams are better depends on the type of building and the forces it needs to resist.

How Do Steel Cables Work as Bracing?

Steel cables help keep buildings stable by resisting sideways forces, such as wind or earthquakes. Instead of staying rigid like steel beams, cables stretch slightly to absorb energy and then pull the structure back into position. This makes them a great choice for buildings that need flexibility.

Steel Cables vs. Steel Beams in Bracing

| Feature | Steel Cables for Bracing | Steel Beams (X/K-Bracing) |

| Weight | Lightweight, reduces overall load | Heavy, adds structural weight |

| Flexibility | Absorbs and distributes forces dynamically | Rigid, limited adaptability |

| Installation | Faster, requires less labor | More complex, requires welding |

| Cost | Lower material and labor costs | Higher costs due to steel usage |

| Best Used For | Large spans, open spaces, earthquake-prone areas | Heavy-load structures, high-rise buildings |

When Should You Use Steel Cables?

Steel cables work best when you need:

✔ Large open spaces – In warehouses, sports arenas, and commercial buildings, cables provide support without blocking space like steel beams do.

✔ Earthquake resistance – Cables bend and absorb shock, helping buildings stay safe during earthquakes.

✔ Lighter structures – For temporary buildings or pre-engineered metal structures, cables reduce weight and make assembly easier.

✔ A modern, open look – Cables are less visible than steel beams, making them ideal for glass buildings and stylish designs.

When Are Steel Beams a Better Choice?

Steel beams (X-bracing or K-bracing) are stronger and better for:

🔹 Heavy load buildings – Factories, bridges, and high-rise buildings need rigid support to carry weight.

🔹 Very tall structures – Skyscrapers and large towers often require rigid bracing to stay steady in high winds.

Cable Bracing System: Installation & Setup

Installing a cable bracing system in a metal building involves several key steps to ensure stability and long-term performance.

1. Structural Analysis & Design

- Engineers determine the optimal bracing locations based on load calculations.

- Wind and seismic load simulations help define the required cable tension levels.

2. Material Selection

- Use high-strength steel cables (typically galvanized or stainless steel) for durability.

- Choose the appropriate anchors and tensioning devices based on the building’s structural needs.

3. Site Preparation

- Inspect the steel frame to confirm structural integrity.

- Clear the work area to ensure safe and efficient installation.

- Verify anchor points based on the engineering plan.

4. Installation Process

- Step 1: Secure anchoring plates to the primary steel frame.

- Step 2: Attach steel cables to the designated bracing points, ensuring proper alignment.

- Step 3: Use turnbuckles or hydraulic tensioners to apply pre-tension.

- Step 4: Conduct load tests to verify structural integrity.

5. Post-Installation Inspection

- Conduct a visual check to ensure all cables are properly anchored and tensioned.

- Perform a load test to confirm the system functions as expected.

- Record initial tension levels for future maintenance checks.

6. Final Adjustments & Maintenance

- Regular inspections should be performed to monitor cable tension and corrosion.

- After extreme weather events, tension readjustments may be required to maintain stability.

FAQs

1. How long does cable bracing last?

Cable bracing can last for decades if made from high-quality steel. In coastal or wet areas, regular checks on corrosion protection are needed.

2. Does the tension need to be adjusted over time?

Yes, the tension in the cables may loosen over time. It should be checked and adjusted, especially after bad weather.

3. Can it be used with existing steel structures?

Yes, cable bracing can be added to existing steel structures to strengthen them.

4. Is it suitable for harsh climates (e.g., typhoon areas)?

Yes, cable bracing works well in harsh climates. The design should focus on wind resistance and corrosion protection.