Hey there, space seekers! 👋 Have you found yourself doing the “metal building shuffle” lately – you know, that awkward dance where you try to squeeze another tool rack into an already-packed workshop? Or maybe you’re eyeing that empty lot beside your warehouse, dreaming of doubling your production capacity. Whatever your situation, let’s start with the most important question:

“What’s really driving your expansion needs?”

According to the Metal Building Manufacturers Association’s 2023 report, 62% of extension projects stem from business growth demands, while 28% address evolving family needs (think: converting that old storage shed into a teen hangout). The remaining 10%? Those are the passion projects – the backyard pottery studios and vintage car sanctuaries that make our hearts race!

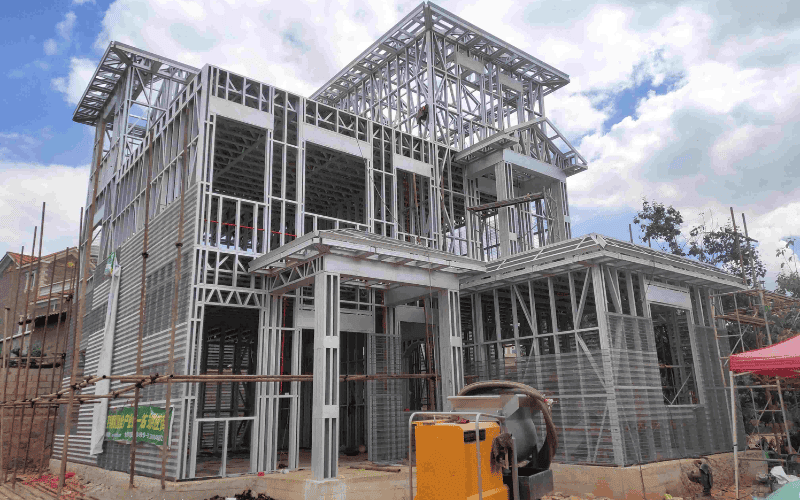

Here’s the beautiful part: Metal buildings adapt like Lego blocks. Want to add a 20ft equipment bay to your auto shop? No need to reinvent the wheel. Dreaming of a glass-walled sunroom extension? Let’s talk about thermal breaks and load-bearing frames. The secret sauce lies in what we call “modular mentality” – approaching your expansion as interconnected components rather than a monolithic structure.

Pro Tip: Before sketching designs, try this exercise:

- Lay out all items you want to accommodate in the new space

- Measure their total footprint

- Add 40% for movement and future growth

You’ll often discover that a 15ft extension solves today’s problem and tomorrow’s possibilities. But wait – before you grab the power tools, let’s talk about…

Table of Contents

Pre-Construction Checklist: The 3 Must-Know Factors

Alright, let’s roll up our sleeves and talk about the real work that happens before the first bolt is tightened. Think of this as your expansion’s “pre-game warmup” – skip it, and you might end up with a building that leans more than the Tower of Pisa (but far less charming). Here’s your triple-threat checklist:

1️⃣ Load Path 101: Follow the Weight

Imagine your building is a superhero – its strength comes from how well it channels forces through its “skeleton.” That’s essentially a load path: the invisible route that weight (like snow, equipment, or even that antique piano you’re storing) takes from your roof down to the ground.

Why it matters for extensions:

- New walls must align with existing structural frames – like adding branches to a tree trunk.

- Mismatched load paths can cause stress fractures (the silent killers of metal buildings!).

Pro Tip: Grab a flashlight and trace your existing columns. If your extension plans to host heavy machinery, mark those zones with red tape. Still unsure? A quick consult with a licensed engineer (we offer free time-limited assessments!) can save you months of headaches.

2️⃣ Foundation Forensics: Don’t Play See-Saw

Here’s a hard truth: 40% of extension failures stem from poor foundation prep (ICC 2021 Structural Compliance Report). Your existing slab might look solid, but can it handle extra weight? Let’s investigate:

The 3-Step Ground Check:

- Core Sampling: Think of it as a soil biopsy – extracts small concrete/soil samples to test density.

- Water Drainage Audit: Puddles near walls? Redirect them unless you want a built-in swimming pool.

- Anchor Alignment: New footings should mirror old ones. ICC Code §1807.2 requires a minimum 12″ overlap for connected footings.

Fun Fact: Uneven settlements cause more drama than reality TV. A 1/8″ slope difference per foot might seem trivial, but over a 30ft extension, that’s nearly 4 inches of tilt!

3️⃣ Climate Chess: Outsmart the Elements

Metal buildings love consistency – but Mother Nature loves surprises. Before expanding, consult NASA’s POWER Data Access Viewer (free online tool!) to map your local climate risks:

| Weather Threat | Design Adjustment |

| High Wind (55+ mph gusts) | Add cross-bracing & wind columns |

| Heavy Snow Load (30+ lbs/sq ft) | Steeper roof pitch (6:12 or higher) |

| Frequent Thermal Swings | Use slotted bolt holes for expansion breathing room |

The Art of Seamless Connection

So, you’ve checked your load paths, prepped the foundation, and outsmarted the weather—now comes the magic moment: making your old and new metal buildings hold hands like lifelong friends. Let’s break down this “metal marriage” into three acts.

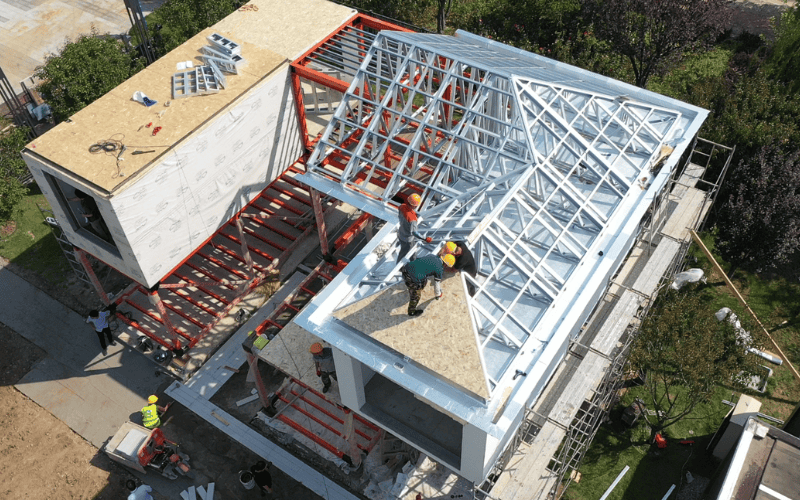

Step 1: The Bolt-Up Ballet

Connecting two metal structures isn’t just about nuts and bolts—it’s a choreography of precision. Here’s how pros ensure a flawless pas de deux:

- Flush Alignment: Use laser levels (not your grandpa’s bubble level!) to align existing and new frames within 1/8″ tolerance.

- Thermal Kiss: Leave a 1/2″ gap between panels for thermal expansion—trust us, metal needs breathing room on hot days.

- Seam Sealing: Apply ASTM C920-approved silicone (the gold standard for elasticity) in a continuous “Z” pattern.

😋 Fun Experiment: Rub two aluminum cans together—hear that screech? Now spray them with WD-40. That’s essentially how anti-seize compounds (like Loctite’s Nickel-based formula) prevent bolt galling!

Step 2: Skin Grafting for Metal

Mismatched cladding isn’t just an eyesore—it’s a leak invitation. Follow this dermatology-for-buildings routine:

Cladding Compatibility Checklist

| Existing Panel | Best Extension Match | Avoid |

| Corrugated Galvalume | 29-gauge Galvalume Plus | Smooth PVC |

| Insulated Sandwich | Same R-value & vapor barrier | Single-skin |

| Rusted Corten Steel | Patina-matching weathering steel | Painted panels |

Pro Tip: Cut a 6″x6″ sample of your old panel and tape it to potential new materials. View it at dawn, noon, and dusk—colors shift more than you think!

Step 3: The “Invisible Transition” Hack

Meet the ASTM A123 Hidden Clip System—the unsung hero of seamless roofs. These zinc-coated steel clips:

- Hide under panels for clean lines

- Allow 1.5″ of lateral movement during earthquakes

- Reduce wind uplift by 34% (per Miami-Dade County wind testing)

When Connections Go Wrong: A Cautionary Tale

In 2022, a Colorado brewery learned the hard way: Their gorgeous glass extension started separating from the original building after six months. Forensic engineers found:

- ❌ Used aluminum bolts on galvanized steel (hello, galvanic corrosion!)

- ❌ Skipped expansion joints in a 100°F annual swing climate

- ❌ Ignored snow load directionality—drifts pushed walls outward

The fix? A $52,000 retrofit with carbon fiber straps. Moral: Even beer can’t wash away connection sins!

When DIY Meets Pro Help

Let’s get real: Not every expansion requires a team of engineers, but some projects will bite back if you underestimate them. Think of this section as your “Swiss Army knife” guide—whether you’re a weekend warrior or a cautious planner, we’ve got your back.

The Red Zone: 3 Times You MUST Call a Pro

(Backed by International Building Code §105.1)

1️⃣ Heightened Horizons

Adding a second story? Even a small loft changes everything. Your existing columns might handle vertical loads, but lateral forces (wind, seismic activity) multiply exponentially.

→ Pro Move: Hire a structural engineer to run a finite element analysis (FEA). This computer simulation predicts stress points—like an X-ray for your building.

2️⃣ Big Box Bonanza

Expanding beyond 50% of the original footprint? Most U.S. counties require:

- Updated zoning permits

- Firewall installations (for buildings over 5,000 sq ft)

- ADA compliance if open to the public

→ DIY Trap: A Florida man tried doubling his 30ft x 40ft workshop without permits. The county made him demolish $28k worth of work. Ouch.

3️⃣ Critical Connections

If your design includes any of these, pause the DIY:

- Cantilevered sections (roofs that “float” beyond supports)

- Multi-slope roof intersections

- Retractable walls or heavy sliding doors

DIY-Friendly Zones: Where to Shine

(With the Right Tools!)

Toolkit for Smart DIYers

| Tool | Pro Use Case | Budget Hack |

| Laser Distance Measurer | Layout accuracy within 1/16″ | Use free app MeasureKit (LiDAR-enabled iPhones) |

| Magnetic Angle Finder | Checking roof pitch alignment | $12.99 at Harbor Freight |

| Thermal Leak Detector | Spotting insulation gaps in existing walls | Borrow from local tool library |

Pro Tip: Rent a metal framing crimper ($45/day) for clean panel cuts. It’s like a paper cutter for steel!

The “Should I Call a Pro?” Quiz

(Flowchart Logic Made Simple)

- Q: Are you modifying load-bearing walls?

→ Yes: Pro required.

→ No: Proceed. - Q: Does your design include curved walls or glass facades?

→ Yes: Consult an architect.

→ No: Proceed. - Q: Is your budget under $15k?

→ Yes: DIY possible with prefab kits (like Bolt-Together Extensions).

→ No: Pro advised for cost efficiency.

Surprise Stat: 73% of DIYers overspend by 22% on first-time metal projects (2024 HomeAdvisor Survey).

Future-Proofing Your Expansion

“Want Your Metal Building to Pay You Back? Let’s Talk Tomorrow-Proofing!”

Imagine your expanded space not just serving today’s needs but evolving with your ambitions—whether that’s adding solar panels next year or doubling your square footage in a decade. Future-proofing isn’t sci-fi; it’s smart design. Let’s break it down.

1. Solar Synergy: Turn Your Roof Into a Power Plant

According to NREL’s 2024 report, metal buildings with integrated solar panels achieve 19% faster ROI than traditional roofs. Here’s why:

- Seamless Mounting: Pre-drilled purlins (those horizontal beams) let you clip on solar rails without drilling.

- Cool Savings: Reflective metal roofs reduce cooling loads by up to 25%, boosting panel efficiency (U.S. DOE 2023 study).

Solar Cheat Sheet

| System | Avg. Cost/Watt | Payback Period | Best For |

| Rooftop PV Panels | $2.10 | 7-10 years | High energy users |

| Solar Carport | $3.50 | 10-12 years | Parking expansions |

| Thermal Cladding | $4.20 | 15+ years | Process heat needs |

Pro Tip: Pair solar with a tax credit trifecta—2024 federal (30% ITC), state rebates, and utility incentives. A Wisconsin warehouse slashed its $50k solar bill to $29k with credits!

2. Modular Mindset: Build Like You’re Playing LEGO®

Modular design lets you snap on future additions like building blocks. Key moves:

- Panelized Walls: Use ASTM E2837-compliant interlocking panels (no welding needed).

- Plug-and-Play Utilities: Install extra conduit runs and junction boxes during initial construction.

- Column Grid Magic: Space primary columns at 25ft intervals—the sweet spot for most equipment layouts.

Real-World Win: A Texas RV storage facility added 12 new bays in 3 days by reusing modular framing. Their secret? LOT-EK’s “Zip-Up” connector system—think giant metal zippers!

3. Maintenance Made Smart: Your Building’s Annual Checkup

Neglect turns small issues into $10k repairs. Here’s your seasonal game plan:

Spring

☑️ Inspect roof seams with a drone

☑️ Clear debris from gutters using a FlexiSnake

Winter

☑️ Check for ice dams with a FLIR thermal camera

☑️ Lubricate door tracks with lithium grease (skip WD-40—it attracts dust!)

Scan your building with Augmenta’s AR app (iOS/Android). Point your phone at a wall, and it overlays maintenance alerts like a video game HUD!

Final Call-to-Action

At SteelPRO PEB, we engineer precision. With 20+ years of expertise and 1,000+ successful cases worldwide, here’s how we simplify your project:

📸 Free Photo Assessment

Email photos of your building to our team. Receive a tailored expansion feasibility report within 24 hours.

🏗️ Custom-Built Expansion Kits

We manufacture code-compliant steel frames, cladding, connectors, and so on tailored to your existing structure.

🛠️ Your Build, Your Way

- Self-Guided: Detailed assembly manuals with numbered components.

- Expert Support: Add remote engineer guidance or onsite installation engineers (global dispatch).

📞 Act Now

Contact us for a no-obligation quote or merely a relaxing consultation.