Steel structures form the foundation of modern construction, providing unmatched strength and longevity. But even the strongest steel can face challenges over time—whether it’s from wear and tear, environmental factors, or changing needs. That’s where steel structure reinforcement comes in. It’s all about strengthening existing steel frameworks to bring them back to their prime, extend their lifespan, and keep everything safe and sound. It’s like giving your structure the boost it deserves!

In this blog, we’ll dive into why reinforcement is so important, explore the methods you can use, and share some practical tips. Plus, we’ll touch on some of the challenges shaping the future of this critical part of engineering.

Why Reinforce Steel Structures?

Steel structures are designed to last, but they are not immune to wear and tear. Here are the most common reasons why reinforcement becomes necessary:

- Aging and Corrosion: Over time, exposure to environmental factors like moisture and chemicals can lead to corrosion, weakening the structure.

- Increased Load Requirements: Changes in building use or additional loads (e.g., new equipment) may exceed the original design capacity.

- Design Flaws or Construction Errors: Mistakes in the initial design or construction phase can compromise structural integrity.

- Seismic and Environmental Factors: Earthquakes, high winds, and other natural forces can expose vulnerabilities in existing structures.

For instance, in cases where corrosion is ignored, steel beams can lose up to 50% of their load-bearing capacity, significantly increasing the risk of failure. Similarly, structures not reinforced for seismic activity are far more likely to suffer catastrophic damage during earthquakes, leading to devastating human and economic consequences.

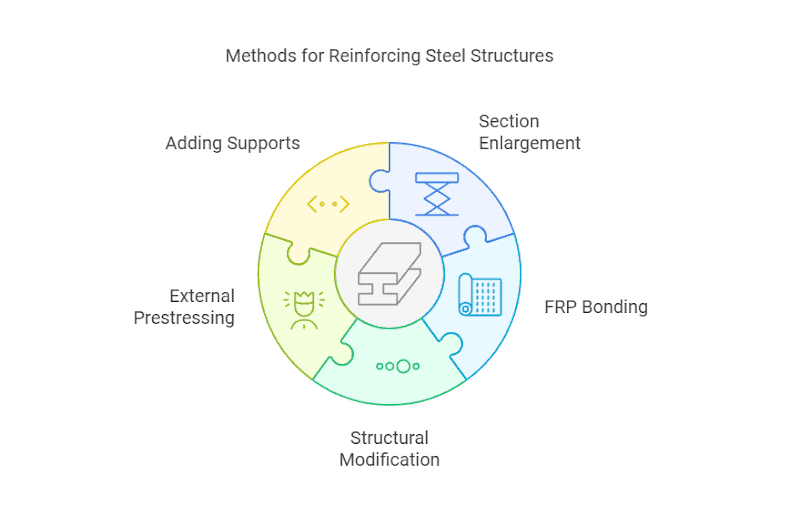

Steel Structure Reinforcement Methods

When it comes to reinforcing steel structures, there’s no one-size-fits-all solution. The choice of method depends on the structure’s characteristics, the desired outcome, and practical considerations like cost and feasibility. Here’s an overview of the 5 most efficient techniques:

1. Section Enlargement Method

- How It Works: Steel plates or sections are welded, bolted, or riveted to the existing structure to increase its cross-sectional area, enhancing load-bearing capacity and stiffness.

- Best For: Beams, columns, and other primary structural elements.

- Pros: Proven reliability, significant strength improvement, and wide applicability.

- Cons: Adds weight, requires extensive surface preparation, and may not be suitable for space-constrained areas.

2. Fiber-Reinforced Polymer (FRP) Bonding

- How It Works: High-strength carbon or glass fiber sheets are bonded to the structure’s surface using specialized adhesives, improving tensile strength and crack resistance.

- Best For: Sections exposed to high tension or bending, like beams and slabs.

- Pros: Lightweight, easy to install, and corrosion-resistant.

- Cons: High material costs, sensitivity to adhesive quality, and limited performance in high-temperature environments.

3. Structural System Modification

- How It Works: The load path is altered by adding supports, bracing, or changing the structural configuration (e.g., converting a simply supported beam to a continuous one).

- Best For: Large-span structures or buildings requiring seismic upgrades.

- Pros: Improves overall structural behavior and can be cost-effective for complex projects.

- Cons: Requires precise analysis and may disrupt building operations during implementation.

4. External Prestressing

- How It Works: Prestressed tendons are installed outside the structure and tensioned to counteract existing stresses, enhancing load capacity and stiffness.

- Best For: Beams, trusses, and other flexural members.

- Pros: Rapid and effective, with minimal damage to the original structure.

- Cons: Complex installation, potential for prestress loss over time, and ongoing maintenance needs.

5. Adding Supports or Bracing

- How It Works: Additional supports, such as braces or trusses, are installed to redistribute loads and improve stability.

- Best For: Multi-story buildings or structures requiring seismic reinforcement.

- Pros: Simple and cost-effective, with minimal impact on existing connections.

- Cons: Limited effectiveness as a standalone solution and may interfere with interior spaces.

Related Reading: Steel Structure Anticorrosion: Essential Protection Methods

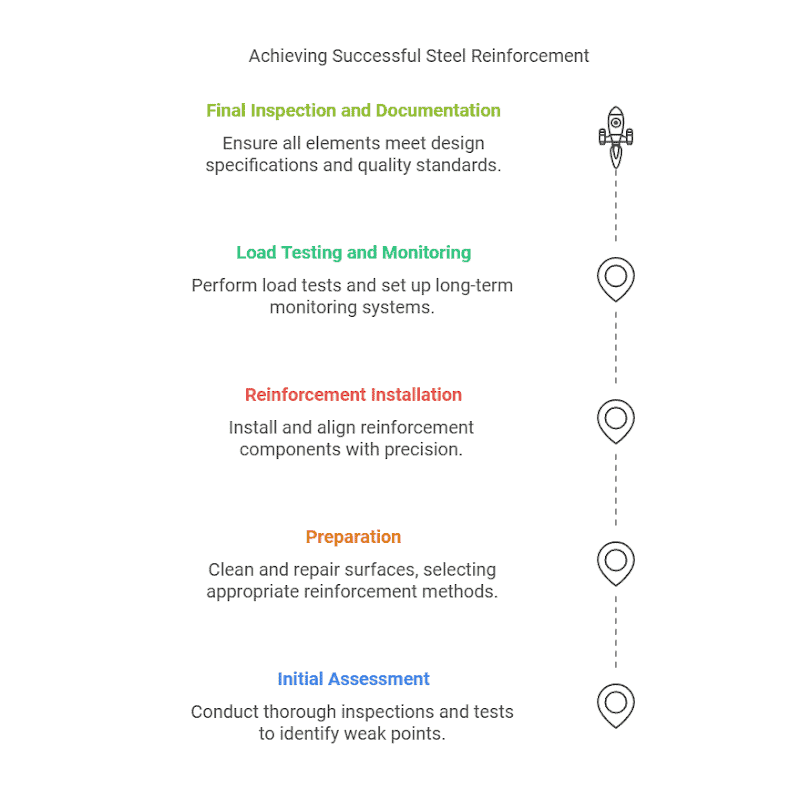

Key Steps in Steel Structure Reinforcement Projects

A successful reinforcement project requires more than just adding steel—it involves thoughtful planning, precise execution, and ongoing care. Here’s a step-by-step guide to ensure your project is a success:

1. Initial Assessment

The journey starts with a thorough inspection. Thorough assessments and load testing are essential to pinpoint weak spots or areas that need extra reinforcement. It’s equally important to perform a damage analysis to pinpoint the causes of the issues—whether it’s excessive load, material aging, or construction defects. This helps in understanding the root cause and ensures that the reinforcement plan is precisely aligned with the structure’s needs.

2. Preparation

Before any reinforcement work begins, the structure requires careful preparation—cleaning and treating surfaces to ensure proper bonding, along with repairing any existing damage. The choice of reinforcement method—whether it’s section enlargement, external prestressing, or system modification—depends on factors like space, functionality, cost, and timeline.

For example, in tight spaces, fiber-reinforced polymer (FRP) bonding is often the ideal solution. Once the method is selected, gathering the necessary materials and equipment ensures a smooth start to the project.

3. Reinforcement Installation

- Installing Reinforcing Components: Install reinforcement elements as per the chosen method—whether welding steel plates, tensioning prestressed strands, or bonding FRP sheets. Ensure proper alignment to the existing structure.

- Connection and Welding: Follow welding procedures carefully and perform checks for defects like porosity. Tighten bolts to the required torque for proper clamping force.

- Quality Control During Construction: Continuously monitor the installation quality, checking alignment, fit, and connection integrity. Conduct regular non-destructive testing to ensure quality.

4. Load Testing and Monitoring

- Load Testing: After reinforcement, perform load testing using strain gauges and sensors to measure deflection, strain, and stress. Compare results with design predictions.

- Long-Term Monitoring: Set up a monitoring system for critical structures, tracking temperature, humidity, and vibration over time to detect any issues with damage or degradation.

5. Final Inspection and Documentation

Conduct a thorough inspection of all reinforcement elements, ensuring they meet design specifications and quality standards before completion.

After reading the above reinforcement steps, please continue reading Steel Structure Building Maintenance: What You Need to Know!

Challenges and Future Trends of Steel Structure Reinforcement

Reinforcing steel structures presents several challenges:

- Cost: Reinforcement projects can be costly, particularly for large or intricate structures.

- Accessibility: Accessing challenging or aging structures often demands specialized equipment and techniques, increasing the project’s complexity.

- Environmental Impact: Traditional reinforcement methods can have a significant environmental footprint, particularly due to the use of additional materials and energy.

- Ongoing Maintenance and Monitoring: Even after reinforcement, continuous monitoring and maintenance are required to ensure the structure’s long-term stability, which adds to the ongoing cost and effort.

Looking ahead, several promising trends are poised to define the future of steel structure reinforcement:

- Advancements in Materials: The development of nanomaterials promises stronger, lighter, and more durable solutions, reducing the frequency of repairs and enhancing the effectiveness of reinforcements.

- Technological Innovations: IoT-based structural health monitoring will enable real-time tracking of structural performance, making it easier to predict maintenance needs and identify potential issues before they become critical.

These advancements hold the potential for more efficient, sustainable, and cost-effective reinforcement solutions, ensuring steel structures are safer and last longer.

Choosing Our Steel Structure Reinforcement Solutions

Steel structures are essential for modern buildings, providing strength and long-term durability. Over time, reinforcement may be required to maintain their safety and functionality. Whether through FRP bonding, corrosion-resistant coatings, or strengthening connections, the right solution ensures lasting performance.

At SteelPRO PEB, we specialize in producing high-quality steel structures and offering customized reinforcement solutions. For example, in a recent project, we reinforced an aging steel bridge by applying advanced FRP bonding to prevent corrosion and enhance structural stability. This solution not only enhanced the bridge’s load-bearing capacity but also significantly prolonged its lifespan.

Whether you’re upgrading an existing structure or planning a new one, we deliver customized steel solutions and expert reinforcement strategies to ensure your buildings remain strong, safe, and future-proof for years to come.