Steel buildings have a challenge that cannot be ignored: heat conduction. Since they are highly conductive to heat and are easily affected by external climate, insulation is particularly important. Good insulation measures can effectively save energy, prevent moisture and sound, and extend the life of the building to ensure a comfortable environment inside the building.

We will take a deep look at the different types of steel building insulation, installation methods, cost-effectiveness, and how to choose the right insulation material. We hope to help you optimize your design and reduce costs while ensuring the efficiency and durability of the building.

Basic principles of steel building insulation

Thermal bridge effect

Thermal bridge refers to the part of the building where the heat flow is more concentrated, usually the beams and columns of the steel structure. These parts have strong thermal conductivity, which can easily lead to heat loss or condensation problems, affecting the energy efficiency of the building and may cause wall damage or mold growth.

R value (thermal resistance value)

The R value signifies the insulation material’s capacity to resist heat conduction. A higher R value translates to a superior insulation effect. When choosing the right material, a higher R value can effectively reduce the flow of heat and improve the energy efficiency of the building.

U value (thermal conductivity coefficient)

The U value is an indicator to measure the thermal conductivity of the building envelope. The lower the U value, the better the insulation effect. The U value of the building’s exterior walls, roofs and windows determines the rate of heat loss and directly affects the building’s energy efficiency performance.

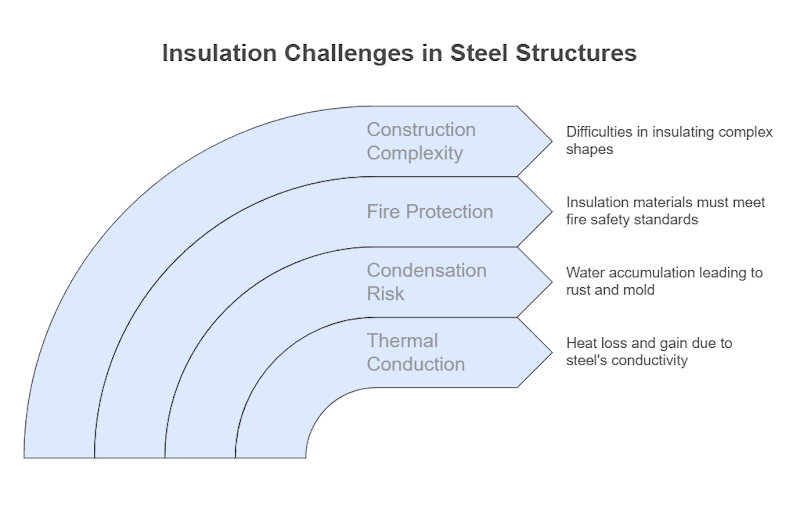

Challenges of steel structure insulation

Main types of steel structure insulation

According to the location and installation type of the insulation material, steel structure insulation is mainly divided into three types: internal insulation, external insulation and interlayer insulation. Each type boasts its own distinct advantages and suitable applications. We will delve into them in greater detail below.

Internal insulation

Internal insulation is to install insulation materials inside the steel structure, usually on the inside of the wall and roof.

- Advantages: The construction process is relatively straightforward and apt for both new builds and renovation projects. It can effectively insulate and will not affect the beauty of the facade.

- Commonly used materials include glass wool, rock wool, polyurethane foam, among others, which exhibit excellent thermal insulation properties.

- Applicable scenarios: Commonly used in places such as industrial plants, warehouses and office buildings, especially projects with low requirements for appearance.

External insulation

External insulation is to add an insulation layer to the outside of the steel structure to improve the overall insulation effect by covering the exterior wall.

- Advantages: It can effectively reduce the thermal bridge effect, improve the insulation performance of the entire building, and does not occupy indoor space.

- Common materials: extruded polystyrene board (XPS), polyurethane board, mineral wool board, etc., which have excellent thermal insulation performance and durability.

- Applicable scenarios: suitable for large public buildings, gymnasiums, exhibition centers, etc., especially buildings that need to consider energy saving and appearance.

Sandwich Panel Insulation

Sandwich insulation is formed by sandwiching insulation materials between two layers of steel plates to form a composite insulation panel. This method is usually used for walls and roofs.

- Advantages: Sandwich panels have good thermal insulation, compression resistance and durability, are easy to construct and have high mechanical strength.

- Common materials: polyurethane, rock wool, glass wool, etc., usually sandwiched between two layers of metal plates as core materials.

- Applicable scenarios: suitable for buildings such as industrial plants, warehouses, cold storage, etc. that require efficient insulation and high strength.

When choosing the right insulation method, you can decide based on the specific building needs, climate conditions and budget. If you have any questions about choosing the right insulation solution, we are happy to provide you with personalized advice and services to help you find the solution that best suits your needs.

Common steel structure insulation methods

Roof Insulation: Roofs are a major area of heat loss, and insulating your roof can help prevent heat loss and condensation. Common roof insulation materials include spray foam and rigid foam board.

Wall Insulation: Wall insulation can prevent thermal bridging, especially in cold or snowy areas. Fiberglass and mineral wool are common wall insulation materials.

Floor Insulation: If the building features concrete floors, implementing floor insulation can minimize heat loss. Typical floor insulation materials encompass rigid foam board and spray foam.

Door and Window Insulation: Insulating doors and windows can prevent drafts and heat loss, usually with weatherstripping or double glazing.

Single & Double-Ply Insulation Systems: Single-ply systems are good for basic needs, and double-ply systems provide higher R-values by adding a second layer of insulation.

Commonly used steel structure insulation materials

In steel buildings, choosing the right insulation materials is the key to ensuring building energy efficiency, comfort and durability. The following is a detailed introduction to several common insulation materials, and you can choose the right material according to your project needs.

| Insulation Material | Advantages | Disadvantages | Applications |

| Fiberglass | Low cost, fire resistance, easy install | Loses performance when wet | Indoor insulation, light steel structures |

| Rock Wool | Fire & sound resistance, high-temp resistant | Complex installation, high density | Industrial facilities, high fire safety buildings |

| Polyurethane Foam | Excellent insulation, lightweight, waterproof | Higher cost, professional install | Cold storage, cold chain logistics |

| Extruded Polystyrene (XPS) | High strength, moisture resistant | Flammable, needs flame retardants | Floor insulation, exterior walls |

| Rigid Foam Boards | Continuous insulation, reduces bridging | Complex installation, higher cost | Roof & wall insulation |

| Reflective Foil | Reflects solar radiation, good for hot climates | Often used with other materials | Hot climates (offices, residences) |

| Insulated Metal Panels | High R-value, aesthetic | Higher cost | High-end buildings (commercial, luxury) |

| Mineral Wool | Fire & moisture resistant, soundproof | Higher cost | High-temp industrial facilities |

How to choose the right insulation material for steel structures

When choosing the right insulation material, you should decide based on the following factors:

Choose based on climate

In high-temperature areas, reflective foil insulation is the most suitable material, which can effectively reflect sunlight and heat to keep the interior of the building cool.

For cold areas, you need to choose insulation materials with high R values, such as spray foam or rigid foam boards, which have stronger thermal resistance and can effectively prevent heat loss and keep the interior warm.

Choose based on building use

Buildings serving diverse purposes necessitate varying insulation solutions. For instance:

- Residential: You can choose fiberglass or spray foam, which can provide good insulation performance and control costs.

- Office: You can choose polyurethane foam, which can provide good insulation while also playing a role in sound insulation and improving comfort.

- Warehouse: Considering the large space and complex use environment of the warehouse, rock wool or rigid foam board are more suitable choices, especially in places with high fire protection requirements.

Choose based on budget

If the project budget is limited, you can choose lower-cost fiberglass, which provides basic insulation while being more economical.

For projects with sufficient budget and higher insulation requirements, you can choose insulated metal panels or polyurethane foam. These high-end materials not only provide higher R-values, but also have better fire and moisture resistance.

Choose according to the building structure

For existing buildings, you can choose insulation systems suitable for renovation, such as internal insulation or spray foam. These materials can be installed without affecting the facade.

For new buildings, you can choose a more efficient double-layer insulation system, which not only improves the insulation effect, but also effectively reduces the thermal bridge effect and improves the overall energy efficiency of the building.

Key considerations for our steel structure insulation design

- Thermal bridge effect: We reduce thermal bridge problems through design optimization, such as using thermal bridge breakers to ensure that heat does not quickly lose through the structure.

- Fire performance: We always choose insulation materials that meet fire safety standards to ensure the overall safety of the building.

- Moisture and waterproof: We pay attention to the moisture resistance of insulation materials to avoid moisture absorption and reduce thermal insulation performance.

- Construction feasibility: Our insulation solutions fully consider the complex shape and connection method of steel structures to ensure that the construction of the solutions is convenient and efficient.

- Cost and benefit: We help customers balance initial investment and long-term energy-saving benefits to ensure that each project can achieve the best cost-effectiveness.

Installation and maintenance of steel structure insulation

Installation precautions

Seamless coverage: Ensure that the insulation material seamlessly covers the building surface to avoid gaps or voids to reduce the thermal bridge effect.

Avoid thermal bridges: Use thermal bridge breakers or local insulation materials where steel components penetrate the insulation layer (such as beam and column connections) to prevent heat loss.

Moisture barrier installation: In a humid environment, install a moisture barrier (such as polyethylene film) to prevent the insulation material from absorbing moisture and affecting performance.

Adapt to complex structures: For steel structures with complex shapes, choose insulation materials that are easy to cut and install (such as glass wool, spray foam) to ensure full coverage.

Maintenance recommendations

Regular inspection: Regularly inspect the insulation layer to ascertain that there is no damage, shedding, or moisture issues.

Repair damage: If the insulation material is found to be damaged or damp, repair or replace it in time to avoid affecting the overall insulation performance.

Moisture-proof treatment: In a humid environment, regularly check whether the moisture barrier is intact and repair or replace it if necessary.

Clean up debris: Make sure there is no debris (such as dust, leaves) accumulated on the surface of the insulation layer to avoid affecting the insulation effect.

Scientific insulation design can not only effectively reduce operating costs, but also improve the long-term value and sustainability of the building. If you need professional steel structure insulation design services or purchase steel structure products, our team will provide you with full support to ensure the smooth completion of the project.

Related Reading: Cheapest way to insulate a metal building

FAQs

What is the best material for insulating a steel building?

The best material to choose depends on the climate, building purpose, and budget. Spray foam and insulated metal panels offer high R-values for projects that require efficient insulation, but they are more expensive. Fiberglass and reflective foil are more economical options for applications where insulation requirements are relatively low.

Does insulation increase building costs?

The initial investment in insulation materials is relatively high, but effective energy-saving design can significantly reduce energy consumption in the long run, saving energy bills and ultimately achieving higher cost-effectiveness.

How to prevent insulation materials from absorbing moisture?

Insulation materials can be effectively prevented from absorbing moisture by using a moisture barrier (such as polyethylene film) or by choosing insulation materials with good moisture resistance (such as spray foam), thereby maintaining their insulation effect.