Steel structure workshops are an ideal choice for industries that require durable, cost-effective, and customizable building solutions. Whether you’re in manufacturing, aerospace, automotive, or construction, the flexibility and strength of steel can meet a variety of industrial needs. However, designing a steel workshop requires careful planning and consideration of various technical, environmental, and operational factors. In this article, we’ll guide you through the key aspects of designing a steel workshop, from choosing the right type to ensuring safety, energy efficiency, and long-term sustainability.

Types of Steel Structure Workshops

The first step in designing a steel workshop is determining which type of structure best suits your needs. The design of your workshop will depend on the available space, the specific industrial activities you plan to conduct, and any future expansion requirements. Here are the common types:

Single-Story Steel Structure Workshop

A single-story workshop is ideal for businesses that don’t require multiple levels for their operations. These workshops offer large open spaces with high ceilings, making them perfect for manufacturing, storage, and assembly. For industries like automotive manufacturing, electronic assembly, or large-scale warehousing, this type of design provides ample floor space and operational flexibility.

Multi-Story Steel Structure Workshop

If you have limited land space but require multiple operational areas, a multi-story steel structure workshop can help maximize vertical space. These buildings are typically used when different functions need to be performed on different floors, such as in complex manufacturing processes or multi-functional assembly lines. Multi-story designs are often ideal for industries like electronics, where different production stages can occur on separate levels.

Single Span Steel Structure Workshop

Single-span workshops feature a clear-span design, meaning there are no internal columns or supports, allowing for flexible use of the interior space. This design is perfect for large-scale production lines and warehouses, where uninterrupted floor areas are necessary. Industries such as logistics, packaging, and food production commonly use this design to optimize workflow and storage capacity.

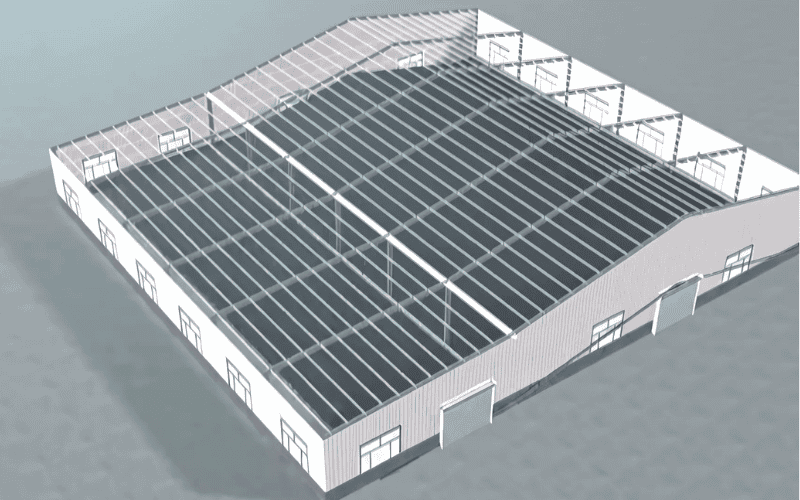

Multi Span Steel Structure Workshop

Multi-span workshops consist of multiple spans, each supported by columns or walls. This design provides more stability and is suitable for industries that require different roof heights or sections for distinct operations. Multi-span workshops are often used for complex manufacturing processes or industries with varying operational requirements, such as automotive assembly or heavy machinery manufacturing.

Key Considerations for Structural Design

When designing your steel structure workshop, the following factors are critical to ensure safety, durability, and efficiency.

Load-Bearing Capacity

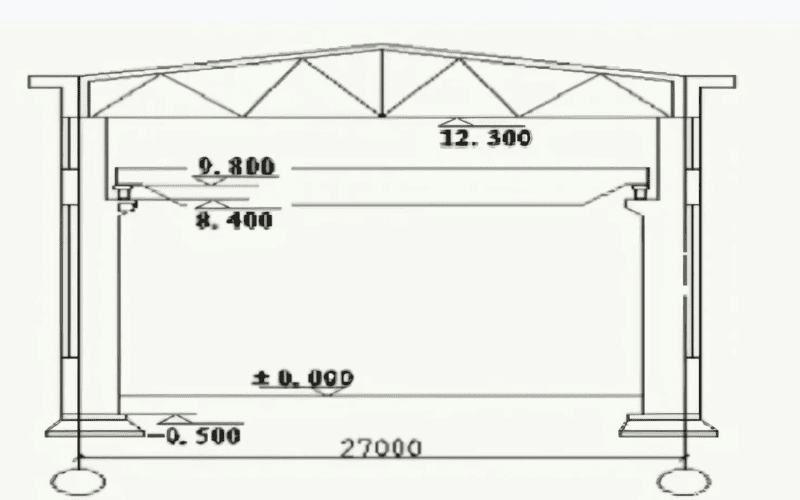

A primary concern in the design process is ensuring the workshop can handle the loads it will experience. The building must support various loads, such as construction loads, maintenance loads, wind, snow, and dust. For example, if your workshop will house overhead cranes or heavy equipment, load-bearing calculations must account for these additional forces.

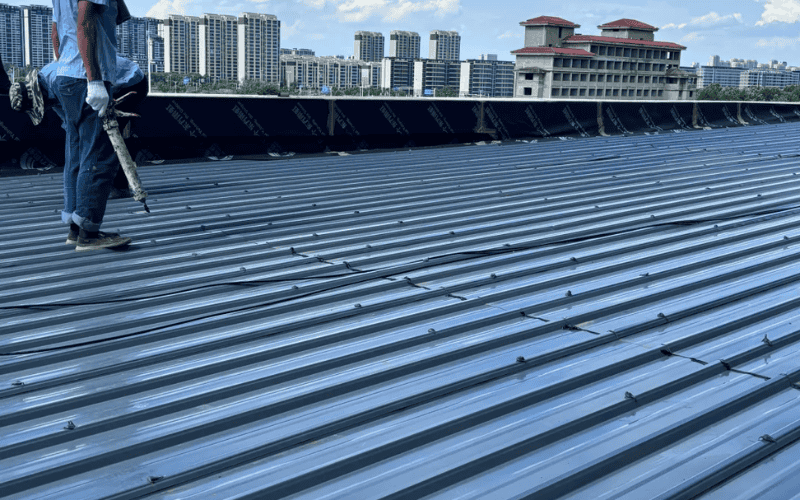

The load-bearing performance of materials (e.g., corrugated metal sheets for the roof) is influenced by factors like thickness, strength, and the spacing of structural elements like purlins. Proper load analysis is essential to avoid potential structural failures. Engineers typically use detailed load calculations, including wind and snow load standards, to ensure stability.

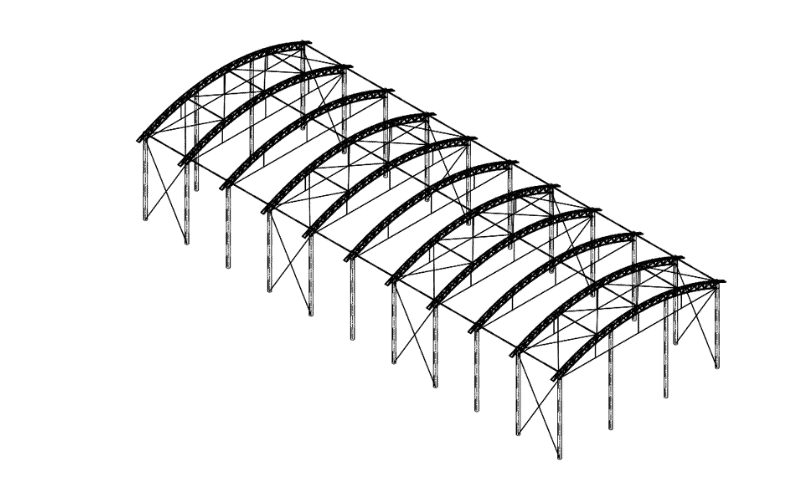

Portal Steel Frame Design

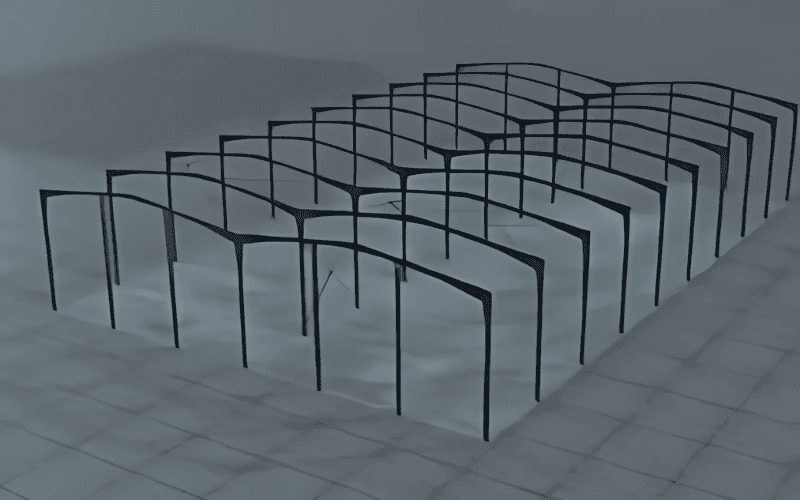

Steel frame workshops are commonly designed with portal frames, which can vary in design, such as single ridge and single slope, single ridge and double slope, multi-ridge and multi-slope, as well as single-span, double-span, or multi-span configurations. The choice of frame design depends on the size and purpose of the workshop. For example, when designing for the inclusion of an overhead crane, a rigid frame with a constant cross-section might be necessary. These frames help provide the necessary structural integrity to support the building’s loads, especially in heavy-duty industrial applications.

The load distribution in portal frames must be carefully calculated, considering the type of equipment used and any dynamic loads generated by machinery or vehicle movements. At this stage of design, the use of finite element analysis (FEA) software is common.

Material Selection and Quality

Selecting the right materials for the workshop is essential for both durability and cost-effectiveness. Steel is generally chosen for its high strength-to-weight ratio, but the quality and type of steel (e.g., galvanized steel, high-strength steel) should align with the workshop’s intended use. For instance, high-strength steel might be required for larger spans or heavy-duty operations, while galvanized steel offers additional protection against corrosion in humid environments.

Related Reading:

A Quick Guide to Steel Types in Steel Buildings

Additionally, the materials used for insulation and exterior cladding play an important role in the building’s overall energy efficiency and protection from environmental factors. Insulation materials like fiberglass, mineral wool, or spray foam are commonly used for thermal and sound insulation.

Environmental Considerations

A steel structure workshop must address several environmental factors to ensure it is functional, comfortable, and cost-efficient.

Lighting Design

Steel structure workshops, especially large ones, can be difficult to light effectively. Incorporating natural lighting through skylights or daylight panels is an excellent way to reduce energy consumption while improving the working environment. Daylighting panels should be carefully positioned to avoid direct sunlight and excessive heat while still providing ample light during the day. The lifespan of these panels should match that of the roof materials to ensure long-term reliability.

Moisture-Proofing and Ventilation

Moisture control is crucial for steel structures, especially in regions with high humidity or heavy rainfall. To prevent moisture buildup under the roof, it’s important to install insulation and a waterproof film. Proper ventilation in the roof design can help remove moisture and maintain a dry environment inside the workshop. This is particularly vital for industries that involve sensitive materials or machinery, such as electronics or food production, where moisture control is crucial to prevent corrosion or spoilage.

Fireproofing

Steel structures can withstand high temperatures, but prolonged exposure to extreme heat can reduce the material’s strength. To mitigate fire risks, it’s important to use fire-resistant coatings on structural elements. These coatings can increase the fire-resistance rating of your building, helping to prevent structural collapse in the event of a fire.

Thermal Insulation

Thermal insulation is another essential design consideration, particularly in regions with extreme temperatures. Insulation materials like rock wool or glass wool can be installed under the metal roof to prevent heat loss in winter and reduce heat gain in summer. Proper insulation ensures a comfortable indoor temperature and lowers energy costs.

Sound Insulation

Industrial activities often generate high levels of noise. Soundproofing materials can be integrated into the building’s design to minimize sound transmission inside and outside the workshop. For instance, insulation cotton can be added to the roof layers to absorb sound and improve acoustics inside the workshop.

Safety and Compliance

Safety is paramount when designing a steel structure workshop. To ensure the building meets all necessary safety standards, it’s important to:

- Follow Building Codes and Regulations: Adhere to local building codes and regulations regarding structural design, fire safety, load-bearing capacity, and other important factors. This ensures compliance and avoids costly legal issues down the line.

- Account for Seismic and Wind Loads: Depending on the geographical location, you may need to consider seismic or wind loads in the design. For areas prone to earthquakes or strong winds, additional reinforcement may be needed to ensure structural stability.

- Design for Future Expansion: A well-designed steel structure workshop can accommodate future growth. Consider leaving room for expanding the building, adding new operational areas, or increasing the capacity of existing ones as your business grows.

Cost Considerations

The cost of designing and building a steel structure workshop will depend on several factors, including the size of the building, the complexity of the design, material choices, and the location of construction. While steel structures are generally more cost-effective than traditional buildings, the costs can still vary significantly. Key factors affecting cost include:

- Material Selection: Higher-grade steel and specialty materials (e.g., fire-resistant coatings and thermal insulation) can increase upfront costs.

- Design Complexity: More complex designs, such as multi-story or multi-span workshops, require additional engineering expertise and time.

- Construction Location: Costs can also vary based on local construction conditions, labor rates, and logistical factors.

It’s crucial to conduct a detailed budget early in the design process. This includes not only construction costs but also long-term operational savings, such as energy efficiency and low maintenance requirements.

What’s Next

Designing a steel structure workshop can be tough. You’re probably dealing with challenges like sticking to a tight budget while ensuring the building is durable and efficient. You’re worried about choosing the right materials, getting the design right from the start, and ensuring the whole project is completed on time. And, of course, the last thing you need is to run into hidden costs or delays once the project is underway.

With over 20 years of experience and more than 1,000 successful projects worldwide, we’ve helped businesses just like yours turn their workshop visions into reality. While we don’t handle construction ourselves, we offer expert remote guidance to keep your project on track. From the initial design to the successful delivery, we’ll be with you every step of the way—helping you avoid costly mistakes like:

- Poor initial design choices (layout, functionality, etc.)

- Incorrect material selection

- Miscalculating load-bearing capacity

- Overlooking energy efficiency or long-term sustainability needs

- Design flaws that cause delays during construction

- And more

Reach out to us today, and let’s turn your steel structure workshop into a reality—on time, on budget, and without the stress.