For many companies, choosing the right materials is not only the key to ensuring the smooth progress of the project, but also the basis for creating a long-lasting, durable, comfortable and livable space. Faced with the various prefabricated house materials on the market, many people may be confused: which material to choose to meet the needs of the project?

In this article, we will introduce the characteristics of different prefabricated house materials in detail and help you understand how to make a wise choice. For those customers who are looking for efficient and reliable solutions, SteelPRO PEB’s steel structure materials will provide strong support for your project.

What materials are needed for prefabricated houses?

In order to meet different design needs, functional requirements and environmental conditions, the construction of prefabricated houses requires the use of a variety of materials. These materials are mainly divided into the following categories:

- Structural materials: used to support and stabilize the main structure of the house.

- Insulation materials: used to improve the thermal insulation performance of the house and reduce energy consumption.

- Decorative materials: used to beautify the appearance and interior space of the house.

- Functional materials: used to meet specific functional requirements, such as waterproofing, fireproofing, sound insulation, etc.

Next, we will introduce the specific types of these materials and their characteristics in detail.

Common Structural Materials for Prefabricated Houses

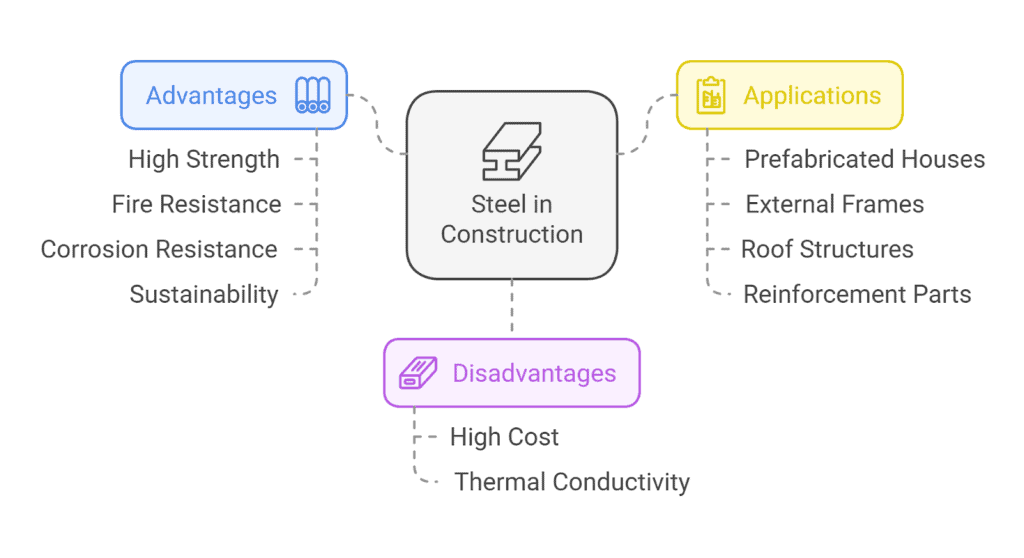

(1) Steel

Advantages:

- High strength, superior wind and earthquake resistance: Steel has extremely high structural strength and is very suitable for use as the frame and support part of the house. Its excellent wind and earthquake resistance enables steel-structured houses to cope with changing climates and natural disasters, especially in earthquake-prone areas.

- Fire resistance: Unlike wood, steel has extremely strong fire resistance and will not burn as easily as wood, which greatly improves the safety of the house.

- Corrosion resistance: Steel can be galvanized or coated to improve its corrosion resistance, especially suitable for humid environments, such as coastal areas or areas with more rain.

- Sustainability: As a recyclable material, steel has significant advantages in environmental protection and sustainable development. The use of steel can reduce resource waste and reduce the impact of buildings on the environment.

Disadvantages:

- High cost: Although steel has excellent durability and performance, the initial cost of steel is relatively high, which may exceed the requirements of projects with limited budgets.

- Thermal conductivity: Although steel has high strength, its thermal conductivity is strong, and it is necessary to consider adding additional insulation layers in the building design to ensure comfort.

Application:

- Steel is a common structural material in prefabricated houses, especially for external frames, roof structures and reinforcement parts. It is very suitable for projects with special environmental requirements such as earthquake resistance and wind resistance, and is particularly suitable for areas that require high-strength support.

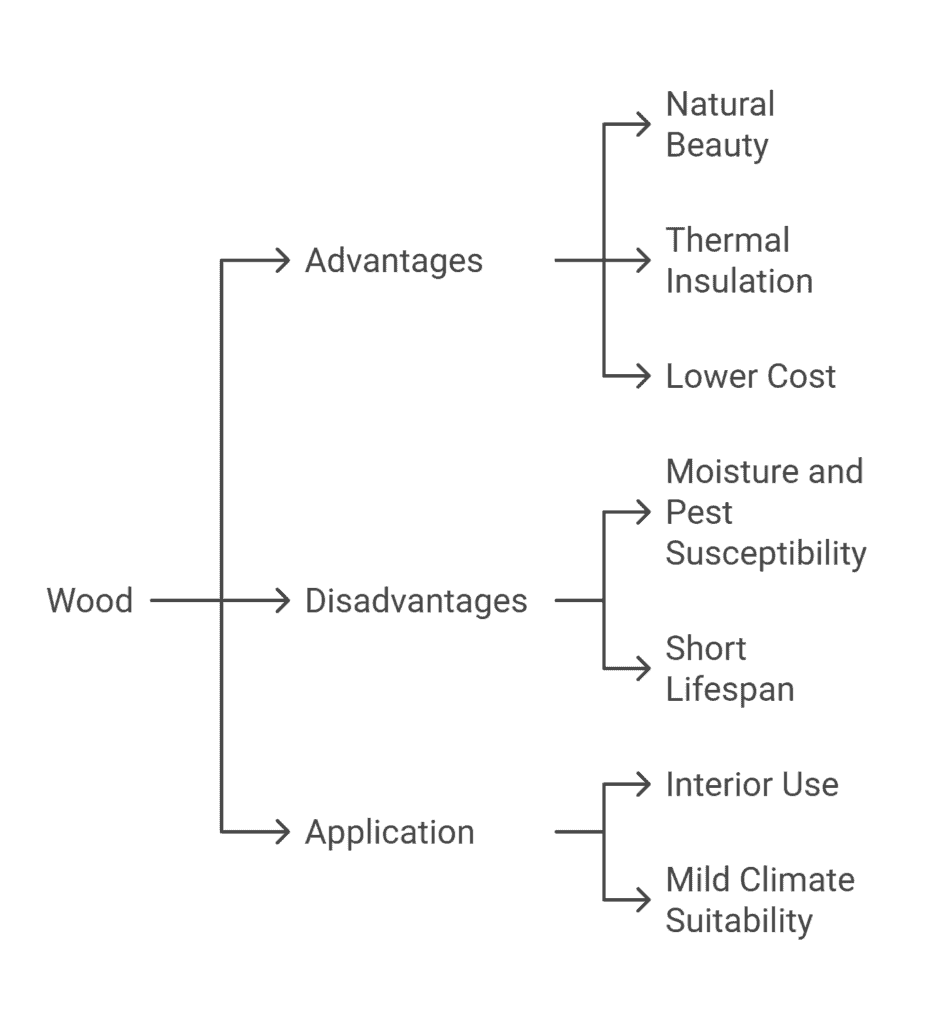

(2) Wood

Advantages:

- Natural beauty: Wood has natural texture and warm tones, which can add unique beauty and comfort to the house, especially suitable for creating a warm indoor environment.

- Good thermal insulation performance: Wood is a natural thermal insulation material that can effectively reduce energy consumption and improve indoor comfort.

- Lower cost: Compared with other materials, wood has a lower cost and is suitable for projects with limited budgets.

Disadvantages:

- Susceptible to moisture, rot and pests: Wood has relatively poor durability and is easily attacked by moisture and pests, especially in humid environments, and requires regular maintenance.

- Relatively short life: Wood is prone to aging during long-term use and requires regular inspection and maintenance.

Application:

- Wood is often used in interior walls, ceilings, roof structures and other parts. It is particularly suitable for areas with mild climates and low humidity, and is not suitable for humid environments or areas with extreme weather.

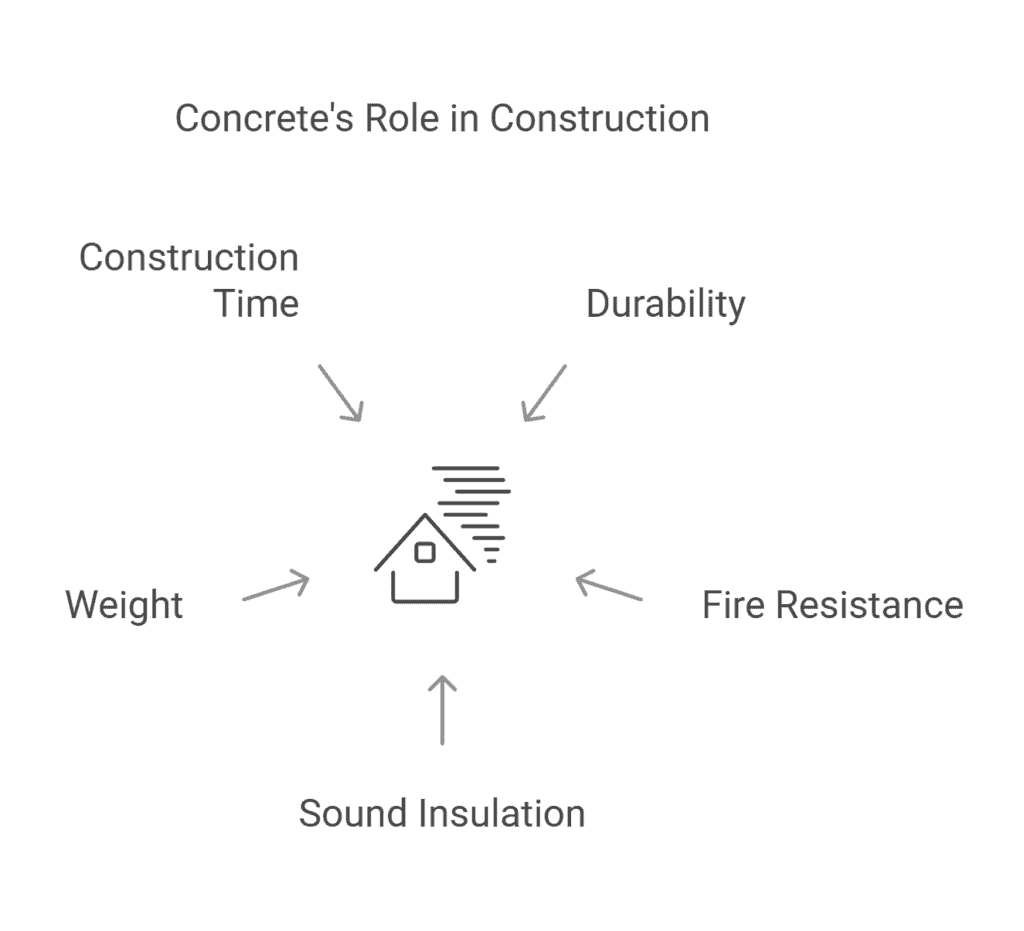

(3) Concrete

Advantages:

- Strong durability: Concrete is a very strong material with excellent durability that can cope with the challenges of various harsh environments, including extreme temperatures and humid weather.

- Fire resistance: Concrete has excellent fire resistance and can effectively protect buildings from fire.

- Sound insulation and heat insulation: Due to its dense structure, concrete can effectively block external noise and heat, providing a quieter and more comfortable living environment.

Disadvantages:

- Heavy weight and difficult to carry: Concrete is heavy and difficult to transport and carry, which may increase the transportation cost of the project.

- Long construction period: Although it is a prefabricated material, the manufacturing period of concrete components is relatively long, and more time is required for installation and curing.

Application:

- Concrete is usually used in parts such as foundations, walls and floors, and is particularly suitable for construction projects that require high durability and high safety. It is very suitable for use in environments that require greater fire protection or sound insulation.

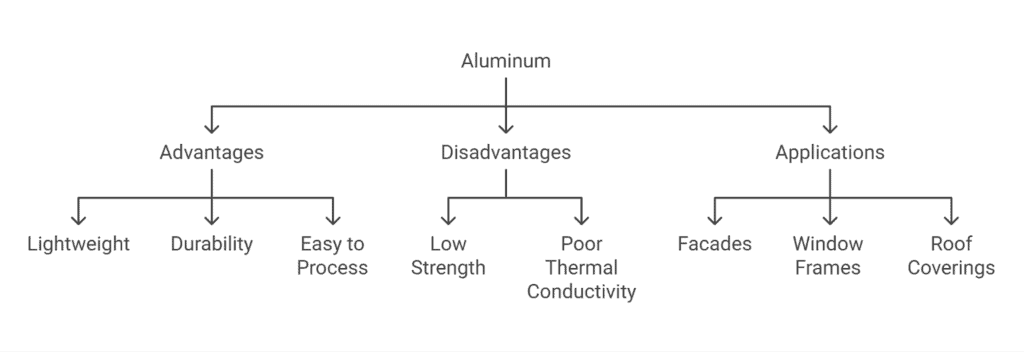

(4) Aluminum

Advantages:

- Lightweight: Aluminum is lighter than steel and is suitable for projects that need to reduce weight. It also has good corrosion resistance.

- Durability: Aluminum is very durable and corrosion-resistant, especially in coastal or humid environments.

- Easy to process: Aluminum can be easily processed and customized to meet different design needs.

Disadvantages:

- Low strength: Although aluminum has good corrosion resistance, it is not as strong as steel, so it is usually used in non-structural parts or combined with other materials.

- Poor thermal conductivity: Aluminum has strong thermal conductivity and requires additional insulation to improve energy efficiency.

Application:

- Aluminum is often used in the facades, window frames, roof coverings and other parts of prefabricated houses. It is suitable for projects that pursue lightweight and modern appearance.

Common insulation materials for prefabricated houses

Insulation materials are the key to improving the energy efficiency of houses, reducing heat loss and energy consumption.

(1) Rock wool

- Excellent fire resistance and high temperature resistance.

- Good sound insulation and thermal insulation effects.

- Environmentally friendly and recyclable.

Application: Commonly used in the insulation layer of walls, roofs and floors.

(2) Polyurethane foam

- Excellent thermal insulation performance, thin thickness but significant effect.

- Good waterproof performance, suitable for humid environments.

- Easy to construct and can be sprayed on site.

Application: Commonly used in the insulation layer of walls, roofs and floors.

(3) Glass wool

- Light weight and easy to install.

- Good sound insulation and thermal insulation performance.

- Relatively low price.

Application: Commonly used in the insulation layer of walls, roofs and floors.

Common decorative materials for prefabricated houses

Decorative materials are used to beautify the exterior and interior space of a house and enhance the living experience.

(1) Exterior wall decorative panels

Types: metal panels, wood veneer panels, fiber cement boards, etc.

Features:

- Durable and beautiful, suitable for various architectural styles.

- Easy to install and maintain.

Application: Commonly used for exterior wall decoration of houses.

(2) Interior wall decorative materials

Types: gypsum boards, wood boards, wallpaper, etc.

Features:

- Provide a variety of textures and colors to meet personalized needs.

- Simple construction and low cost.

Application: Commonly used for interior wall decoration.

(3) Floor materials

Types: wood floors, tiles, laminate floors, etc.

Features:

- Durable and easy to clean.

- Provide a variety of style options to suit different spaces.

Application: Commonly used for interior floor decoration.

4. Common functional materials for prefabricated houses

Functional materials are used to meet specific needs of houses, such as waterproofing, fireproofing, sound insulation, etc.

(1) Waterproof materials

Types: waterproof coatings, waterproof membranes, etc.

Features:

- Effectively prevent water penetration and protect building structures.

- Easy to construct and durable.

Applications: Commonly used in roofs, basements and bathrooms.

(2) Fireproof materials

Types: fireproof boards, fireproof coatings, etc.

Features:

- Improve the fire resistance of houses and enhance safety.

- Meet building code requirements.

Applications: Commonly used in walls, roofs and stairwells.

(3) Sound insulation materials

Types: sound insulation cotton, sound insulation boards, etc.

Features:

- Effectively reduce noise and improve living comfort.

- Easy to construct and effective.

Applications: Commonly used in walls, floors and ceilings.

What is the best material for prefabricated houses?

The best material for prefabricated houses depends on factors like durability, cost, insulation, and environmental impact.

Steel is one of the most popular choices due to its strength, fire resistance, and ability to withstand extreme weather conditions. Wood is another common material, valued for its affordability and natural insulation properties. Concrete and composite materials are also used for enhanced energy efficiency and longevity.

What material is used for modular homes?

Modular homes are built using a variety of materials, with steel, wood, and concrete being the most common. Steel frames provide strength, durability, and resistance to termites and rot, making them ideal for modern modular homes. Wood is frequently used for framing and paneling, offering cost-effectiveness and insulation. Concrete panels and composite materials are sometimes incorporated for enhanced thermal performance and structural integrity.

Advantages of SteelPRO PEB’s Steel Prefabricated Houses Materials

High Strength and Durability

Our steel structure materials undergo strict quality control to ensure that they have extremely high strength and long-term durability. The tensile strength of steel enables it to withstand the test of extreme weather conditions, and is particularly suitable for areas that require high earthquake and wind resistance.

For example, in earthquake-prone areas, the stability and toughness of steel structures can effectively ensure the safety of buildings. In addition, the corrosion resistance of steel itself also allows it to have the advantage of long-term use in wet or harsh environments, greatly reducing the cost of repair and replacement.

Fast construction and precision manufacturing

Compared with traditional construction methods, SteelPRO PEB’s steel structure solutions can significantly shorten the construction period. Our steel structure products are precision manufactured and prefabricated in the factory, and only simple assembly is required during on-site construction.

This factory prefabrication and on-site assembly method not only improves construction efficiency, but also effectively reduces the risks and uncontrollable factors of on-site construction. At the same time, precision manufacturing ensures the high quality standards of each component and reduces the problems that may be caused by on-site processing errors.

Energy saving and environmental protection

Our steel structure materials have excellent recyclability, which makes our products very suitable for environmentally friendly construction projects. The durability of steel means that the life cycle of the house is long, reducing the frequency of material replacement, thereby reducing construction waste and resource consumption. Since steel can be fully recycled, it is an ideal choice for sustainable building materials, in line with the needs of modern construction for environmental protection and efficient use of resources.

Flexibility and Customizability

The steel structure solutions we provide are not only superior to traditional materials in strength and durability, but also highly flexible and customizable. We are able to provide steel structure products of different specifications, sizes and functions according to the specific needs of our customers, ensuring that each project can achieve the best architectural effect.

Whether it is a small residential, commercial building or a complex industrial project, SteelPRO PEB can provide tailor-made steel structure solutions to help customers achieve efficient and sustainable construction goals.

How to Choose the Right Materials for Prefabricated Houses?

Consider climate and environmental factors

When choosing materials, climate and environmental factors are crucial. The climate in different regions directly affects the performance and durability of materials. For example, in humid or seaside areas, the corrosion resistance of steel structures is particularly important because sea breezes and humidity can easily cause corrosion in other materials.

Steel is galvanized or coated to effectively prevent corrosion and ensure the stability of the structure for a long time. In cold areas, wood and concrete may provide better insulation, reduce energy consumption, and keep the room warm.

Budget and long-term costs

When choosing materials, in addition to the initial purchase cost, long-term maintenance and service life are also important considerations. Although the initial investment of steel structures is higher, its durability and low maintenance requirements make it more cost-effective in long-term use. In contrast, wood has a lower initial cost, but requires more maintenance and has a shorter service life, which may increase costs in the long run.

Building purpose and design requirements

Choose the most suitable material based on the purpose and design requirements of the building. If the project requires a large span or high-strength structure, steel is undoubtedly the best choice. SteelPRO PEB’s steel structure designs can meet the needs of large-scale buildings such as warehouses, office buildings and multi-story residential buildings, and can easily cope with complex construction challenges.

If you have difficulty in selecting materials, SteelPRO PEB can provide you with professional consultation and customized solutions to help you obtain the most cost-effective solution while controlling your budget, ensuring that your project has both high performance and economical budget.

Steel Prefabricated Houses Supplier

SteelPRO PEB’s steel structure materials are the ideal material choice for prefabricated houses due to their high strength, excellent durability and fire resistance. In addition, the environmentally friendly characteristics and low maintenance requirements of steel make it significantly economical in long-term use.

Compared with other materials, SteelPRO PEB’s steel structure not only meets the high requirements of modern construction for durability and safety, but also reduces the cost of daily maintenance and improves the overall cost performance.

If you are looking for a reliable, long-lasting prefabricated house solution that meets modern environmental standards, SteelPRO PEB’s steel structure products will be your best choice. We are committed to providing you with tailor-made solutions to ensure the smooth implementation and long-term sustainability of your project.