Steel structures are the backbone of countless industrial, commercial, and infrastructure projects worldwide. Whether you’re designing a warehouse, a stadium, or a high-rise office building, choosing the right platform structure is crucial to ensuring your project is both efficient and durable. According to OSHA, improper platform design and lack of adequate safety features are leading causes of industrial accidents, particularly in construction, where falls account for a significant portion of fatalities. The right steel structure platform can dramatically reduce risks, optimize space, and increase the longevity of your facility.

In this article, we’ll explore the different types of steel structure platforms, their compositions, and the critical factors to consider when selecting or designing one. We’ll cover everything from load requirements to safety features, ensuring you clearly understand what makes a steel platform a solid foundation for your next project. By the end of this guide, you’ll be equipped with the knowledge to make an informed decision and choose the best platform for your operational needs.

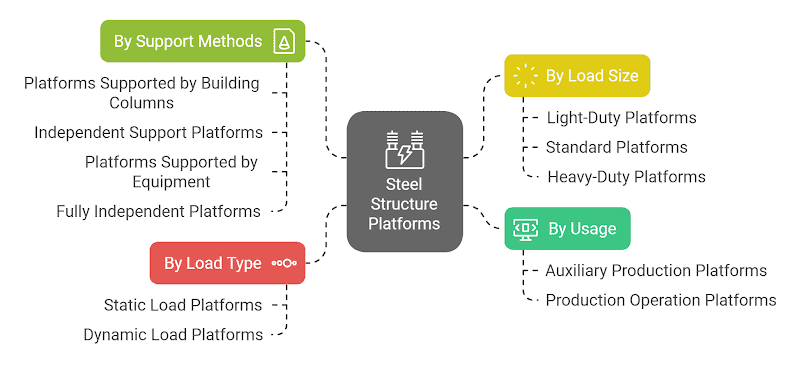

Main Classifications of Steel Structure Platforms

Steel structure platforms are designed for various uses, and they can be classified based on how they are used, the type and size of load they support, and how they are supported. Knowing these classifications helps you choose and design the right platform for your specific project.

By Usage

- Auxiliary Production Platforms: These platforms are used for lighter tasks, such as storing tools and materials or supporting small machinery. They are common in factory workshops and designed to carry lighter loads, supporting daily activities.

- Production Operation Platforms: These are built to handle heavier loads and are directly used in production areas. They include:

- Medium-Duty Platforms: Designed for loads between 4.0–8.0 kN, these platforms are ideal for tasks like machine maintenance or general storage in industrial settings.

- Heavy-Duty Platforms: Built for loads over 10.0 kN, these platforms are used in environments with very heavy loads, like steel plants or other heavy industrial operations.

By Load Type

- Static Load Platforms: These platforms carry fixed, unchanging loads, such as equipment or storage racks. They are commonly found in warehouses and workshops, and their design is simpler since the load doesn’t change.

- Dynamic Load Platforms: These are designed to handle loads that vary, such as those caused by vibrations or impacts. These platforms are essential in environments like steel mills or factories, where equipment or processes create fluctuating loads.

By Load Size

- Light-Duty Platforms: These platforms typically support loads around 2.0 kN. They are perfect for pedestrian walkways, observation decks, or smaller maintenance areas.

- Standard Platforms: Designed to handle medium loads (4.0–8.0 kN), these platforms are commonly used for equipment storage, material handling, or general workspaces.

- Heavy-Duty Platforms: These platforms support heavy loads (above 10.0 kN) and are suitable for industries where large machinery or heavy materials need to be managed.

By Support Methods

- Platforms Supported by Building Columns: This is a common and cost-effective design where the building’s structural columns support the platform. It is often used for lighter loads.

- Independent Support Platforms: These platforms are supported by separate columns, offering more flexibility. They are ideal for larger spaces, such as warehouses or areas for heavy machinery maintenance.

- Platforms Supported by Equipment: These platforms are attached to large equipment, using the equipment’s structure for support. They are ideal when the equipment is central to the workspace.

- Fully Independent Platforms: These platforms stand on their own structure, providing strong stability. They are well-suited for large, open spaces or situations where flexible placement of equipment is needed.

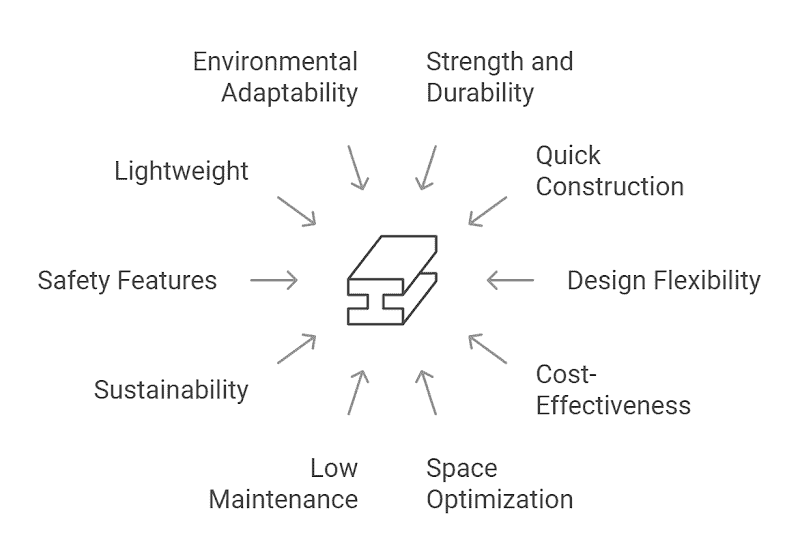

Advantages and Features of Steel Structure Platforms

1. Strength and Durability

Steel platforms are built to last, handling heavy loads without sacrificing stability. Their strength makes them ideal for industrial environments where reliability and long-term performance are essential.

2. Quick Construction and Reduced Downtime

Steel platforms are quick to design, manufacture, and install. Prefabricated components are easily assembled on-site, which reduces construction time and minimizes disruption to ongoing operations—perfect for businesses that need to reduce downtime.

3. Flexibility in Design

One of the standout features of steel platforms is their design flexibility. They can be customized in size, shape, and load-bearing capacity, making them suitable for everything from large industrial setups to small storage solutions.

4. Cost-Effectiveness

While the initial cost might be higher, steel platforms offer significant long-term savings. Their durability, low maintenance needs, and faster construction times result in a lower total cost of ownership, making them a more economical choice than traditional building materials over time.

5. Space Optimization

Steel platforms maximize available space. With fewer support columns and the ability to span larger areas, they are particularly valuable in industries like warehousing, where space efficiency directly impacts operational capacity.

6. Low Maintenance Requirements

Steel platforms require very little maintenance, especially when treated with coatings like galvanization or paint. Unlike wood or concrete, steel is resistant to rot, cracking, and corrosion (when properly maintained), reducing long-term maintenance costs and effort.

7. Sustainability and Recyclability

Steel is 100% recyclable, making steel platforms an eco-friendly choice. The ability to recycle steel helps reduce environmental impact, while the platform’s long lifespan ensures sustainability for businesses that prioritize green practices.

8. Safety Features

Safety is built into every steel platform. With features like handrails, guardrails, and anti-slip decking, steel platforms create a secure working environment that helps prevent accidents and improves safety for workers.

9. Lightweight and Easy to Transport

Despite their strength, steel platforms are lightweight and easy to transport. This makes handling and installation smoother, reducing logistical challenges and transportation costs—especially on large-scale projects.

10. Adaptability to Different Environments

Steel platforms are designed to perform well in a variety of environmental conditions. They can be tailored with the right coatings to suit any location or industry, whether facing extreme temperatures, high humidity, or corrosive environments.

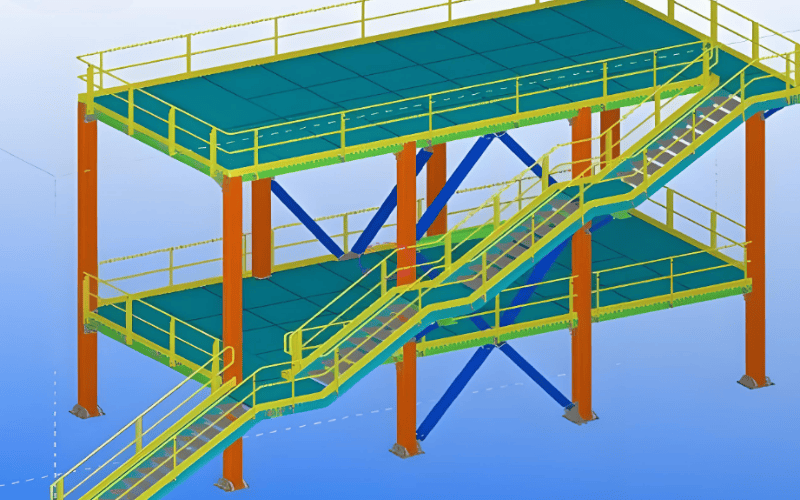

Composition of Steel Structure Platforms

Steel structure platforms are made up of several key components that ensure strength, stability, and functionality. The design of these components depends on the platform’s load-bearing needs, available space, and the type of operation it will support. Understanding these elements is crucial to ensuring both safety and efficiency.

Primary Components

- Beams (Primary and Secondary):

- Primary Beams: These are the main structural elements that bear the bulk of the load. They are typically made of hot-rolled steel or welded I-beams and placed across the platform to provide horizontal support.

- Secondary Beams: Lighter than primary beams, secondary beams support the floor decking and transfer the load to the primary beams. They help distribute weight evenly across the platform.

- Columns: Vertical elements that support both the beams and the floor decking. Columns are made from various steel profiles like H-sections or circular hollow sections. The number and placement of columns depend on the platform’s size, load, and operational needs.

- Floor Decking (Planks or Slabs): The surface on which workers walk or equipment is placed. It’s typically made from steel or a steel-concrete combination, designed to bear the operational load. Non-slip surfaces can be added for safety, especially in high-traffic or hazardous environments.

- Bracing and Cross Bracing: These components provide lateral stability to the platform. Bracing helps resist wind, seismic forces, or other lateral loads. Steel rods or angles are used to form diagonal braces, ensuring rigidity and preventing sway.

Auxiliary Components

- Ladders and Staircases: Safe access to and from the platform is vital. Ladders are used for shorter platforms, while staircases are preferred for taller structures. Both should include safety features like handrails and anti-slip steps.

- Railings and Guardrails: Essential for worker safety, railings (typically 1 meter high) prevent falls and can be customized with toe boards or safety nets. Skirting boards may be added if the platform is over 2 meters high.

- Supports and Corbels: These elements provide additional support, especially in designs where platforms need to span long distances. Corbels extend from building columns, offering extra stability without needing additional columns.

Materials and Coatings

- Steel Profiles: Common materials for platform components include I-beams, H-beams, and channel sections. Structural steel grades like ASTM A36 or A992 are often used for their strength and ease of fabrication.

- Anti-Corrosion Design: Steel is vulnerable to corrosion, especially in harsh environments. Common corrosion protection options include hot-dip galvanizing for long-lasting rust protection, protective paint coatings for moisture and chemical resistance, and stainless steel for superior corrosion resistance in aggressive environments. The selection depends on the environmental conditions and desired durability.

- Non-slip Surface Coating: To improve safety, floor decking often has a non-slip coating or texture, particularly in wet or oily environments. This ensures safe movement for workers and reduces slip hazards.

Related Reading:

A Quick Guide to Steel Types in Steel Buildings

Customization Based on Specific Requirements

- Design Flexibility: Steel platforms are highly customizable to meet specific load, operational, and spatial requirements. For instance, larger platforms may need additional bracing or stronger beams, while smaller platforms can focus on cost-efficiency and ease of assembly.

- Modular Construction: Many steel platforms are designed with modular components, which can be quickly assembled or disassembled. This makes them ideal for temporary structures or areas requiring frequent layout changes.

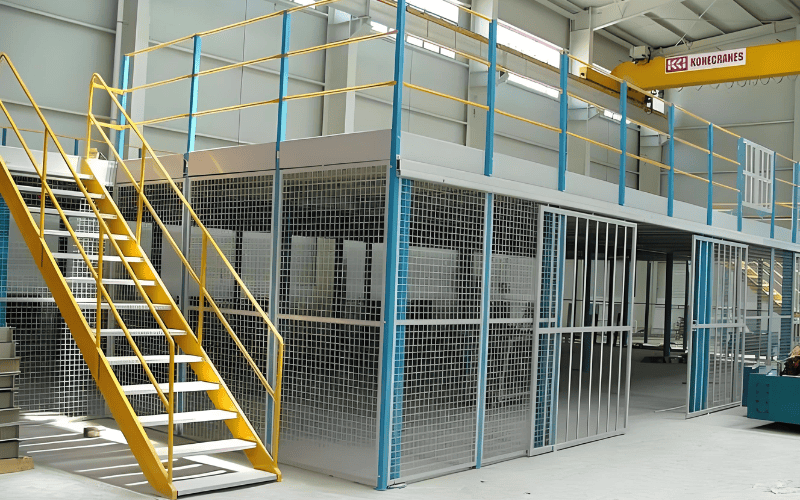

Installation and Layout Requirements for Steel Structure Platforms

Proper installation and layout of steel structure platforms are crucial for safety, efficiency, and functionality. Consider these key factors during the design and installation process:

Meeting Operational and Safety Requirements

- Clearance and Accessibility: Ensure the platform offers a height of at least 1.8 meters for workers to move comfortably. This clearance is important for avoiding obstructions and facilitating smooth operations. The design should also allow easy access to maintenance tasks.

- Safety Features: Install protective railings (typically 1 meter high) around the platform and provide ladders or stairs for safe access. If the platform exceeds 2 meters in height, skirting boards are necessary to prevent items from falling. These features are essential for worker safety and efficient operations at height.

Structural Layout and Support

- Beam and Column Arrangement: Plan the layout of beams and columns carefully to evenly distribute the load. Larger spans require wider spacing between beams to maintain stability. Consider both static loads (e.g., heavy equipment) and dynamic loads (e.g., moving machinery) when designing the layout.

- Load Distribution: Ensure the platform design accounts for concentrated loads, like heavy machinery. Dynamic loads, such as vibrations from moving equipment, require extra support to prevent long-term structural stress.

Space Utilization

- Efficient Use of Space: Optimize the layout to make the most of available space without overcrowding. Be mindful of equipment, pipes, and other systems that may intersect with the platform. A well-planned design helps maintain workflow and prevents interference with operations.

- Flexibility: Design the platform with flexibility in mind. This allows for future modifications or expansions as operational needs evolve. Flexibility could mean easily removable beams, adjustable load-bearing points, or reconfigurations to accommodate new equipment.

Foundation and Stability

- Stable Support: Ensure the platform is supported by a stable foundation, whether directly on the ground or with additional columns and beams. This ensures the platform remains secure under varying loads. The foundation should be tailored to local soil conditions, load distribution, and environmental factors.

- Environmental Considerations: Account for environmental factors like seismic activity, wind, and temperature variations, which can affect stability. In seismic areas, consider additional bracing or reinforced foundations. Opt for corrosion-resistant materials in humid or coastal environments to extend the platform’s lifespan.

Key Considerations for Industrial Platform Design

Industrial steel platforms play a crucial role in manufacturing, warehousing, and processing facilities. To ensure safety, efficiency, and durability, the design process must take into account various factors, including load-bearing capacity, material selection, accessibility, and environmental considerations.

1. Load Capacity for Industrial Use

The primary factor in industrial platform design is the ability to support both static and dynamic loads effectively:

- Static Loads: These include permanently installed machinery, equipment storage, and fixed workstations. The platform structure must be designed to handle long-term weight without deformation.

- Dynamic Loads: Moving equipment, forklifts, conveyor systems, and worker foot traffic introduce variable forces. The platform must have reinforced bracing and vibration-resistant connections to handle these fluctuations.

- Load Distribution: Heavy industrial platforms typically require evenly spaced support columns, cross-bracing, and reinforced beams to prevent localized stress that could compromise structural integrity.

Related Reading:

Understanding Loads on Steel Structures: Types, Calculations and Design Key Points

2. Adaptation for Harsh Industrial Environments

Industrial platforms must be tailored to the specific conditions of the facility, such as:

- High-Temperature Resistance: Steel platforms in foundries, power plants, or manufacturing units with high heat exposure should use heat-treated steel and expansion joints to prevent warping.

- Corrosion Resistance: In chemical plants, food processing facilities, or marine environments, galvanized steel or stainless steel coatings are necessary to prevent degradation.

- Dust and Moisture Protection: In environments prone to dust accumulation (e.g., cement plants) or moisture exposure (e.g., wastewater treatment facilities), sealed decking and anti-slip coatings are essential for safety and longevity.

3. Worker Accessibility and Pathways

Proper layout planning ensures safe and efficient movement for workers and equipment:

- Clearance and Height Requirements: Platforms should allow a minimum clearance of 1.8 meters for easy movement, avoiding obstructions from pipes, ducting, or machinery.

- Staircases and Ladders: Depending on platform height and usage, OSHA and ANSI standards recommend safe access points, including anti-slip steps, handrails, and well-lit passageways.

- Material Flow Efficiency: In warehouse and manufacturing settings, platforms should be designed to integrate seamlessly with conveyor belts, loading docks, and material handling systems.

4. Structural Reinforcement for Heavy Equipment

Industries such as mining, automotive, and steel production require platforms that support extremely heavy loads and continuous mechanical operations:

- Beam Reinforcement: Double-beam configurations or box-section girders are often used to provide additional strength.

- Seismic and Vibration Resistance: Facilities in earthquake-prone areas require additional bracing and flexible connections to absorb shocks and prevent failure.

- Non-Slip Flooring and Safety Rails: Heavy-duty grating or textured flooring prevents slipping, while high-visibility guardrails reduce fall risks.

5. Flexibility for Future Modifications

Industrial platforms should be designed with adaptability in mind:

- Modular Components: Prefabricated steel platforms with bolt-together connections allow for easy expansion or reconfiguration.

- Removable Panels: In maintenance-heavy industries, having removable floor panels simplifies equipment repairs and upgrades.

- Load Upgrade Potential: If future expansions are planned, selecting oversized support columns and beams can accommodate increased loads without requiring complete structural overhauls.

How to Choose the Right Steel Structure Platform

Choosing the right steel structure platform is key to maximizing its performance and longevity. Here are the main factors to consider when selecting the right platform for your needs:

Load Requirements: What Will Your Platform Hold?

- Light vs. Heavy Loads: The platform must be designed to handle the correct load. A simple structure may suffice for light storage, but a more robust design is necessary for heavy machinery.

- Static or Dynamic Loads: Will your platform support stationary equipment or machines in motion? Dynamic loads require extra support to withstand vibrations and movement.

Space and Layout: Fit Your Platform to Your Facility

- Available Space: Assess the space available to avoid overcrowding. The platform should make efficient use of height without interfering with daily operations.

- Access and Clearance: Ensure there’s enough room for workers and equipment to move safely. A clearance of at least 1.8 meters is ideal for comfort and ease of movement.

Material Durability: Choose the Right Material for Your Environment

- Environmental Factors: Think about the environment where your platform will be used. If it’s exposed to moisture, choose corrosion-resistant steel to ensure longevity.

Safety and Compliance: Stay Safe and Legal

- Regulatory Compliance: Make sure your platform meets local safety standards and building codes to avoid costly delays or legal issues.

- Safety Features: Guardrails, anti-slip flooring, and safe access points are must-haves, especially for platforms used at heights.

Customization: Tailor the Platform to Your Needs

- Function-Specific Design: Whether you need a platform for storage, maintenance, or operational tasks, ensure the design is customized for your specific needs.

- Future Flexibility: Opt for a design that can be easily modified as your business grows or requirements change over time.

Budget: Balance Cost and Value

- Initial Cost: Consider the upfront cost of materials, design, and installation, but don’t sacrifice quality for a lower price.

- Long-Term Value: Remember, steel platforms have a long lifespan with minimal maintenance. Think about the long-term savings they offer.

Get Your Custom Steel Structure Platform Today!

Are you in need of a durable, high-capacity steel structure platform tailored to your operational needs? SteelPRO PEBp has over 20 years of experience in designing and manufacturing customized steel platforms that meet the toughest industry requirements. Whether you need a platform for heavy-duty production or a space-efficient storage solution, we have the expertise and capacity to deliver.

We provide reliable, high-quality solutions for industries worldwide, with 1,000+ successful projects and an annual production capacity of 120,000 MT/year for steel structures. Our engineering team is ready to help—we can design a platform specifically for your needs or work from your existing plans.

Contact us today to start your project and ensure it meets your exact specifications—on time, on budget, and built to last!