What is Light Gauge Steel Frame (LGSF)?

Light Gauge Steel Frame (LGSF) is a building system that uses thin-walled steel (usually cold-rolled steel) as the main structural material. The LGSF system is widely used in residential, commercial and some light industrial buildings.

So, what is so special about lightweight steel frames? What are its advantages and what are its possible limitations? Today we will analyze these issues in detail for you. If you have any questions about lightweight steel frames, we can also provide professional consulting services to help you optimize your design, choose the right materials, and ensure the smooth progress of your project.

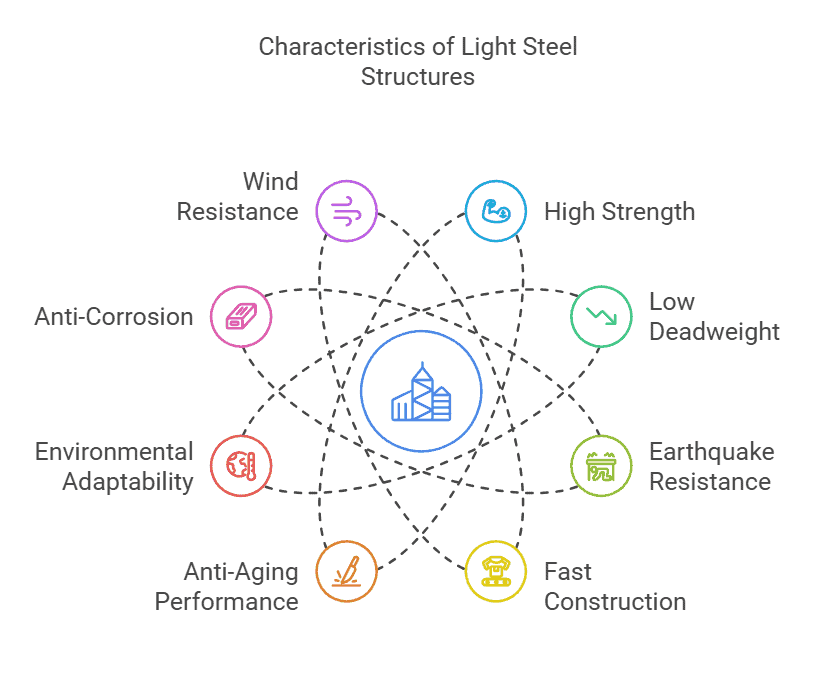

Characteristics of light steel framing material

13 Light Gauge Steel Framing Advantages

1. High strength and low weight

A significant advantage of light steel frame is its combination of high strength and low deadweight. Compared with other building materials, light steel materials greatly reduce the weight of the structure while ensuring strength, which can effectively reduce the burden of the building on the foundation. This not only improves the stability of the overall structure, but also enables the design of larger spans and meets various building needs.

In this regard, our light steel frame solutions can withstand large loads, while paying special attention to safety and durability during the design phase. Our team ensures that each structure meets or exceeds industry standards through precise engineering calculations and designs, providing a solid and stable foundation.

2. Fast construction speed

Since light steel frame uses a large number of prefabricated components, it can significantly shorten the construction period and save a lot of time and labor. The factory production of prefabricated components ensures the accuracy of each component, and there is almost no error in the installation work on site, which greatly improves the construction efficiency.

Our efficient production line can ensure the accuracy and high quality of parts, thereby accelerating the overall project progress and ensuring the project is delivered on time. Whether it is an industrial plant, commercial building or residential project, our solutions can help customers quickly start and complete the project and put it into use as soon as possible.

3. Earthquake resistance and wind resistance

The advantages of light steel structure frames in earthquake resistance and wind resistance are very obvious. Steel has high strength, excellent toughness and ductility, so it can effectively resist the impact of natural disasters such as earthquakes and strong winds, especially suitable for earthquake zones and areas with strong winds.

Our design and construction team will conduct detailed structural analysis in each project to ensure that each building can withstand the test of extreme weather and natural disasters and ensure the safety of users. Our light steel frame solution, with its excellent earthquake resistance and wind resistance, provides customers with solid and reliable building protection.

4. Durability and low maintenance cost

Light steel frame has strong durability and is not easily affected by moisture, corrosion or pests, so it can ensure a long service life. Compared with other building materials, the weather resistance and corrosion resistance of steel make its maintenance cost low and the building life long.

Our light steel frames undergo rigorous quality certification and testing to guarantee sustained excellent performance and stability over the long term. This robust durability significantly minimizes subsequent maintenance costs, thereby substantially saving customers on operational expenses.

5. Environmental protection and recyclability

In today’s era of increasing environmental awareness, light steel frame, as a green building material, has extremely high recyclability. Steel can be 100% recycled and will not burden the environment. At the same time, light steel frames also generate less waste during the construction process, which meets the green building standards.

We are dedicated to utilizing sustainable building materials and processes, aiming to mitigate the environmental impact of construction projects through meticulous design and construction practices. By opting for our light steel frame solutions, customers not only gain access to efficient and cost-effective building alternatives but also contribute to environmental conservation and sustainable development efforts.

6. Design flexibility

Light steel frame provides greater flexibility for architectural design. Whether it is a complex spatial layout or a personalized building appearance, light steel frame can be easily achieved. Its components can be tailored to meet the unique requirements of customers, accommodating a diverse range of architectural designs.

We offer personalized design solutions, addressing the specific needs of each project, from structural layout to aesthetics, to ensure that every building fulfills the precise demands of our clients. Whether it is aesthetic requirements or functional requirements, we can achieve the best architectural effect through flexible design.

7. Quickly adapt to changing needs

The flexibility of light steel frames enables them to quickly adapt to design changes or changes in space requirements. If you need to add rooms or change the layout during the project, you can adjust and expand more easily, which is more adaptable than traditional buildings.

8. Easy integration of modern technology

Because light steel frames are simple and easy to customize, they can easily integrate modern building technologies such as smart home systems, solar panels, green roofs, etc., providing more options for future sustainable development and energy management.

9. Efficient space utilization

Light steel frames use lightweight steel frames to provide greater space utilization. Compared with traditional concrete structures, it can reduce the area occupied by walls and floors while maintaining structural strength, freeing up more available space.

10. Good fire resistance

Although steel itself softens at high temperatures, modern light steel frames usually use fire-retardant coatings or suitable insulation layers to improve fire resistance. In a fire, light steel frames are more stable than wood structures and some other materials, reducing the risk of structural failure caused by fire.

11. Low-carbon construction

The low material waste and short construction period of light steel frames mean that their construction process has low carbon emissions. The high recycling rate of steel and its ability to be recycled multiple times help reduce resource consumption during the construction process.

12. Optimize transportation and logistics

Since light steel frames are usually prefabricated in factories, they can be transported and assembled using standardized components. The transportation process is more efficient and avoids material loss and environmental impact during on-site construction.

13. Adapt to extreme weather conditions

Light steel frames are well suited to harsh environments and extreme weather, especially in areas with strong winds, heavy snow, or large temperature differences. The high compressive and tensile strength of steel enables buildings to better cope with the challenges of extreme climates.

Disadvantages of Light Gauge Steel Construction

1. High Thermal Conductivity

The high thermal conductivity of light steel materials means that in extreme weather conditions, the temperature inside a light steel building may be uneven, which may increase the burden on the air conditioning or heating system and affect comfort.

To address this problem, we pay special attention to the thermal efficiency of the building during the design and construction process. By adding additional insulation layers and adopting advanced insulation technology, we can effectively reduce heat conduction, improve the thermal insulation performance of the building, ensure a more balanced temperature inside the building, and improve the comfort of living and use.

2. High Initial Cost

Although light steel frames have lower maintenance costs and longer service life in long-term operation, their initial construction costs are relatively high, especially for large-scale construction projects. This is because the material cost, design complexity and high-precision construction requirements of light steel frames make the initial investment higher than traditional construction methods.

However, as the service life increases, the high strength, low maintenance requirements and long-term energy saving advantages of light steel frames will gradually make up for the initial cost investment. By reducing long-term maintenance costs and improving building durability, light steel frames can bring customers a higher return on investment.

3. Professional construction required

The installation of light steel frames requires high precision, and a professional team is needed to ensure the correct installation of each component and the safety of the structure. Improper installation may compromise the stability and safety of the building.

We are well aware of this challenge, so we provide a full set of professional engineers and remote guidance at any time to ensure that each project can be successfully completed as designed. Our team boasts extensive experience and provides thorough technical support for every project, ensuring precision in the execution of every detail.

4. Fire resistance is not as good as some materials

Although light steel frames have excellent strength and stability, their fire resistance under high temperature conditions is weaker than traditional building materials such as bricks. At high temperatures, steel may deform, which affects the overall safety of the building.

To meet this challenge, we specially consider fire prevention issues in our design, and use advanced fire-resistant coatings and fire-resistant materials to ensure that the building can maintain sufficient safety at high temperatures. In addition, our construction team will strictly follow the fire protection standards to ensure that each project has the necessary fire resistance and provide additional safety for building users.

Related Reading: Pros and Cons of Light Steel Framing

Comparison of advantages and disadvantages of light gauge metal framing and wood framing

Strength and weight: Light steel structural materials have high strength and durability, can withstand large loads, and are suitable for large spans and complex building designs. Its lightweight nature diminishes the overall load on the building, thereby lowering the demands placed on the foundation. Wood itself is light, and the strength and bearing capacity of wooden structures are relatively low, and the applicable span and load capacity are limited.

Construction speed: Due to the use of prefabricated components, the construction speed of light steel structures is significantly higher than that of wooden structures, which can accelerate the progress of the project and shorten the construction period. The construction of wooden structures is more cumbersome, requiring more on-site processing and treatment, and the construction period is longer.

Durability: Light steel structures are not easily affected by pests, moisture or corrosion, and have a long service life. Wooden structures are susceptible to pests, moisture, corrosion and other factors, require regular maintenance, and have a short service life.

Earthquake and wind resistance: Light steel structures have excellent earthquake and wind resistance, are suitable for earthquake zones or strong wind areas, and can withstand the test of extreme weather and natural disasters. Wooden structures have weak earthquake, wind and fire resistance, especially in extreme weather conditions, and safety may be affected.

Environmental protection: Light steel structure uses recyclable materials, meets the requirements of green buildings, and has a lower environmental impact, but the energy consumption in the production process is high. Wood structure uses natural materials and is highly environmentally friendly. The renewability and low energy consumption of wood make it advantageous in terms of sustainability.

Thermal insulation: Light steel material has a high thermal conductivity and requires additional insulation materials to improve thermal insulation. Its high thermal conductivity requires additional energy-saving design. Wood is naturally good at thermal insulation, which helps to maintain indoor warmth or coolness, reduce energy consumption, and improve living comfort.

Aesthetics: The appearance of light steel structure is modern and simple, suitable for modern architectural style, but it is relatively cold and hard in visual effect. Wood structures are renowned for their natural texture and warmth, making them a popular choice for residential buildings. It can create a unique natural aesthetic and give people a sense of warmth and intimacy.

What is the difference between light gauge and heavy gauge framing?

The difference between light gauge and heavy gauge framing lies in the thickness of the steel, the structural applications, and their respective uses in construction. Here’s a breakdown:

1. Material Thickness (Gauge)

- Light Gauge Steel (LGS): Typically made from thin sheets of cold-formed steel, usually ranging from 25 to 12 gauge (0.018 – 0.104 inches thick).

- Heavy Gauge Steel (Structural Steel): Uses thicker, hot-rolled steel members, generally 10 gauge and thicker, including beams, columns, and heavy-duty load-bearing components.

2. Applications

- Light Gauge Framing:

- Used for non-structural and structural elements in residential and light commercial buildings.

- Common for wall studs, joists, and trusses.

- Ideal for multi-family modular homes, small buildings, and partition walls.

- Heavy Gauge Framing:

- Used for primary structural frameworks of large buildings, bridges, and industrial facilities.

- Includes I-beams, H-columns, and load-bearing steel members.

- Found in high-rise buildings, warehouses, and infrastructure projects.

3. Strength and Load Capacity

- Light Gauge Steel: Lighter but still strong, commonly used for non-load-bearing or moderately loaded structures.

- Heavy Gauge Steel: Designed to support heavier loads and large spans, capable of handling significant structural stress.

4. Fabrication & Installation

- Light Gauge Steel: Manufactured through a cold-forming process, allowing for easier transportation, on-site assembly, and prefabrication.

- Heavy Gauge Steel: Requires welding, bolting, and specialized equipment for fabrication and installation.

5. Cost and Efficiency

- Light Gauge Steel: More cost-effective for smaller projects, faster to install, and reduces labor costs.

- Heavy Gauge Steel: Higher material and labor costs but necessary for projects requiring extreme durability and load-bearing capacity.

Light steel building supplier: Choose SteelPRO PEB’s solution

SteelPRO PEB has many years of design and construction experience in the field of light steel structure, with rich technical accumulation, and can provide customers with efficient and reliable solutions. We provide light steel structure products of different sizes and functions. The design team possesses a profound understanding of project requirements and is committed to delivering bespoke solutions.

Through advanced design and technical means, we can give full play to the advantages of light steel structure in terms of high strength, fast construction speed, good durability, earthquake resistance, wind resistance, etc. Provide customers with more efficient and reliable construction solutions, and help customers gain an advantage in market competition.

We welcome your consultation at any time, help you analyze your specific project needs, provide professional advice, and ensure that your construction project achieves the best results.

FAQs

What is Light Gauge vs Heavy Gauge Metal?

Light gauge metal, also known as cold-formed steel, is thinner and lighter, ideal for residential and commercial construction, such as steel studs, modular construction, and light steel buildings. It allows faster construction and is more durable than wood.

Heavy gauge metal is thicker, used in industrial buildings, portal frames, and structural steel applications. It supports heavier loads but is more expensive and harder to install.

What Are the Disadvantages of Light Gauge Metal Framing Walls?

- Higher cost than traditional wood framing

- Thermal conductivity requires insulation

- Corrosion risks without proper coatings

- Limited heavy load capacity compared to structural steel

- Framing installation needs specialized skills

- Steel frame house disadvantages include temperature expansion issues

Despite these cons of light gauge steel, it is widely used in residential and commercial construction for its numerous advantages.

What is Light Gauge Steel Used For?

- Home construction (single & multi-family modular homes)

- Garage with light steel frame

- Light commercial buildings (offices, retail)

- Partition walls & framing installation

- Industrial buildings with light steel frame

- Light steel frame solar structures

Its advantages of steel frame make it a choice for construction where quick construction and durability of steel are needed.

Is Light Gauge Steel Sustainable?

Yes! Steel can be recycled, reducing waste and deforestation. Using light gauge steel lowers material consumption, and its durability means less maintenance. Faster construction reduces site energy use, making it a sustainable construction material.