Need space for livestock, equipment, or a mix of agricultural and residential use? Deciding between a pole barn and a metal structure can be easier with some background.

Pole barns have been staples of rural life since the Great Depression, with a wooden frame and steel exterior offering practicality and lasting appeal. Rising in the mid-20th century, metal structures are built entirely from steel for superior durability and sustainability.

This article breaks down these structures’ history, materials, and benefits to help you pick the right one. Let’s get started!

What Is a Pole Barn?

A pole barn is a traditional and practical building made using wooden poles embedded firmly into the ground as its main support structure. These poles are spaced evenly and connected by horizontal beams and rafters, creating a sturdy frame for the roof and walls. Originally designed for agricultural use, pole barns often feature open sides for animal shelters or are enclosed with materials like plywood or corrugated metal. Known for their simplicity and affordability, they have been a reliable choice for farmers to house livestock, store equipment, or create versatile spaces suited for various rural needs.

What Is a Metal Barn?

A metal barn is a durable structure made from steel, ideal for agricultural or multi-purpose use. Built with a rigid-frame design, it withstands harsh weather like wind and snow. Metal barns are low-maintenance, resisting rot, pests, and fire, making them longer-lasting than wooden barns. They can be customized in size, layout, and features like insulation and doors. Pre-engineered for quick assembly, these barns are perfect for storing equipment, housing livestock, or serving as workspaces.

The Difference Between Pole Barns and Metal Barns

Understanding the differences between pole barns and metal barns involves examining their framework, roofing systems, cost, sustainability, and durability, all of which impact their functionality and long-term value.

Framework Structure

The framework of a building determines its strength, stability, and suitability for different uses, making it a crucial factor when comparing pole barns and metal barns.

Supporting Components

- Pole Barns: Pole barns use vertical wooden or metal posts embedded in the ground as the main support. Posts are spaced 8 to 12 feet apart. Wooden posts are cheap and flexible, while metal posts are stronger, more durable, and resist corrosion. The posts transfer the building’s weight into the ground, forming a stable base that can be quickly assembled with proper alignment.

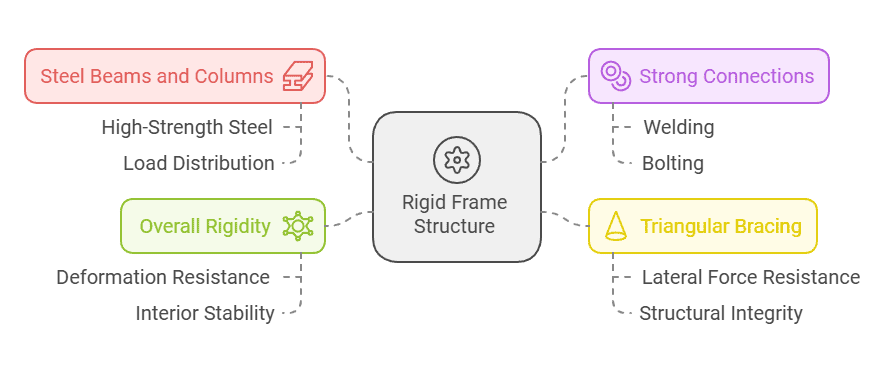

- Metal Barns: Metal barns have steel beams and columns pre-engineered for accuracy and consistency. Steel parts are joined with welds or bolts, creating a rigid structure that efficiently handles loads. Metal barns offer better force distribution and resist external pressure more effectively than pole barns.

Connection Methods

- Pole Barns: Wooden posts use bolts, mortise-and-tenon joints, or metal fasteners. Metal posts rely on welding or bolts. Wooden joints can rot over time, and metal connectors may rust if untreated, requiring maintenance. While flexible, the durability depends on material quality and care.

- Metal Barns: Metal barns use welding for strong, seamless joints and bolts for easy assembly and repairs. These methods ensure long-lasting stability and meet strict standards, making metal barns more reliable for heavy loads and extreme conditions.

Framework Assembly Difficulty

- Pole Barns: Assembly depends on on-site processing. Wooden posts use mortise-and-tenon joints, requiring skilled work that affects stability. Metal posts rely on bolts or welding, but welds can have defects like porosity, and uneven bolts may loosen.

- Metal Barns: Factory-precut steel beams are assembled with cranes, making it simpler. Welds follow strict standards, and bolts are tightened to exact torque. Standardization reduces errors and ensures efficiency.

Roofing Systems

The roofing system is an important factor that distinguishes pole barns from metal barns. Design, materials, installation, drainage, and durability highlight their differences.

Materials and Installation

- Pole Barns: Roofing materials like galvanized or color-coated steel sheets install quickly and are durable. Asphalt shingles provide waterproofing and a rustic look but need more upkeep. Installation is complex. Wooden walls need precise alignment and sealing. Metal panels require accurate screw placement to prevent deformation or leaks. Shingle roofs need careful layering, while metal roofs depend on proper spacing and overlap of purlins.

- Metal Barns: Metal barns use steel or aluminum for roofs and walls, with pre-fabricated panels ensuring precision. Installation is simpler. Panels are lifted into place with cranes and joined using standard sealants and waterproof pads. Metal panels are uniform, avoiding warping or misalignment, making the process smoother.

Drainage

- Pole Barns: Sloped roofs guide rainwater to the ground or basic gutters. Poor design may cause pooling, requiring careful attention to roof angles and gutter placement.

- Metal Barns: Engineered roof panels like corrugated or trapezoidal designs channel water into drainage systems efficiently, preventing pooling even in heavy rain.

Durability

- Pole Barns: Metal roofs last 15-30 years with regular maintenance. Asphalt shingles and thatched roofs need frequent repairs due to wear.

- Metal Barns: Metal roofs with anti-corrosion coatings last 30-50 years with minimal upkeep, offering long-term cost-effectiveness.

Other comparative terms of Pole Barns and Metal Barns:

| Aspect | Pole Barns | Metal Barns |

| Cost | Lower initial cost due to simpler materials like wood and basic metal roofing. | Higher initial cost because of factory-precut steel components and advanced engineering. |

| Sustainability | Less sustainable due to reliance on wood, which contributes to deforestation, and shorter material lifespan requiring frequent replacements. | Highly sustainable with recyclable materials like steel and aluminum. Longer lifespan reduces waste and environmental impact. |

| Durability | Moderate durability. Wooden posts and asphalt shingles require regular maintenance and are prone to damage from pests, rot, or severe weather. | High durability. Steel is resistant to pests, fire, and corrosion (with proper coatings). Aluminum roofs excel in coastal or humid environments. |

That is to say, pole barns and metal barns are popular for storage and workshops. Pole barns are cheap and quick to build but need more maintenance and have a shorter lifespan. Metal barns are stronger, last longer, and cost more upfront but require less upkeep.

So, Which Option Is Best for You?

In conclusion, as experts in metal structure barn building, we provide steel structures that are more durable, quicker to build, and offer better value than traditional wood barns. Plus, we offer customizable designs to match your barn with your home. Whether you’re looking for pole barns with glass garage doors, pole barn stables, or stylish white and black pole barns, we’ve got you covered with our prefabricated options. Let us help you create the perfect barn that fits your needs!

Related Reading: What is the Best Material to Build a Barn?