What You’ll Discover in This Blog:

What is a Single-Story Steel Structure?

A single-story steel structure is a building with just one level, constructed primarily using steel. These buildings are widely used in industries like manufacturing, warehousing, retail, and agriculture because they offer large open spaces, quick construction, and cost efficiency.

Unlike multi-story buildings, single-story steel structures focus on functionality and flexibility, making them ideal for businesses that need wide, uninterrupted areas. Whether you are planning a factory, storage facility, or commercial building, understanding how these structures work can help you make an informed decision.

Why Choose a Single-Story Steel Structure?

Single-story steel buildings are popular for a reason—actually, for many reasons. Let’s explore their key benefits:

1. Large, Open Spaces

- Steel allows for long spans without interior columns.

- Ideal for warehouses, logistics centers, and sports facilities.

2. Fast Construction

- Prefabricated steel components are manufactured off-site and assembled quickly.

- Minimal on-site work = faster project completion.

3. Cost-Effective

- Lower material and labor costs compared to traditional concrete buildings.

- Reduced maintenance costs due to steel’s durability and resistance.

4. Flexible and Expandable

- Easy to modify, extend, or repurpose.

- Suitable for businesses that anticipate future growth.

5. Sustainable & Eco-Friendly

- 100% recyclable steel reduces waste.

- Energy-efficient designs can lower heating and cooling costs.

3 Key Components of a Single-Story Steel Structure

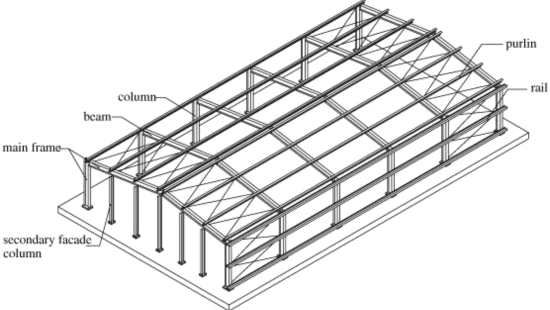

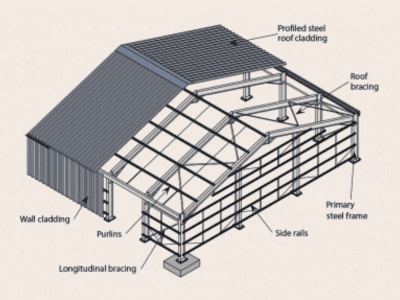

1. Primary Steel Frame (The Backbone)

- Columns: Vertical supports, usually hot-rolled steel sections.

- Beams & Trusses: Horizontal supports that hold up the roof.

- Portal Frames: The most common structural form for wide spans.

2. Secondary Steelwork (Support System)

- Purlins & Side Rails: Support roof and wall panels.

- Bracing Systems: Prevent movement from wind and earthquakes.

3. Building Envelope (Walls & Roof)

- Metal Cladding: Provides insulation and protection.

- Composite Panels: Improve thermal efficiency.

- Transparent Roofing: Allows natural light, reducing electricity costs.

In-Depth Technical Analysis of Single-Story Steel Structures

Now, let’s go deeper into the technical side of single-story steel structures, covering key structural forms, material choices, connection types, load considerations, roofing options, fire protection, and special equipment considerations.

Structural Forms: Choosing the Right Framework

The structural form of a single-story steel building depends on function, budget, and required span length. The most common types include:

1. Portal Frame (Most Common Choice)

✅ Best for medium-to-large spans (15m – 45m).

✅ Rigid frame provides excellent resistance to bending.

✅ Cost-effective and easy to construct.

✅ Ideal for warehouses, factories, and retail stores.

2. Multi-Span Frames (For Very Large Buildings)

✅ Used when one span is too large (e.g., over 50m wide).

✅ Requires interior columns to support the load.

✅ Ideal for aircraft hangars, logistics hubs, and distribution centers.

3. Truss Roofs (Lighter and More Efficient for Long Spans)

✅ Trusses use less material while maintaining strength.

✅ Ideal for large sports halls, exhibition centers, and auditoriums.

✅ Can be made from hot-rolled sections or tubular members.

4. Curved Roofs (Unique Aesthetic and Load Efficiency)

✅ Steel arches and curved frames enhance weight distribution.

✅ Often used in transportation hubs, museums, and custom projects.

✅ Provides a modern, sleek look.

Steel Types Used in Single-Story Buildings

Steel is not just “steel”—different types are used for different parts of the structure.

1. Hot-Rolled vs. Cold-Formed Steel

- Hot-Rolled Steel (HRS)

- Used for columns, beams, and main structural members.

- Stronger and more durable, ideal for high-load applications.

- Manufactured by rolling at high temperatures, making it thicker and heavier.

- Example: I-beams (H-beams), Wide-Flange Beams (W-beams).

- Cold-Formed Steel (CFS)

- Used for purlins, side rails, and secondary steelwork.

- Lighter and more flexible, ideal for roofing and cladding support.

- Made by bending thin steel sheets at room temperature.

- Example: C-sections, Z-sections.

📌 Why This Matters:

- HRS is strong and handles heavy loads → Best for major structural elements.

- CFS is lightweight and cost-effective → Best for secondary framing.

2. High-Strength Steel (HSS) vs. Standard Carbon Steel

- High-Strength Steel (HSS)

- Lighter but stronger, allowing for thinner yet more durable structures.

- Reduces the amount of steel needed, saving costs.

- Example: S355, S460 steel grades.

- Standard Carbon Steel

- More affordable but requires thicker sections for the same strength.

📌 Why This Matters:

- HSS reduces weight and material use, making the structure more efficient.

- Standard steel is still viable but needs careful structural design.

Related Reading:

A Quick Guide to Steel Types in Steel Buildings

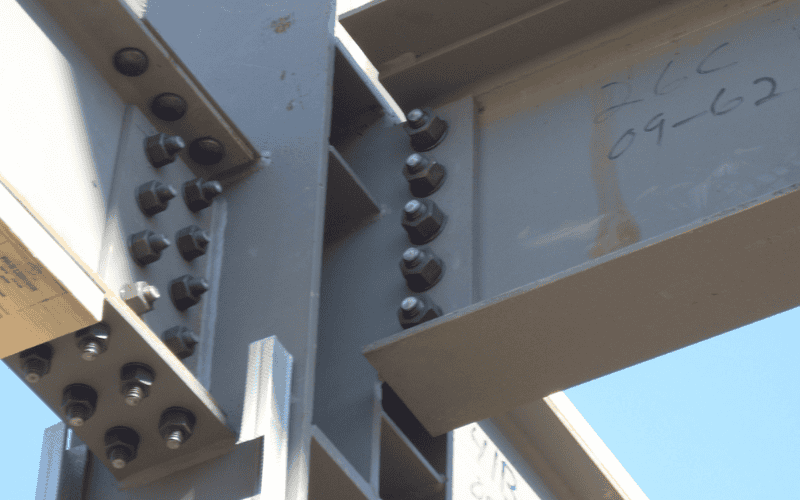

Connection Types: Bolted vs. Welded Joints

How steel parts are connected affects strength, cost, and construction speed.

1. Bolted Connections (Most Common in Prefabrication)

✅ Faster installation.

✅ Easier to replace or modify.

✅ No need for on-site welding.

✅ More common in pre-engineered buildings (PEBs).

2. Welded Connections (For Custom or Heavy Structures)

✅ Provides stronger, seamless joints.

✅ Reduces the number of bolts & plates.

✅ Often used in heavily loaded structures.

❌ Requires on-site skilled welding, which increases labor cost.

📌 Industry Trend:

- Most single-story steel buildings use bolted connections for speed and cost efficiency.

- Welded connections are only used for high-load or custom designs.

Roof Types: Flat vs. Pitched

The choice of roof type impacts drainage, insulation, and structural requirements.

1. Flat Roofs

✅ Common in commercial buildings.

✅ Requires good drainage systems (internal or external).

✅ Often uses waterproof membranes to prevent leaks.

✅ Can support solar panels and HVAC systems.

2. Pitched Roofs

✅ Better for rain and snow drainage (reduces ponding risk).

✅ Reduces structural load from accumulated water.

✅ More common in industrial buildings, warehouses, and agricultural facilities.

📌 Engineering Consideration:

- Steel purlins support cladding panels in both roof types.

- Roof slope affects wind resistance and energy efficiency.

Load Considerations: Wind, Earthquakes & Heavy Equipment

A single-story steel building must resist external forces such as wind, seismic activity, and heavy internal loads. We’ve written a blog article about loads on steel structure if you want to learn more.

1. Wind Load Protection

✅ Bracing systems (cross-bracing or diaphragm action).

✅ Anchor columns to foundations to prevent uplift in storm-prone areas.

2. Earthquake Resistance

✅ Flexible joints: Allow the building to move without breaking.

✅ Ductile steel framing prevent brittle failure during earthquakes.

✅ Moment-resisting frames help absorb seismic forces.

📌 Why This Matters:

- If your building is in a hurricane or earthquake-prone area, design considerations must include stronger bracing and flexible joints.

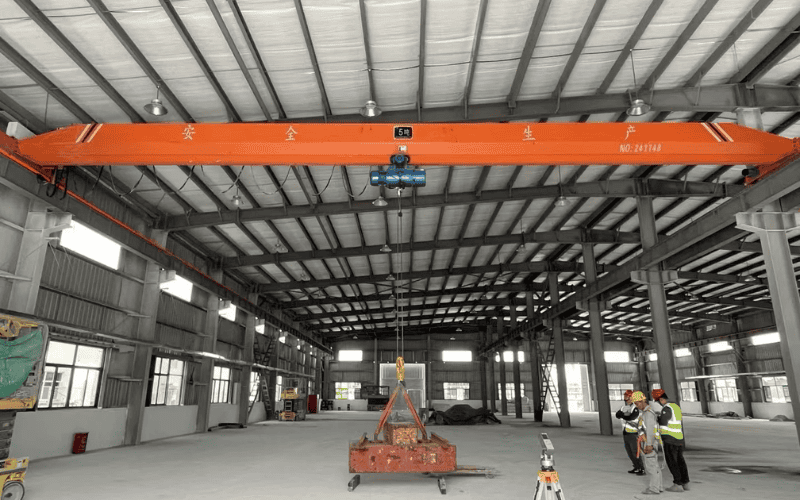

3. Overhead Cranes & Heavy Machinery Considerations

If your building requires cranes or heavy equipment, you need additional structural reinforcement.

✅ Crane Beams & Runway Systems: Support loads from overhead movement.

✅ Bracing & Stiffeners: Prevent horizontal sway.

✅ Independent Support Structures for Heavy Cranes (10+ tons).

📌 Common Crane Types in Steel Buildings:

- Bridge Cranes → Move across the width of the building.

- Gantry Cranes → Free-standing or attached to structure.

- Jib Cranes → Mounted on walls or columns for localized lifting.

Fire Protection & Durability

Steel is non-combustible, but high temperatures reduce its strength. Fire protection measures include:

✅ Fire-Resistant Coatings (Intumescent paints).

✅ Encapsulation with Fire-Resistant Panels (for critical areas).

✅ Smoke Ventilation & Escape Planning in high-risk buildings.

🔹 Durability Enhancements:

✅ Galvanization & Powder Coatings prevent rust and corrosion.

✅ Regular inspections extend the building’s lifespan.

Single-Story Modular Classroom: A Smart and Efficient Solution

A single-story modular classroom is a prefabricated steel structure designed for schools, training centers, and temporary learning spaces. Unlike traditional buildings, modular classrooms are built off-site in sections and then assembled on location, offering speed, flexibility, and cost savings.

Why Choose a Modular Steel Classroom?

1. Fast Construction & Minimal Disruption

- Prefabricated steel modules are manufactured in a controlled environment.

- On-site assembly takes weeks instead of months, reducing construction downtime.

- Ideal for schools needing rapid expansion without long-term disruption.

2. Flexible & Expandable

- Modular design allows easy expansion or relocation.

- Interior layouts can be customized with partition walls, windows, and ventilation systems.

- Can be repurposed for different educational needs over time.

3. Cost-Effective & Sustainable

- Lower material waste compared to traditional construction.

- Energy-efficient insulation panels reduce heating and cooling costs.

- Can be disassembled and reused, reducing environmental impact.

Related Reading:

Modular Construction: Driving Innovation in Renewable Energy

4. Durable & Safe

- Steel framing ensures structural integrity, resisting earthquakes and extreme weather.

- Fire-resistant coatings and ventilation systems enhance safety.

- Meets modern building codes and regulations for educational facilities.

📌 Who Uses Modular Classrooms?

- Schools expanding to accommodate growing student populations.

- Universities needing temporary lecture halls or labs.

- Training centers requiring cost-effective learning spaces.

- Remote or disaster-affected areas needing quick classroom setups.

Whether you’re looking for a permanent or temporary learning space, a single-story modular classroom is a smart, scalable solution that meets modern educational demands.

Common Misconceptions About Steel Buildings

❌“Steel buildings look industrial and unattractive.”

✅ Reality: Modern cladding and architectural finishes can make steel buildings look sleek and stylish.

❌“Steel structures rust easily.”

✅ Reality: With proper coatings and galvanization, steel resists corrosion for decades.

❌“Steel buildings are expensive.”

✅ Reality: Although initial costs may seem high, lower labor, faster construction, and minimal maintenance make them more affordable in the long run.

Who Should Consider a Single-Story Steel Structure?

Single-story steel structures are ideal for:

- Businesses that need large, open floor areas.

- Companies looking for quick and cost-effective construction.

- Facilities that require heavy equipment, cranes, or future expansion.

- Anyone who wants a low-maintenance and durable building.

Before making a decision, consider:

- Your budget.

- Space requirements (clear span, interior layout).

- Future growth – Will you need to expand?

- Weather conditions – Flat or pitched roof? Insulation needs?

Final Thoughts: Why Single-Story Steel Structures Are the Future

Steel is the go-to material for modern single-story buildings. Whether you’re in manufacturing, logistics, retail, or agriculture, a steel structure offers the best balance of strength, cost, and flexibility.

As technology advances, new trends like smart buildings, automation, and eco-friendly designs will continue to shape the industry. If you’re considering a steel building for your next project, now is the perfect time to explore your options.

Need help planning your steel building? Contact us today for expert advice! 🚀