An industrial warehouse is a large, functional space designed for storing, manufacturing, distributing, and managing goods. Unlike self-storage units, which cater to individuals, industrial warehouses are built for businesses with specific needs like logistics and large-scale operations. These warehouses can be single or multi-story and feature large or clear spans depending on the requirements. While traditional construction involves on-site work, pre-engineered buildings (PEBs) are now offering businesses faster, more efficient alternatives. In this blog, we’ll look at the main advantages of using PEB metal warehouses for your industrial needs.

Consistent Quality

Pre-engineered metal warehouses offer consistent quality that traditional buildings just can’t match.

Thanks to CAD and CNC technologies, everything is built with precision, which means fewer errors and more reliability.

What sets PEBs apart is the multi-stage quality control. Each component is checked multiple times, from raw materials to final assembly, ensuring any issues are caught early. With traditional builds, weather and other factors can cause delays and defects, which isn’t an issue in a controlled factory setting.

Many businesses, especially in manufacturing and logistics, now see pre-engineered warehouses as safer and more durable. Since they’re built in a factory, there’s no risk of weather damage, and projects are completed faster with less room for error. This means a longer-lasting, higher-performing building with less hassle for you.

Easy Integration with Smart Technology

As industrial warehouses continue to evolve, integrating the latest technologies can significantly boost efficiency. Pre-engineered metal warehouses, with their flexible design, can seamlessly accommodate smart systems like automated mobile robots (AMRs), smart inventory management, and building management systems (BMS).

Our pre-engineered metal structures are designed with adaptability in mind, allowing for easy integration of advanced technologies. Whether it’s leaving space for sensors, ensuring proper mounting locations for surveillance systems, or creating access points for automation systems, we build with the future in mind.

This means your warehouse can easily incorporate these technologies as your business grows, without the hassle of major redesigns down the line.

By combining our durable, flexible designs with cutting-edge technology, your warehouse can meet modern demands while staying ahead of the curve.

Faster Completion Time

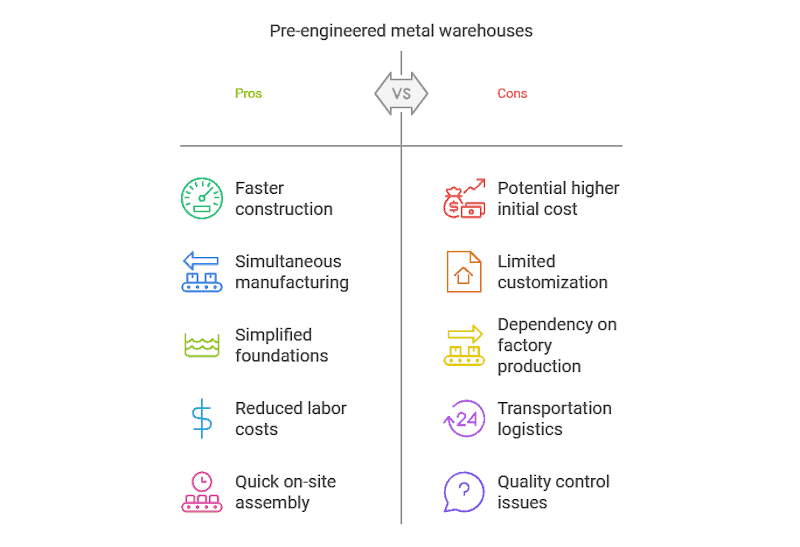

One of the key benefits of pre-engineered metal warehouses is the faster construction timeline.

Unlike traditional methods, where different tasks depend on one another, pre-fabricated components like walls, roofs, beams, and columns are manufactured simultaneously in a factory. This parallel production process reduces overall build time significantly.

Simplified foundations also speed up the process. With shallow, independent foundations, less concrete is needed, and curing time is faster compared to traditional, deep foundations. This means the warehouse construction process is accelerated, allowing your business to start operations sooner.

On-site assembly is quick and efficient, with fewer workers required for tasks like lifting and connecting. This reduces labor costs and keeps the project on track, so you can avoid delays and get your warehouse up and running without the usual setbacks of traditional construction.

High Cost-Effectiveness

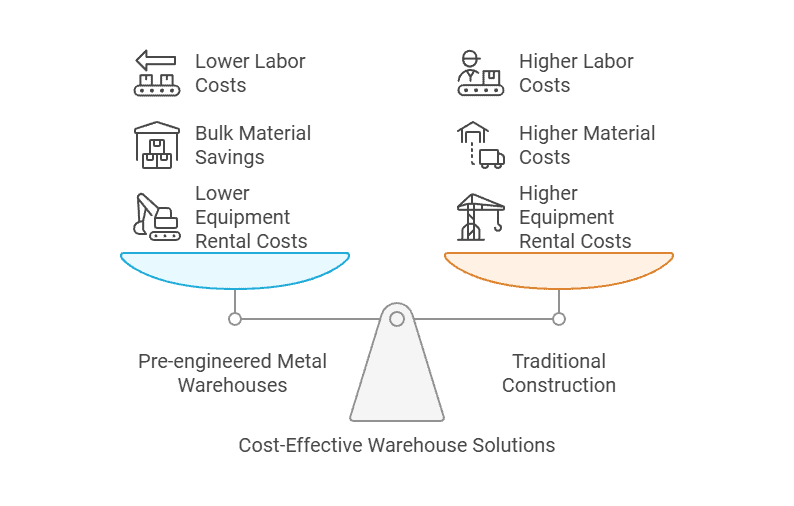

Pre-engineered metal warehouses offer a huge cost advantage over traditional builds.

In traditional construction, you’re often stuck renting heavy machinery like cranes and mixers for weeks, which can get pretty pricey. But with pre-fabricated warehouses, most of that equipment is only needed for short, focused tasks, slashing rental costs by up to 50%.

The bulk production of components also drives savings. As a pre-engineered metal warehouse manufacturer, we purchase raw materials in larger quantities, which lets us secure 10-20% lower prices compared to traditional buying methods. Plus, factory-based production is highly efficient, minimizing waste. For example, our computerized cutting system makes the most out of every piece of metal, reusing scraps whenever possible.

Finally, labor costs are lower. With simpler, faster assembly, fewer specialized workers are needed, and the project is completed more quickly. This means you can get your warehouse up and running sooner, saving both time and money in the long run.

More Durable

Pre-engineered metal warehouses are built to last. We use high-strength steel like Q345 and Q355, which can handle heavy loads—both static and dynamic—without breaking a sweat. This means your warehouse can stand strong even under tough conditions.

The factory-applied anti-corrosion coating is another key factor in the durability of pre-engineered metal warehouses:

- Shot blasting: Steel parts are first cleaned to remove rust and impurities.

- Multiple layers of protective coatings: A base coat, intermediate coat, and finish coat are applied for maximum protection.

- Superior rust and corrosion resistance: The factory-applied process provides long-lasting protection, much better than on-site construction methods.

- Weather resistance: The coating ensures your warehouse can withstand rain, humidity, and even harsh chemicals.

Finally, the modular design enhances the strength of these buildings. Each module is pre-assembled and tested in the factory, then shipped to the site for quick assembly. Think of it like a well-engineered puzzle—each piece fits perfectly into place, creating a stable and secure structure that can better withstand natural disasters like earthquakes and strong winds.

Larger, More Flexible Spaces

Pre-engineered metal warehouses provide larger, more adaptable spaces compared to traditional warehouse designs. By utilizing steel structures, which offer exceptional strength-to-weight ratios, these warehouses can easily span vast areas—without relying on the numerous internal columns typically required in brick or concrete construction.

This design feature enables a wide, open floor plan, optimizing the use of space for storing and moving goods with minimal disruption. Our clear-span warehouse can reach 100 feet or more, with a more diverse layout that enables businesses to meet various storage and operational needs.

In addition, the modular design allows for the easy addition of mezzanine levels, which provide extra storage for smaller, lighter items. This setup can help you maximize vertical space and improve storage efficiency, making your warehouse more adaptable to your needs.

Your Trusted Partner for Pre-Engineered Metal Warehouses

The benefits of pre-engineered warehouses are clear – quicker construction, reduced costs, better quality, and seamless integration with the latest tech. But the real advantage comes when you work with a trusted manufacturer who can help you tackle your unique challenges every step of the way.

And it’s not just about the practical benefits. Pre-fabricated warehouses are also eco-friendly, energy-efficient, and help enhance your company’s reputation.

In today’s competitive market, standing out is key. A high-quality pre-engineered steel warehouse can give your business the edge it needs. That’s where we come in – offering expert design, manufacturing, shipping, installation guidance, and up to 50 years of warranty.

We also specialize in custom solutions such as portal frame or truss industrial warehouses, barns, and cold storage facilities—tailored to meet your specific requirements and business needs.

Related Reading: What factors affect the cost of steel structure warehouse building