Light Gauge Steel Framing Systems are revolutionizing modern construction, combining cold-formed steel, strength, flexibility, and sustainability in ways traditional materials just can’t keep up with. As a leading steel structure manufacturer, we’ve seen firsthand how this innovative system is changing the game in building design and construction.

In this article, we’ll break down what LGS framing is made of, how it’s designed, and why it’s quickly becoming the go-to choice for so many projects. Plus, we’ll explore its many advantages, including its strength and durability, and how it compares to the traditional materials we’ve been using for years.

What is Light Gauge Steel Framing?

Light Gauge Steel Framing (LGS) is a modern steel construction method that uses cold formed, thin-walled steel sections to create a precise, high-strength structural framework for buildings. Unlike wood or traditional steel framing, LGS is lightweight yet exceptionally durable, offering superior resistance to fire, moisture, and seismic forces.

Material Science

- 550 MPa Yield Strength Steel (vs. wood’s 5-20 MPa)

- Hot-Dip Galvanized Coating (G90 coating for 50+ years corrosion resistance)

- Non-Combustible (Class A fire rating per ASTM E136)

Structural Efficiency

- Weight-to-Strength Ratio: 1/4 the weight of concrete with equivalent load capacity

- Seismic Resilience: 2.5x higher ductility than wood framing (per FEMA P-795)

- Span Capabilities: Up to 12m clear spans without intermediate supports

Sustainability Edge

- 100% Recyclable: 93% recycled content in our steel (verified by SCS Global Services)

- Zero VOC Emissions: No formaldehyde or chemical treatments required

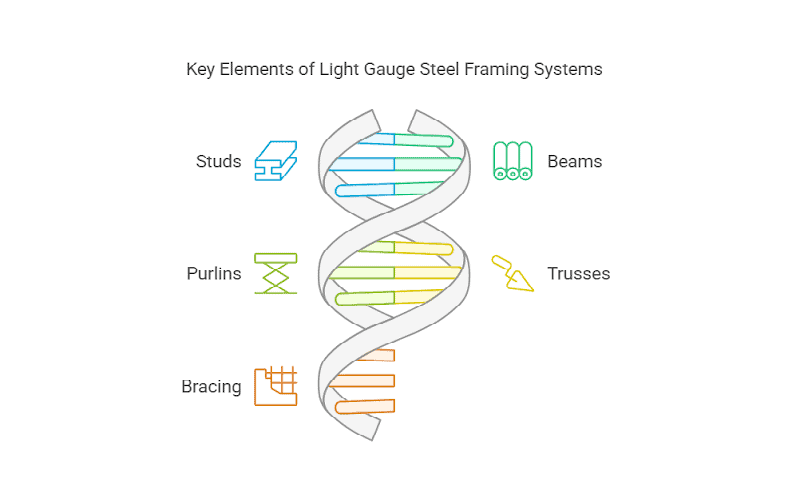

Composition of Light Gauge Steel Framing Systems

The strength of a light gauge steel framing system comes from its core components and connection systems. Every part is built to maximize structural integrity and ensure reliable performance throughout the life of the building.

Main Structural Components

The main structural components of light gauge steel framing work in tandem to deliver strength, stability, and efficiency in both design and installation.

Studs

- Material: Typically made from C-shaped or U-shaped steel.

- Purpose: Serve as vertical load-bearing members for walls and partitions.

- Features: Lightweight yet strong, easy to cut and install.

Beams

- Material: Commonly C-shaped, Z-shaped, or rectangular steel tubes.

- Purpose: Act as horizontal load-bearing members for floors and roofs.

- Features: Excellent bending resistance, ideal for long spans.

Purlins

- Material: Usually Z-shaped or C-shaped steel.

- Purpose: Support roof or wall panels.

- Features: Lightweight design reduces overall structural weight.

Trusses

- Material: Assembled from multiple C-shaped or Z-shaped steel members.

- Purpose: Used for large-span roofs or bridges.

- Features: Triangular units ensure even load distribution and stability.

Bracing

- Material: C-shaped steel, angle steel, or flat steel.

- Purpose: Enhances structural stability against lateral forces like wind or seismic loads.

- Features: Can be designed as horizontal or vertical supports. Steel Structure Bracing plays a crucial role in maintaining overall frame stability, ensuring the structure remains secure even under extreme conditions.

Connection Systems

Connection systems in light gauge steel framing are designed to ensure strong, stable, and efficient assembly, allowing each component to work together seamlessly, please refer to the table below for specific details.

| Category | Purpose | Features |

| Bolted Connections | It is used to connect structural elements, ensuring strong and dependable joints. | – High-strength bolts: Designed for primary load-bearing joints, such as beam-to-column connections. – Standard bolts: Suitable for secondary connections, like purlin-to-beam joints. – Installation: Easy to install, removable, and ideal for maintenance. |

| Welded Connections | Creates high-strength, integral joints for critical structural nodes. | – Materials: Welding rods or wires matched to the base metal. – Performance: Provides superior strength but requires skilled on-site execution. – Applications: Commonly used in truss nodes and other high-stress areas. |

| Connectors | Reinforce and secure connections between structural components. | – Gusset plates: Reinforce critical joints, such as beam-to-column connections, by distributing stress. – Angle brackets: Secure different components, such as walls to floors, ensuring stability. – Stiffeners: Prevent local buckling in load-bearing members, enhancing structural integrity. |

| Anchoring Systems | Secures the steel structure to its foundation, ensuring stability and load transfer. | – Anchor bolts: Designed to fasten steel columns to concrete bases securely. – Chemical anchors: Provide high-strength anchoring in seismic zones or high-load applications. |

Corrosion Protection and Surface Treatment

Hot-Dip Galvanizing

- Purpose: Protects outdoor or harsh-environment steel components.

- Features: Long-lasting corrosion resistance, extending the lifespan of the structure.

Powder Coating

- Purpose: Used for indoor or mildly corrosive environments.

- Features: Aesthetic appeal with added corrosion protection.

As a professional manufacturer, we provide high-quality hot-dip galvanizing (including ASTM A123 and A153 standards) and durable powder coatings (such as polyester, epoxy, and hybrid coatings) to ensure superior corrosion resistance tailored to your project’s environmental needs.

A light steel structure frame system is a type of steel frame system. Read related articles: What is a steel framing system.

Advantages of Light Gauge Steel Framing

Light gauge steel framing provides a range of advantages, making it an exceptional option for contemporary construction:

- Lightweight yet Strong: Provides strength for large-span structures without adding unnecessary weight, making it perfect for high-performance designs.

- Rapid Construction: Prefabricated components streamline on-site assembly, significantly reducing construction time.

- Eco-friendly: Made from recyclable materials, light gauge steel minimizes environmental impact and construction waste.

- Seismic Resilience: Its flexibility makes it well-suited for earthquake-prone regions, ensuring superior performance under seismic forces.

- Design Versatility: Easily adaptable to diverse architectural styles and functional needs, offering flexibility for a wide range of projects.

This combination of strength, efficiency, sustainability, and design freedom is why light gauge steel framing is quickly becoming a preferred choice in modern construction.

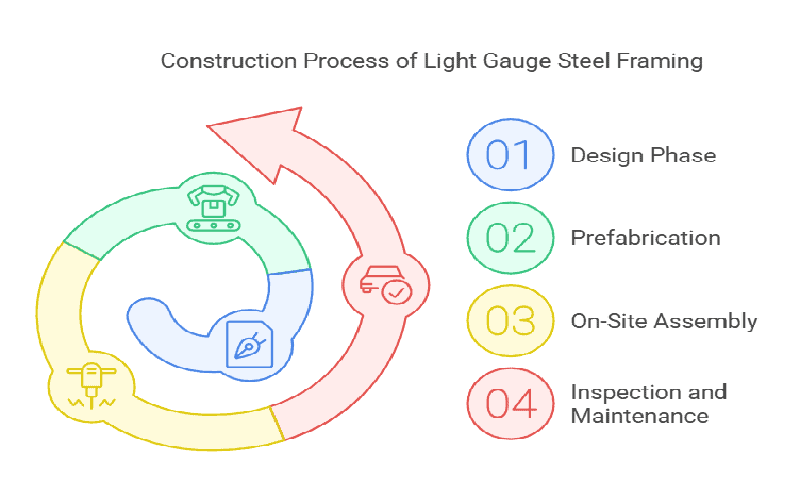

Construction Process of LGS Framing

The construction of a light gauge steel framing system involves several key stages:

- Design Phase: Structural analysis, load calculations, and wind load simulations optimize performance.

- Prefabrication: Components are produced in a controlled factory environment with ±0.5mm precision, ensuring consistency and reducing onsite modifications.

- On-Site Assembly: Rapid installation with pre-engineered bolted connections, minimizing labor time and disruptions.

- Inspection and Maintenance: Structural verification and multi-layer anti-corrosion protection (hot-dip galvanizing, powder coating) enhance durability.

Our CNC machining and robotic welding ensure high-precision fabrication, eliminating weak points in structural joints. With automated quality control, every frame meets industry standards for residential, commercial, and public infrastructure projects. Whether for multi-story housing, schools, hospitals, or retail spaces, our advanced manufacturing guarantees strength, efficiency, and long-term performance.

Design Considerations for Light Gauge Steel Framing

A well-designed light gauge steel framing (LGS) system isn’t just about meeting load-bearing requirements—it’s about ensuring efficiency, durability, and adaptability. Proper planning results in faster assembly, lower costs, and better long-term performance. Here’s what should be prioritized when designing with LGS.

1. Match Framing Systems to Building Function

One of the most common mistakes in LGS design is applying the same framing approach across different building types. Instead:

- For residential projects, prioritize flexibility—post-and-beam systems allow for open layouts that adapt to future modifications.

- For industrial and commercial buildings, portal frames should be the default choice. They provide large, column-free spans, ideal for storage, manufacturing, and retail.

- For multi-story construction, a hybrid system combining LGS walls with structural steel beams improves load distribution and floor stability.

Choosing the right structural system from the start reduces material waste, simplifies installation, and optimizes long-term performance.

2. Adapt Structures to Site Conditions

A one-size-fits-all approach doesn’t work in steel framing. Site conditions dictate framing choices, and ignoring this leads to unnecessary structural modifications later.

- On sloped terrain, stepped or stilted foundations should be integrated into the design to reduce excavation work.

- For seismic-prone regions, bracing must be strategically positioned to dissipate lateral forces effectively. Over-reliance on bolted connections in high-seismic areas should be avoided—welded reinforcements at key stress points will improve performance.

- In high-wind environments, designers must control a building’s aspect ratio. Buildings taller than their base width require additional lateral bracing to avoid excessive wind sway.

Properly considering site conditions at the design stage saves time, prevents costly retrofits, and ensures structural safety from day one.

3. Optimize Wind Load Performance from the Start

Many designers underestimate wind forces in low-rise buildings, assuming that wind uplift is a problem only for high-rises. This is a costly mistake. Wind forces affect all structures, and LGS designs should integrate roof slope and bracing solutions early.

To minimize wind-induced stress:

- For flat or low-pitched roofs, using wind-resistant fasteners and additional bracing on overhangs prevents uplift failures.

- For taller structures, lateral bracing should be designed with wind tunnel test data or CFD simulations, rather than relying on standard load assumptions.

- For large-span buildings, designers should specify purlins and girts with optimal spacing to avoid deflection under wind pressure.

Ignoring wind load considerations in early-stage design increases material costs and can lead to long-term structural instability.

4. Select the Right Steel Sections for Efficiency

Selecting steel sections based solely on cost leads to overengineering or material waste. Instead, match the profile to structural function:

- Use C-shaped and Z-shaped sections for purlins and secondary framing to reduce weight while maintaining strength.

- For columns and primary load-bearing elements, H-shaped and rectangular tubes offer better stability and load transfer.

- In areas with concentrated loads, reinforcing with stiffeners and gusset plates prevents local buckling without overusing heavier steel sections.

Proper section selection balances cost-efficiency with performance, keeping materials optimized without compromising safety.

5. Connection Design: Balance Speed with Structural Integrity

Steel framing fails at connections, not in the members themselves. A well-planned connection system speeds up assembly while maintaining load transfer efficiency.

- Bolted connections should be pre-drilled in fabrication, ensuring alignment accuracy and reducing field modifications.

- Welded joints are essential for seismic zones and high-load areas—but should be minimized in fast-track projects to keep construction time short.

- Gusset plates and stiffeners should be used strategically, not excessively—unnecessary reinforcements add weight and cost.

Well-designed connections reduce installation errors and prevent structural weaknesses from developing over time.

6. Corrosion Protection: Design with Environment in Mind

Steel durability isn’t just about material choice—it’s about matching the right corrosion protection to the exposure environment.

- For indoor applications, standard zinc coatings (Z120/Z180) are enough.

- For high-humidity or coastal areas, use hot-dip galvanizing (ASTM A123/A153) with a minimum 85µm coating thickness.

- For chemical-heavy environments, opt for dual protection—galvanizing plus powder coating or epoxy sealants.

Specifying the right corrosion protection from the start extends lifespan, reduces maintenance, and improves cost efficiency over decades of use.

Light Gauge Steel Framing vs. Other Materials

Choosing the right framing material is crucial for balancing strength, cost, and long-term performance. Light gauge steel not only competes but often surpasses traditional materials in many key areas, offering a modern solution to the evolving demands of construction.

| Material | Advantages of Light Gauge Steel | Key Comparisons |

| Wood Framing | Superior strength, durability, fire resistance, pest and moisture resistance | Compared to wood, light gauge steel offers better longevity and low maintenance. |

| Concrete Framing | Lighter weight, faster installation, better seismic performance | Light gauge steel is less heavy, reduces foundation load, and performs better in seismic conditions. |

| Heavy Steel Framing | Lower cost, easier handling, suitable for low-to-mid-rise structures | Light gauge steel is more cost-effective and ideal for smaller structures, where heavy steel is overkill. |

Light gauge steel framing strikes a balance between cost, speed, strength, and performance, making it a smart choice in modern construction.

Applications of Light Gauge Steel Framing

The versatility of light gauge steel framing makes it perfect for various applications, such as:

- Residential buildings: Suitable for everything from single-family homes to multi-story apartments, providing flexible and durable solutions.

- Commercial structures: Perfect for offices, retail spaces, hotels, where both design and strength are essential.

- Industrial facilities: Ideal for warehouses, factories, and logistics centers, providing open, expansive spaces.

- Public buildings: A reliable choice for schools, hospitals, and sports arenas, ensuring safety and scalability.

- Institutional buildings: Well-suited for government offices and civic centers that require efficient, long-lasting frameworks.

- Recreational facilities: Ideal for gyms, fitness centers, and community halls, where functionality and durability are key.

This adaptability enables light gauge steel framing to address the varied demands of modern construction, blending strength, efficiency, and design versatility.

Conclusion

Light gauge steel framing systems have revolutionized modern construction with their remarkable strength, flexibility, and sustainability. As an integral part of steel structure systems, they seamlessly combine with other structural components to deliver superior performance and versatility. Whether it’s for residential homes or large industrial complexes, these systems offer distinct advantages that make them a superior choice for a wide range of projects.

As a leading steel structure manufacturer, we pride ourselves on our advanced fabrication techniques, including hot-dip galvanizing and powder coating, which ensure durability and long-lasting performance. Our focus on cutting-edge corrosion protection further enhances the lifespan of our structures, allowing them to withstand even the harshest environments.

In essence, light gauge steel framing is more than just a construction system—it represents a new era of innovation, efficiency, and reliability in building design. With these advantages, it’s clear why this system is becoming the go-to choice for projects that demand strength, speed, and sustainability.

Frequently Asked Questions About Light Gauge Steel Framing

What Is the Difference Between Light Gauge and Heavy Gauge Framing?

Light gauge framing uses thinner steel and is lighter, cost-effective, and more suited for smaller to mid-rise buildings, while heavy gauge framing offers superior strength for larger structures.

How Does Light Gauge Steel Framing Perform in Seismic Zones?

Light gauge steel framing is flexible, allowing it to absorb and dissipate seismic forces effectively, which reduces the risk of structural damage in earthquake-prone areas.

What Types of Buildings Benefit Most From Light Gauge Steel Framing?

Light gauge steel is ideal for residential, commercial, and industrial buildings, especially those requiring quick construction, flexibility, and high durability.

How Is Corrosion Protection Applied to Light Gauge Steel?

Corrosion protection is achieved through hot-dip galvanizing and powder coating, providing long-lasting resistance to rust, moisture, and harsh weather.

What Are the Cost Benefits of Using Light Gauge Steel Over Traditional Materials?

Light gauge steel is economical thanks to quicker construction times, minimized material waste, and lower labor costs compared to traditional materials such as wood and concrete.