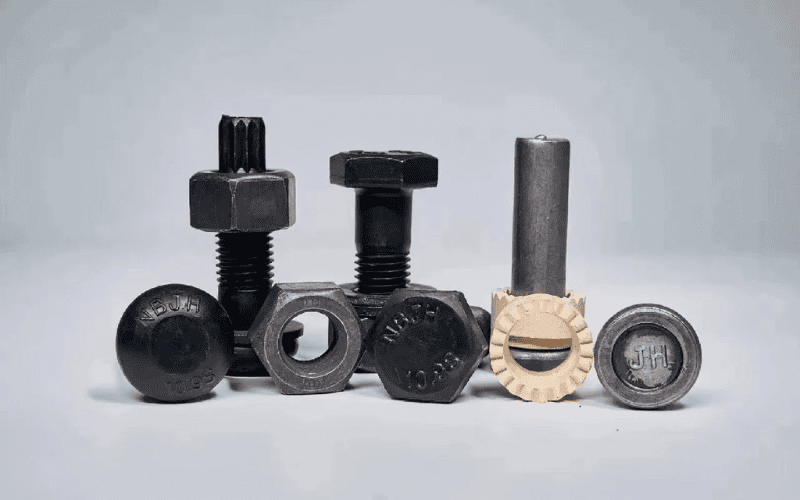

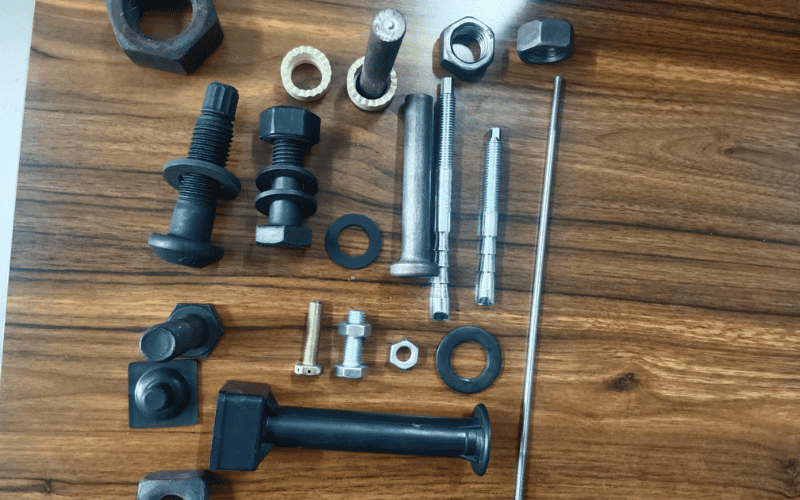

Steel structure bolts are essential fasteners that connect and stabilize every part of a steel building — from columns and beams to foundations and joints.

This comprehensive guide explains the different types of bolts used in steel structures (ordinary bolts, high-strength bolts, anchor bolts, and others), their main applications in buildings, bridges, and industrial projects, and the advantages and challenges of using bolted connections.

You’ll also learn how to choose the right bolt accessories based on load, environment, and cost factors, understand the proper installation and tightening procedures, and compare bolt connections vs. welded connections.

Finally, the FAQ section provides quick answers to practical questions about bolt size, material, grade, and maintenance, helping engineers, builders, and contractors ensure safe, efficient, and long-lasting steel structure performance.

What Bolts Are Used for Steel Structures?

1. Ordinary Bolts (A307 Bolts)

| Feature | Ordinary Bolts (A307 Bolts) |

| Specifications | Diameter: M6 to M100 |

| Length: 1 inch to 12 inches | |

| Thread: Full or partial thread (customizable) | |

| Material | Low carbon steel, galvanized or hot-dip galvanized, strength grade Grade A or Grade B, tensile strength ~60,000 psi |

| Application Scenarios | Secondary structures, temporary connections, non-critical parts (e.g., brackets, platforms, stairs) |

| Advantages | Low cost, easy installation, high versatility, suitable for most non-high-stress applications |

| Disadvantages | Limited load-bearing capacity, poor anti-slip performance, not suitable for high-load or extreme environments |

2. High-strength Bolts (A325 and A490 Bolts)

| Feature | High-Strength Bolts (A325 and A490 Bolts) |

| Specifications | Diameter: M12 to M36 |

| Length: Customizable | |

| Thread: Full or partial thread options | |

| Material | Medium carbon steel or alloy steel, heat-treated for high strength, strength grades 8.8, 10.9, 12.9 |

| Application Scenarios | Main structural connections in bridges, high-rise buildings, and industrial facilities; parts under high loads and stresses |

| Advantages | High load-bearing capacity, excellent anti-slip performance, ASTM-compliant, ensures structural safety |

| Disadvantages | High cost, requires precise preload control, special tightening equipment needed |

Common grades include Class 8.8, 10.9, and 12.9, compliant with ASTM A325 / A490 standards. These bolts are widely used in industrial facilities, bridges, and high-rise PEB steel buildings, ensuring secure connections and long service life.

3. Torsion Shear Bolt (TC Bolt)

| Feature | Torsion Shear Bolts (TC Bolts) |

| Specifications | Diameter: M16 to M30 |

| Length: Customizable | |

| Design: Tail designed for torque control and stable connection | |

| Material | Alloy steel, heat-treated for enhanced strength, better shear and tensile resistance |

| Application Scenarios | Connections requiring anti-loosening or anti-slippage (e.g., steel structures, bridges, large equipment) |

| Advantages | Reliable connection, easy preload control, suitable for high-strength applications |

| Disadvantages | Requires precise torque control; incorrect tightening may cause connection failure |

4. Anchor Bolts

| Feature | Anchor Bolts |

| Specifications | Diameter: M12 to M100 |

| Length: Customizable based on base and installation requirements | |

| Material | Mostly alloy steel or stainless steel, with strong corrosion resistance and durability |

| Application Scenarios | Foundation construction for fixing steel structures on concrete or ground (e.g., buildings, bridges, equipment foundations) |

| Advantages | Reliable fixation, strong corrosion resistance, suitable for harsh environments |

| Disadvantages | Complex installation, requires accurate drilling for optimal performance |

Especially suitable for metal buildings and foundation anchoring, ensuring long-term durability under vibration and wind loads.

5. Heavy Hexagonal Bolts

| Feature | Heavy Hex Bolts |

| Specifications | Diameter: M16 to M36 |

| Length: 50mm to 200mm (customizable) | |

| Material | High-strength alloy steel or stainless steel, surface-treated (e.g., galvanizing, hot-dip galvanizing) |

| Application Scenarios | Connections bearing large static or dynamic loads (e.g., bridges, steel structures, industrial equipment) |

| Advantages | Strong load-bearing capacity, suitable for high-stress environments, stable installation |

| Disadvantages | More expensive than ordinary bolts, requires special tools for installation |

6. Other Types of Bolts

Besides ordinary and high-strength bolts, several specialized types serve unique structural purposes:

- Turnbuckle Bolts: For tension adjustment in steel cables or tie rods (used in viaducts, cranes).

- Eye Bolts: For lifting and rigging applications in ships, cranes, and mechanical systems.

- U-Bolts: To fix pipes or mechanical equipment on steel frames.

All structural bolts undergo strict material testing, dimensional inspection, and anti-corrosion treatment to ensure performance under high loads and harsh conditions.

Application of Steel Structure Bolts

Building Structure

In steel structure buildings, bolts are used to connect beams, columns, nodes, and supports. Bolted connections are not only quick to install but also easy to adjust and maintain, ensuring structural stability and flexibility during construction.

In PEB buildings and steel warehouses, high-strength bolts are preferred for beam-to-column joints to achieve precise alignment and quick on-site assembly.

Bridges

In bridge engineering, bolts connect main beams, cross beams, and bridge decks. They provide high load-bearing capacity and vibration resistance, ensuring the long-term safety of bridges under dynamic and wind loads.

In modern steel bridges, A490 high-strength bolts are often used for structural steel connections, offering superior fatigue resistance and maintenance convenience.

Industrial Facilities

For heavy machinery installation, pipe racks, and equipment supports, bolts are selected to withstand high tensile and shear forces. They ensure the stability of equipment foundations and maintain reliability under continuous operation.

Bolts for structural steel connections and industrial shed fasteners are specially designed to resist dynamic vibration and high-frequency loads, ensuring long-term operational stability in manufacturing plants and logistics centers.

Temporary Structures

Bolts are widely used in temporary supports, scaffolding, and removable bridges. Their easy assembly and reusability make them ideal for rapid construction and disassembly at project sites.Temporary steel structures often rely on standardized high-strength bolts for repeated installation without deformation, ensuring safe and efficient reuse.

Advantages of Bolted Connections

As a common method in steel structures, bolted connections have the following significant advantages:

- Easy Installation: Bolted connections are simpler than welding and do not require complex equipment or highly specialized personnel. They improve construction efficiency, shorten on-site assembly time, and lower overall project costs.

- Flexibility: Bolted joints can be easily disassembled, replaced, or adjusted, making them ideal for projects that may require expansion, relocation, or future modification. This flexibility enhances the adaptability of steel structures in various construction environments.

- Quality Control: The quality of bolted connections can be visually inspected and verified during and after installation. This facilitates consistent quality assurance and ensures the reliability of the overall structure, especially for projects with strict inspection requirements.

- Environmental Protection: Compared with welding, bolted assembly minimizes on-site light pollution, fumes, and energy consumption — aligning with sustainable construction and low-carbon principles.

Compared with welding, bolted steel connections ensure easier inspection, faster construction, and greater adaptability for prefabricated PEB structures. Their modular, replaceable nature also makes them suitable for modern industrial and commercial buildings where efficiency and precision are equally important.

Challenges and considerations of bolted connections

Although bolted connections have many advantages, there are also some challenges and considerations in practical applications. Understanding these issues will help you better select and use bolted connections.

- Risk of Loosening: Bolts may gradually loosen when exposed to vibration, dynamic loads, or temperature fluctuations. Regular inspection and re-tightening are necessary. Auxiliary anti-loosening measures, such as lock nuts, spring washers, or chemical adhesives can significantly improve connection stability.

- Corrosion Issues: Bolts can corrode in humid or chemically active environments. To enhance corrosion resistance, galvanized, hot-dip galvanized, or stainless steel bolts are commonly used. Protective coatings and regular maintenance can extend their lifespan, especially in marine or outdoor structures.

- High Cost of Materials and Accessories: High-strength bolts and accessories (washers, nuts, coatings) are more expensive than ordinary fasteners. A balanced selection should consider both budget and structural safety, with cost-effective materials chosen for non-critical parts.

- Installation Accuracy Requirements: Bolted joints demand precise hole positioning and alignment. Inaccurate drilling or assembly may reduce load capacity or cause premature wear. During installation, torque calibration and alignment control are essential to maintain connection integrity.

For professional selection of anti-corrosion and anti-loosening bolt systems, or to address site-specific design challenges, you can consult our engineering team for project-specific recommendations and technical support. Our experts provide solutions covering bolt selection, installation standards, and maintenance strategies for steel and PEB structures.

How to Choose the Right Bolt Accessories

Selecting appropriate bolt accessories is essential for ensuring structural safety, improving construction efficiency, and minimizing maintenance costs. Different projects have unique performance and environmental demands, so accessories should always be chosen based on technical requirements and site conditions.

Load Requirements

- High-load scenarios: Choose high-strength bolts (A325, A490) or heavy hex bolts to support greater tension and shear forces — ideal for bridges, industrial facilities, and steel warehouses.

- Medium-load scenarios: Use torsion shear bolts (TC bolts) or standard high-strength bolts for general building structures and secondary frames.

Proper selection ensures that both the main bolt and its accessories (washers, nuts, sleeves) share the same strength grade and performance class.

Environmental Factors

- Corrosive environments: Opt for galvanized, hot-dip galvanized, or stainless steel accessories to enhance corrosion resistance and longevity.

- High-temperature environments: Choose heat-resistant alloy steel bolts and nuts to maintain performance stability under elevated temperatures.

For marine or coastal projects, dual-layer anti-corrosion systems combining galvanizing and epoxy coatings are recommended to extend service life.

Installation Conditions

- Limited space: In confined areas, torsion shear bolts simplify installation and minimize manual errors.

- High-precision applications: Use tension control bolts (TC bolts) or pre-calibrated fasteners to ensure preload accuracy and minimize maintenance needs.

Always verify torque settings using calibrated tools to achieve consistent tightening and prevent overloading.

Cost and Efficiency

- Limited budget: Ordinary high-strength bolts offer a balanced choice between cost and performance, suitable for general structural applications.

- Tight schedule: Heavy hexagonal bolts and TC bolts can improve installation speed, reducing labor time and on-site costs.

Selecting accessories that match the project’s priority—budget, speed, or precision—can optimize both performance and overall construction efficiency.Our factory provides complete bolt accessory solutions, including nuts, washers, and anchor systems, manufactured under ISO 9001 and ASTM standards.

All accessories are available for bulk export and OEM customization, ensuring compatibility with global steel and PEB structure projects.

Installation and Tightening of Steel Structure Bolts

The stability and safety of steel structures depend to a large extent on the correct installation and tightening of bolts. In bolted steel construction fabrication, precise preload control and torque calibration are essential to guarantee connection reliability and long-term performance.

Installation Method and Preload Control

- Torque Method: Use a calibrated torque wrench to control the bolt preload.

This method is reliable and suitable for most standard bolts, providing consistent tightening accuracy. - Angle Method: Control the preload by the degree of bolt rotation. Commonly used when uneven loading or limited access requires more flexible tightening control.

- Tension Control Method: Employ torsion shear bolts (TC bolts) that automatically break off the tail at a set torque value, ensuring accurate preload and quick verification. This method is highly suitable for high-strength structural connections and industrial prefabricated buildings.

Proper preload ensures both anti-slip performance and joint stability. Bolt arrangement should be designed based on load type — parallel for uniform loads, staggered for uneven stress distribution — to maintain consistent connection integrity.

Secondary Tightening

Why Secondary Tightening:

Even if bolts are initially tightened to the specified preload, they may loosen over time due to vibration, temperature variation, or structural settling. A secondary tightening ensures long-term stability and eliminates micro-gaps that can lead to fatigue.

How to Perform Secondary Tightening:

Perform secondary tightening within several hours or days after installation. During this stage, verify the torque values and adjust preload using the torque or angle method to restore optimal clamping force.

Secondary tightening is especially important for bridges, PEB buildings, and dynamic-load industrial structures, where fatigue and vibration resistance are critical.

Inspection and Maintenance

Regular Inspection:

Inspect bolted connections periodically to ensure that no bolts are loose, corroded, or damaged. In high-vibration or corrosive environments, increase the inspection frequency to maintain safety.

Maintenance Measures:

Lubricate bolts periodically to prevent rust and galling. In corrosive areas, use galvanized, hot-dip galvanized, or stainless steel bolts for improved resistance and longevity.

Every batch of bolts and accessories is tested under simulated load conditions to comply with ASTM F3125 and ISO 17025 standards, ensuring global reliability and project certification readiness.

Bolt Connection vs Welded Connection

Both bolted and welded connections are widely used in steel construction. The choice between them depends on structural design, load requirements, construction schedule, and maintenance considerations.

| Criteria | Welded Connection | Bolted Connection |

| Strength & Rigidity | Provides higher static strength and rigidity; ideal for permanent, heavy-load structures. | Offers sufficient strength with flexibility; suitable for adjustable or demountable structures. |

| Aesthetics | Smooth and uniform appearance; preferred for exposed or architectural structures. | More visible joints; ideal for concealed or industrial frameworks. |

| Cost & Time | Higher fabrication cost but less long-term maintenance; requires skilled welders. | Lower installation cost and faster assembly; ideal for prefabricated and modular systems. |

In modern PEB and modular steel structures, bolted connections have become the preferred method for their ease of fabrication, cost efficiency, and global standardization. They enable quicker on-site assembly, simpler quality control, and easier disassembly—key advantages in today’s sustainable and fast-paced construction environments.

How to determine the size of steel structure bolts?

The size depends on design standards, load requirements, and connection types. Typical diameters range from M12 to M24, with lengths usually twice or more than the plate thickness. Structural engineers should verify bolt sizing based on the applied stress and shear conditions.

What strength grade is required for steel structure bolts?

Common strength grades include 8.8, 10.9, and 12.9. Grade 8.8 is suitable for general applications, while 10.9 or higher is used in high-stress or dynamic load environments, such as bridges and industrial buildings.

What are the material requirements for bolts?

Bolts are generally made from Q235, Q345, or alloy steels. In corrosive environments, galvanized or stainless steel bolts are recommended to ensure long-term durability. In high-temperature or coastal conditions, heat-resistant or corrosion-resistant alloys are preferred.

Do steel structure bolts need anti-loosening measures?

Yes. For structures subject to vibration or impact, anti-loosening measures such as lock washers, double nuts, or self-locking nuts should be used. These prevent fatigue loosening and ensure long-term stability in critical joints.

How long is the service life of steel structure bolts?

Service life varies depending on material and environment. Galvanized bolts can last several decades under normal conditions, while bolts in high-humidity or marine settings may require periodic replacement. Regular inspection and timely maintenance extend service life effectively.

What should I do if bolts become loose?

Loose bolts should be inspected, re-tightened, or replaced immediately. For high-strength bolts, ensure the specified torque is applied during re-tightening to restore preload. Persistent loosening may indicate underlying connection design issues that require engineering evaluation.

Can I get bulk or factory-direct pricing for steel structure bolts?

Yes. We provide factory-direct supply and wholesale pricing for high-strength and anchor bolts, supported by ISO 9001 and ASTM-compliant manufacturing standards. Global shipping and OEM packaging options are available for distributors and project contractors.

Do you provide customized sizes or finishes?

Absolutely. We can produce custom lengths, diameters, coatings (galvanized, hot-dip galvanized, zinc-plated), and grades (8.8 to 12.9) according to your project’s specifications. Special finishes such as black oxide, Dacromet, or duplex coating can also be applied upon request.