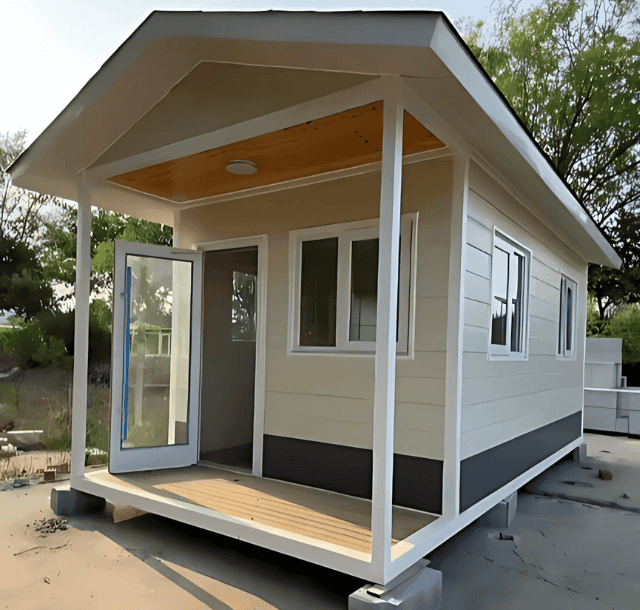

Imagine standing in front of a brand-new steel structure—maybe a massive warehouse or a modern stadium. As you look up at the roof’s edge, you notice a seemingly simple metal strip. It might not stand out, but it plays a crucial role in both protecting and enhancing the building.

This unsung hero is the fascia.

You may not have paid much attention to it before, but fascia in steel structures is as essential as the frame around your phone’s screen. It shields the internal structure while giving the building a polished, finished look. Now, let’s dive in and uncover fascia’s hidden “superpowers”!

What Is Fascia in Steel Structures?

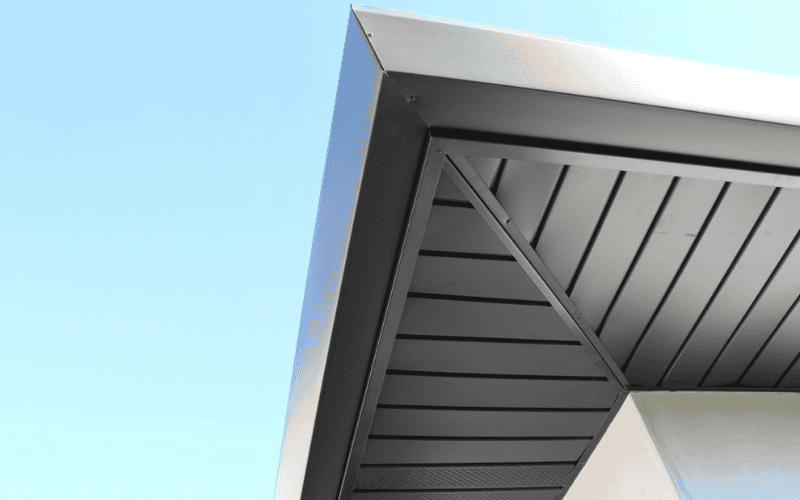

Fascia board is a small but critical part of steel buildings. Think of it like the rim of a hat—it sits at the edge where the roof meets the walls, covering the exposed steel beams. Just like a phone screen frame protects its inner components, fascia shields the roof edges from wind, rain, and other elements while giving the building a clean, polished look.

Typically installed at the outermost part of the roof, fascia connects the roofline to the walls and serves six key functions:

- Keeps Water Out – It blocks rain from sneaking into gaps between the roof and walls, preventing rust and structural damage.

- Stops Wind Damage – Strong winds can lift exposed roof edges. Fascia keeps them secure and helps maintain the building’s stability.

- Holds Up Gutters – Gutters need a solid base, and fascia provides just that, ensuring proper drainage and preventing water buildup.

- Adds Fire Protection – Some fascia panels have fire-resistant coatings, helping slow down flames in case of a fire.

- Cleans Up the Look – It hides exposed steel beams, giving the building a sharp, finished appearance. Plus, you can choose colors and styles to match the design.

- Keeps Pests Away – By sealing off gaps, fascia stops birds from nesting and keeps insects from creeping in.

At the end of the day, fascia board is the unsung hero of steel structures. It plays a major role in durability, safety, and aesthetics, keeping the building strong and visually appealing, no matter the weather. Without fascia, a building is like a painting without a frame—unfinished and open to damage.

Common Types of Fascia and How to Choose the Right One

Fascia board isn’t a one-size-fits-all component. Different types are designed to suit various structural and environmental needs. Below are some of the most common types of fascia, along with their key features and recommended applications.

| Type | Key Features | Best Applications |

| Standard Vertical Fascia | Straight-line design, stable, cost-effective | Industrial buildings, warehouses, logistics centers, steel workshops |

| Ventilated Fascia | Built-in ventilation holes to improve airflow and reduce condensation | High-humidity or rainy areas, equipment rooms |

| Curved/Decorative Fascia | Arched or wavy design for enhanced aesthetics | Commercial buildings, exhibition halls, modern industrial facilities |

| Insulated Fascia | Integrated thermal insulation to minimize heat transfer | Cold storage warehouses, temperature-controlled logistics centers, steel refrigeration units |

| Bottom Curved Fascia | Curved at the bottom for a smoother visual transition | Commercial buildings, modern steel factories, public structures |

| Top and Bottom Curved Fascia | Curved edges on both sides for a more elegant look | High-end commercial buildings, signature steel projects |

| Center Curved Fascia | Curved in the middle, offering a balance of aesthetics and modern appeal | Tech parks, innovative steel buildings |

| Parapet Fascia | Extends the wall up to the roofline for a flat-roof appearance | Shopping malls, commercial towers, industrial buildings |

| Aluminum Fascia | Lightweight, corrosion-resistant, excellent weather durability | Coastal steel structures, large-span steel projects |

| Galvanized Steel Fascia | Durable, corrosion-resistant, cost-effective | Factories, warehouses, logistics centers, industrial parks |

| Stainless Steel Fascia | High-strength, weather-resistant, low-maintenance | Premium steel buildings, marine environments, chemical plants |

When selecting fascia board, consider these three key factors:

1. Climate Conditions

- Humid/Coastal/Industrial Environments → Aluminum, Stainless Steel, or Galvanized Steel Fascia for better corrosion resistance.

- High-Temperature Facilities → Insulated Fascia to reduce heat transfer and improve energy efficiency.

- Rain-Prone Areas → Ventilated Fascia to prevent condensation buildup and extend durability.

2. Building Purpose

- Industrial Facilities, Warehouses, Logistics Centers → Standard Vertical, Ventilated, or Galvanized Steel Fascia for affordability and durability.

- Commercial Steel Buildings → Decorative, Curved, or Parapet Fascia to enhance aesthetics.

- Cold Storage or Temperature-Controlled Spaces → Insulated Fascia to minimize energy loss.

3. Budget Considerations

- Cost-Effective Options → Galvanized Steel Fascia offers the best balance of durability and price.

- Premium, Low-Maintenance Solutions → Aluminum or Stainless Steel Fascia for long-term investment with minimal upkeep.

Fascia Material Comparison & How to Pick the Right One

The material you choose for fascia board affects durability, maintenance, and overall appearance. It’s important to balance environmental conditions, budget, and performance needs. Here’s a breakdown of the most common fascia materials and their pros and cons:

| Material | Pros | Cons | Best For |

| Galvanized Steel | Strong, budget-friendly, easy to fabricate | Needs rust protection, may corrode over time | Industrial plants, warehouses, logistics centers |

| Aluminum | Lightweight, corrosion-resistant, low maintenance | Less impact-resistant, pricier than galvanized steel | Coastal areas, humid environments, commercial buildings |

| Stainless Steel | Extremely durable, corrosion-proof, maintenance-free | Expensive, heavier than other metals | Chemical plants, food processing, marine structures, high-end projects |

| PVC-Coated Steel | UV-resistant, customizable colors, weatherproof | Limited fire resistance, not ideal for extreme heat | Commercial buildings, shopping centers |

| Pre-Painted Galvanized Steel (PPGI) | Long-lasting finish, good corrosion resistance, color variety | Can scratch easily, requires touch-ups if damaged | Offices, industrial buildings, retail spaces |

| Insulated Composite Steel Panel | Built-in thermal insulation, moisture-resistant | Higher cost, requires professional installation | Cold storage, temperature-controlled spaces, healthcare facilities |

When selecting fascia material, please consider:

1. What’s Your Budget?

- Need a cost-effective option? → Galvanized Steel (affordable but requires maintenance).

- Looking for a long-term investment? → Stainless Steel or Aluminum (higher upfront cost, but minimal upkeep).

2. What’s the Environment Like?

- High humidity, coastal areas, or chemical exposure? → Stainless Steel or Aluminum (top-notch corrosion resistance).

- Hot or temperature-sensitive environments? → Insulated Composite Steel Panels (best for climate control).

- General warehouses and industrial use? → Galvanized Steel or PPGI (solid durability at a reasonable cost).

3. Does Appearance Matter?

- Need custom colors for commercial projects? → PVC-Coated Steel or PPGI (variety of colors and finishes).

- Want a tough, industrial look? → Galvanized Steel or Stainless Steel (functional and durable).

Why Is Fascia Essential for Steel Structures?

Fascia might not be the most noticeable part of a steel building, but it’s the last line of defense that keeps everything in check. Here are five key reasons why fascia board is a must-have:

✅ Prevents Costly Damage – Without fascia, roof edges are exposed to water accumulation, leading to corrosion, structural weakening, and even collapse.

✅ Reduces Maintenance Costs – A one-time fascia board installation significantly cuts down on future waterproofing and repair expenses.

✅ Ensures Code Compliance – Most building codes require fascia to meet fire resistance and wind load standards for safety.

✅ Boosts Property Value – A well-installed fascia enhances the building’s appearance, increasing its asset value and rental appeal.

✅ Adds Extra Functionality – Fascia isn’t just protective—it can integrate lighting, drainage systems, and other useful features.

Final Thoughts

Fascia may be small, but it’s the unsung hero of steel structures. It not only protects your building from the elements but also enhances its overall aesthetics and functionality. Choosing the right type and material can extend the building’s lifespan while adding a professional and polished touch to your project.

If you’re planning a steel structure or unsure about the best fascia option, talk to our engineering team today! We’ll help you find the best-fit solution tailored to your project’s needs—ensuring your building is strong, stylish, and built to last.

Fascia FAQs

Is fascia part of the roof?

Yes, fascia is an essential part of the roofing system. It’s a horizontal board installed along the roof edge, covering the ends of rafters or trusses. Fascia provides structural support, gives the roof a finished look, and serves as the mounting point for gutters.

What is the difference between fascia and soffit?

Fascia is the vertical finishing board that runs along the roof edge, supporting the gutters and protecting the rafter ends. Soffit, on the other hand, is the horizontal panel installed underneath the eaves, bridging the gap between the fascia and the exterior wall. Soffits help ventilate the attic and prevent moisture buildup, while fascia provides structural integrity and aesthetic appeal.

What is fascia vs. trim?

Fascia is a specific type of trim that runs along the roofline, covering and protecting the exposed rafter ends. Trim, in general, refers to any finishing material used around doors, windows, and other architectural elements. While fascia is technically a type of trim, not all trim functions as fascia.