Many landmark buildings use advanced steel structure systems, which not only ensure the safety of the building, but also greatly improve the beauty and practicality of the building.

We will focus on several widely used types of steel structure systems, and analyze in detail their respective characteristics and application scenarios in different types of buildings. We hope to help you better understand the elements of steel structure systems, and thus provide valuable reference for your building design, construction or investment decisions.

Advantages of Steel Structure System

High Strength and Durability: Due to its high strength, steel can withstand heavy loads and extreme environmental conditions, making it suitable for high-rise buildings and large-span structures. Its excellent corrosion resistance and durability ensure the long-term use of steel structures in harsh environments and reduce maintenance costs.

Design Flexibility: The plasticity and lightweight characteristics of steel enable designers to achieve complex and innovative architectural designs to meet various building forms and functional requirements. Steel structures can flexibly adapt to different architectural styles and structural forms, and support open layouts and large space designs.

Construction Efficiency: The rapid installation of prefabricated steel structures greatly shortens the construction period, while reducing the labor intensity of on-site construction, thereby reducing the overall construction cost. This makes steel structures particularly prominent in projects that require rapid delivery.

Sustainability: The recyclability of steel makes it meet green building standards, helps reduce construction waste, and can be reused after the building is demolished. As a sustainable building material, steel structures help promote environmentally friendly and energy-saving architectural concepts.

Common Steel Structure System Types

1. Plane load-bearing structure system

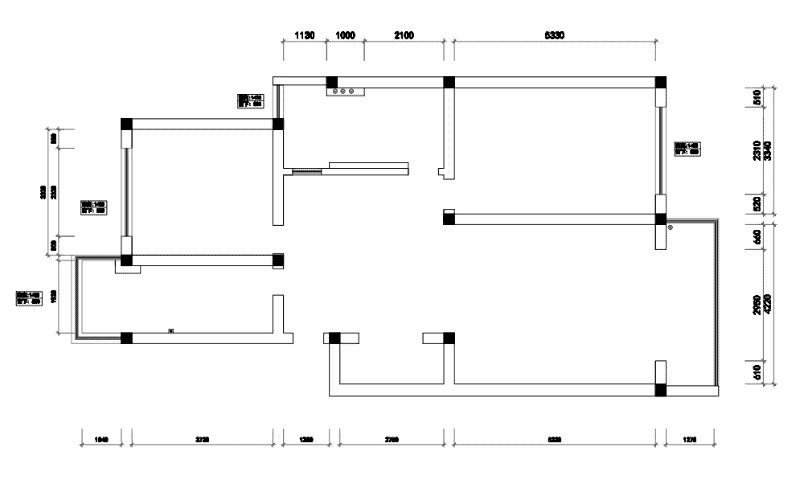

The plane load-bearing structure is composed of parallel planes, which mainly bear vertical loads and part of horizontal loads. This type of system is usually simple in structure and easy to construct, and is suitable for relatively simple functional requirements.

It is suitable for factories, warehouses, commercial buildings, etc. These buildings have relatively balanced load requirements and relatively regular structural layouts. The plane load-bearing system can efficiently meet these requirements.

2. Rigid frame system

The rigid frame resists vertical and horizontal loads through the rigid connection between steel beams and steel columns. Its rigid connection can effectively disperse and transfer loads, and is particularly suitable for structures that require high strength and high stability.

It is suitable for high-rise office buildings, hotels, apartments and other buildings. These buildings usually need to withstand large horizontal forces and vertical loads. The rigid frame system can provide solid support and earthquake resistance.

3. Support frame and shear wall system

The support frame or shear wall system resists lateral loads (such as wind force and earthquake force) by setting support columns or shear walls to enhance the stability and earthquake resistance of the overall structure.

Widely used in high-rise buildings in earthquake-prone areas, such as high-rise residential buildings, commercial buildings, etc. Shear wall systems can effectively improve seismic performance and are the preferred solution for buildings in high-risk areas.

4. Cantilever system

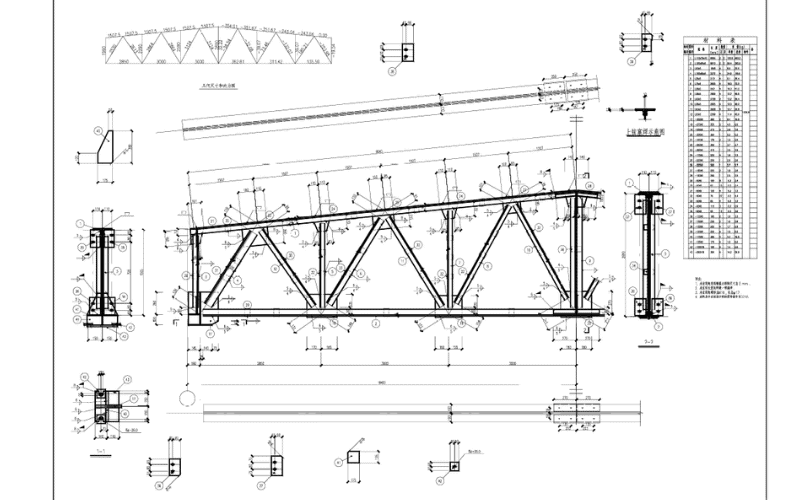

The cantilever system reduces the impact of high-rise vibrations in buildings through horizontal trusses or steel frames connecting the core tube and the peripheral structure. Its design is capable of effectively enhancing the seismic resilience and dynamic stability of the structure.

Suitable for super-high-rise buildings, such as skyscrapers, which have height and wind load requirements. The cantilever system can effectively improve the stability and comfort of the building.

5. Tubular system

The tubular system uses triangular or square support tube structures to enhance overall stability. This design efficiently distributes the load and offers a high level of structural stability.

Common in large-span buildings such as stadiums and exhibition centers. These buildings usually require a large open space, and the tubular system can provide great spatial flexibility while ensuring stability.

6. Framed tube system

The framed tube system uses steel or concrete tubes to enhance the seismic performance of the structure. Tubular components usually have high stiffness and strength, which can effectively resist the lateral forces of natural disasters such as earthquakes.

Suitable for high-rise and super-high-rise buildings, especially in earthquake-prone areas, can provide stronger seismic resistance and overall stability.

7. Bundled tube system

The bundled tube system is composed of multiple tubular structures connected to enhance the overall load-bearing capacity. This system can significantly enhance the structure’s resistance to compression and bending, making it ideal for buildings with stringent load-bearing demands.

Mainly used in super-high-rise buildings and complex structures, it can provide great load-bearing capacity and higher structural stability.

8. Spatial force structure system

The spatial force structure system refers to a structural system composed of various forms of structural elements (such as rods, cables, membranes, etc.), which uses the interaction between these elements to bear the load. It mainly includes the following types:

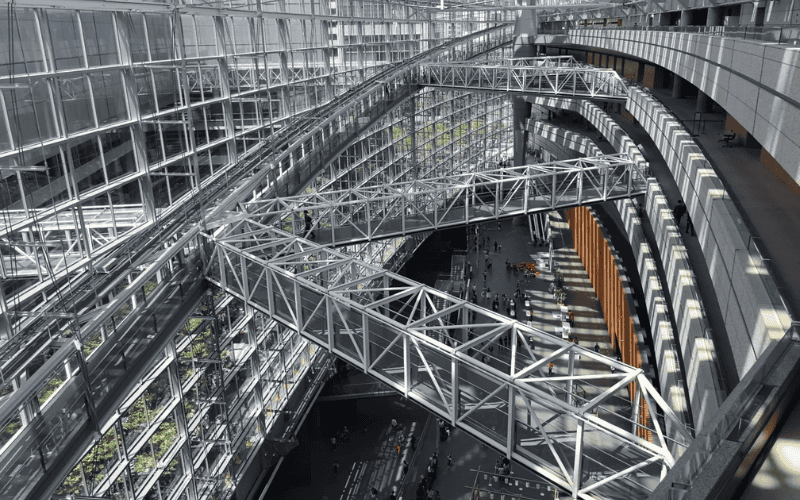

- Grid structure: It is composed of multiple staggered rods to form a grid-like structure, which is suitable for large-span buildings. It is often used in places such as stadiums, exhibition centers and airports, and can provide a large open space.

- Cable suspension structure: It bears loads through tensioned cables, usually used in bridges or large-span roofs. The cable suspension structure can effectively disperse the load and adapt to a wide range of spans.

- Cable membrane structure: It combines the characteristics of cables and membranes, and is usually used in temporary buildings or exhibition halls. Through the tension of cables and membranes, a lightweight and efficient structural form can be achieved.

Application of Steel Structure System in Different Building

High-rise buildings

In high-rise buildings, rigid frame systems, frame tube systems and bundled tube systems are common steel structure applications.

- The rigid frame system provides strong load resistance through the rigid connection of steel beams and steel columns, which is suitable for the vertical and horizontal load requirements of high-rise buildings.

- The frame tube system uses steel or concrete tubes to enhance the seismic performance, which is particularly suitable for high-rise buildings in earthquake-prone areas.

- The bundled tube system combines multiple tubular structures to improve the overall bearing capacity, which is common in super high-rise buildings.

Long-span buildings

Long-span buildings such as gymnasiums and exhibition centers usually use grid structures, cable structures and cable membrane structures.

- The grid structure can withstand large span loads and is suitable for buildings that require open space.

- The cable suspension structure is usually used in bridge and roof design, which can effectively distribute loads and is suitable for structures spanning long distances.

- The cable membrane structure is lightweight and possesses high tensile strength, making it widely utilized in temporary structures and exhibition halls.

Industrial buildings

Industrial buildings mostly use plane load-bearing structure systems and support frame systems.

- Flat load-bearing structures are suitable for buildings such as factories and warehouses. Their straightforward design and efficient construction traits fulfill the requirements of industrial buildings.

- Braced frame systems are used for industrial buildings that require stronger lateral resistance, especially in earthquake-prone areas.

Bridges and infrastructure

Cable suspension structures and tubular systems are often used in bridges and other infrastructure such as tunnels and transportation hubs.

- Cable suspension structures are a common design for bridges that can accommodate large spans and varying load conditions.

- Tubular systems increase the stability of the structure through tubular supports and are common in infrastructure projects such as large bridges and tunnels.

Construction Requirements of Steel Structure System

Design phase

During the design phase, the loads, environmental conditions and functional requirements of the building must be fully considered. Loads include vertical loads (such as deadweight, use loads) and horizontal loads (such as wind and seismic loads).

We consider spatial layout and use efficiency when designing to ensure that our steel structure can effectively carry these loads while adapting to factors such as climate, temperature changes, earthquakes, etc. in the environment.

Material selection

Material selection is crucial to the performance of steel structures. To select high-strength steel with excellent bearing capacity, the steel should also be treated with anti-corrosion. Our common anti-corrosion treatment methods include hot-dip galvanizing and anti-corrosion coating to ensure the durability of steel under various environmental conditions and extend the service life of the structure.

Construction safety

Relevant safety standards and construction processes must be strictly followed to ensure the safety of construction workers and the construction quality of the structure. A detailed risk assessment is required at the construction site, and necessary safety protection measures are taken, such as protective nets, safety belts, and regular inspections of mechanical equipment.

Environmental impact

Noise, dust and other pollutants may be generated during the construction of steel structures, so measures need to be taken to reduce these impacts on the surrounding environment. Use advanced construction equipment and technology to control noise and dust emissions to ensure that the construction process does not cause adverse effects on surrounding residents and the ecological environment.

Steel structure supplier

The world of steel structure is full of infinite possibilities. Are you looking for a reliable partner to help you turn these possibilities into reality? We focus on steel structure design consultation and technical support, and are committed to providing you with innovative and efficient solutions. You are welcome to contact us to start an in-depth conversation about steel structure.