What is a steel framing system?

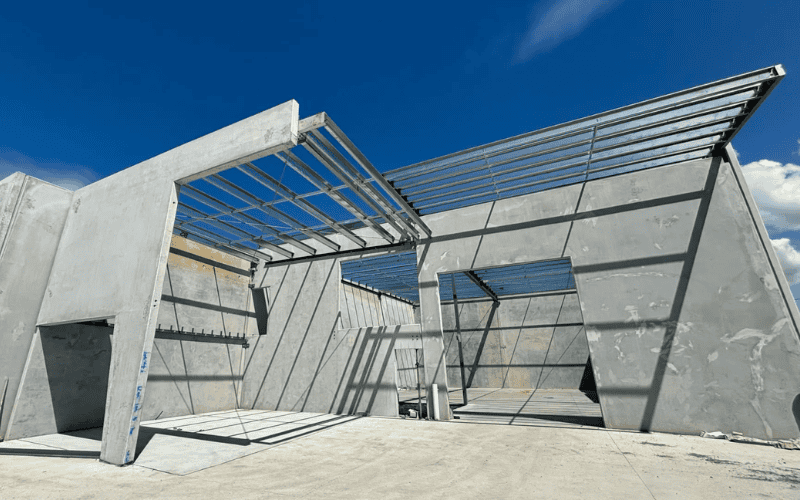

SFS (Steel Framing System) is a modern building solution in the construction industry that uses steel frames (such as columns, beams, hangers, tracks, etc.) to build frame structures. Specifically, SFS usually refers to a light steel frame system used to support building exterior walls or wall curtain systems.

Steel framing systems follow standards such as AISI (American Iron and Steel Institute) and ASTM to ensure product quality, safety and durability. Our steel strictly meets these standards, providing strength, stability and efficient construction.

What Materials Are Steel Frame Systems Made of?

Steel frame systems are mainly made of cold-formed steel, structural steel, galvanized steel, stainless steel and composite materials.

- Cold-formed steel is often used for non-load-bearing walls and light structures due to its light weight and high strength;

- Structural steel is used for load-bearing components, such as beams and columns, and is suitable for high-rise buildings.

- Galvanized steel is treated with zinc for corrosion protection and is suitable for exterior wall frames or humid environments.

- Stainless steel is used in situations where high corrosion resistance is required, such as exterior decoration or special purposes.

- In addition, some steel frames also use composite materials, such as fiberglass or aluminum, to meet lightness or insulation requirements.

Components of a Steel Frame System

| Component | Details |

| Main Structures | Studs, Tracks, Beams, Trusses |

| Connectors | Bolts and Screws, Braces and Reinforcements |

| Accessories | Shims and Fixings, Anti-vibration Components |

| Peripheral Systems | Insulation and Thermal Materials, Cladding Materials |

| Auxiliary Systems | Ceiling Systems, Window and Door Frames |

What Are the Different Types of Steel Frame Systems?

1. Skeleton Steel Framing

Skeleton matal framing are one of the most common forms of high-rise building structures. In this system, a steel frame forms the “skeleton” of the building, and all floors, roofs, and other structures are attached to this frame.

The frame is mainly composed of vertical columns and horizontal beams, which can effectively share and transfer loads. This type of frame is particularly important in high-rise buildings and complex structures because it can provide strong bearing capacity while maintaining the stability of the building.

2. Wall Bearing Framing

Wall bearing steel framing is another common form of steel structure. In this system, the bearing role of the steel frame is not limited to the frame itself, but the wall also bears part of the load. The steel frame shares the weight of the superstructure through its connection with the wall. This design is often used in low-rise buildings because it allows for simpler structural design and construction.

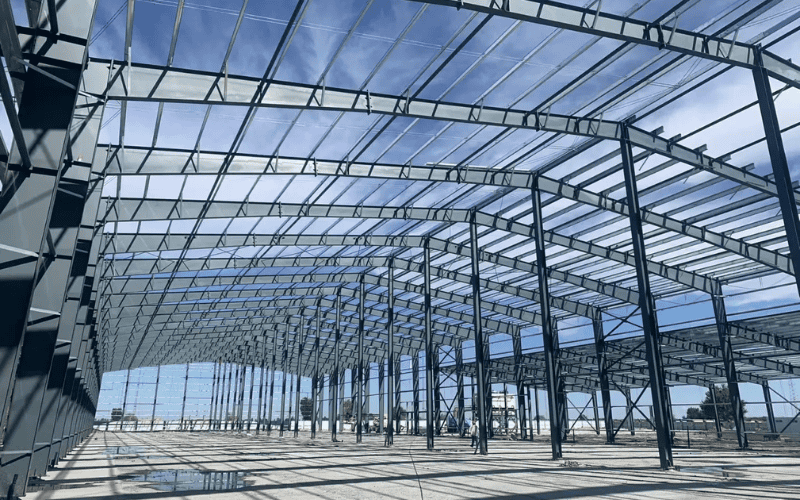

3. Long Span Steel Framing

Long span steel framing systems are mainly used for building structures that require large bays and few supporting columns. By using longer steel beams and trusses, long-span steel frames can provide spacious interior spaces for buildings and reduce or avoid the interference of intermediate columns. This design is ideal for buildings with large space requirements such as large venues, warehouses or sports stadiums.

4. Structural Steel Framing

Used for large commercial buildings, high-rise buildings, multi-story buildings or industrial facilities, suitable for load-bearing structures such as beams, columns and trusses, with high strength and stability.

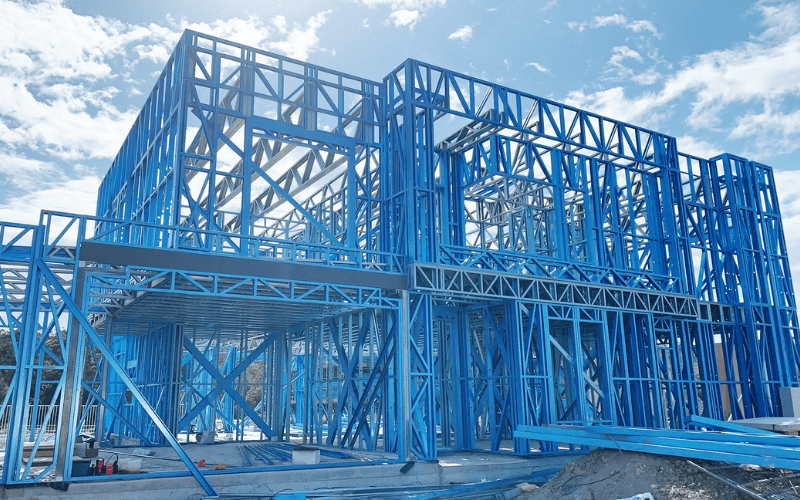

5. Light Gauge Steel Framing, LGSF

The light steel framing system uses thinner steel (such as cold-bent thin-walled steel) as the main material and is suitable for lightweight buildings. It is more economical and faster to construct than traditional steel framing systems, and is usually used for low-rise residential or small commercial buildings. The light steel framing system is ideal for projects with tight budgets or that need to be built quickly.

6. Pre-Engineered Steel Framing

The prefabricated steel framing system involves fabricating, processing, and assembling steel components in a factory setting before transporting them to the construction site for swift installation. This approach enhances construction efficiency while guaranteeing superior quality control and precision. Prefabricated steel framing systems are often used in large projects that require rapid construction or standardized design, such as factories, schools, residential homes, commercial buildings, etc.

These different types of sfs framing are each suitable for different engineering needs. Choosing the right system can ensure that the building achieves the best balance in terms of safety, durability and economy. According to your project needs, we can provide you with detailed technical support to help you choose the most suitable steel frame type to ensure the smooth progress of the project.

Benefits of Steel Framing Systems for You

More Durable, Longer Lifespan

Steel has high strength and resistance to deformation, cracking, moisture, and corrosion. Compared to wood or traditional materials, it ensures a longer lifespan with lower maintenance costs.

Faster Construction, Shorter Project Timeline

Since steel framing components are prefabricated, they can be quickly assembled on-site, reducing construction time by 30% or more compared to conventional methods.

Flexible and Customizable SFS Designs

Steel framing systems are adaptable to residential, commercial, and industrial projects. They allow for customized layouts and can be modified or expanded in the future.

Efficient Transportation, Lower Logistics Costs

Lightweight steel components are easier to transport than traditional building materials. Prefabrication reduces on-site processing, lowering both transportation expenses and construction waste.

Energy-Efficient and Eco-Friendly

Steel is a fully recyclable metal, making it a sustainable choice. Combined with insulation layers and energy-saving glass, steel structures enhance building efficiency and reduce long-term energy costs.

Superior Safety: Earthquake & Wind Resistance

Steel framing offers exceptional resistance to seismic activity and strong winds, making it ideal for areas prone to earthquakes and extreme weather conditions. This enhances building safety and reduces repair risks.

Higher Cost-Effectiveness, Lower Long-Term Expenses

While initial costs may be slightly higher than traditional materials, faster construction, lower maintenance, and superior durability make steel framing systems a cost-effective investment over time.

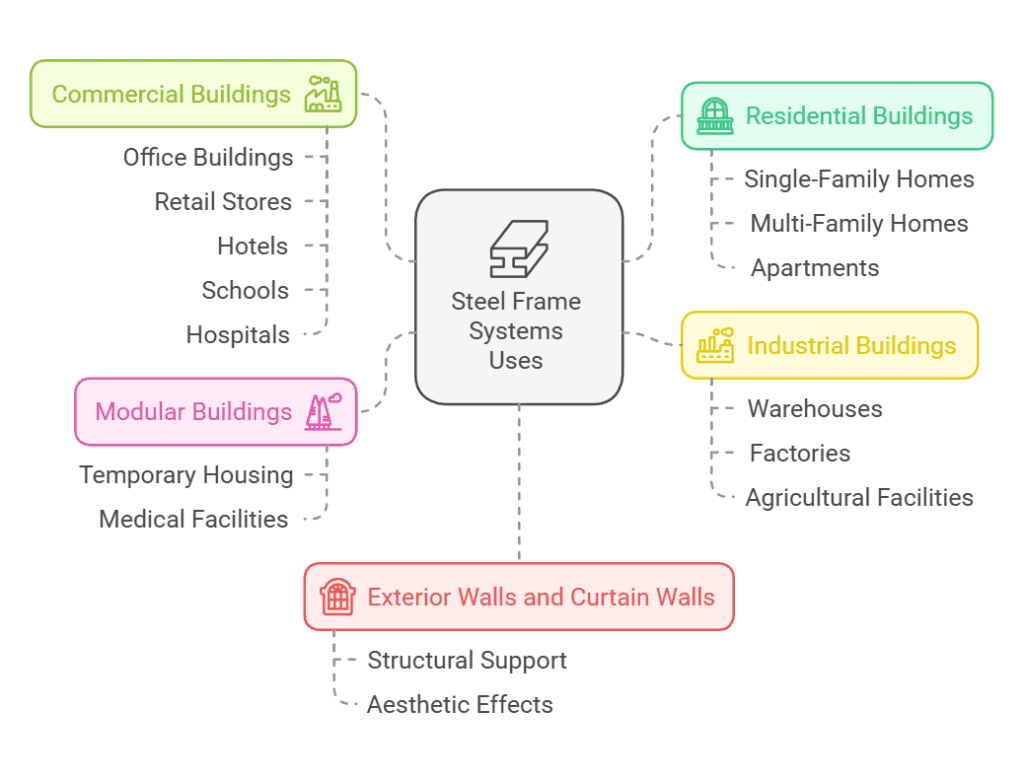

Application of Steel Frame System

Steel structural frames are widely used in high-rise buildings, industrial plants, commercial facilities, infrastructure and residential buildings. Their high strength and earthquake resistance make them ideal for office buildings, stadiums and bridges.

Lightweight steel structures are also suitable for modular homes and temporary buildings, enabling fast construction and environmental protection and energy saving. Steel frames can also be used in hospitals, schools and logistics centers to ensure stability and long-term durability.

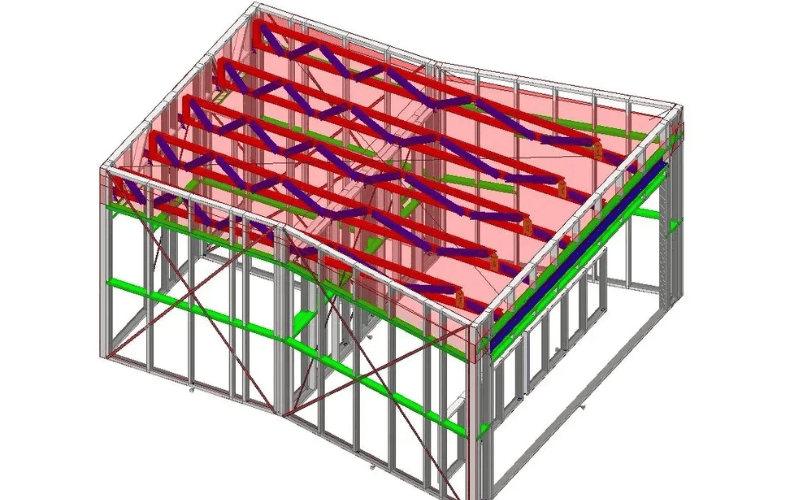

Manufacturing and Installation of Steel Frame Systems

The manufacturing of steel frame systems usually adopts the cold rolling process, which makes the steel components light and strong by rolling the steel into shape at room temperature. This process not only enhances the strength of the steel, but also ensures the high precision and consistency of the components, which is very suitable for mass production.

Most steel frame components undergo initial manufacturing in a factory setting before being transported to the construction site for assembly. This method not only saves on-site construction time, but also reduces costs and improves the quality and efficiency of construction.

The installation of steel frames is very simple, usually connected by bolts or welding, and no wet work is required, which means that construction can be carried out smoothly even in bad weather. The overall installation process is faster and more efficient, and adapts to various construction environments.

Maintenance of Steel Frame Systems

Before our steel framing products leaving the factory, we have completed the anti-corrosion treatment, and all surface coatings have been strictly inspected to ensure uniformity without omissions.

The component dimensions and tolerances meet the requirements, and the welding parts have been non-destructively tested to ensure structural stability, and the service life is usually more than 50 years. To further extend the service life, we recommend that you perform regular maintenance inspections during use:

Regular inspections: Perform a comprehensive annual inspection of the load-bearing structure, connection points and welding parts of the steel frame, as well as the corrosion of the steel surface, especially in humid, salt spray or highly polluted environments. When cracks, deformation or corrosion are found, repair them in time to prevent the problem from expanding.

Anti-corrosion maintenance: Reapply damaged or worn surface coatings as needed, and clean the surface of the steel frame regularly to avoid material accumulation and accelerated corrosion.

Drainage system maintenance: Ensure that the drainage system is unobstructed, check the drainage channel after rain, and avoid water accumulation from damaging the steel structure.

Load and safety management: Avoid applying items or equipment that exceed the design load on the steel frame, and check regularly to prevent equipment from colliding with the frame.

Prevent vibration and impact: If there is a strong vibration source around the system, regularly check the connection parts and add shock absorption measures.

Is Steel Framing Worth the Investment?

- Higher initial costs: The initial investment in steel frame systems is usually higher than wood and concrete, but the overall cost is relatively manageable due to its lower long-term maintenance costs.

- Low insurance costs: Steel frames have good fire and disaster resistance, so insurance costs are usually low, further reducing overall costs.

- Quick payback: The fast construction and low maintenance requirements of steel frame systems allow buildings to be put into use earlier, resulting in a faster return on investment.

Comparison of Steel Framing System with Other Materials

| Comparison Item | Steel Framing System | Wood | Concrete |

| Strength & Durability | High strength, durable, fire-resistant, and seismic-resistant. | Prone to moisture, rotting, and pest damage, less durable. | High strength but heavier, lower seismic performance. |

| Maintenance Requirements | Low maintenance, minimal repairs needed. | Requires regular checks and maintenance, affected by environmental factors. | Low maintenance, but may require crack repairs. |

| Construction Time | Fast construction, with prefabricated components for quicker assembly. | Longer construction time, especially for large projects. | Construction time can be lengthy due to curing and setting. |

| Cost | Higher initial cost but lower long-term maintenance costs. | Generally lower initial cost, but higher long-term maintenance. | Moderate initial cost, but can be expensive due to material and labor costs. |

| Environmental Impact | Steel is recyclable, reducing environmental impact. | Renewable but less sustainable over time due to potential for decay. | Concrete is energy-intensive to produce, but durable. |

Structural System vs Steel Frame

Structural System

- What it is: The complete framework that supports a building, including foundations, walls, floors, and roofs.

- Materials: Can be made of concrete, wood, masonry, or steel.

- Scope: Broader, covering all load-bearing elements.

- Examples: Load-bearing walls, concrete frames, shell structures.

Steel Frame

- What it is: A specific type of structural system using steel beams, columns, and connections.

- Materials: Exclusively steel.

- Scope: Focused on the steel skeleton of a building.

- Examples: Skeleton framing, light gauge steel, long-span steel frames.

Key Differences of Steel Frame & Structural System

- Material: Structural systems use various materials; steel frames are only steel.

- Flexibility: Steel frames offer more design flexibility.

- Applications: Steel frames are ideal for high-rise, industrial, and long-span buildings.

- Speed: Steel frames are faster to construct due to prefabrication.

After the above detailed introduction, I trust you now have a comprehensive understanding of the types, benefits, and maintenance practices associated with steel frame systems.

We are committed to providing customers with high-quality steel frame solutions and providing professional support in every link from design to construction. We aim to achieve “zero defects” and every steel beam and every connection point undergoes strict quality inspection.

If you are considering using a steel frame system or have any questions about steel frames, we are happy to provide you with professional advice and solutions. Please contact us now to learn more and start your construction project!

FAQs

Is the steel frame system more expensive than wood?

Yes, the initial cost of the steel frame system is usually higher than that of wood, but the long-term return on investment is higher due to its lower maintenance cost and longer service life.

Is the steel frame system suitable for high-rise buildings?

Yes. The steel frame system is very suitable for high-rise buildings because it has strong load-bearing capacity and good earthquake resistance, and can support larger loads and building heights.

How does the steel frame system perform in a fire?

The steel frame system has high fire resistance, steel is not easy to burn, and can maintain its strength at high temperatures, so it can effectively improve the safety of the building.

How is the environmental performance of the steel frame system?

The environmental performance of the steel frame system is good. Steel is a recyclable material and can be reused after the building is demolished, reducing the negative impact on the environment. In addition, steel frame buildings can usually meet green building standards and help obtain environmental certifications such as LEED.