A steel roof system is a sophisticated integration of metal panels and a robust support framework, engineered to deliver durable, efficient, and versatile coverage for buildings. It’s not just there to look good—it handles everything from waterproofing to thermal insulation and provides solid structural support. Steel roof systems are especially loved for how they bring strength and flexibility to the entire structure. They’re not just standalone elements—they play a key role in supporting the building as a whole.

In this article, we’ll break down what makes up a steel roof, what makes them tick, and exclusive design principles provided. Whether you’re designing for an industrial space, a commercial building, or something more specialized, understanding these systems will give you the edge in creating a reliable and efficient roofing solution.

Composition of Steel Roof Systems

Steel roof systems are built from key components—steel frames, coverings, connectors, and insulation—each designed to ensure strength, weather resistance, and energy efficiency. Together, they create a durable and adaptable solution for various building needs.

Main Components

The main components of a steel roof system—steel frame, roof covering materials, connectors and fasteners, and waterproofing and insulation layers—work together to create a robust, durable, and efficient structure tailored to meet diverse architectural and environmental demands.

Steel Frame

The steel frame acts as the backbone of the roof system, providing the necessary structural support and integrity. Made from high-strength steel, it comes in different forms—trusses, beams, and girders—each customized to fit specific architectural needs. Designed to handle heavy loads, like snow, wind, and seismic forces, steel frames are incredibly lightweight thanks to their high strength-to-weight ratio. This not only makes them strong but also reduces the load on the building’s foundation, making them a smart and cost-effective choice for large-span structures.

Roof Covering Materials

Selecting the right roofing materials greatly affects the system’s efficiency and performance. Common options include corrugated steel sheets, standing seam panels, and insulated sandwich panels. We provide cold-rolled steel sheets and galvanized steel panels, manufactured in-house and rigorously tested to ensure superior mechanical properties. These materials are engineered to endure harsh weather conditions, from heavy snowfall to strong winds, ensuring long-term protection for your building.

Connectors and Fasteners

Connectors and fasteners are key players in steel roof systems, making sure every part works together smoothly. Connectors include elements like plates, brackets, and gussets, which join various components. Bolts, screws, and rivets are the common fasteners used, each chosen based on load requirements and environmental conditions. Quality fasteners are a must—they prevent loosening over time and help keep the system stable and safe. Their durability and precision are crucial for the roof’s long-term performance.

Waterproofing and Insulation Layers

Waterproofing and insulation are essential to ensuring a comfortable, dry, and energy-efficient interior. Materials like PVC membranes, EPDM rubber, and polyurethane foam are highly recommended for waterproofing, as they provide excellent protection against water ingress. For insulation, fiberglass and mineral wool are proven to be effective, offering both thermal resistance and soundproofing benefits. These layers not only prevent leaks but also significantly improve energy efficiency by minimizing heat transfer, which can reduce long-term operational costs.

Failing to use these materials correctly can lead to water infiltration, increased thermal loss, and compromised structural integrity, which may shorten the roof’s lifespan and increase maintenance costs.

Auxiliary Systems

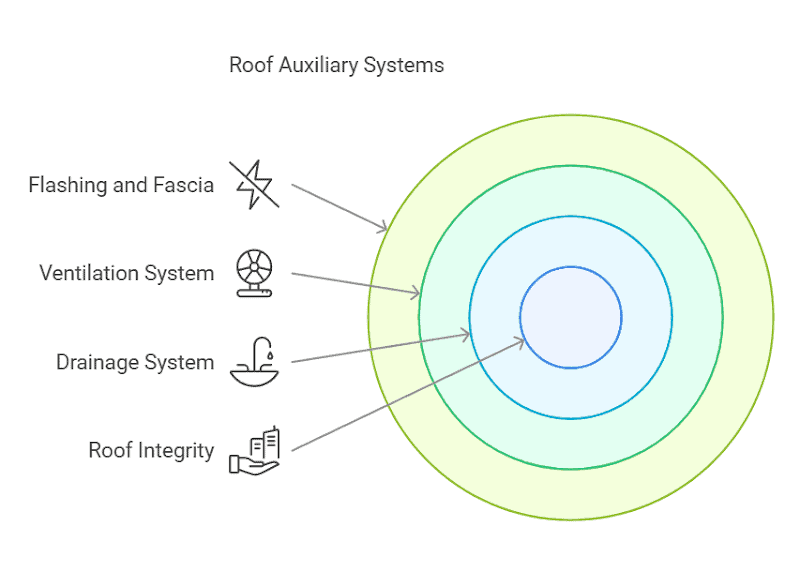

Auxiliary systems, including drainage, ventilation, and protective elements like flashing and fascia, are integral to the performance and longevity of a steel roof system, ensuring it remains functional, durable, and visually cohesive.

Drainage System

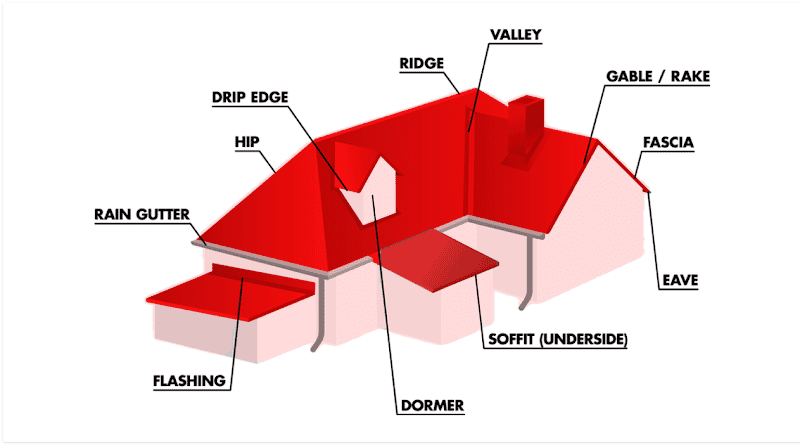

A properly designed drainage system is crucial to avoid water accumulation, which can cause leaks and long-term structural damage. Key components like valleys, drip edges, and rain gutters must work in harmony to direct water away from both the roof and foundation. Valleys, where two roof slopes converge, are especially important for guiding water flow efficiently.

Drip edges are crucial for stopping water from infiltrating the roof structure, preventing corrosion or long-term weakening. Without them, the entire structure’s integrity could be at risk.

Ventilation System

Effective ventilation is vital for controlling temperature and moisture within the building, especially in spaces like attics or warehouses. Properly placed soffits, ridge vents, and other venting components help maintain airflow, preventing the buildup of heat and humidity. Without adequate ventilation, moisture can lead to mold growth, while poor air circulation could result in temperature imbalances that affect both the roof and interior environment.

Flashing and Fascia

Flashing is a crucial element in any steel roof system, typically made of durable metal, and is installed at roof intersections and edges to prevent water infiltration. It’s designed to act as a continuous waterproof barrier, effectively handling thermal expansion and structural shifts that naturally occur over time. Proper flashing installation is vital to prevent leaks and ensure lasting roof protection.

Fascia, the vertical board along the roof’s edge, plays a dual role. Not only does it support the gutter system, but it also enhances the overall aesthetic of the roof, giving it a clean and finished look. Proper installation of fascia is key to maintaining both functionality and appearance, ensuring that water flows effectively into the gutters without compromising the structural integrity of the roof.

Design Principles of Steel Roof Systems

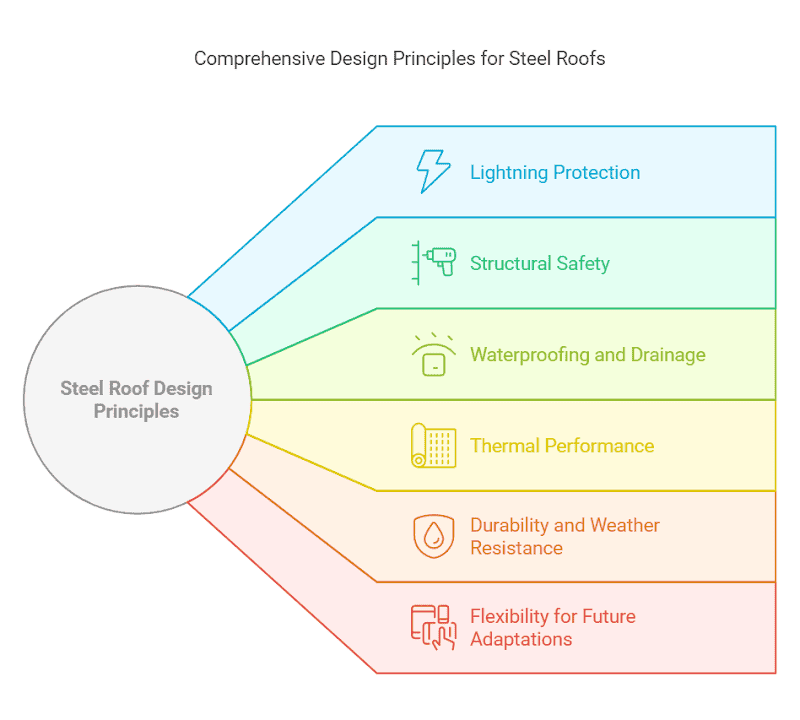

Creating a steel roof system demands a careful balance of strength, functionality, and visual appeal. The following principles ensure that the system performs reliably, efficiently, and sustainably over its lifespan.

Lightning Protection System

Steel roofs are naturally conductive, for large steel structure roofs, we don’t suggest install traditional tall lightning rods. Instead, the roof’s design itself handles lightning protection through a network of conductors. The grid size for the lightning protection system is carefully selected based on the building’s specific lightning protection category, with attention to local standards. When designing the roof panels, the thickness is determined by factors such as wind load, snow load, and clearance distances to ensure structural integrity and allow proper integration of the lightning protection system. This ensures lightning is safely redirected while maintaining the roof’s strength and stability.

Prioritize Structural Safety

A steel roof system must be designed to withstand various loads, including dead loads (e.g., self-weight, insulation), live loads (e.g., maintenance activities), wind, snow, and seismic forces. Accurate load calculations and proper material selection are critical to ensure the structure remains stable under extreme conditions. Additionally, fire safety measures, such as fire-resistant coatings or cladding, should be incorporated to maintain structural integrity during emergencies.

Ensure Effective Waterproofing and Drainage

The main purpose of a roof is to guard against water intrusion. A well-designed system should include proper slope gradients, durable waterproofing materials, and efficient drainage components like gutters and downspouts. These elements work together to prevent leaks and water accumulation, which can compromise the roof’s performance and longevity.

Optimize Thermal Performance

To minimize heat transfer between the interior and exterior, insulation materials such as mineral wool or polyurethane foam should be integrated into the roof system. The thickness and placement of these materials should be tailored to the local climate, ensuring energy efficiency and maintaining a comfortable indoor environment.

Enhance Durability and Weather Resistance

Steel roofs are exposed to harsh environmental conditions, including UV radiation, temperature fluctuations, and moisture. Using weather-resistant materials, such as galvanized or coated steel panels, ensures the system remains functional and visually appealing over time. Regular maintenance, including inspections and timely repairs, further extends the roof’s lifespan.

Incorporate Flexibility for Future Adaptations

Designing with future needs in mind is essential. Providing load allowances and adaptable features, such as pre-planned areas for solar panel installation, allows the roof system to evolve with changing requirements. This forward-thinking approach supports sustainability and reduces the need for costly modifications later.

Balance Aesthetics with Functionality

While functionality is key, the aesthetics of a steel roof are equally important. Modern options provide a range of finishes, colors, and profiles to enhance the building’s design. Functional elements, such as skylights or integrated ventilation systems, can be seamlessly incorporated to enhance both usability and aesthetics. We’ve already provided skylight designs for numerous steel structure warehouses, enhancing both natural light and overall functionality while maintaining the building’s aesthetic appeal.

Designed to Meet Your Needs

Steel truss systems continue to shape the future of construction, with advancements in smart design and sustainable practices driving innovation. As a leading steel truss manufacturer, we are committed to delivering high-quality, efficient, and cost-effective solutions tailored to your needs. Our expertise goes beyond trusses to encompass complete steel structure systems, ensuring every component of your project is seamlessly integrated for optimal performance.

As a leading steel structure building manufacturer, our strength lies in tailoring roof systems to your specific needs. For warehouses, we prioritize load-bearing capacity and waterproofing; for swimming pools, we focus on light transmission and anti-condensation technology; and for industrial facilities, we ensure easy installation and maintenance access. Our expertise in large-span steel structure buildings enables us to design roof systems that seamlessly integrate with the overall framework, ensuring both functionality and aesthetic harmony. Whatever your project needs, we provide solutions that blend innovation, quality, and dependability.

By choosing steel roof systems, you’re investing in a durable, sustainable, and cost-effective solution that stands the test of time. Let us help you build a steel structure building with a sturdy roof system that not only protects your space but also enhances it.

FAQ

What Is the Best Type of Metal Roofing System?

The best type depends on your project needs, but standing seam metal roofs are often preferred for their durability, weather resistance, and sleek appearance.

What Is a Metal Roof System?

A metal roof system is a type of roofing made from metal panels or tiles, offering strength, longevity, and weather resistance, often used in commercial and residential buildings.

Do Steel Roofs Require Additional Structural Support?

Yes, steel roofs require additional structural support, such as steel framing or trusses, to handle the weight and ensure stability.

Are Metal Roofs Noisy When It Rains?

Metal roofs may be noisy during heavy rain, but adequate insulation and underlayment can greatly minimize the sound.