Steel grid structures are advanced load-bearing systems that combine light weight, high strength, and architectural flexibility. They use interconnected steel members to form planar or space grids—ideal for stadiums, exhibition halls, and industrial buildings that require large, open spans.

In this guide, you’ll learn the main types of grid systems, their engineering advantages, and the step-by-step production process that ensures precision and reliability. You’ll also see how these systems are applied across modern construction projects worldwide and why choosing a certified steel structure manufacturer can significantly improve project efficiency, quality, and cost control.

At SteelPRO PEB, a global PEB structures manufacturer and producer, every grid system is designed and fabricated under ISO and CE standards to meet international engineering codes. With advanced automation and proven expertise, we help architects, builders, and contractors achieve durable, efficient, and aesthetically refined steel grid solutions—from design concept to final installation.

Types of Steel Grid Structures

Steel grid structures come in various forms, each suited to different engineering and architectural needs. From simple planar grids to complex three-dimensional systems, every type of structural grid system offers unique mechanical behavior and load advantages. Understanding these differences helps engineers select the most efficient and economical solution for any project.

Structural Grid System Overview

Before diving into specific types, it’s important to understand the core idea of a structural grid system.

This system refers to a geometric arrangement of steel members—beams, trusses, or tubular elements—connected at nodes to form a load-bearing framework.

Grid systems are commonly classified by their spatial configuration (planar or space type) and their structural composition (single-layer or multi-layer), which determine how forces are distributed across the structure.

Planar Steel Grid Structures

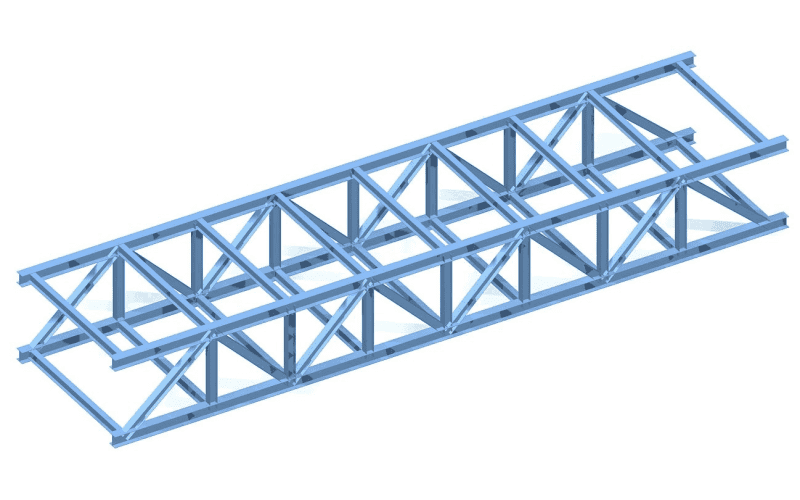

Planar steel grid structures use parallel or intersecting members to form flat frameworks—usually rectangular, square, or triangular.

They are lightweight, cost-efficient, and ideal for medium-span buildings such as warehouses and workshops.

These grids work with beams or columns to distribute loads evenly across the roof or floor surface, providing a simple yet reliable design for many industrial and commercial facilities.

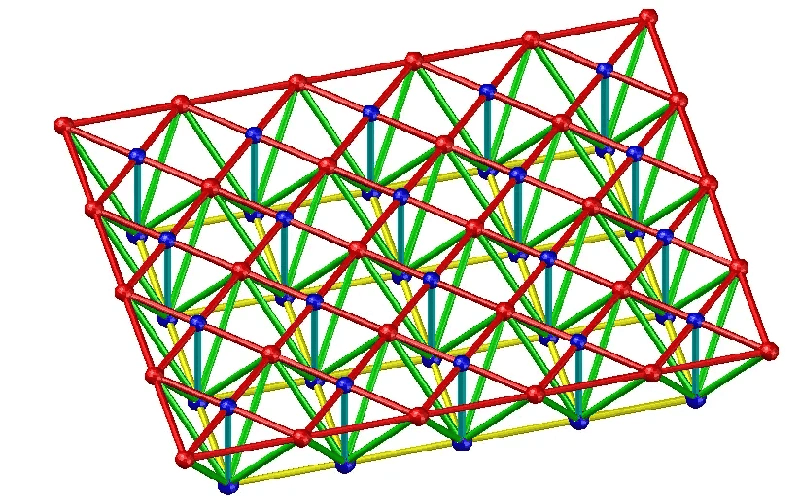

Space Steel Grid Structures

Space grid structures take the concept further, combining multiple planar layers into a three-dimensional lattice.

Their triangulated design gives them outstanding rigidity and large-span performance, allowing for column-free spaces used in stadiums, exhibition halls, and airports.

Because of their modular and prefabricated nature, they can be produced in factories and assembled rapidly on-site—balancing strength, beauty, and efficiency.

Key Considerations for Building Space Steel Grid Structures

- Material Selection: High-strength steel grades (Q345, S355) for load capacity and durability.

- Load Distribution: Reinforced nodes to ensure uniform stress transfer.

- Modular Fabrication: Pre-assembled sections improve efficiency and reduce installation time.

Working with a certified steel grid system manufacturer ensures quality consistency across design and fabrication.

Single-Layer & Double-Layer Grid Systems

- Single-Layer Grids: Lightweight, simple to install, suitable for temporary or small-span structures.

- Double-Layer Grids: Provide higher stiffness and stability, ideal for airports, large warehouses, and industrial complexes.

Structural Grid System Composition and Load Behavior

Steel grid structures can also be classified by geometric form, which determines their load transfer and architectural potential:

- Crossed Truss System: Intersecting trusses for medium to large spans, widely used in industrial roofs.

- Triangular Pyramid System: Excellent stability, suitable for cultural or exhibition centers.

- Square Pyramid System: Balanced strength and versatility, perfect for stadiums or terminals.

Hexagonal Pyramid System: Distinctive visual effect for specialized architectural projects.

Advantages of Steel Grid Structures

Steel grid structures provide a combination of technical performance and manufacturing efficiency, making them one of the most advanced solutions for modern steel construction.

High Strength-to-Weight Ratio

Due to their triangulated configuration, grid systems achieve exceptional strength while remaining lightweight. This reduces foundation loads and material costs, offering superior structural efficiency compared to traditional beam-column systems.

Large-Span Capabilities

The space grid design allows for expansive, column-free interiors ideal for industrial plants, stadiums, and exhibition halls. By minimizing intermediate supports, steel grids create open and flexible layouts for a wide range of architectural purposes.

Modularity and Factory Prefabrication

Each component of the steel grid is prefabricated in the factory using automated production lines for cutting, welding, and surface treatment. This factory-based process shortens on-site construction time, lowers labor costs, and ensures precise dimensional accuracy—helping project owners achieve faster delivery and stable quality.

Quality Assurance and International Certification

At SteelPRO PEB, all steel grid systems are produced under strict ISO 9001 and CE-certified processes. Every piece undergoes inspection for strength, weld quality, and corrosion protection. This ensures long-term reliability and compliance with global standards such as Eurocode 3 and AISC 360.

Sustainability and Environmental Performance

Steel grid structures are fully recyclable and support green construction initiatives. Factory fabrication minimizes waste and emissions, aligning with sustainable building goals. By optimizing material use and transportation efficiency, steel grids contribute to reducing the carbon footprint of large-scale projects.

Aesthetic and Functional Flexibility

The geometric freedom of grid structures allows architects to design elegant, lightweight, and visually striking forms without compromising performance. Whether it’s a dome, vault, or wave-shaped roof, grid systems combine form and function seamlessly.

The Production Process of Steel Grid Structures

At SteelPRO PEB, a certified PEB Structures Manufacturer and Steel Structure Producer, every grid system is manufactured under strict quality management and international standards. The entire process—from design to inspection—is conducted within our modern factory, ensuring high precision, cost efficiency, and consistent performance for global projects.

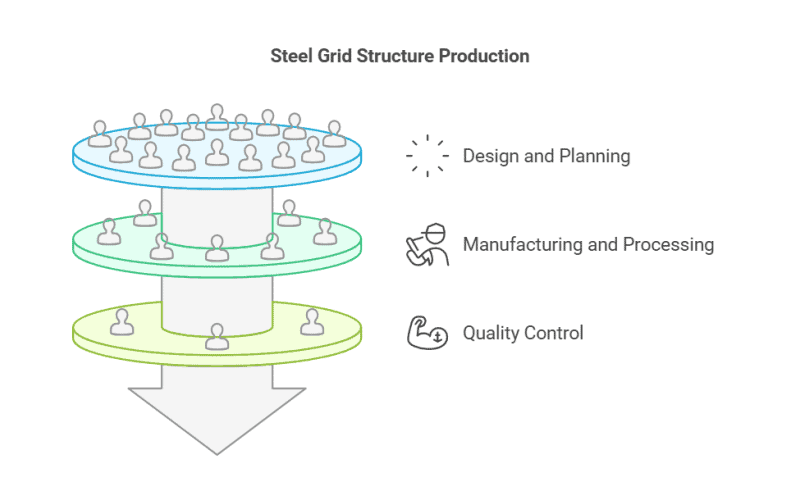

Design and Planning

The foundation of every grid structure lies in accurate design and detailed planning. This stage involves load analysis, geometric optimization, and material selection to achieve structural balance between strength, economy, and aesthetics. Using advanced modeling tools and simulation software, we ensure the grid system meets both architectural intent and engineering performance.

Manufacturing and Processing

Once the design is finalized, all fabrication takes place in our automated production facility. High-precision CNC cutting machines, intelligent welding robots, and laser processing systems are used to produce each member and node with millimeter accuracy.

Factory-controlled fabrication provides the following benefits:

- Reduced installation time and on-site welding

- Enhanced quality uniformity and safety assurance

- Seamless integration of modular sections for faster assembly

Every step—cutting, drilling, welding, and surface treatment—is performed under ISO 9001 and CE certification standards.

Quality Control and Testing

Quality is the cornerstone of every grid structure we deliver. All steel members undergo tensile and dimensional testing, while welded joints are inspected through ultrasonic and X-ray analysis. Surface coatings are checked for thickness and adhesion to ensure long-term corrosion resistance. Our QA process follows international standards including Eurocode 3 and AISC 360, guaranteeing global compliance and durability for decades of service life.

Through strict factory production control and continuous testing, SteelPRO PEB ensures every steel grid system meets structural, aesthetic, and sustainability requirements. All prefabrication and quality inspections are completed in-house, ensuring faster on-site installation, lower costs, and superior precision.

Applications of Steel Grid Structures in Modern Construction

Steel grid structures are widely recognized for their large-span capabilities and modular precision, making them ideal for a broad range of engineering and architectural projects.

Steel space grid structures, in particular, are extensively used for roofing systems in stadiums, exhibition centers, and airport terminals—delivering both strength and visual appeal while minimizing internal supports.

| Application | Benefits of Steel Grid Structures |

| Sports Stadiums | Large-span space grid roofs create unobstructed views and open interiors, improving the spectator experience. |

| Exhibition & Conference Centers | Flexible layouts with column-free halls enable easy event reconfiguration and high aesthetic value. |

| Airport Terminals | Lightweight steel grids support expansive, skylit roofs while ensuring structural stability and energy efficiency. |

| Industrial Facilities | High-strength grids provide durable and low-maintenance enclosures for factories, warehouses, and assembly plants. |

| Commercial Buildings | Open-plan structures allow for adaptable spaces and faster construction timelines. |

| Bridges & Overpasses | Lightweight yet strong grid members reduce dead loads and improve seismic performance. |

Beyond these applications, space grid systems are also employed in transportation hubs, exhibition pavilions, and industrial logistics centers, demonstrating their versatility and reliability in modern infrastructure.

At SteelPRO PEB, we have successfully delivered grid structure systems for large-scale projects across Asia, the Middle East, and Southeast Asia—including stadiums, airport roofs, and high-tech industrial warehouses. Our factory-engineered systems ensure optimal performance and installation speed for every project.

Why Choose SteelPRO PEB for Your Steel Grid Structure Project

When you’re investing in a steel grid structure, your biggest risks are delays, misalignment, and cost overruns. That’s where SteelPRO PEB makes the difference — not just as a manufacturer, but as a partner who helps you deliver projects faster and safer.

Every grid member and node is fabricated in our ISO- and CE-certified factory with millimeter precision, so your onsite installation fits perfectly the first time—no costly rework or welding adjustments. Because production runs on 24 automated lines, your schedule stays on track even for large-span stadiums or industrial roofs. Our quality control system based on Eurocode 3 and AISC 360 ensures each module passes load and weld testing before shipping, giving you structures that meet international audit requirements effortlessly.

You don’t just get steel components — you get a reliable, installation-ready system that cuts labor time, minimizes risk, and protects your project margins.

Talk to SteelPRO PEB to see how factory-engineered grid systems can simplify your next build.

What’s the difference between a steel grid structure and a space frame structure?

While both systems distribute loads through interconnected members, steel grid structures typically use two or more intersecting layers forming flat or slightly curved surfaces. Space frames, on the other hand, are fully three-dimensional frameworks capable of forming complex shapes like domes or vaults. Grid systems emphasize modularity and cost efficiency, whereas space frames focus on flexibility in geometric design.

How are steel grid structures connected and assembled on site?

Each module is prefabricated in the factory, then connected through bolted nodes or welded joints according to design drawings. Bolted joints allow faster installation and easier maintenance, while welded connections enhance rigidity for heavy-load applications. This hybrid assembly method ensures accuracy and long-term performance even in large-span projects.

Can steel grid systems be customized for different architectural needs?

Yes. Every grid system can be tailored in span, geometry, and finish to meet project-specific requirements. Architects often adjust grid spacing and shape to balance aesthetics and load efficiency, while manufacturers handle precise fabrication and surface protection. SteelPRO PEB provides full customization for structure type, size, and coating systems to suit diverse climate and design conditions.

What quality checks are performed before delivery?

All grid members and nodes undergo dimensional inspection, weld testing, and surface treatment verification. Load-bearing components are tested under simulated stress to ensure strength and stability. Each batch includes full quality documentation compliant with ISO 9001, CE, and Eurocode 3 standards.