A steel structure foundation is the essential element that supports and stabilizes every steel building — from light PEB warehouses to complex industrial plants. It transfers loads safely to the ground, ensuring strength, durability, and long-term performance.

In this guide, you’ll learn the types of foundations used in steel construction (shallow, deep, and mixed systems), the key design factors that influence safety and cost, and the construction process that ensures precision and reliability. We’ll also cover essential maintenance and inspection practices that extend service life, along with professional guidance from the manufacturer’s perspective.

Backed by certified engineering expertise, SteelPRO PEB provides complete foundation design, fabrication, and installation support — helping you build safer, more efficient, and cost-effective steel structure foundations from the ground up.

Types of Steel Structure Foundations

The types of steel structure foundations can be selected based on the nature of the soil, the size of the building load, and the specific needs of the structure. Foundations are generally divided into three categories: shallow foundations, deep foundations, and mixed foundations. Each type of foundation has its applicable scenarios. Next, we will introduce these foundation types in detail.

Shallow foundation

Shallow foundations are commonly used where the soil has good bearing capacity and the structural load is relatively light. Typical applications include light industrial steel workshops, PEB warehouses, and low-rise commercial buildings.

- Isolated Foundation: Simple and economical, ideal for single-column steel structures or light industrial workshops.

- Joint Foundation: Combines multiple columns on a shared base to distribute loads evenly — suitable for multi-column industrial buildings.

- Strip Foundation: Long continuous footing used beneath walls or aligned columns; effective for steel frame warehouses and factory buildings.

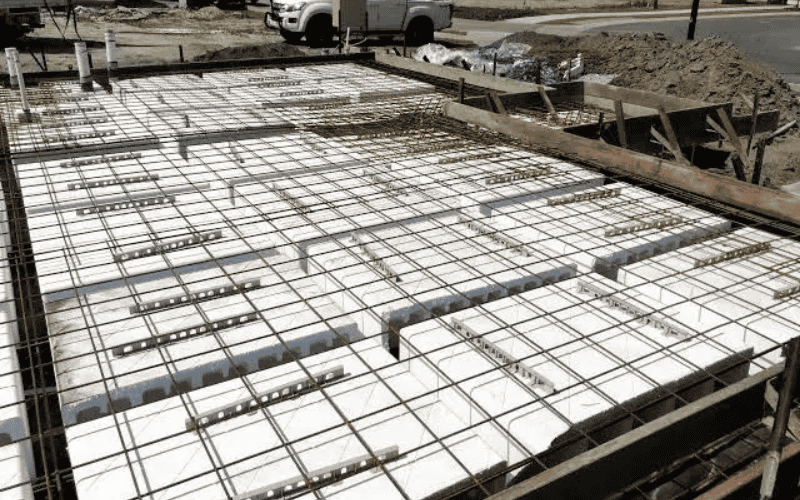

Raft Foundation: Used where soil bearing capacity is low, especially in soft soil areas or industrial sites with large equipment. It spreads load uniformly and prevents differential settlement.

Deep foundation

Deep foundations transfer building loads to deeper, stronger soil layers or bedrock. They are commonly used for large-span steel structures, high-rise buildings, or PEB plants in areas with weak surface soil.

- Pile Foundation: Suitable for soft or waterlogged soil. By extending piles deep underground, the structure achieves stability and load transfer.

- Bored Pile Foundation: Provides high precision and adaptability for heavy-load industrial or bridge projects.

- Pier Foundation: Medium-depth design used for bridges and special structures requiring both strength and economy.

Caisson Foundation: Designed for underwater or coastal projects like ports or offshore steel structures, ensuring safe load transfer in challenging conditions.

Mixed foundation

When soil conditions vary or structures have uneven loads, a mixed foundation combines the strengths of both shallow and deep systems.

- Pile Raft Foundation: Blends pile and raft design to handle complex soil conditions, ensuring uniform load distribution and preventing settlement. Widely applied in large steel structure buildings, PEB warehouses, and urban infrastructure projects.

- Floating Foundation: Used for marine or lake-based structures such as offshore platforms or floating docks, balancing buoyancy and load. This special foundation form allows construction in locations where soil bearing capacity is limited.

At SteelPRO PEB, our engineers provide foundation design and material support tailored to your soil conditions and structural layout — ensuring cost efficiency, accuracy, and long-term reliability for every project.

Key Considerations for Steel Structure Foundation Design

Designing a steel structure foundation requires more than calculations. It’s a balance between soil conditions, load requirements, and environmental resilience. Each factor must be analyzed to ensure long-term stability, cost efficiency, and compatibility with the overall steel structure system.

Soil and Site Analysis

The performance of any foundation begins with the soil beneath it. A thorough geotechnical survey determines bearing capacity, water levels, and settlement risk.

- Soil Type: Defines the suitable foundation form — shallow for firm soil, deep or mixed for soft or variable layers.

- Bearing Capacity: Establishes the necessary foundation dimensions and reinforcement levels.

- Groundwater Level: High groundwater requires special drainage and waterproofing measures to maintain stability.

By understanding these parameters, designers can select the most economical and durable foundation type for each project.

Load and Structural Design

Accurate load calculation ensures that every column and footing work together safely and efficiently.

- Dead Load & Live Load: Includes the structure’s self-weight and operational loads.

- Wind & Seismic Loads: Critical for regions prone to earthquakes or high winds, ensuring foundation anchorage strength.

- Column Base Plates & Anchor Bolts: Must be precisely designed to transfer loads evenly and prevent displacement.

Professional foundation design services ensure these calculations meet engineering standards and practical needs. SteelPRO PEB’s design team applies AISC, Eurocode, GB, and other international standards, using tools like TEKLA, STAADPRO, and ETABS to deliver certified foundation drawings for PEB and steel frame buildings. This approach guarantees precision, reliability, and seamless coordination with the upper structure.

Environmental and Durability Factors

Environmental forces can significantly affect long-term performance.

- Seismic Considerations: Reinforced connection systems to prevent structural fatigue.

- Temperature & Soil Movement: Expansion joints and flexible base designs to mitigate stress.

- Corrosion Protection: Anti-rust coatings or cathodic systems safeguard steel interfaces from moisture or chemicals.

Combining these environmental design elements ensures the foundation remains strong, safe, and serviceable for decades, even under changing site conditions.

Steel Structure Foundation Construction Process

Building a reliable foundation for a steel structure requires both precision and coordination. Each stage must meet engineering standards to ensure long-term strength, alignment, and safety.

1. Site Preparation

Every successful foundation begins with proper site preparation.

- Clearing & Leveling: Remove debris and vegetation, then level the site according to design specifications.

- Excavation: Dig to the required depth and ensure stable trench edges.

- Soil Improvement: For weak soils, apply reinforcement methods such as gravel compaction or chemical stabilization to increase bearing capacity.

2. Formwork and Reinforcement Installation

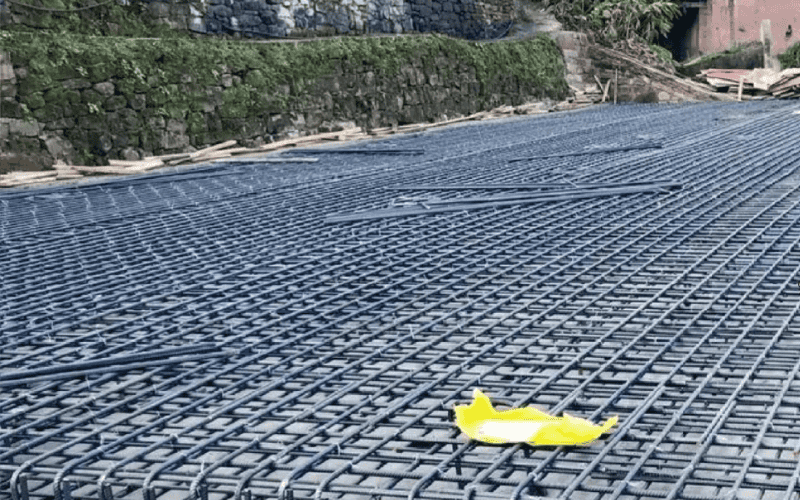

Accurate formwork and reinforcement layout determine the foundation’s strength.

- Formwork: Construct formwork that matches the design shape and dimensions.

- Reinforcement: Place rebar grids precisely to control cracking and improve load transfer.

- Anchor Bolts: Install anchor bolts or embedded plates to connect the steel structure with the foundation accurately — a key step for alignment during erection.

3. Concrete Pouring and Curing

The quality of concrete work defines the foundation’s durability.

- Even Pouring: Ensure consistent vibration and no air pockets.

- Controlled Curing: Maintain moisture and temperature for proper hydration and strength development.

- Surface Finishing: Smooth and level the surface for precise column placement.

Note: Temporary bracing and formwork should remain in place until the concrete achieves full design strength and stability verification.

4. Foundation Alignment and Inspection

After concrete curing, alignment checks are crucial.

- Any deviation is corrected immediately to maintain the accuracy of the steel frame connection.

- Verify anchor bolt positions and foundation levelness.

- Conduct load-bearing and material strength tests before structure installation.

5. Quality Control and Troubleshooting

Even minor foundation issues can affect the entire building.

- Settlement or Unevenness: Addressed by soil strengthening or micro-piling.

- Corrosion Protection: Apply coatings or waterproof layers to exposed components.

- Cracks or Voids: Fill with epoxy or grout for structural restoration.

- Inspection: Conduct periodic checks during and after installation to maintain compliance with safety standards.

Documentation and inspection reports are prepared for every foundation stage to ensure full compliance with international construction and safety standards.

Our experienced engineering team provides on-site technical guidance and installation coordination, ensuring seamless integration between foundation fabrication and steel structure erection. From the ground survey to final inspection, SteelPRO PEB supports every step of your construction process with precision and accountability.

Steel Structure Foundation maintenance and inspection

Even after construction, the foundation remains a living part of the structure — continuously interacting with soil, water, and loads. Proper maintenance and inspection ensure that it performs reliably throughout the building’s service life.

Regular Inspection

A consistent inspection plan helps identify and address potential issues before they compromise structural safety.

Key inspection points include:

- Crack Inspection: Check for visible cracks or surface deformation. Small cracks can signal settlement or thermal stress.

- Corrosion Monitoring: Inspect anchor bolts, exposed rebar, and embedded steel parts for rust or moisture damage, especially in humid or chemical environments.

- Settlement Observation: Measure differential settlement using laser or total station instruments to detect uneven load distribution early.

- Drainage and Waterproofing: Verify the function of drainage systems to prevent water accumulation that could weaken the foundation base.

A detailed foundation inspection checklist should be followed periodically — monthly for new structures, and at least annually for existing industrial facilities.

Maintenance Measures

Preventive and corrective maintenance keeps the foundation in optimal condition and extends its service life.

- Crack Repair: Seal or grout cracks with high-performance repair compounds to restore integrity and prevent water ingress.

- Waterproofing Renewal: Reapply protective coatings or membranes in high groundwater or rainfall areas.

- Corrosion Protection: Use anti-rust paints, galvanizing, or cathodic protection to prevent steel component degradation.

- Soil Protection: Reinforce or compact surrounding soil if erosion or softening is detected.

All foundations designed and supplied by SteelPRO PEB come with structural warranty and technical support, ensuring that each maintenance action aligns with the original engineering specifications.

Long-Term Structural Monitoring

Modern foundations benefit from data-driven monitoring systems. SteelPRO PEB supports clients with long-term tracking of:

- Settlement & Tilt Sensors for real-time subsidence detection.

- Load and Strain Sensors to monitor column reaction and stress.

- Temperature & Moisture Sensors to anticipate soil expansion or contraction cycles.

These monitoring tools not only enhance maintenance efficiency but also provide essential data for evaluating the foundation’s structural health over decades of service.Regular inspection, timely repair, and continuous monitoring form the foundation of reliability. With ISO- and CE-certified engineering standards, SteelPRO PEB ensures that every steel structure foundation remains durable, safe, and fully compliant with international performance benchmarks.

Factory-Direct Steel Structure Foundation Solutions

A strong foundation is the cornerstone of every successful steel structure project. From soil analysis and design calculations to on-site construction and long-term maintenance, each stage determines the building’s safety, stability, and lifespan. When properly engineered, the foundation distributes loads evenly, resists environmental forces, and ensures that the steel structure performs reliably for decades.

Designing and building such foundations requires more than experience.

It demands precision, certification, and technical coordination between design, fabrication, and installation teams. That’s why SteelPRO PEB, a certified PEB & steel structure manufacturer, provides end-to-end foundation design and fabrication support for industrial, commercial, and modular steel buildings. Backed by ISO and CE certifications, advanced production lines, and global engineering expertise, we ensure your foundation system is not only structurally sound but also cost-efficient and compliant with international standards.

Contact SteelPRO PEB today to discuss your foundation design or project requirements. Our technical team will provide a factory-direct quotation and deliver certified steel structure foundation solutions built for long-term reliability and performance.