Steel floor systems began in the 19th century, when cast iron was widely used for its load-bearing and durability. With the emergence of high-strength steel, steel floors gradually replaced cast iron. After entering the 20th century, modern steel floor systems became lighter and stronger, with better earthquake resistance, fire resistance and environmental protection performance, and were widely used in various types of buildings.

We will deeply analyze the types and selection criteria of steel floor systems, how to choose the right floor system according to different building needs, and ultimately provide efficient, economical and sustainable solutions for your project.

What is a steel floor system?

A steel floor system is a structural system supported by steel beams and steel joists, usually combined with concrete slabs to form a composite structure. It mainly supports ground loads through the high strength and durability of steel, and is often used in construction projects that require large spans and high load-bearing capacity.

Main types of steel floor systems

When choosing a steel floor system, the span, structural requirements and budget of the building will determine the appropriate type. Various steel floor systems possess unique characteristics and cater to distinct building requirements. Subsequently, we will delve into the specifics of several prevalent types of steel floor systems.

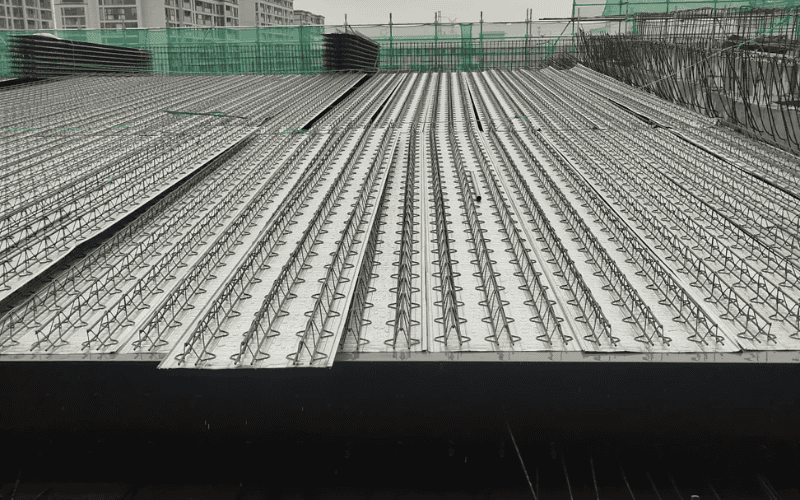

Short span composite beams and metal plate composite floors

Applicable scenarios: This system is particularly suitable for small span buildings, usually used in buildings with a span of 3-4 meters. For example, some small construction projects such as low-rise buildings, warehouses, and shops.

Advantages:

- Low cost: Due to the simple structure and less steel consumption, short span composite beams and metal plate composite floors have cost advantages. For small projects with limited budgets, it is an economical and efficient choice.

- Light weight: Compared with some traditional materials, steel is lighter, which reduces the requirements for foundations and supporting structures and simplifies the construction process.

Disadvantages:

- More columns are required: In order to support the floor, short span structures often require more columns, which will affect the utilization of space. Especially in places where open space is required, it may not be suitable.

- Thick floor: In order to meet the load-bearing requirements, thicker floors are usually required, which may affect the overall height or appearance of the building in some cases.

Long-span composite beams and metal plate composite floors

Applicable scenarios: This system is suitable for buildings with large spans and column-free spaces (10-18 meters). It is extensively utilized in commercial structures, office towers, airports, stadiums, and various other venues that necessitate wide spans.

Advantages:

- Provide large space: The biggest advantage of this system is that it can provide large-span open space, reduce the number of internal columns, and provide more flexible use of space. For example, internal pillars can be removed in office buildings to create a more open and flexible space layout.

- Reduce the number of columns: The long-span design allows the building to reduce the number of supporting columns, save space inside the building, and provide greater flexibility and aesthetics.

Disadvantages:

- Thick floor: Due to the need to bear greater loads, long-span composite beams usually require thicker floors to ensure the stability of the structure, which will increase the difficulty of construction and transportation.

- High steel consumption: The amount of steel required for long-span design is large, resulting in an increase in overall costs. In projects with limited budgets, it may be necessary to weigh whether to choose this type.

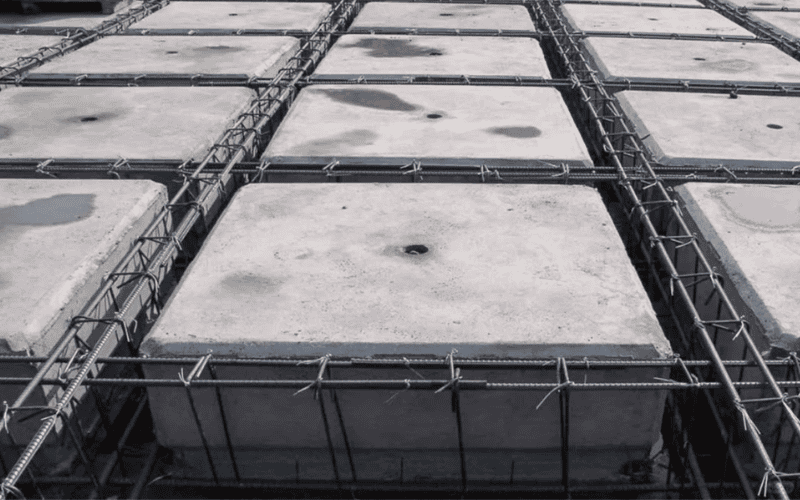

Composite beams and precast concrete units

Applicable scenarios: This steel floor system is suitable for medium span (6-9 meters) buildings. It is often used in projects such as commercial buildings, industrial plants, garages, etc., especially in situations where a higher load-bearing capacity is required.

Advantages:

- Reduced number of secondary beams: Compared with traditional structures, composite beams combined with precast concrete units can reduce the need for secondary beams, thereby simplifying structural design and reducing construction burden.

- High construction efficiency: Since the concrete units are precast, they can be installed quickly during the construction process, greatly shortening the construction period. The use of this precast component makes construction projects more efficient and time-saving.

Disadvantages:

- Complex installation of precast units: Although the use of precast units improves construction efficiency, their installation requires precise positioning and technical support. If the site conditions are poor or the technology is not mature enough, it may increase the difficulty of installation and affect the construction progress.

Non-composite beams and precast concrete units:

Applicable scenarios: Suitable for buildings with a span of 6-7.5 meters, especially suitable for small and medium-sized construction projects, such as low-rise commercial buildings, residential buildings and some light industrial facilities.

Advantages:

- Simple structure: The design structure of non-composite beams and precast concrete units is simple, and the construction is relatively easy, which is suitable for rapid construction, especially in projects with tight budgets.

Disadvantages:

- Steel beams are prone to torsion: Steel beams are prone to twisting during the force process, so temporary support is required to ensure the stability of the structure, which may increase the complexity and time of construction.

- Requirement of temporary support: Due to the easy torsion characteristics of steel beams, additional support systems are required during construction, which increases the cost and workload of temporary support.

Honeycomb composite beams and composite panels

Applicable scenarios: Suitable for long-span buildings of 10-18 meters, commonly seen in places that require large spaces and fewer columns, such as gymnasiums, large exhibition centers, airports, etc.

Advantages:

- Provide large space: The honeycomb composite beam system is very suitable for buildings that require large spans and column-free spaces. By reducing the number of columns, this system provides a larger open space.

- Openings can be used to install service facilities: Due to the unique structural form of the honeycomb beam, it can allow enough space between the beams for burying infrastructure such as pipes and wires, avoiding the addition of additional pipe shafts in the building.

Disadvantages:

- Higher manufacturing cost: Due to the complex structure of honeycomb beams and composite panels, the manufacturing cost is high, which is suitable for projects with sufficient budget and high structural requirements.

Each of these steel floor systems boasts its unique characteristics and suitable applications. When making a selection, factors such as the span, intended use, and budget of the building must be taken into account. Should you have any specific needs or inquiries, please feel free to reach out to us. We will analyze which system is most suitable for your project based on the actual situation.

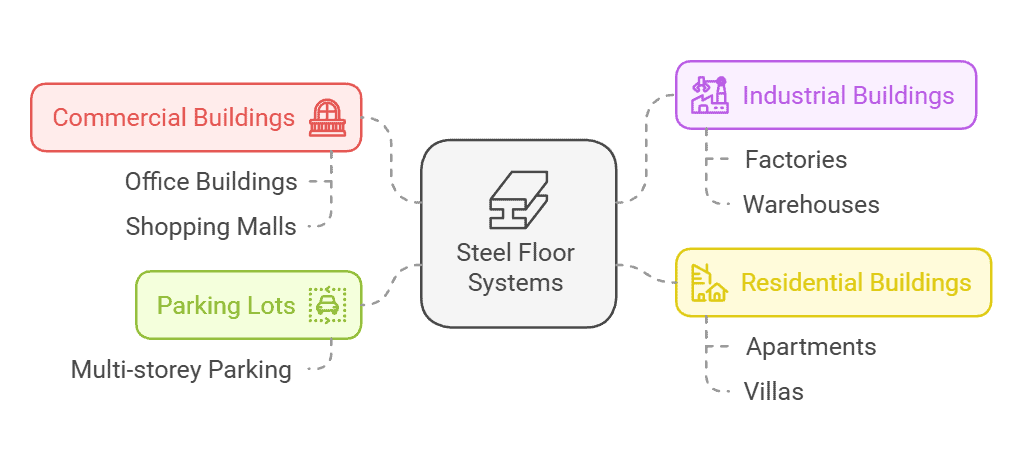

Applications of steel floor systems

Steel floor systems are widely used in many fields due to their superior performance, especially in buildings that require large spans and high load-bearing capacity.

- Commercial buildings: such as office buildings, shopping malls, etc., steel floor systems can provide large spans and open spaces, suitable for commercial environments that require flexible design and efficient use of space.

- Industrial buildings: such as factories, warehouses, etc., can withstand heavy loads, suitable for heavy equipment and cargo storage, ensuring the stability and safety of the structure.

- Residential buildings: such as apartments, villas, etc., suitable for residential designs that require flexible layouts, providing greater spatial flexibility and comfort.

- Parking lots: Multi-storey parking lots require large spans and column-free spaces. Steel floor systems are very suitable in this scenario, which can maximize the use of space and simplify structural design.

Design and construction considerations for steel floor systems

When designing and constructing steel floor systems, we take into account building functions, safety, and construction efficiency to ensure the best performance of the system.

Design considerations

Span and load: We will select the appropriate span and load capacity based on the purpose of the building. Commercial buildings usually require large spans (such as more than 10 meters) to provide flexible space, while industrial buildings need to withstand large loads, so when designing, we must ensure that the bearing capacity and span of the floor meet actual needs.

Fire protection and sound insulation: Although steel has certain fire resistance, for residential and commercial buildings, especially high-rise buildings, it is usually necessary to use fire-resistant coatings or composite with concrete to enhance fire resistance. Fire safety is crucial in these projects, and we always follow strict standards to ensure that customer needs are met.

Service integration: In the design, the integration of service facilities such as pipes and cables must also be considered. We will ensure that there is enough space when designing the steel floor system to facilitate the layout and installation of these service facilities and ensure the efficient realization of functions.

Construction considerations

Prefabrication and on-site installation: The use of prefabricated components can increase construction speed and shorten construction period, but it also requires more precise construction plans to ensure accurate docking between prefabricated components and on-site installation.

Cost and Economic Benefits of Steel Floor Systems

Initial Cost: The initial investment in steel floor systems may be relatively high, mainly due to the complexity of steel and structural design. However, in the long run, its economic benefits are considerable. The durability and low maintenance requirements of steel floor systems enable them to effectively control costs throughout their life cycle, especially in terms of extending service life and reducing maintenance costs.

Construction Efficiency: Due to the prefabricated nature of steel floor system components, the construction process is expedited, leading to a substantial reduction in the overall construction timeline. This quick installation not only helps to improve the overall progress of the project, but also effectively reduces labor costs and additional costs caused by delays during construction.

High Quality Steel Floor System, You Can Rest Assured

The steel floor system products we provide, combined with high-quality steel and advanced design concepts, can meet the needs of various construction projects. Whether it is to improve construction efficiency or ensure long-term stability, our solutions can bring significant economic benefits and performance advantages to your project.

If you are interested in our products, please feel free to contact us. We will provide you with professional advice and help you achieve the best steel floor system application in your project.