Steel structure recycling and reuse are no longer theoretical concepts — they are reshaping how modern construction approaches sustainability and cost efficiency. Many builders ask: Is steel truly recyclable, and how does it perform after reuse? The answer lies in its unique ability to be remelted, reformed, and reassembled without losing strength.

This article explores the full picture behind steel’s recyclability — why steel can be reused indefinitely, what environmental and economic benefits it brings, which components resist recycling, and how builders can integrate efficient recycling practices into new and existing projects. It also examines the roles of architects, contractors, manufacturers, and policymakers in building a truly circular construction system.

As a global prefabricated steel structure manufacturer, SteelPRO PEB contributes to this transformation through modular, factory-engineered systems designed for disassembly and reuse — proving that sustainable construction is not just possible but practical, profitable, and ready to scale.

Why is Steel Recyclable and Reusable?

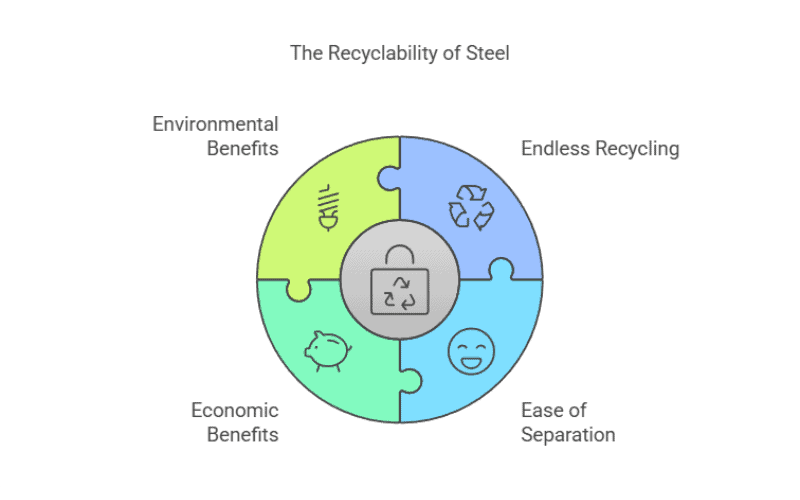

Steel’s recyclability is one of its most impressive qualities. But what exactly makes it stand out?

To commence, steel is distinctive in that it can be recycled indefinitely without diminishing any of its robustness or characteristics. Unlike many other materials, steel’s chemical structure remains stable even after being melted down and reformed multiple times.

Another element aiding its recyclability is the simplicity with which steel can be isolated from other substances. Many steel structures, especially those in prefabricated buildings, are bolted rather than welded together, which makes dismantling and separating steel components much simpler during demolition. This design choice makes it possible to recycle steel more efficiently.

Additionally, the recycling of steel provides both economic and environmental benefits. By reusing steel, we reduce the need for virgin iron ore, which cuts down on mining activities and lowers carbon emissions. To provide a clearer understanding, recycling merely one tonne of steel conserves 1.5 tonnes of iron ore and diminishes CO2 emissions by 58%.

In the context of steel structures, especially prefabricated or PEB buildings, this recyclability translates into tangible lifecycle benefits. Components can be reused across projects with minimal reprocessing, extending the value of each steel element through multiple building lifecycles.

The Benefits of Recycling and Reusing Steel

Recycling steel is not only a green choice—it’s also a smart business move that brings environmental, economic, industrial, and social value to the entire construction sector.

Environmental Benefits

Recycling steel drastically reduces carbon emissions. In reality, utilizing recycled steel in building can decrease emissions by as much as 75% compared to using virgin steel. This reduction directly contributes to cleaner air and a lower carbon footprint across construction projects.

Furthermore, steel recycling prevents waste from accumulating in landfills. Every year, millions of tons of construction waste—especially from demolished steel structures—are diverted from landfills, significantly reducing environmental impact.

Economic Benefits

Recycled steel is typically 20%–40% less expensive than new steel, depending on market conditions and processing methods. This price advantage makes it a key factor for contractors and developers pursuing both sustainability and cost efficiency.

In addition, factory-certified recycled steel is increasingly used in warehouses, workshops, and modular structures that meet green construction standards at a lower overall project cost. This dual benefit—environmental and economic—has made recycled steel a preferred choice for large-scale and prefabricated building projects.

Steel recycling also supports local economies by creating thousands of jobs across collection, sorting, and processing. The recycled steel industry sustains a wide range of employment opportunities while reducing reliance on raw material extraction.

Industrial and Construction Benefits

Recycled steel has become an essential resource in modern construction and industrial architecture. It is widely used in manufacturing prefabricated buildings, PEB warehouses, logistics centers, and modular factories, where reusable components allow for quick assembly, relocation, and future recycling.

In addition to cost and sustainability, recycled steel enhances project flexibility — beams and columns can be repurposed across projects without compromising structural strength or compliance. For industrial developers, this translates to reduced material waste and greater lifecycle efficiency.

Social Benefits

Recycled steel plays a key role in advancing sustainable construction practices. Using it not only helps companies meet environmental targets but also strengthens their brand reputation as responsible, forward-looking builders.

Moreover, cities and regulatory bodies increasingly favor projects built with recycled materials, often offering fast-track permits or tax incentives for sustainable construction. In this sense, choosing recycled steel isn’t just an environmental statement — it’s a competitive advantage in today’s market.

What Parts of Steel Structures Can’t Be Recycled?

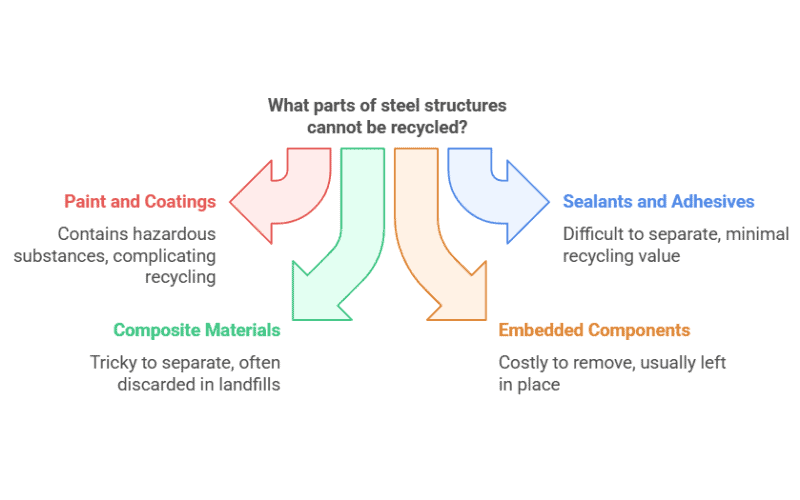

Although steel is highly recyclable, some components of a steel structure cannot be reused. This is often due to the difficulty in separating certain materials or the low recycling value of some elements. Here’s a closer look:

Paint and Coatings

Steel structures are often coated with anti-corrosion and fire-resistant coatings. Unfortunately, many of these coatings contain hazardous substances like lead or chromium, which complicates the recycling process. While advances in separation technologies are being made, these coatings are typically removed and treated as hazardous waste before the steel can be recycled.

Sealants and Adhesives

Materials like silicone or polyurethane sealants are often used in steel structures to provide waterproofing and insulation. However, these sealants are difficult to separate from the steel and have minimal recycling value. As a result, only the steel is recovered, while the sealants are discarded.

Composite Materials

Steel is frequently used in combination with other materials, like in insulated panels that have polystyrene or rock wool cores. These composite materials are tricky to separate and usually end up being discarded in landfills, as the non-steel components cannot be easily reused.

Embedded Components

Some steel structures contain embedded components, such as precast elements or fixtures, that are too costly or difficult to remove without damaging the surrounding materials. These components are generally left in place during demolition.

Modern coating technologies and modular detailing are helping manufacturers reduce these non-recyclable components, improving the circular efficiency of steel structures. With innovations like detachable joints and low-toxicity coatings, the proportion of recyclable steel in new construction projects continues to increase year after year.

Key Considerations When Recycling Steel

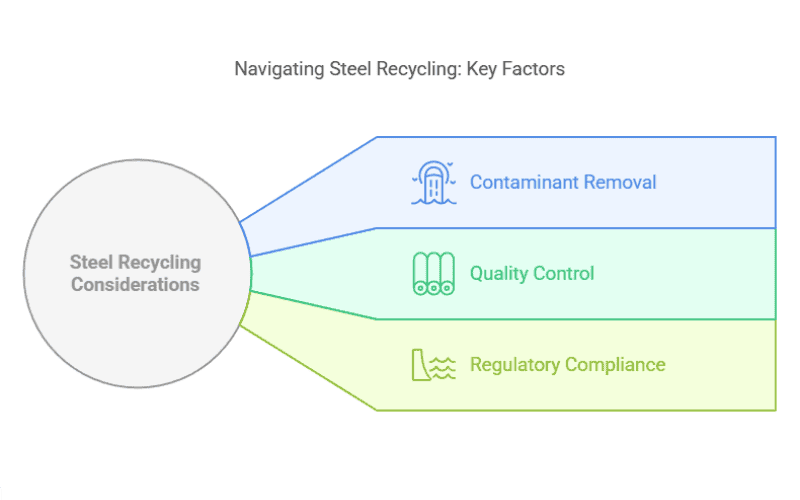

Recycling steel may seem straightforward, but there are important factors to consider to ensure the process is efficient and effective:

Contaminant Removal

Before steel can be recycled, it must be cleaned thoroughly. Contaminants such as paint, oil, or rust can compromise the quality of the final product. Proper treatment—like sandblasting or chemical removal—is essential to maintain structural integrity. If done incorrectly, the recycled material can weaken, making it less reliable for construction use.

Quality Control

Recycled steel undergoes rigorous testing before being reused in major projects.

- Tensile Strength: Measures how much force the steel can handle before breaking, crucial for structural integrity.

- Impact Toughness: Ensures resistance to shocks, important for regions exposed to extreme conditions.

- Corrosion Resistance: Tests how well the steel withstands rust and environmental wear.

- Hardness & Composition: Ensures durability and purity, preventing hidden weaknesses in reused components.

These tests are especially critical when recycled steel is intended for high-performance structures such as warehouses, modular buildings, or industrial factories.

Regulatory Compliance

Recycling steel also requires adherence to strict environmental and safety standards. Local and international frameworks—such as the EU’s Waste Framework Directive or national recycling codes—govern how metal waste is managed. Failing to meet these can lead to penalties or reputational damage.

In the building industry, compliance also extends to green certification systems such as LEED and BREEAM, which recognize the use of recycled steel as a key sustainability credit. Many global developers now require certified recycled content to meet ESG goals and project-level sustainability benchmarks.

How Many Times Can Steel Be Recycled?

The great thing about steel is that it can be reused repeatedly without degrading its quality. Each recycling cycle retains the same strength, flexibility, and corrosion resistance as the original material.

For example, structural steel frames in prefabricated factories can be dismantled and reused multiple times across different projects without any loss of performance — making them a cornerstone of sustainable industrial construction.

How to Recycle Steel Effectively

Recycling steel isn’t a one-size-fits-all process—it requires a blend of smart design, meticulous planning, and cutting-edge technology. But how exactly is it done? Let’s break it down.

In New Construction Projects

- Design for Deconstruction: Modular designs make future recycling easy. By using bolted connections instead of welded joints, steel parts can be quickly dismantled, reducing waste when the building’s life ends.

- Source Recycled Steel: Using recycled steel not only helps the environment but also cuts costs—by 20%-40%, depending on market conditions, without compromising quality.

Partnering directly with steel manufacturers or certified suppliers helps ensure recycled materials meet both structural standards and cost targets. This approach guarantees that the steel used in new buildings aligns with quality benchmarks while maintaining economic competitiveness.

In Renovation and Demolition Projects

- Careful Dismantling: Dismantling carefully, rather than demolishing recklessly, ensures steel stays intact for reuse. Steel beams, for instance, can be reused directly, saving energy and money.

Partner with Recyclers: Collaborate with specialized recyclers who know how to clean and separate contaminants like coatings or adhesives, making steel ready for the next life. - Steel isn’t just for construction—it’s also perfect for creative repurposing. From furniture to machinery parts, recycled steel has endless possibilities!

Steel isn’t just limited to construction. Its versatility means it can be repurposed for a variety of creative and industrial uses. From stylish furniture to intricate art installations, the possibilities are endless.

For large-scale steel structures, sourcing from verified PEB manufacturers ensures traceability, consistent material quality, and cost efficiency throughout the recycling loop. These manufacturers often maintain closed-loop production systems — tracking recycled content, optimizing processing energy, and minimizing waste — making them key partners in sustainable steel construction.

Recommendations for Different Stakeholders

So, how can different groups contribute to improving steel recycling and reuse? Here are targeted recommendations for each key stakeholder in the construction and manufacturing chain.

For Architects and Engineers

Treat steel as more than a structural element — view it as part of your sustainability strategy. Integrating reused or recycled steel can drastically lower a project’s embodied carbon footprint while aligning with international green building standards such as LEED or BREEAM.

Architects can also design for modularity and deconstruction. Using standardized bolted systems instead of welded joints allows future reuse and relocation of steel components, reducing lifecycle costs and waste.

For Construction Managers

A successful recycling strategy begins with a plan. Conduct early assessments to identify which steel components can be reused before demolition begins. Document these parts carefully and create a deconstruction roadmap that outlines removal, cleaning, and reinstallation.

Incorporating recycling into project timelines ensures smoother logistics and reduces disposal expenses. Many construction teams are now collaborating directly with certified recyclers to close the loop between demolition and new builds.

For Steel Manufacturers

Investing in advanced recycling and production technology isn’t just environmentally responsible — it’s a profitable strategy. Producing recycled steel requires up to 60% less energy than manufacturing virgin steel, lowering operational costs and carbon emissions simultaneously.

Manufacturers can also differentiate themselves by offering certified recycled steel products, reinforcing brand trust and ensuring environmental compliance in line with global green standards. This certification adds transparency for developers and builders who need verified sustainable materials to meet project-level ESG requirements.

Furthermore, adopting modular-friendly production — such as pre-engineered bolt-connected frames — facilitates future reuse, positioning manufacturers as key enablers in circular construction.

For Policymakers

Governments and local authorities play a crucial role in promoting steel recycling. Tax incentives, green subsidies, and stricter recycling standards can accelerate adoption among manufacturers and builders alike.

By encouraging public-private partnerships and funding research into recycling technologies, policymakers can help establish a sustainable supply chain for steel — one that supports both environmental goals and industrial competitiveness.

Our Perspective as a Prefabricated Steel Structure Manufacturer

At SteelPRO PEB, we believe recycling only matters when it becomes measurable at the project level. That’s why our prefabricated steel systems are engineered for disassembly, reuse, and traceable material cycles — turning sustainability into a practical construction advantage.

Each steel component is designed to be bolted, not welded, allowing it to be removed, inspected, and reinstalled across multiple projects. This reduces fabrication waste by up to 30% and lowers lifecycle material costs for developers and contractors.

By integrating factory-certified recycled steel into our production, we help clients meet LEED and ESG requirements while ensuring consistent quality and structural integrity. Our process isn’t just greener — it’s leaner, faster, and more cost-efficient.

For builders seeking to balance sustainability with profitability, SteelPRO PEB offers a proven pathway: durable, reusable steel structures built for long-term performance and a truly circular economy. Explore how our Detachable Container House demonstrates real-world reusability — a modular building system designed for repeated assembly, transport, and recycling.