Imagine this: a coastal warehouse battered by hurricane-force winds, an industrial plant engulfed in flames, or an office tower trembling during a seismic event. These aren’t merely fictional situations—they’re genuine obstacles that steel structures must confront on a daily basis. The difference between a building that collapses and one that stands tall often comes down to its ability to resist these extreme forces. In this article, we’ll dive into the essential resistances every steel structure needs, from weathering storms to surviving fires and earthquakes, and how we ensure these qualities are built into every project.

Weather Resistance

Steel constructions are constructed to endure severe climatic conditions. Weather Resistance covers wind, corrosion, temperature extremes, and impacts. Let’s explore how each of these resistances helps steel stay strong in tough conditions.

Wind Resistance

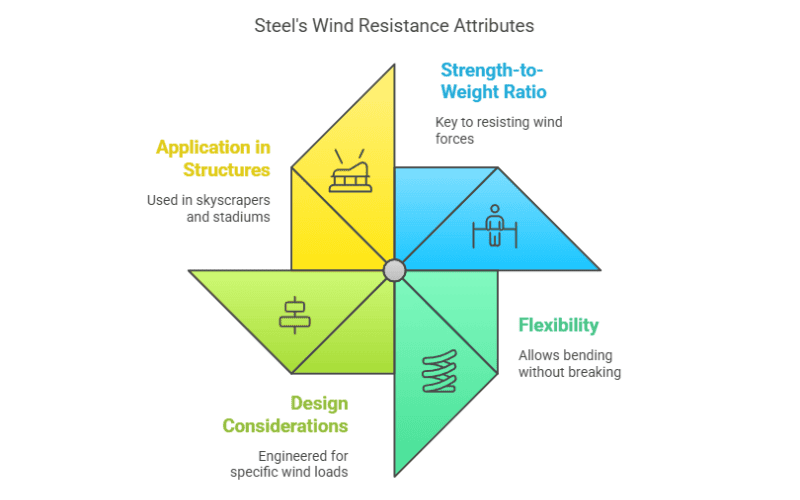

Steel’s strength-to-weight ratio is key to its resistance against wind forces. A meticulously planned steel framework can withstand winds reaching speeds of 150 miles per hour—comparable to a Category 4 hurricane.

The pliability of steel enables it to flex without snapping, assimilating wind energy and diminishing the likelihood of severe malfunction. This is why steel is the material of choice for skyscrapers, stadiums, and other large-span structures, where wind loads are a major concern. In fact, many of these structures are engineered with specific wind load calculations, designed to ensure stability in high-wind areas like coastal cities or regions prone to severe storms.

Corrosion Resistance

Steel is naturally prone to rust, but through years of experience, we’ve seen how modern coatings can significantly improve its ability to resist corrosion. Weathering steel, for example, develops a protective oxide layer when exposed to moisture, helping prevent further deterioration. Beyond that, coatings like epoxy, polyurethane, and zinc-rich primers are commonly used to protect steel from the elements, especially in challenging environments like coastal or industrial areas. By combining these coatings with weathering steel, we’ve been able to reduce maintenance needs and extend the life of steel structures.

To ensure long-term protection, factors like environmental exposure and proper coating methods—such as hot-dip galvanization or multi-layer systems—must be carefully matched to site conditions.

Temperature Resistance

Steel performs exceptionally well in environments with extreme temperature fluctuations. Whether it’s the bitter cold of the Arctic or the scorching heat of the desert, steel retains its robustness and form. This is attributed to its minimal thermal expansion, indicating that it doesn’t broaden or narrow significantly with fluctuations in temperature.

For example, if steel is exposed to a temperature shift from -40°C to 50°C, its change in length is very minimal—only about 0.024 mm per meter in either direction. This might not sound like much, but it’s enough to keep steel stable while materials like wood or concrete can crack or warp under similar conditions.

Here’s a quick breakdown of how steel behaves at different temperatures:

| Temperature (°C) | Thermal Expansion (Change in Length per meter) | Steel Strength (approx.) |

| -40°C | ~ -0.024 mm (per meter) | High (Minimal Reduction) |

| 0°C | ~ 0 mm | High (Stable) |

| 25°C | ~ 0 mm | High (Stable) |

| 50°C | ~ +0.024 mm (per meter) | High (Stable) |

Steel’s coefficient of thermal expansion (around 11-13 x 10^-6/°C) means for each degree Celsius the temperature changes, steel expands or contracts by just 11 to 13 micrometers per meter. This tiny change helps steel structures stay intact, even when exposed to extreme temperature shifts.

Impact Resistance

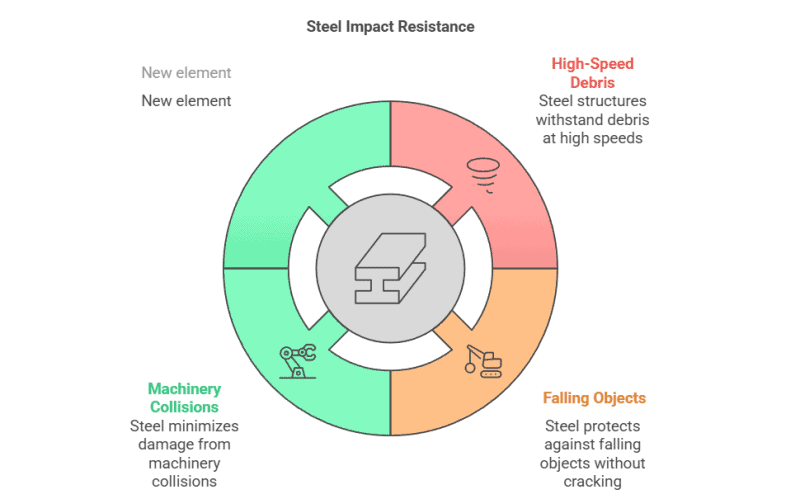

Steel’s toughness allows it to absorb and resist various impact forces, from hail and flying debris to the impact of heavy equipment or machinery. For example, steel structures in tornado-prone regions are designed to withstand debris traveling at speeds of up to 100 mph. This capacity to withstand rapid collisions is vital in preserving both the structural integrity and the safety of those inside.

Additionally, steel’s energy-absorbing qualities make it highly effective in protecting against impacts from falling objects or machinery collisions, where materials like concrete or wood might crack or fail. Steel constructions are designed to disseminate these forces uniformly, lessening harm and decreasing the chance of structural collapse during severe occurrences.

Structural Resistance

Steel structures are not only built to resist weather—they also handle physical forces and extreme conditions that challenge their integrity.

Blast Resistance

Steel’s ductility (its ability to deform without breaking) makes it ideal for blast-resistant designs. In high-risk areas like military bases or critical infrastructure, steel structures are engineered to absorb and dissipate explosive energy. For example, some steel frames can withstand blast pressures of over 100 psi. The design of these frames—featuring reinforced connections—allows the structure to flex under stress, reducing the risk of catastrophic collapse.

Fatigue Resistance

Steel’s ability to handle repetitive loads is crucial, especially for structures like bridges, which experience millions of load cycles over their lifespan. High-strength steels, such as ASTM A514, can withstand over 2 million load cycles without developing cracks. This makes steel the go-to material for long-span bridges and highways, where fatigue resistance is essential for safety and long-term performance.

Earthquake Resistance

Steel is perfect for areas with earthquakes because it’s naturally flexible. When the ground shakes, steel structures can bend and sway without breaking, which helps absorb the energy from the quake. Imagine it like steel “dancing” with the earthquake rather than fighting it. This means the building stays intact, and people inside stay safe.

To make this even better, base isolators and damping systems are often added. A base isolator is like a shock absorber for a building, allowing it to shift slightly without passing all the shaking to the structure itself. This can cut down building movement by up to 80%, keeping things steady when the earth moves. Damping systems act like the dampers in a car, absorbing extra vibrations and reducing the shaking felt in the building.

For projects in seismic regions, Seismic Resistance Steel Structures are designed to handle these challenges, ensuring the building remains safe even in the toughest conditions.

Fire Resistance

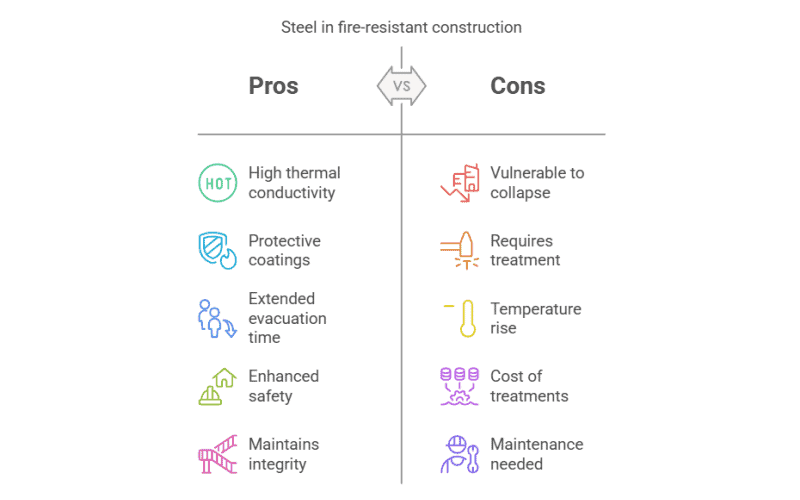

While steel performs better than wood in fire situations, it’s not immune to the dangers of extreme heat. Steel’s high thermal conductivity means it can heat up quickly in a fire, and as temperatures rise, its strength starts to weaken. This makes it more vulnerable to collapse during a fire compared to other materials like concrete.

As mentioned earlier, steel structures are often treated with protective coatings like intumescent paints, which expand when exposed to heat. This forms an insulating layer that slows down the rise in temperature, helping to keep the steel’s strength intact for longer. These coatings not only give people more time to evacuate but also provide emergency responders with more time to manage the situation.

For projects in areas like California, where wildfires are a concern, we make sure to incorporate these fire-resistant treatments to ensure the structure can withstand high temperatures. With adequate safeguards, steel can uphold its structural integrity in the event of a fire, lowering the danger of collapse and augmenting the overall safety of the edifice.

Our Unique Advantages as a Prefabricated Steel Structure Manufacturer

At SteelPRO PEB, we don’t just build steel structures—we engineer peace of mind. Here’s what makes us stand out:

- Durable Steel Sourcing: We use only high-strength, weather-resistant steel, ensuring our structures can withstand harsh conditions like extreme temperatures, corrosion, and impact forces.

- Tailored Structural Solutions: From warehouses with wind resistance to Steel Structure Office Building with earthquake resistance, we design and manufacture steel structures that meet specific environmental challenges, enhancing safety and durability.

- Efficient and Reliable Construction: Through our prefabrication process, we streamline steel structure production, cutting construction time by up to 50%, while maintaining top-notch quality and structural integrity.

Steel structures are more than just buildings—they’re shields against the unpredictable. From enduring tempests to withstanding blazes and seismic activities, the appropriate design and materials make a crucial impact.

We are dedicated to providing structures that not only fulfill but surpass these demanding situations. With our expertise and innovative solutions, you can trust that your project will stand strong, no matter what comes its way.