Imagine a world without steel: skyscrapers would crumble, bridges would sag, and factories would lack the strength to house heavy machinery. In steel buildings, steel isn’t just a material—it’s the skeleton and lifeblood that defines durability, sustainability, and design freedom.

At its core, every steel building is a symphony of metallurgy and engineering. But here’s the catch: even the strongest steel can fail if chosen incorrectly. Why does selecting the right steel type make or break your project? The answer lies in understanding steel’s “DNA” – its composition, shape, and specialized properties.

Whether you’re an architect designing the next landmark or a factory owner prioritizing cost efficiency, this guide will equip you with actionable insights to turn steel from a commodity into a strategic advantage. Let’s dive in.

By Composition

Think of steel composition like a chef’s recipe—the right mix of elements unlocks unique properties. Here’s how three key types shape modern steel buildings:

Carbon Steel

- What’s in it? Primarily iron and carbon (0.05%–2.1%), with trace elements.

- Why it shines:

- Low-carbon steel (≤0.3% carbon): Easy to weld and form, ideal for beams, columns, and roofing.

- Medium-carbon steel (0.3%–0.6%): Balances strength and ductility, used in bolts and machinery mounts.

- High-carbon steel (≥0.6%): Ultra-strong but brittle, perfect for cables and springs.

- Best for: Warehouses, agricultural buildings, and projects where cost efficiency trumps extreme durability.

High-Strength Low-Alloy (HSLA) Steel

- What’s in it? Small doses of chromium, nickel, or vanadium (≤3.5% total alloys) boost strength without weight penalties.

- Why it shines:

- 20% stronger than carbon steel, allowing slimmer structural sections.

- Resists corrosion better than plain carbon steel.

- Best for: Airport terminals needing wide-span roofs, earthquake-resistant frameworks, and green buildings aiming to reduce material waste.

Stainless Steel

- What’s in it? At least 10.5% chromium forms an invisible shield against rust.

- Common grades:

- Grade 304: All-purpose hero for indoor structures and mild climates.

- Grade 316: Adds molybdenum to battle salty air—essential for coastal factories or chemical plants.

- Pro tip: Use stainless steel cladding on carbon steel frames for cost-effective corrosion resistance.

By Shape

Steel isn’t just about chemistry—it’s a masterclass in physics. The shape of steel components determines how they bear loads, resist stress, and even influence construction speed. Let’s break down the “steel alphabet” that shapes modern buildings:

Structural Steel Shapes

- H-Beams (Wide Flange Beams):

- Why engineers love them: Symmetrical flanges and thick web provide unmatched axial and lateral strength.

- Think: Skyscraper columns, multi-story parking garages.

- Fun fact: An H-beam can span 30% farther than an I-beam of the same weight.

- I-Beams (Standard Beams):

- Classic workhorse: Deep vertical web resists bending, perfect for horizontal spans.

- Go-to uses: Bridge girders, factory crane rails, and rooftop solar panel supports.

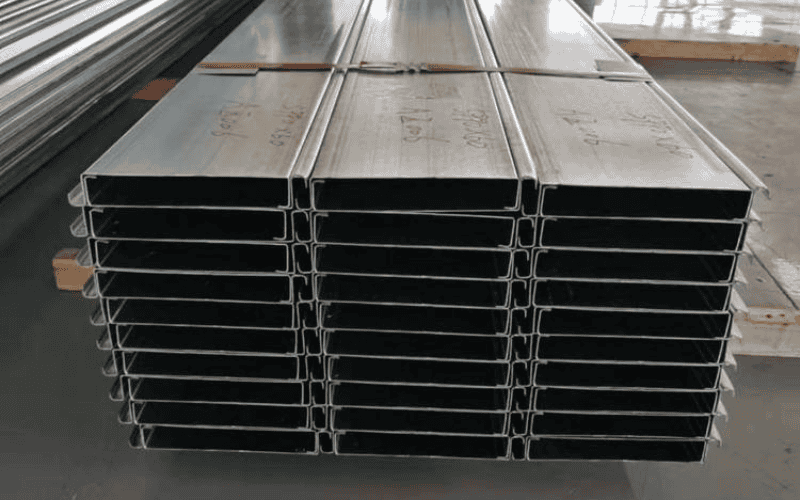

- C-Purlins (Channel Sections):

- Lightweight champions: U-shaped design optimizes roof/wall cladding support.

- Hidden advantage: Nesting capability reduces shipping costs by 15%.

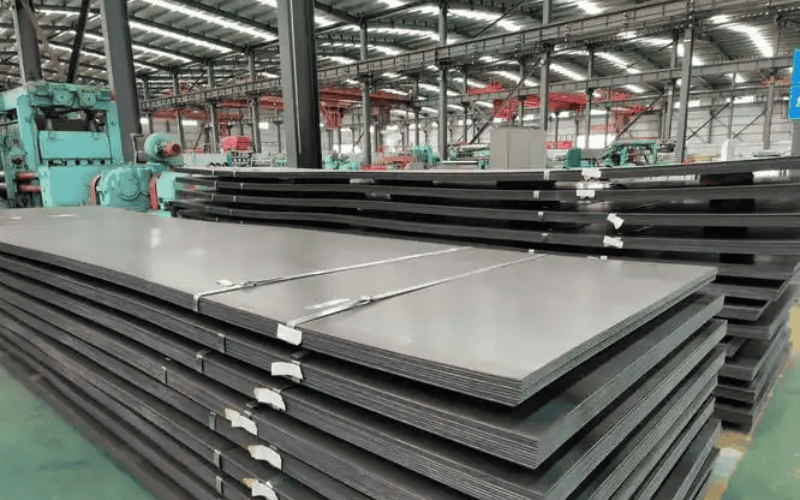

Plates & Sheets

- Thick Plates (6mm–300mm):

- Role: Reinforce joints, create shear walls, or anchor heavy machinery.

- Pro tip: Plasma-cut plates allow custom bolt patterns for modular designs.

- Corrugated Sheets:

- Ribbed magic: The waves aren’t just decorative—they add stiffness, letting thinner steel span wider areas.

- Top applications: Quick-install warehouse roofs, sound-dampening industrial partitions.

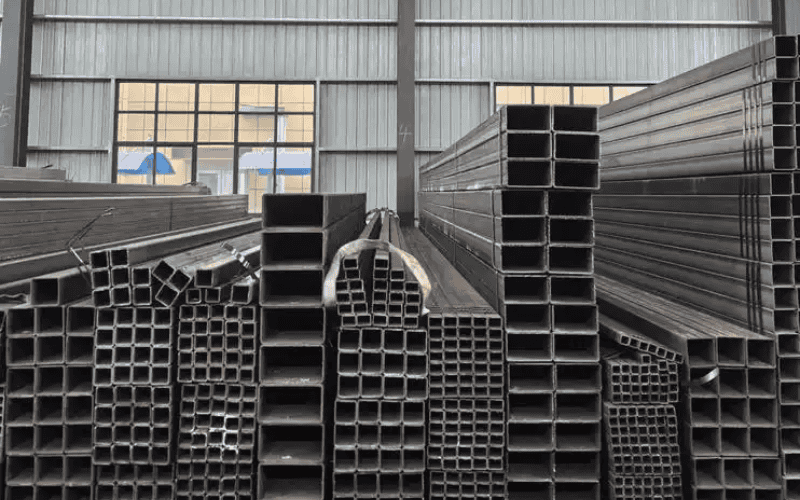

Hollow Structural Sections (HSS)

- Square/Rectangular Tubes:

- Aesthetic edge: Clean lines for exposed structures like atriums or glass curtain wall mullions.

- Structural perk: Uniform strength in all directions, ideal for seismic zones.

- Circular Tubes:

- Fluid dynamics: Naturally resists wind/water forces—think offshore platforms or stadium floodlight masts.

- Bonus: Seamless tubes (no welded joints) handle high-pressure fluids in HVAC systems.

Specialized Steel

When ordinary steel isn’t enough, these advanced alloys step in to tackle extreme conditions—from blazing fires to corrosive seas. Here’s how innovation meets necessity:

Fire-Resistant Steel

- Science behind the shield:

- Molybdenum and vanadium form stable carbides at high temperatures, slowing strength loss.

- Can withstand 600°C for 2+ hours (vs. 15 minutes for standard steel).

- Life-saving applications:

- High-rise emergency stairwells that buy evacuation time.

- Steel-framed data centers protecting server integrity during fires.

Weathering Steel (Corten®)

- Self-protecting genius:

- Copper, chromium, and phosphorus create a dense oxide layer that blocks further corrosion.

- No painting needed—cuts maintenance costs by 40% over 50 years.

- Iconic projects:

- The rust-red façade of the Broad Art Museum in Los Angeles.

- Bridges in coastal zones where repainting is logistically nightmarish.

Cold-Formed Steel (CFS)

- Why it’s disrupting construction:

- Roll-formed from thin-gauge sheets (1–3mm) into precise C/Z shapes.

- 30% lighter than hot-rolled steel, ideal for prefab modular buildings.

- Sustainability edge:

- Up to 90% recycled content.

- Enables “steel-frame tiny homes” with near-zero onsite waste.

Pro insight: Combining specialized steels with smart design can slash project timelines. For example, using pre-galvanized CFS purlins eliminates post-installation coating work.

Material Selection Flowchart: 5 Steps to Steel Success

Choosing the right steel isn’t guesswork—it’s strategic engineering. Follow this roadmap to align your project’s needs with steel’s superpowers:

Step 1: Map the Loads

- Static vs. Dynamic:

- Roof trusses (static): Carbon steel I-beams.

- Crane runways (dynamic): HSLA steel for fatigue resistance.

- Concentrated vs. Distributed:

- Heavy machinery bases → Thick carbon steel plates.

- Warehouse mezzanines → Lightweight CFS joists.

Related Reading: Understanding Loads on Steel Structures: Types, Calculations and Design Key Points

Step 2: Diagnose Environmental Threats

Corrosion Risk Matrix:

| Environment | Steel Solution |

| Coastal (salt spray) | Galvanized HSLA or Grade 316 |

| Chemical plant fumes | Stainless steel cladding |

| Rural (low humidity) | Painted carbon steel |

Temperature Extremes:

- Arctic warehouses → Nickel-alloyed steels to prevent brittleness.

- Foundries → Fire-resistant steel for columns near furnaces.

Step 3: Match the Construction Method

- Welding vs. Bolting:

- Welded frames → Low-carbon steel (easy to weld).

- Bolt-up structures → Pre-drilled HSLA sections.

- Prefab Friendly Picks:

- Cold-formed steel (CFS) for modular wall panels.

- Hollow sections for plug-and-play truss systems.

Related Reading: Mastering Steel Structure Welding Technology: Types, Materials, Techniques and Safety

Step 4: Aesthetics or Invisible?

- Exposed Structural Steel:

- Corten® for rustic appeal.

- Stainless steel mirror finishes for modern lobbies.

- Hidden Framing:

- Standard carbon steel with primer (cost-optimized).

Step 5: Crunch the Lifetime Costs

- Upfront vs. Long-Term:

- Budget-tight: Carbon steel + periodic repainting.

- Long-term play: Weathering steel (higher initial cost, near-zero maintenance).

- Recycling Endgame:

- HSLA and stainless steels retain 80%+ value as scrap.

Real-World Example:

A coastal resort’s open-air restaurant:

- Loads: Moderate (snow loads + wind) → HSLA beams.

- Environment: Salt air → Hot-dip galvanizing.

- Construction: Prefab trusses → HSS tubes for easy assembly.

- Aesthetics: Exposed rafters → Corten® for “industrial chic”.

- Cost: Higher initial spend justified by 50-year corrosion resistance.

Stuck between two steel types? Ask: “Which option saves more time/money/headaches over 20 years?”

Conclusion: Building Tomorrow with Today’s Steel

Steel isn’t just a material—it’s a language of innovation. As skyscrapers climb higher and factories grow smarter, steel answers with new dialects:

- Smart Steels: Embedded sensors in beams to monitor stress in real-time.

- Green Steels: Hydrogen-reduced iron ore slashing CO₂ emissions by 95%.

- 3D-Printed Steel: Custom nodes optimizing weight-to-strength ratios.

But amidst these advances, one truth remains: Great buildings begin with perfectly matched steel. Whether you’re crafting a humble workshop or the next Sydney Opera House, every rivet and beam tells a story of calculated choices.

At SteelPRO PEB, we live by the mantra: “Know the steel, know the solution.” For over 20 years, we’ve turned metallurgical mysteries into client triumphs—from earthquake-proof factories to hurricane-resistant schools.

Your next step?

Chat with our experts to turn this guide into your project’s success blueprint. After all, in the world of steel buildings, the right choice today becomes the legacy of tomorrow.

CTA (Call to Action):

📞 [Book a Steel Consultation] | 📧 [Ask Our Metallurgist]

Final Thought:

“Architecture begins where engineering ends.” But without the right steel, neither can begin.