Steel structure maintenance is the key to ensuring long-term safety, performance, and cost efficiency in any metal building. Regular inspection and timely repair prevent corrosion, deformation, and coating failure that often shorten a structure’s lifespan.

This guide explains the most common issues found in steel buildings, how to recognize early warning signs, and the most effective strategies for inspection, preventive care, and corrective repair. It also highlights why structures produced by certified Pre-Engineered Building (PEB) manufacturers, such as SteelPRO PEB, require less maintenance and deliver greater reliability over time.

By combining engineering expertise, ISO-certified fabrication, and factory-level quality control, SteelPRO PEB ensures each steel structure is designed for durability and easier maintenance throughout its life cycle—helping owners maintain safety, reduce downtime, and protect their investment with confidence.

Common Issues in Steel Structures and Their Causes

Steel buildings are durable but not immune to wear and tear. Identifying typical problems enables you to tackle them proactively.

- Corrosion stands as one of the most significant threats to steel structures. It often occurs due to environmental factors like humidity, salt spray, or acid rain, especially in coastal or industrial areas. Weak points such as joints, welds, and areas with damaged coatings are particularly vulnerable.

- Additionally, degradation of protective paint layers and thermal expansion-induced joint loosening are common but often overlooked issues, especially in regions with large temperature fluctuations. For coastal or chemical plant environments, additional anti-corrosion measures such as epoxy zinc-rich coatings are highly recommended.

- Deformation can result from design flaws, construction errors, or excessive loads. Beams, columns, and supports are the most affected components.

- Loose connections are another frequent issue, often caused by bolt loosening, weld cracks, or damaged connectors. These problems are commonly found at beam-column joints or bracing connections.

- Fire resistance degradation is a critical concern. Over time, fireproof coatings may wear off, or fire protection systems may fail, compromising the building’s safety.

Signs Your Steel Structure Buildings Needs Maintenance

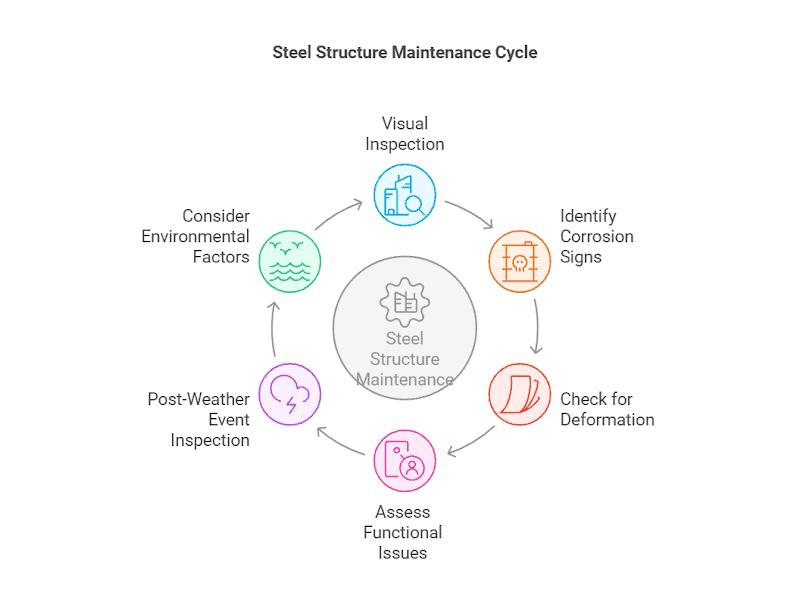

Regular inspections act as the first line of defense. Look for peeling, bubbling, or cracking in protective coatings — these are early indicators of corrosion. Rust spots, especially around joints or welds, should not be ignored. Deformed beams or columns and loose bolts are also red flags.

Deformation and dents are critical signs that your structure may be under stress. Visible bending, bowing, or dents in structural components often indicate overloading or localized yielding of the steel. For example, a dented column from an impact or noticeable sagging in a long-span beam not only affects the building’s appearance but also compromises its integrity.

Functional issues such as difficulty in opening or closing doors and windows, water leaks, or unusual vibrations can also signal hidden structural problems.

After extreme weather events — earthquakes, strong winds, or floods — even if the building appears undamaged, a thorough inspection is essential. Such events may cause hidden deformations or weld fatigue, which can escalate over time if not addressed.

Environmental factors also influence maintenance needs. Buildings located in coastal or industrial zones require more frequent inspections due to salt and chemical exposure that accelerates corrosion. Combining these environmental insights with visual inspections helps identify and address potential problems early.

By remaining vigilant and addressing these signs promptly, you can stop minor issues from developing into significant problems — ensuring the durability and safety of your steel structure.

Effective Maintenance & Repair Strategies for Steel Structures

A well-planned maintenance strategy is key to preserving the integrity and appearance of your steel structure. Below are the most effective approaches compiled by our engineering team.

Regular Inspections: The Foundation of Maintenance

Routine inspections form the cornerstone of any maintenance strategy. For new buildings, a comprehensive check every six months is recommended, followed by annual inspections. Older structures or those located in coastal or industrial zones should be inspected quarterly due to higher corrosion risk.

Focus on critical areas such as joints, coatings, and fireproofing systems. Where possible, complement visual inspections with tools like ultrasonic thickness gauges and coating thickness meters to detect internal or hidden flaws.

Preventive Maintenance: Prolonging Structural Life

Preventive maintenance significantly extends the lifespan of a steel structure by addressing small issues before they escalate.

- Surface Cleaning: Clean all exposed surfaces every six months to remove dirt, debris, and salt residues that retain moisture. Use neutral cleaning agents to prevent damage to protective coatings.

- Connection Care: Tighten and lubricate bolts every six months. Use torque wrenches following manufacturer guidelines to maintain joint strength.

- Moisture Control: In humid environments, ensure proper drainage and ventilation to prevent condensation buildup.

Recommended Frequency: Preventive inspections should be conducted every 6–12 months, depending on local climate conditions and building usage intensity.

Surface Coating Maintenance: Protecting Against Corrosion

Protective coatings are the first barrier against environmental damage. Their maintenance is essential for long-term durability.

- Inspection: Examine coatings for cracks, blisters, or peeling.

- Minor Repairs: Clean damaged areas, apply primer, and recoat using a compatible top layer.

- Severe Damage: For extensive degradation, sandblast the surface and reapply the full coating system according to ISO standards.

- Special Environments: In coastal or chemical regions, use epoxy zinc-rich or polyurethane coatings for superior corrosion resistance.

Proper coating maintenance not only prevents corrosion but also enhances the aesthetic appearance of your building.

Fire Safety: A Non-Negotiable Priority

Fire safety is crucial for all steel structures. Perform annual inspections of fireproof coatings and systems, focusing on areas most exposed to wear, such as joints and beam edges.

Key Areas to Inspect:

| Area | Potential Hazards | Recommended Actions |

| Fireproof Coatings | Aging or damage due to impact/weather | Inspect annually, reapply or replace coatings if worn. |

| Steel Joints | High heat exposure in active zones | Check for cracks or corrosion; add protection if necessary. |

| Beam & Column Edges | Direct exposure risk | Ensure coatings are intact and no raw steel is visible. |

Other components like insulation or weld seals can be reviewed during major maintenance intervals rather than every inspection. Regular fire safety checks maintain the structure’s compliance and ensure occupant safety.

Corrective Maintenance: Addressing Issues Promptly

When problems are detected, take immediate corrective actions to prevent further damage.

| Action | Description | When to Apply | Follow-Up |

| Recoating | Restore protective layers to prevent corrosion/fire damage. | When coatings show peeling or thinning. | Confirm adhesion and uniformity after drying. |

| Reinforcement | Strengthen beams or joints showing deformation. | When stress or bending is observed. | Re-check load-bearing performance post-repair. |

| Replacement | Swap components beyond repair. | Cracks, severe corrosion, or failed welds. | Test new elements under load conditions. |

| Welding Repairs | Fix cracks or defects in welded joints. | When weld integrity is compromised. | Inspection per certified welding codes. |

| Sealing Gaps | Block moisture/air infiltration at seams. | When water ingress or draft is detected. | Conduct water-tightness test after sealing. |

Documentation & Long-Term Monitoring

Record every maintenance action — materials used, inspection dates, and test results. Use digital logs or maintenance management systems for traceability. For critical load-bearing areas, install stress or corrosion sensors to enable real-time monitoring. This proactive approach ensures long-term stability and cost-effective operation of your steel structure.

What Tools Are Used for Steel Structure Inspection?

Professional inspections use tools like ultrasonic thickness gauges, coating thickness meters, and infrared thermography to detect internal corrosion, joint weakness, or hidden defects.

How Can I Prevent Corrosion in My Steel Building?

Keep the structure clean, check coatings regularly, and repair any exposed or cracked areas promptly. In high-humidity or coastal regions, apply epoxy zinc-rich or polyurethane coatings for added corrosion resistance.

The Role of Certified PEB Manufacturers in Reliable Steel Structure Maintenance

Long-term maintenance efficiency begins with how a steel structure is engineered and produced. Certified Pre-Engineered Building (PEB) manufacturers such as SteelPRO PEB ensure that each structural component is designed for durability, corrosion resistance, and easy upkeep throughout its lifespan.

At the factory level, SteelPRO PEB follows ISO- and CE-certified production standards, employing automated welding, precision cutting, and controlled coating processes. These steps reduce deformation, ensure uniform connections, and minimize potential maintenance points. By integrating strict fabrication quality control from the outset, our structures require fewer repairs and maintain structural integrity even in harsh environments.

For project owners and engineers, this translates to lower maintenance costs, longer service intervals, and reliable long-term performance. Choosing a steel structure built by a certified manufacturer like SteelPRO PEB means investing in a system engineered not just for construction efficiency—but for sustainable, maintenance-ready performance backed by international standards.