Industrial buildings hold a significant position in modern society, particularly within the manufacturing and warehousing sectors. Steel structures have become the preferred material in industrial building design due to their efficiency, durability and flexibility.

Today, we will take you to an in-depth understanding of the key principles of steel structure industrial building design and discuss how to improve building quality and cost-effectiveness through steel structures. With these principles, you will be able to ensure that your construction projects are not only strong and durable, but also maximize the space and functional advantages.

What is an Industrial Building?

Industrial buildings are buildings dedicated to production, processing, storage or other industrial activities. These buildings are usually designed to accommodate large-scale equipment, machines, storage systems and complex production lines. Whether it is a manufacturing plant, warehouse or commercial building, industrial buildings are designed to optimize workflow and improve efficiency.

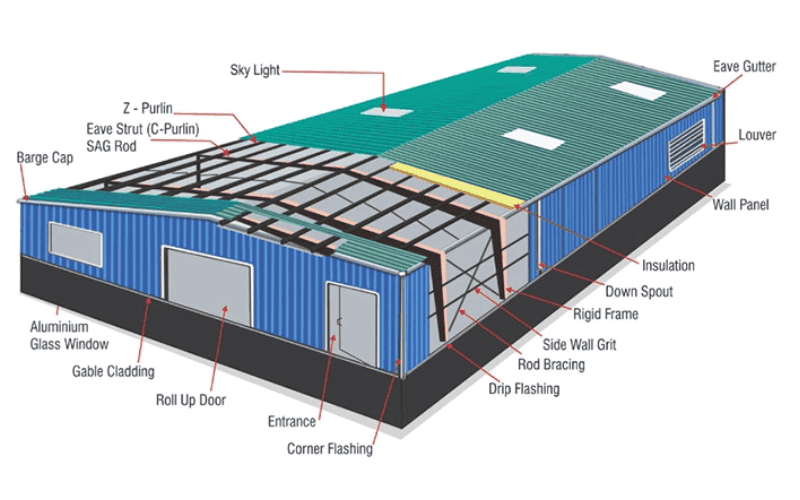

Components of Steel Structure Industrial Building

Foundation: The foundation is the foundation of the building. Steel structure buildings usually have a simpler foundation design because they are lighter in weight, which helps to reduce the burden, save materials and speed up construction time. At the same time, the foundation design of steel structures is flexible and can be adjusted according to land conditions and needs.

Frame: The frame is the skeleton of an industrial building. The biggest advantage of a steel structure frame is that it can be designed with a large span, creating open space, facilitating equipment and item storage, and improving work efficiency. Its flexibility also allows the frame to be customized according to demand.

Roof: The steel structure roof is light and strong, and can be designed as a large span structure, reducing redundant supports, providing more space and shortening construction time. It can also complete construction more quickly and accelerate the commissioning of the project.

Wall: Steel structure walls are usually made of light steel or metal plates, which not only ensures structural stability, but also reduces weight, making construction convenient and fast. They can be tailored to meet demand, achieving a harmonious blend of functionality and aesthetics.

Doors and windows: Steel structure doors and windows are not only sturdy and durable, but can also be customized in size and style according to demand to meet special requirements such as fire protection and sound insulation, ensuring the accessibility, lighting and safety of the building.

Ground: The ground of an industrial building needs to have good bearing capacity. The design of the steel structure ground emphasizes wear resistance and earthquake resistance to ensure stability under heavy machinery and high-frequency use.

Types of Steel Structure Industrial Buildings

Depending on the purpose and function, steel structure industrial buildings can be divided into several types, and each type has different design requirements. Understanding these building types will help you choose the most suitable steel structure solution.

Warehouse

Warehouses are mainly used to store goods, and the design focus is to provide large spaces and ensure that goods are easy to enter and exit. Steel structure warehouses increase spatial flexibility through large-span design, reduce the space occupied by support columns, and improve storage efficiency. At the same time, the construction speed of steel structures is relatively fast, which is suitable for projects that need to be put into use in a short period of time.

Production workshop

The production workshop is the core area for production, processing and assembly. The design focuses on spatial flexibility, load-bearing capacity and equipment layout. The steel structure workshop can provide open space, reduce restrictions on equipment layout, and has strong earthquake resistance and wind resistance, which is suitable for different production needs. Our steel structure design can provide the most suitable layout plan according to your needs and improve work efficiency.

Factory

The factory is used for production and processing. The production line layout and equipment weight need to be considered during design. The steel structure factory can provide strong load-bearing capacity and flexible space allocation to meet the needs of large loads. At the same time, the safety and earthquake resistance of steel structures provide protection for the factory and reduce long-term maintenance costs.

Logistics Center

The logistics center mainly provides services for cargo storage, sorting, loading and unloading, and distribution. In the design, space utilization and cargo flow efficiency are crucial. Steel structures can provide large spans and open spaces to ensure smooth cargo flow and improve storage and transportation efficiency. We can customize the most suitable steel structure solution according to your logistics needs to ensure the efficient operation of your logistics business.

Principles of Steel Structure Industrial Building Design

The design of steel structure industrial buildings requires a comprehensive consideration of multiple factors to ensure the safety, economy, flexibility and sustainability of the building. Here are a few core principles to follow in the design:

1.Strength and Stability

The building must possess the capability to endure diverse loads and guarantee long-term stability. Steel structures provide excellent strength and rigidity to cope with various pressures such as equipment weight and wind loads. Through accurate load calculations and structural analysis, the safety and reliability of each component are ensured to adapt to different environments and conditions.

2.Material Selection

The choice of steel directly affects the durability and performance of the building. According to the project requirements, we will select the most suitable type of steel, such as high-strength low-alloy steel or anti-corrosion steel, to ensure that the building has the best strength and corrosion resistance. Our design team will recommend the right material based on your specific needs to ensure long-term stability and safety.

3.Cost-Effectiveness

When designing, we focus on optimizing the use of structure and materials, reducing waste and reducing costs while ensuring quality. Steel structures often offer cost savings to clients due to their speed of construction and the reusability of materials, especially for large-scale projects.

4.Flexibility

A significant advantage of steel structures is their high degree of flexibility and ability to be customized to meet client needs. Whether it is a production workshop or a warehouse, steel structures provide large spans for equipment layout and future expansion. As your business grows, steel structures can be easily adjusted and transformed to meet changing needs.

5.Sustainability

Steel structures are highly recyclable, reducing their impact on the environment. We are committed to providing environmentally friendly design solutions, using recyclable materials, optimizing the energy efficiency of buildings, reducing carbon emissions, and ensuring that buildings not only meet existing needs, but also have long-term sustainability.

SteelPRO Group incorporates these design principles into every project, providing clients with steel structure design solutions that meet high standards and have long-term value. Our design team will tailor the most suitable solution based on your needs to ensure that your building achieves the best balance in terms of safety, economy and sustainability.

Why Steel Structures are Chosen for Industrial Buildings?

- Durability and Strength: Steel is highly durable and possesses an excellent strength-to-weight ratio, enabling it to withstand heavy loads, extreme weather, and other stressors, crucial for industrial reliability and stability.

- Cost Efficiency: Steel structures are cost-effective due to their minimal maintenance needs and long lifespan. They also expedite construction, thereby lowering labor and overall project costs.

- Flexibility and Customization: Steel can be readily fabricated and tailored to meet specific building requirements, making it suitable for large spans, intricate designs, and specific load-bearing needs.

- Speed of Construction: Prefabricated steel components reduce on-site construction time, enabling businesses to start operations sooner.

- Sustainability: Steel’s high recyclability makes it an environmentally friendly choice. Structures can be reused or recycled at end-of-life, supporting sustainability efforts.

- Fire Resistance: Steel’s natural fire resistance, which can be enhanced through treatments, adds a safety layer to industrial buildings where fire protection is paramount.

- Adaptability and Expansion: Steel structures offer easy future expansion or modifications, allowing businesses to add sections or alter designs without significant structural alterations, providing long-term flexibility.

Your steel structure industrial building designer

We have accumulated rich design experience and successfully completed multiple steel structure projects, including warehouses, production workshops, factories, etc. Welcome to view our projects. Our design services not only focus on functionality and economy, but also emphasize quality control and project flexibility, providing full customization.

Our design process:

- Demand analysis and preliminary design: We communicate with customers in depth to fully understand their needs, including the purpose of the building, budget, time requirements, etc. On this basis, we will provide a preliminary design plan to ensure that every detail meets the actual needs of the customer.

- Customized design and optimization: Based on the preliminary plan, our design team will conduct detailed structural calculations and optimization. By selecting the most suitable steel and structural form, the design will take into account cost-effectiveness and high strength, ensuring that the building not only meets functional requirements, but also has long-term stability and durability.

- Strict quality control: During the design process, we will implement strict quality control standards to ensure that all details meet industry specifications and customer requirements. Each stage of the design will undergo multiple rounds of review to ensure the accuracy of the design and the safety of the structure.

- Efficient delivery: once the design plan is confirmed, we will immediately enter the production stage and quickly complete the manufacturing and transportation through prefabricated components. The prefabricated nature of steel structures greatly speeds up on-site construction, thereby shortening project cycles and helping customers put the structure into use faster.