The construction industry is one of the biggest offenders when it comes to global carbon emissions, making up over 40% of the total. With environmental concerns at an all-time high, the question is: how do we build smarter, without hurting the planet? Enter steel buildings—a solution that’s strong, efficient, and surprisingly eco-friendly. In this article, we’ll take you through 15 key reasons why steel structures are a game-changer for sustainability, backed by real-world examples. Whether you’re an architect, developer, or just curious about green building, stick with us—we’ll show you how steel is shaping a brighter, greener future.

High Strength and Lightweight Design

Steel’s strength allows for lighter, more efficient structures. In large industrial warehouses, for example, steel framing can cut material use by 30% or more. This reduces the overall environmental impact, while the lighter load on foundations minimizes excavation and reinforcement needs. It’s all about using just what’s necessary—less material, less disruption.

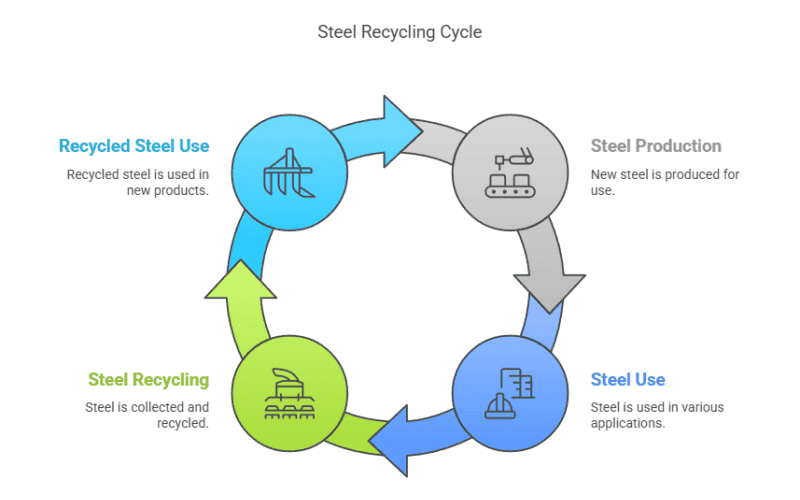

Recyclability and Circular Use

Steel stands as one of the most enduring materials available. It boasts 100% recyclability, and it can be liquefied and repurposed without compromising its strength. Around 600 million tons of steel are recycled globally every year, drastically reducing the need for virgin resources. Our prefabricated structures often incorporate a high percentage of recycled steel, which is not only good for the planet but makes a lot of sense for long-term sustainability.

Longevity and Durability

When considering durability, steel is challenging to surpass. A meticulously designed steel construction can endure for more than 50 years with minimal maintenance requirements. Steel’s resistance to corrosion and seismic activity means it’s ideal for harsh environments. This enduring quality diminishes the necessity for recurrent repairs, thereby causing less disturbance to the environment and decreasing the amount of materials that end up as waste.

High Construction Efficiency and Reduced Carbon Emissions

Prefabricating steel components off-site leads to faster construction times—up to 40% faster, in fact. The result? Reduced energy consumption, fewer emissions, and a quicker project turnaround. Compared to traditional concrete, steel construction can cut carbon emissions by 30% or more during the building phase, making it a clear winner when it comes to lowering the environmental cost of construction.

Minimized Construction Waste

Steel manufacturing is precise, and we take advantage of this. Thanks to advanced digital cutting technologies, we minimize waste throughout the process—often reducing scrap by up to 80%. Most of that scrap is recycled back into the production cycle, so the environmental impact is minimal. This precision in manufacturing makes steel one of the most waste-conscious materials in the industry.

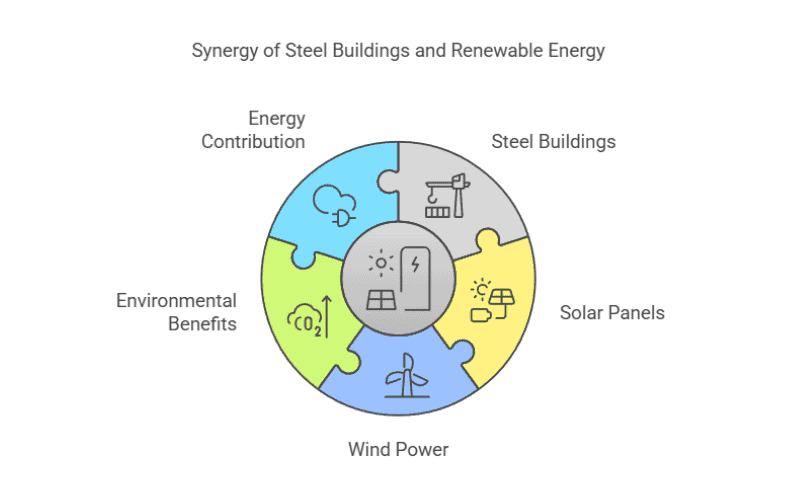

Energy-Efficient Design and Green Certifications

Steel buildings are highly adaptable to energy-efficient technologies like solar panels and high-performance insulation.We guarantee that our designs fulfill rigorous sustainable building criteria such as LEED and BREEAM. For instance, integrating solar panels into a steel-framed office building can reduce energy consumption by 40%, not just saving money but also reducing the building’s overall carbon footprint.

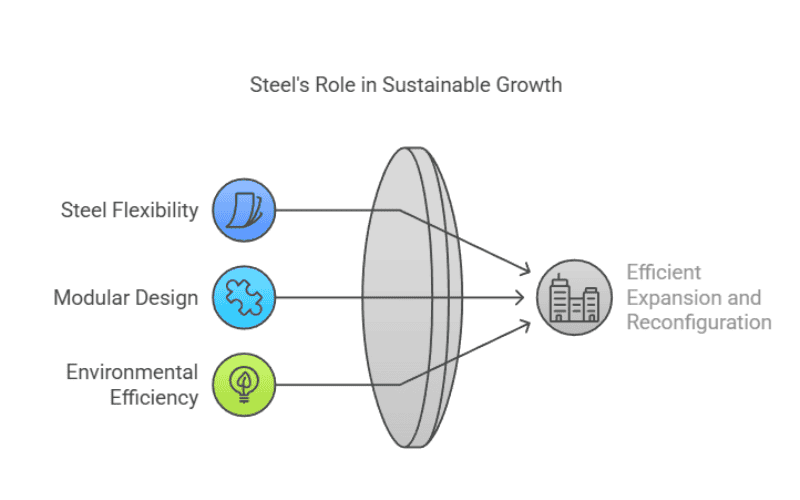

Adaptability and Modular Design

One of steel’s standout qualities is its flexibility. Modular steel constructions can be readily enlarged or rearranged to accommodate shifting requirements, rendering them perfect for enterprises aiming to expand without generating unnecessary waste. Whether you need to add more space to a warehouse or reconfigure office layouts, steel makes the process more efficient, with a smaller environmental footprint.

Reduced Reliance on Natural Resources

More than 30% of global steel production is made from recycled steel. By prioritizing low-carbon steel and recycled materials, we’re helping reduce the demand for iron ore and coal, which are both resource-intensive. This sustainable approach helps support a more circular economy while keeping environmental impacts low.

Lower Transportation Costs and Emissions

Steel elements are weight-reduced, facilitating their transport and enhancing efficiency in doing so. When you combine this with optimized logistics—such as placing manufacturing facilities closer to project sites—you can cut transportation-related emissions by up to 25%. This implies fewer lorries on the highways, diminished fuel consumption, and decreased carbon emissions overall.

Integration with Renewable Energy

Steel buildings provide the perfect platform for renewable energy systems like solar and wind power. For example, a steel warehouse outfitted with solar panels can generate enough electricity to offset its own consumption, while even contributing excess energy back to the grid. It’s a win-win for both building owners and the environment, helping cut emissions by hundreds of tons annually.

Reduced Construction Noise

Since most steel components are prefabricated in controlled factory environments, on-site construction is quieter compared to traditional methods. In busy urban areas, this can reduce noise pollution by up to 50%, improving living conditions for nearby residents and minimizing disturbances to local wildlife. Less noise means less stress on people and ecosystems alike.

Minimal Use of Harmful Chemicals

Steel doesn’t need chemicals to protect it from pests or decay, unlike materials like wood, which require heavy chemical treatments. This makes steel a more eco-friendly option, as it eliminates the need for harmful substances that could leach into soil and water, protecting both the immediate environment and surrounding ecosystems.

Superior Seismic Performance

Steel’s inherent pliability and robustness position it as an exemplary material for structures that are resilient to earthquakes. In earthquake-prone regions, steel buildings often perform better than conventional structures, reducing the likelihood of structural failure and minimizing environmental damage from debris or collapsed buildings. This results in diminished waste and reduced resource utilization during the reconstruction phase.

Promoting Green Supply Chains

The growing demand for steel buildings is pushing the entire steel industry toward more sustainable practices. From more energy-efficient manufacturing methods to increased recycling, steel suppliers are adopting greener technologies. This ripple effect encourages innovation across the construction industry, helping to create a more sustainable, low-carbon future for all.

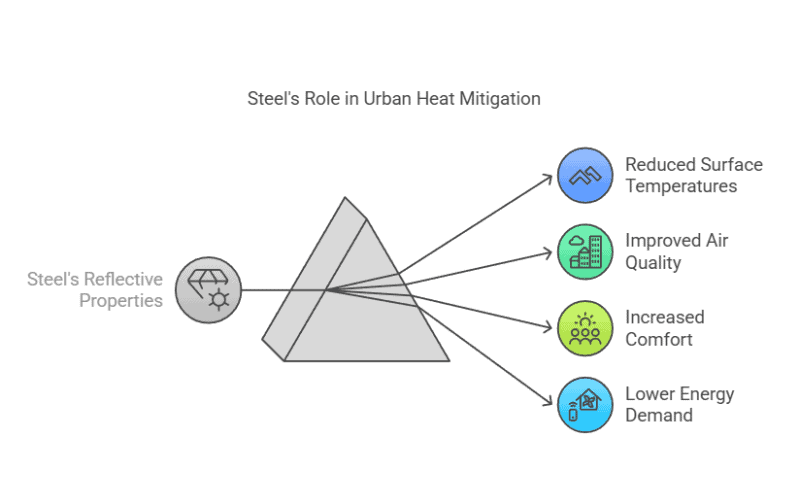

Mitigating Urban Heat Island Effects

Steel’s reflective properties help reduce heat absorption, which is especially important in urban areas prone to the urban heat island effect. For example, a steel-clad building in a city can reduce surface temperatures by 10%, improving air quality and making the space more comfortable. By deflecting more solar radiation, steel likewise aids in decreasing the demand for air conditioning, thereby conserving energy and curbing emissions.

Our Unique Solutions as a Prefabricated Steel Manufacturer

As a pioneer in the production of prefabricated steel, we are dedicated to sustainability throughout each stage of the procedure. Using advanced BIM technology and low-carbon steel production, we reduce waste and emissions while creating custom designs that balance functionality, aesthetics, and environmental responsibility. Whether it’s a Modular Medical Clinic that offers flexible, eco-friendly healthcare solutions or a Solar Power Warehouse designed for maximum energy efficiency, our buildings are built with the future in mind. From design to maintenance, our lifecycle services ensure that our structures remain sustainable throughout their lifespan. By collaborating with industry leaders and continually investing in R&D, we’re setting new benchmarks for green steel construction.