A reasonable and scientific workshop design can ensure production efficiency, construction quality, and later safety and sustainability. This requires designers to fully consider factors such as steel selection, structural layout, and construction process optimization during the design process.

We will gradually analyze how to grasp the key points in different design stages to ensure that the design plan not only meets engineering standards, but also meets actual use needs. I hope that these detailed introductions can help everyone better design future projects.

Basic Principles of Steel Structure Workshop Design

Structural System Selection

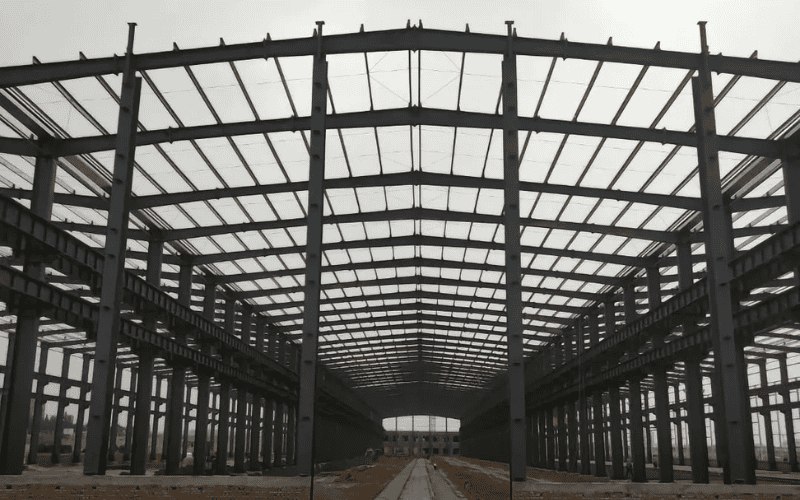

Due to the requirements of process layout, steel structure workshops generally require a larger space and usually adopt frame structures. However, when there are more floors and process conditions permit, frame shear structures can also be used.

The principle of structural layout is to make the column grid symmetrical and evenly arranged as much as possible, so that the rigidity center of the house is close to the center of mass to reduce the spatial torsion of the house. The structural system requires simplicity, rules, and clear force transmission.

Two common structural systems are frame structure and portal frame structure.

Frame structure: Suitable for workshops with large span requirements or flexible separation. This structural system has a high load-bearing capacity and a large span, and is suitable for customers with high requirements for space use. We can adjust the design of the frame according to the customer’s production process to make the structure both stable and effectively utilize space.

Portal frame structure: This is a structural form commonly used in industrial workshops, especially suitable for buildings with small and medium spans. Its advantages are simple construction, high material utilization, and good wind and earthquake resistance. For customers who need fast construction and have limited budgets, we recommend the portal frame structure, which can complete high-quality construction in a short time.

Load calculation

Steel structure workshops bear construction loads, rain, dust, snow pressure, and maintenance loads. The load-bearing performance of metal roof panels is related to the cross-sectional characteristics of the panels, the strength and thickness of the materials, the force transmission method, and the spacing of the purlins (sub-purlins).

Material selection

The choice of materials directly affects the quality, cost and service life of the steel structure workshop.

Steel selection: Commonly used steels are Q235 and Q345. Q235 is suitable for workshops with general load-bearing requirements, while Q345 is suitable for structures that require higher strength. We will recommend the most suitable type of steel to customers based on load requirements and project budget to balance cost and safety.

Roof and exterior wall materials: For the roof and exterior walls of the workshop, we usually recommend the use of color steel plates or composite plates. These materials not only have good durability, but also perform well in thermal insulation, heat insulation and sound insulation. Color steel plates are suitable for workshops with high requirements for appearance, while composite plates are suitable for projects that require higher thermal insulation performance.

11 Key Design Considerations of Steel Structure Workshops

In the design of steel structure workshops, not only the basic functions of the structure should be ensured, but also issues such as fire protection, corrosion resistance and temperature expansion should be considered in depth.

1. Fire Protection Design

Steel will change its performance at high temperatures, mainly manifested as decreased strength and increased plasticity, so fire protection design is crucial.

- Selection and construction of fire retardant coatings: Fire retardant coatings can effectively improve the fire resistance of steel. The selection of coatings should comply with relevant standards. During construction, it is necessary to ensure that the coating is uniform and thick enough to ensure that the fire resistance limit of the steel structure in a fire meets the design requirements. We will select appropriate fire retardant coatings based on the nature of the workshop and the fire protection level.

- Division of fire partitions and personnel evacuation design: According to the function of the building and the density of personnel, the fire partitions are reasonably divided to reduce the risk of fire spread. At the same time, evacuation passages and safety exits should be considered during the design to ensure that personnel can evacuate quickly and safely in the event of a fire.

2. Anti-Corrosion Design

Steel is prone to rust in humid or corrosive environments, such as industrial areas or marine climates. Corrosion will cause the strength of steel to decrease and may cause structural failure. Depending on the environmental conditions, we will recommend customers to adopt different levels of anti-corrosion measures.

- Selection and construction of anti-corrosion coatings: Select appropriate anti-corrosion coatings according to environmental conditions, such as epoxy resins, polyurethane coatings, etc. The thickness and adhesion of the coating are the key to the anti-corrosion effect. The construction must be carried out in accordance with the standards to ensure that the coating is uniform and firm.

- Protection of underground steel columns: The underground steel columns are susceptible to water and soil corrosion, so measures such as concrete wrapping are often required to further improve the anti-corrosion performance.

3. Moisture-proof

Especially in the rainy season in summer, prevent water vapor from condensing in the bottom layer and metal roof layer of the metal roof, and drain the water vapor in the metal roof layer. The solution is to fill the metal roof layer with insulation cotton, lay a waterproof membrane on the bottom plate of the metal roof, and have ventilated nodes on the metal roof panel.

4. Lightning protection

There are many thunderstorms in summer. When designing steel structure workshops, lightning needs to be directed to the ground to prevent lightning from penetrating the metal roof and entering the room.

6. Seepage prevention

In addition to doing a good job of leak prevention, steel structure workshops must also prevent rainwater from seeping into the metal roof panel from the outside. Rainwater mainly enters the metal roof through overlapping gaps or nodes.

To achieve the function of anti-seepage, it is necessary to use a sealing gasket at the screw mouth and use a hidden fixation, use sealant or welding at the overlap of the board, it is best to use a full-length board to eliminate the overlap, and perform strict waterproofing at various node locations.

7. Sound insulation

General steel structure workshops are mostly used in production workshops. During the production and construction process, noise is inevitable. Steel structure workshops prevent sound from being transmitted from the outside to the inside or from the inside to the outside.

Fill the metal roof layer with sound insulation material (usually insulation cotton), and the sound insulation effect is expressed by the difference in decibels of sound intensity on both sides of the metal roof layer. The sound insulation effect is related to the density and thickness of the sound insulation material.

It should be noted that the sound insulation material has different blocking effects on sounds of different frequencies.

8. Insulation

Do a good job of rainwater in summer, and on the other hand, do a good job of insulation in winter. Prevent heat from transferring on both sides of the metal roof of the steel structure workshop to stabilize the indoor temperature.

The insulation function is achieved by filling insulation materials (commonly used are glass wool and rock wool) under the metal roof panel. The insulation effect is expressed by U value, the unit is W/M2K.

The insulation performance is determined by the following factors: the raw material, density and thickness of the insulation cotton; the humidity of the insulation cotton, the connection method between the metal roof panel and the lower structure (to prevent the “cold bridge” phenomenon); the repeated ability of the metal roof layer to resist heat radiation.

9. Lighting

The building area of steel structure workshops is generally large. Skylights are used to improve indoor lighting during the day to save energy. When arranging skylights or lighting glass at specific locations on the metal roof, the service life of the skylight should be coordinated with the metal roof panel, and waterproof treatment should be done at the connection between the skylight and the metal roof panel.

10. Temperature Expansion Joints

Steel will expand or contract when the temperature changes, so temperature expansion joints need to be considered during design. Key design points include:

- Reasonable setting of expansion joints: Expansion joints should be set in appropriate locations, especially in long spans or large workshops, which can effectively absorb the expansion and contraction stress caused by temperature changes.

- Materials and construction of expansion joints: Expansion joints usually require specific materials, such as flexible rubber or metal joints, to ensure that they can work properly when the temperature changes and avoid adverse effects on the steel structure.

11. Support System Design

The design of the support system needs to ensure that the structure can withstand the loads of the roof and other parts while maintaining sufficient rigidity and flexibility.

- Roof support system: The roof support system usually includes straight support and diagonal support. When designing, it is necessary to reasonably select the support method according to the scale of the workshop, roof load and structural layout. Through force analysis, the support system can be optimized to reduce unnecessary material waste and improve the safety and economy of the structure.

We will fully consider each of the above key points during the design process to ensure that your steel structure workshop can not only meet production needs, but also operate safely and stably for many years.

Aesthetic and Functional Design of Steel Structure Workshop

Appearance Design

Steel structure workshops usually adopt a simple style, which can highlight the modern sense and facilitate later maintenance.

- Color matching: Appropriate color matching can make the workshop blend harmoniously with the surrounding environment. Neutral tones with a strong industrial feel are often selected, which are both simple and dirt-resistant.

- Facade effect: The facade design of the workshop should be coordinated with the industrial function to ensure beauty without affecting the practicality of the structure.

Eco-friendly design

The design of steel structure workshops should follow the concept of green buildings, adopt energy-saving and thermal insulation materials, natural ventilation systems, etc., to improve energy efficiency and reduce carbon emissions.

Steel Structure Workshop Design Optimizes Construction Process

The design of a steel structure workshop should be convenient for construction and installation, which should not only improve work efficiency but also effectively control quality.

Prefabrication design

This means that most components will be prefabricated in the factory, and all welding, drilling, spraying and other processes will be completed at the same time to ensure the accuracy and quality of each component. This method reduces the complexity of on-site construction, greatly shortens the construction period of steel structure workshops, and also reduces the errors and quality risks caused by on-site processing.

Connection node design

The design and construction of connection nodes should be carried out strictly in accordance with the standards to ensure that each connection can withstand the design load.

Beam-column node design: The connection node between beams and columns is usually connected by welding or bolts. When designing, factors such as load transfer, node strength and stability should be considered.

Beam-beam node design: When two beams need to be connected, the design of the beam-beam node must ensure sufficient strength, especially for areas that need to withstand large concentrated loads.

Column foot node design: As a key part supporting the entire workshop structure, the column foot must pay special attention to the bearing capacity of the foundation and the connection method of the column foot. It is common practice to firmly fix the steel column to the foundation by bolts or welding.

Optimize Your Steel Structure Workshop Design

In the design of steel structure workshops, we not only focus on functionality and safety, but also emphasize economy and environmental protection. Through optimized design, we can provide customers with solutions that are both cost-saving and meet the requirements of sustainable development.

If you want to create a set of practical and cost-effective design solutions for your steel structure workshop, contact us now! Our professional team will provide you with tailor-made solutions to help you save costs, shorten construction time and achieve environmental protection goals while ensuring quality.