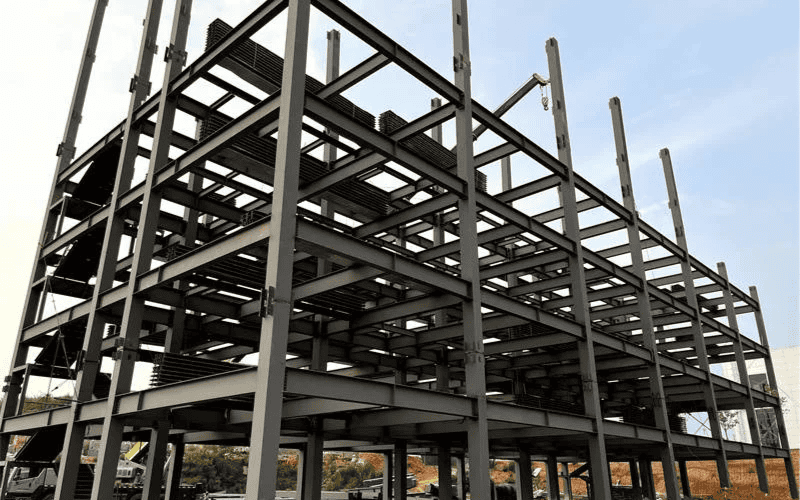

Steel structure design is more than just simple structural calculations. It is a combination of science and art. To ensure the safety, economy and aesthetics of the structure, designers need to follow a series of important principles.

We will explore the core principles of steel structure design in depth, covering everything from material selection to construction details. Whether you are a novice designer or an experienced engineer, you can draw inspiration from these principles to improve the quality of your design and ensure the smooth implementation and long-term use of your project.

Key principles of steel structure design

Steel structure design is an important part of modern architecture, and its design principles directly affect the safety, economy and functionality of the building. The following are the key principles in steel structure design, which I hope will help you better understand the core points of steel structure design.

1. Safety principle

Goal: Ensure that the steel structure can remain stable under different working conditions, withstand all expected loads, and avoid structural damage.

How to ensure:

- Accurate load calculation: Conduct detailed load analysis, consider various possible load types (such as deadweight, live load, wind load, snow load, earthquake load, etc.), and apply reasonable load combinations.

- Strength analysis: Ensure that the strength of each steel component is sufficient through strength analysis, especially in places with large forces, such as columns, beams, nodes, etc.

- Safety factor design: According to different loads and working conditions, reasonably design the safety factor to ensure that the bearing capacity of the steel structure meets safety standards.

2. Economic principle

Goal: On the basis of ensuring safety and functionality, reduce material and construction costs and achieve optimal use of resources.

How to ensure:

- Reasonable selection of materials: Select appropriate types of steel (such as carbon steel, alloy steel, etc.), and optimize materials according to the specific needs of the project to avoid excessive use of expensive materials.

- Structural optimization design: Through calculation optimization algorithms (such as structural topology optimization), rationally arrange components, reduce unnecessary steel use, and ensure efficient material use.

- Standardization and prefabrication: Use standardized components and prefabrication technology to reduce the workload of on-site production and assembly, shorten the construction period, and reduce costs.

3. Durability principle

Goal: Ensure that the steel structure can resist the influence of the natural environment (such as corrosion, weathering, etc.) during long-term use and extend its service life.

How to ensure:

- Anti-corrosion design: Select corrosion-resistant steel, use anti-corrosion coatings (such as hot-dip galvanizing) or other anti-corrosion treatment methods to ensure the stability of the structure in a humid or corrosive environment.

- Regular inspection and maintenance: Consider the maintenance needs of the structure during design to ensure that the steel structure can be regularly inspected and repaired after it is put into use, and timely discover and deal with potential problems.

4. Functionality and flexibility principle

Goal: Ensure that the steel structure meets the use needs, and is flexibly designed according to functional requirements, and can adapt to possible future expansion, transformation or functional changes.

How to ensure:

- Space planning and layout: According to the use function (such as factories, warehouses, commercial buildings, etc.), the layout and space design of the steel structure are reasonably arranged to ensure that the structure meets the use requirements.

- Adaptive design: Consider future functional expansion and changes during design, reserve appropriate space and flexible interfaces, and ensure that the structure can adapt to possible changes in the future.

- Modular design: Through modular and standardized design, the steel structure can be expanded or transformed according to future needs.

- Detachable components: The use of detachable and reconfigurable components makes future reconstruction or reorganization simple and economical.

5. Aesthetic principle

Goal: In addition to meeting functional requirements, steel structure design should also have a good appearance and visual effect to enhance the overall beauty of the building.

How to ensure:

- Reasonable steel structure layout: Through the layout design of steel beams, columns, supports and other components, create beautiful lines and shapes, so that the steel structure can meet the load-bearing requirements while also integrating the aesthetic design of the building.

- Surface treatment: Through the surface treatment of steel (such as painting, coating, etc.), improve its appearance quality and increase corrosion resistance.

- Design innovation: Use the flexibility and expressiveness of steel structures to design unique facade shapes and complex spatial structures to enhance the artistic sense of the building.

6. Environmental adaptability principle

Goal: Ensure that steel structures can adapt to different natural environmental conditions, such as climate, geology, and seismic zones.

How to ensure:

- Consider local climate and geological conditions: When designing, consider factors such as the climate, soil type, and earthquake risk of the building location, and choose the appropriate type of steel and structural form.

- Wind and earthquake resistant design: Especially in areas with strong winds or frequent earthquakes, steel structures should have high wind and earthquake resistance. Use reasonable earthquake-resistant components, damping systems, and structural reinforcement technologies during design.

7. Constructability principle

Goal: Ensure that the steel structure design is easy to construct, safe and efficient during construction, and reduce the difficulty of on-site construction.

How to ensure:

- Reasonably simplify the design: Try to avoid complex structural design, use standardized components and nodes, and reduce the difficulty of on-site construction.

- Prefabrication and modular design: Use prefabricated steel structure components and modular design to shorten the construction period, reduce the workload of on-site workers, and improve construction efficiency.

- Optimize connection nodes: Rationally design the connection parts to ensure that the installation, welding and connection of steel components are simple and easy.

8. Sustainability and environmental protection principles

Goal: Consider environmental protection and sustainability in the design process, reduce resource consumption, and reduce the impact on the environment.

How to ensure:

- Material selection: Select environmentally friendly renewable materials, reduce the use of harmful substances, and give priority to steel and building materials with low carbon emissions.

- Life cycle design: Consider the life cycle of materials during design, optimize building design to improve energy efficiency, reduce energy consumption and resource waste.

- Building disassembly and reuse: Consider the detachability of steel structures during design to ensure that buildings can be disassembled, recycled and reused after the end of their life cycle.

Design Process of Steel Structures: Concept to Completion

Steel structure design is a systematic process that covers multiple links from conceptual design to construction drawing. The following is the main process of steel structure design, which I hope will help you better understand how we work.

1. Determining Suitability

At the beginning of the design, we will first evaluate whether the steel structure is suitable for your project. Steel structure is particularly suitable for the following scenarios due to its high strength, light weight and fast construction speed:

- Long-span buildings: such as stadiums, exhibition halls and airport terminals.

- Heavy-loaded structures: such as factories, warehouses and logistics centers.

- Complex frames: such as high-rise buildings and bridges.

We will provide you with the most appropriate suggestions based on your specific needs, combined with the project’s geographical location, functional requirements and budget.

2. Structure Selection and Layout

After determining the suitability of the steel structure, we will select the appropriate structural form based on the functional requirements of the building.

- Load distribution: Distribute the load reasonably to ensure the overall structural stability.

- Uniformity of stiffness: Avoid insufficient or excessive local stiffness by optimizing the layout.

- Lateral force design: For high-rise buildings or earthquake-prone areas, we will specially design lateral force resistance systems, such as braced frames or core tube structures.

Conceptual design is particularly important at this stage, as it lays the foundation for subsequent detailed design.

3. Cross-Section Estimation

In the preliminary design, we will estimate the cross-sectional dimensions of beams, columns, and supports to ensure that the structure can withstand the expected load.

- Common steel types: such as Q235, Q345, etc., select appropriate materials based on strength, ductility, and economy.

- Selection basis: We will comprehensively consider the load type, span size, and environmental conditions to recommend the most suitable steel for you.

4. Structural Analysis

Structural analysis is the core link in the design process. We guarantee the safety and stability of the structure by conducting precise calculations and simulations.

- Linear elastic analysis: Applicable to most conventional structures.

- Geometric nonlinear and elastic-plastic analysis: For complex structures or special load conditions, we will use more advanced analysis methods.

- Software assistance: Use professional software such as SAP2000 and Autodesk Revit to ensure the accuracy and efficiency of the analysis.

5. Engineering Judgment

We will adjust and optimize the design based on the software calculation results and actual engineering experience. Although software tools play an important role in design, we always pay attention to engineering judgment.

6. Component Design

During the component design stage, we will select appropriate materials according to the stress conditions, and perform cross-section verification and optimization design.

- Elastic-plastic method: In cross-section verification, we will use elastic-plastic method to ensure that the component can remain stable under the limit state.

- Optimized design: Through reasonable design, reduce material consumption, reduce costs, and ensure the safety of the structure.

7. Node Design

Nodes are crucial components in steel structures, as their design has a direct impact on the overall structural performance.

- Connection method: We select appropriate connection methods according to structural requirements, such as rigid connection, hinged connection or semi-rigid connection.

- Node performance: Through precise design and calculation, we ensure that the nodes can effectively transmit force and avoid local failure.

8. Drawing Preparation

After the design is completed, we will draw detailed construction drawings to ensure smooth manufacturing and construction.

- Design drawings and construction details: Design drawings show the overall structural layout, and construction details provide detailed dimensions and connection methods for each component.

- Ensure accuracy: We will carefully check each drawing to ensure that it is accurate and convenient for manufacturing and construction.

What Are the Three Design Methods for Steel Structures?

| Design Method | Key Concept | Applications |

| Allowable Stress Design (ASD) | Limits stress in structural components to a safe level. | Used for simpler, smaller-scale designs. |

| Limit State Design (LSD) | Ensures the structure can withstand both strength and serviceability limit states. | Common in modern design of large and complex structures. |

| Plastic Design (PD) | Utilizes plastic deformation and redistribution of forces for efficient design. | Primarily used for frame structures subject to bending and moment. |

Good assistant for steel structure design

We provide customers with professional steel structure design solutions, from material selection to construction optimization, from anti-corrosion treatment to earthquake-resistant design, to ensure that your project is safe, stable and cost-effective.

Whether you need a large-span industrial plant, flexible commercial space, or complex public infrastructure, we can tailor the best solution for you. Contact us now to achieve higher performance and longer life for your next project with the support of steel structure!

FAQs

What are the main advantages of steel structures?

Steel structures are characterized by high strength and light weight. They are fast to construct, and prefabricated components can shorten the construction period. Steel is recyclable and meets environmental protection requirements. Steel structures have good seismic performance, strong ductility, can effectively absorb seismic energy, have high design flexibility, and can achieve complex geometric shapes and large spans.

What are the main differences between welded connections and bolted connections?

Welded connections have high strength and good integrity, but are complex to construct and difficult to disassemble; bolted connections are easy to install, easy to disassemble and adjust, but have relatively low strength and may require more connectors. When selecting a connection method, it is crucial to consider both structural needs and construction conditions.

What are the common specifications for steel structure design?

- International standards: European standards (Eurocode 3), American standards (AISC).

- Chinese standards: “Steel Structure Design Code” (GB 50017), “Building Seismic Design Code” (GB 50011).

How to choose the right type of steel?

When selecting steel, you need to consider strength, ductility, corrosion resistance and economy. Choose steel of appropriate strength (such as Q235, Q345) according to the load size, choose steel with good ductility in earthquake areas, choose rust-proof steel in humid environments, and choose steel with lower cost while meeting performance requirements.

How to control the cost of steel structure design?

Methods for controlling costs include optimizing design to reduce material waste, using modular design and standardized components, improving construction efficiency to reduce construction delays, and choosing durable materials to reduce later maintenance costs.