When planning a steel building, one of the most common questions is: should I use trusses or rafters? Both systems serve the same purpose—supporting the roof and transferring loads—but their structure, span capacity, and design flexibility differ greatly.

This guide explains what trusses and rafters are, how each functions within modern steel and pre-engineered building (PEB) systems, and the key structural differences that influence cost, performance, and installation time. You’ll also learn how to decide between them based on project size, complexity, and architectural goals.

Drawing on the engineering experience of SteelPRO PEB, a global steel structures manufacturer with ISO-certified production, this article provides practical insight to help you choose the most efficient and durable roof framing system for your next project.

What are the Trusses?

A truss is a structural system made up of multiple interconnected components, usually triangular in shape, that work together to distribute loads across the structure. It is commonly used to support roofs, bridges, and other large-span structures.

The fundamental elements of a truss consist of the top chord, bottom chord, and numerous diagonal web members that interconnect the chords, forming a triangular structure. This arrangement provides the truss with exceptional stability and robustness.

In modern pre-engineered steel buildings (PEB), trusses are widely applied as factory-fabricated roof support systems, providing fast installation and uniform quality across industrial projects.

Types of Trusses

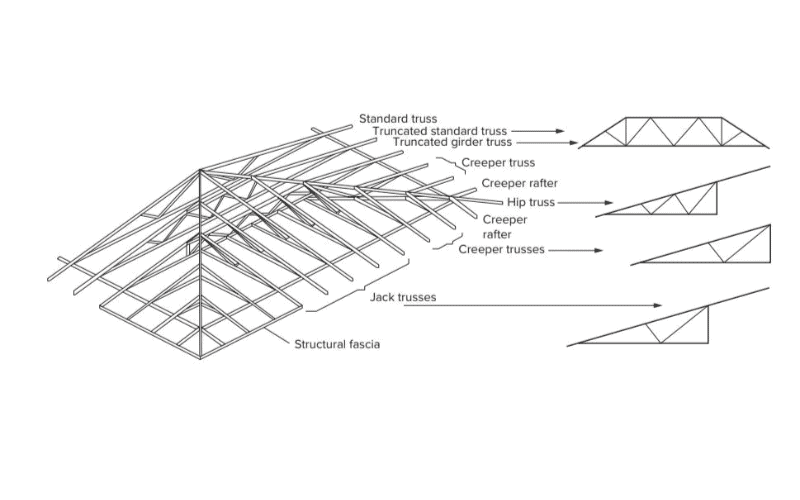

There exist various types of trusses, each tailored to meet distinct design specifications and spans:

- King Post Truss: Consists of two sloping members, a central vertical member, and a horizontal member. It’s suitable for shorter spans and simple structures.

- Queen Post Truss: Analogous to the King Post truss, but featuring two vertical posts instead of one, offering supplementary support for roofs with medium spans.

- Fink Truss: A common truss design that features a series of small triangular units, providing good support while using less material.

- Howe Truss: Characterized by sloping members that angle outward, this truss is often used for heavy loads and large spans.

- Pratt Truss: In contrast to the Howe truss, the sloping members of a Pratt truss angle inward. It’s commonly used for bridges and large-span structures.

- Truncated Truss: Used where the roof slope changes, offering a practical solution for mixed-pitch or hipped roofs.

- Girder Truss: Serves as the main load-bearing truss that supports secondary trusses or concentrated loads across large spans.

- Creeper Truss: Applied in areas where roof slopes intersect or vary, commonly used around valleys or hips to maintain continuity and support.

Advantages of Using Trusses

- Prefabrication for Faster Installation: Trusses are often prefabricated in factories, allowing for quicker on-site installation and reducing construction time.

- Ability to Span Longer Distances Without Intermediate Support: The triangular design of trusses allows them to support long spans without needing additional columns or supports in the middle.

- Cost-Effectiveness for Larger Projects: Trusses offer significant cost savings for large-scale projects due to their efficient material use, prefabrication, and quick installation.

Disadvantages of Using Trusses

- Limited Design Flexibility: Trusses are typically pre-designed and may offer less flexibility compared to traditional framing systems, particularly for custom designs.

- Requires Specialized Equipment for Installation: Due to their size and weight, trusses often require cranes or other heavy equipment to be properly installed, which can add to the overall cost.

- Difficult to Modify After Installation: Once a truss is in place, making modifications to the structure can be challenging and costly.

What Are the Rafters?

A rafter is a sloped beam that forms part of the framework of a roof. Rafters are usually arranged in parallel lines to uphold the roofing material and facilitate the transfer of the roof’s weight to the walls or beams beneath.

While traditional rafters are made from timber, in modern pre-engineered steel buildings (PEB), steel rafters provide greater durability, higher load-bearing capacity, and superior resistance to environmental stress. They are commonly used for smaller to medium-span roofs or for architectural designs that demand more flexibility in form.

Rafters constitute the foundational structural skeleton for a wide array of roof types, ranging from straightforward gable roofs to more intricate designs.

Types of Rafters

Rafters are available in various types, each tailored to fit particular roof designs:

- Common Rafters: The basic type of rafter, commonly used in gable roof designs. They slope from the ridge of the roof down to the eaves.

- Hip Rafters: Rafters that form the diagonal angle of a hip roof. They connect the ridge to the eaves at an angle and are used in roofs with four sides sloping towards the center.

- Valley Rafters: These rafters form the intersection of two sloped roof sections, commonly seen in roofs with valleys where two slopes meet.

- Jack Rafters: Short rafters that connect to a hip or valley rafter, filling the space between the main rafters and the eaves.

Advantages of Using Rafters

- Greater Design Flexibility and Customization Options: Rafters allow for more flexibility in roof design, as they can be adjusted or customized for a variety of shapes, slopes, and complexities.

- Easier to Modify or Repair After Installation: Unlike trusses, which are pre-assembled, rafters are easier to modify or repair after installation, providing more options for future changes.

- Suitable for Complex Roof Designs: Rafters are often the go-to option for more intricate and custom roof designs, such as multi-angled roofs, dormers, and irregular shapes.

Disadvantages of Using Rafters

- Requires Skilled Labor for Installation: Installing rafters requires a higher level of skill and precision compared to trusses, as each rafter must be cut and placed correctly.

- Longer Installation Time Compared to Trusses: The installation process for rafters typically takes longer than for pre-fabricated trusses, as each component is installed individually.

- May Require Additional Support for Longer Spans: For larger spans, rafters may require additional structural supports, such as beams or posts, to maintain stability.

- Compared to trusses, steel rafters require more site assembly, which can extend installation time for large-span projects.

Key Differences Between Trusses and Rafters

| Aspect | Trusses | Rafters |

| Structure | Pre-fabricated triangular framework | Individual sloped beams forming the roof frame |

| Span | Can span longer distances (up to 60 feet or more) | Typically used for shorter spans (10-30 feet) |

| Installation Time | Faster, as they are pre-assembled | Slower, requires individual installation |

| Design Flexibility | Limited design options | Highly flexible, customizable designs possible |

| Cost | More cost-effective for large projects | Lower initial cost, but can be more expensive for custom work |

| Modifications | Difficult to modify after installation | Easier to modify or repair after installation |

| Support | Can span longer distances without support | May require additional support for longer spans |

| Labor Requirement | Requires less skilled labor | Requires skilled labor for accurate installation |

| Complexity | Simpler to install, less flexible | More complex, suitable for intricate designs |

| Suitable for | Large-span structures, simple roof designs | Custom, complex, or irregular roof designs |

| Weight | Lighter, as they distribute load effectively | Heavier, requires more material for support |

| Maintenance | Low maintenance once installed | Requires more maintenance and attention |

In modern steel and PEB (Pre-Engineered Building) systems, both trusses and rafters serve crucial but distinct roles.

- Span: Trusses outperform rafters when it comes to long-distance coverage, making them ideal for warehouses, factories, and industrial sheds.

- Load: Trusses distribute load more evenly through their triangular geometry, reducing stress concentration.

- Flexibility: Rafters, on the other hand, offer greater flexibility for architectural or aesthetic roof forms where customization matters.

In summary, trusses are ideal for large-span industrial and warehouse structures, while rafters are preferred in projects requiring architectural flexibility or visual design variations.

Choosing Between Trusses and Rafters

Selecting between trusses and rafters depends on several factors, including the size, complexity, and intended use of your project. Each system has its advantages and is better suited for specific conditions.

Project Size and Complexity

If your project involves large spans or industrial-scale structures, trusses are typically the better choice due to their ability to cover long distances without the need for intermediate supports.

For industrial steel workshops and warehouses, prefabricated trusses are more efficient and reduce on-site labor.

For residential, aesthetic, or small-scale projects, rafters are preferred due to their flexibility and adaptability to unique roof shapes.

Budget Constraints

Trusses are generally more cost-effective for large projects, especially when prefabrication and factory-controlled production are considered.

However, for smaller or custom projects where design flexibility is important, rafters can be more affordable — though installation may require more skilled labor.

Desired Roof Design and Aesthetics

If your project emphasizes architectural uniqueness or complex geometries, rafters provide more creative freedom.

Trusses, on the other hand, are optimized for structural efficiency and speed, making them ideal for functional buildings such as warehouses, workshops, and commercial storage facilities.

Local Building Codes and Regulations

Always verify local building codes to ensure compliance. Some regions prefer trusses for their engineered consistency and strength, while others may favor rafters for heritage or custom structures.

Choose Trusses When:

- Your building requires long spans, high load capacity, or clear internal space.

- You need faster installation and factory-prefabricated components.

- The design is relatively simple and cost efficiency is a priority.

- You’re constructing industrial or commercial PEB buildings.

Choose Rafters When:

- The roof design is complex, custom, or decorative.

- You want flexibility for future modifications or architectural details.

- Skilled labor is available for precision site assembly.

- The structure is residential or architectural, where form matters as much as function.

For factory-built steel structures, consulting a certified PEB manufacturer like SteelPRO PEB ensures you receive the most efficient structural design, accurate fabrication, and cost-effective solution tailored to your project’s requirements.

How do I tell if I have trusses or rafters?

To determine whether your roof is supported by trusses or rafters, check for the following characteristics:

- Trusses: Prefabricated triangular frameworks made up of horizontal, vertical, and diagonal members. They appear as large, interconnected triangular shapes and are evenly spaced. Common in factory-fabricated steel buildings.

- Rafters: Individual sloped beams extending from the ridge to the eaves. They are spaced farther apart and lack the triangular webbing typical of trusses. Often found in traditional or custom roof systems.

Can you replace rafters with trusses?

Yes, it is possible to replace rafters with trusses, but this often requires structural modifications to the building. Trusses are typically pre-engineered and can be installed with less labor, but the existing structure may need adjustments to support their geometry and load paths. Always consult a qualified structural engineer or steel building manufacturer before conversion.

Can I use both trusses and rafters together?

Yes, in certain cases, it is feasible to utilize both trusses and rafters simultaneously. For example, trusses can form the main structural framework, while rafters may be used in custom roof sections such as valleys, dormers, or decorative slopes. Proper planning and design coordination are essential to ensure compatibility between systems.

Can girder trusses and rafters be used in the same steel building?

Yes. In pre-engineered steel structures, a girder truss often serves as the main supporting member, carrying loads from secondary rafters or trusses. This hybrid system provides both span efficiency and design flexibility, commonly used in industrial workshops and warehouse roofs.

Making the Right Choice Between Trusses and Rafters with a Trusted Steel Building Manufacturer

Choosing between trusses and rafters is ultimately a balance between structural performance, project scale, and design intent. Trusses excel in long-span, high-load steel buildings where efficiency, speed, and cost control matter most. Rafters, by contrast, offer the flexibility and craftsmanship needed for complex or visually expressive roof forms.

For engineers, builders, or project owners, understanding these distinctions ensures that each structure achieves both strength and practicality. In modern pre-engineered steel building (PEB) systems, combining accurate design with factory-fabricated components minimizes construction errors and guarantees predictable performance over decades of use.

With years of global project experience and ISO-certified production, SteelPRO PEB provides structural solutions that align with engineering best practices—helping clients select, design, and implement the optimal roof system for their specific application. If you’re planning a steel building and unsure whether a truss or rafter suits your project, our engineering team can help you evaluate both options based on span requirements, load design, and cost efficiency.