What is a steel mezzanine?

A steel mezzanine is an intermediate structure added to the original space of an existing building to create more usable space. It is not an independent floor like a traditional multi-story building, but is suspended or supported on the existing structure of the building and used as an additional floor. This structure can effectively utilize vertical space and improve the efficiency of floor use.

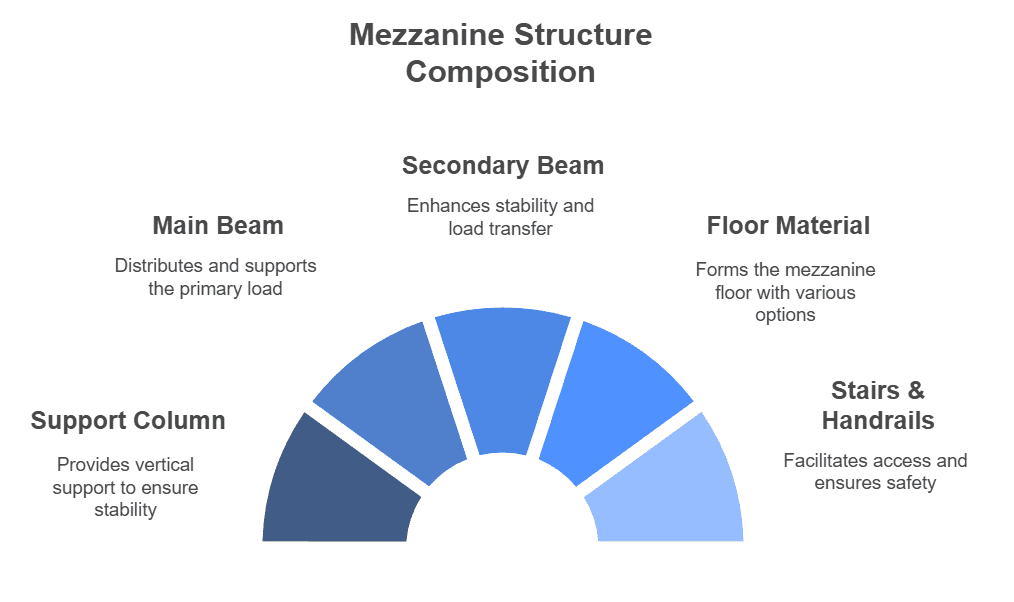

Components of a Steel Mezzanine

Structural Steel Frame

- Beams & Columns: H-shaped steel beams and square steel columns form the primary framework to support loads.

- Connections: Bolted or welded joints ensure stability of the mezzanine steel structure.

Steel Mezzanine Floor

- Materials: Steel plates or grating, providing slip-resistant and ventilated surfaces.

- Modular Design: Prefabricated steel mezzanine details allow quick installation and adjustments.

Structural Support System

- Column Bases: Embedded steel plates or chemical anchors transfer loads for metal building mezzanine setups.

- Bracing & Crossbeams: Reinforce the steel structure mezzanine floor against lateral forces.

Connectors & Accessories

- Standardized Parts: Prefab structural steel mezzanines include pre-drilled beams, stairs, and guardrails.

- Expansion Options: Bolt-ready interfaces enable vertical extensions like multi-story steel mezzanines.

Optional Add-Ons

- Stairs & Walkways: Fixed or foldable designs compliant with steel mezzanine safety standards.

- Guardrails & Lighting: Integrated into the steel mezzanine design for offices or warehouses.

Types of Steel Mezzanines

Prefabricated Steel Mezzanines: Factory-built modular components (e.g., steel mezzanine kits) for fast on-site assembly, ideal for standardized warehouse spaces.

Free-Standing Steel Mezzanines: Self-supported structures that don’t rely on walls, perfect for warehouse or factory retrofits.

Multi-Story Steel Mezzanines: Vertical steel-framed layers, designed for multi-level storage or office setups.

Temporary Steel Mezzanines: Adjustable and removable steel mezzanine systems, ideal for short-term events or flexible storage needs.

Clearspan Steel Mezzanines: Column-free designs for open spaces, suited for machinery or exhibitions.

Structural Steel Mezzanines: Heavy-duty structural steel mezzanines with beams and columns to support equipment or dense shelving.

Office-Ready Steel Mezzanines: Integrated mezzanines office portable designs with wiring and soundproofing for workspaces in industrial settings.

Warehouse Steel Mezzanines: Space-efficient steel warehouse mezzanines paired with shelving and logistics pathways.

Barn Steel Mezzanines: Moisture-resistant barn mezzanine designs for agricultural storage of hay or equipment.

Custom-Built Steel Mezzanines: Tailored steel mezzanine structures for irregular spaces or specialized load requirements.

What are the benefits of Steel Mezzanine?

High Strength and Durability

Steel possesses significantly greater strength than wood or concrete, enabling it to support heavy loads without undergoing deformation. This means that whether it is storing heavy equipment, large amounts of cargo, or serving as a production platform, steel mezzanine can easily cope with it. Its durability is also excellent, especially after rust-proofing, it can be used in harsh industrial environments for a long time and can last for decades. You can rest assured that the steel mezzanine will not lose its stability over time.

Flexibility

Steel mezzanine is designed to be flexible and can be customized in size, shape and function according to your needs. Whether you need a simple storage platform or a complex multi-story office space, steel mezzanine can meet your needs. Its modular design allows it to adapt to various building structures and even bypass existing obstacles such as pipes or equipment. This flexibility makes steel mezzanine ideal for responding to diverse needs.

Quick Installation

Steel mezzanine can be installed very quickly, thanks to its modular design. All components are manufactured in the factory in a prefabricated manner and then easily assembled on-site, akin to constructing with building blocks.

This means that the installation process will have minimal disruption to existing operations, and you can start using it in the shortest possible time, reducing the losses caused by downtime. Typically, a standard steel mezzanine installation takes only 1 to 4 weeks, depending on the size and complexity of the project.

Economical

Compared to expansion or relocation, steel mezzanines are a more economical space expansion solution. Not only are steel mezzanines cheap to install, they can also quickly increase the usable area in existing buildings, helping you maximize the use of existing resources. Its return on investment is very high, especially when you consider the long-term benefits it brings.

Detachable and movable

Some steel mezzanines are designed to be removable and movable, which means they can be adjusted according to future needs. If you need to change the layout or relocate equipment, steel mezzanines can be easily disassembled and reinstalled to a new location. This flexibility is particularly suitable for companies whose business needs change frequently, ensuring that your investment can play a role in the long run.

What is the use of mezzanines?

Warehousing and logistics

In the field of warehousing and logistics, space is money. Steel mezzanines can increase storage capacity and help you maximize the vertical space of the warehouse. By adding mezzanines, you can store more goods without expanding the warehouse area. This not only improves space utilization, but also optimizes logistics processes and reduces the time and cost of moving goods.

Production and manufacturing

In production and manufacturing environments, steel mezzanines can provide additional production or assembly space. You can install production lines or equipment on the mezzanine, freeing up floor space for other uses. This layout not only improves production efficiency, but also makes the factory operation more flexible and efficient.

Office space

If you need more office space but don’t want to relocate or expand, steel mezzanines are a perfect solution. It can create additional office areas in existing buildings, whether it is a simple desk layout or a complex meeting room and lounge area, steel mezzanines can meet your needs. Its design is versatile and can be tailored to align with your brand image and office requirements.

Retail environment

In retail environments, steel mezzanines can expand sales or storage space and enhance customer experience. You can use the mezzanine as an additional display area to increase the display area of goods, or use it as backstage storage to ensure that the sales area is neat and orderly. The mezzanine’s design can also complement the store’s overall aesthetic, thereby enhancing the brand image.

Special uses

Steel mezzanines can also be used for some special purposes, such as equipment platforms, observation decks, etc. For example, in a factory, you can use the mezzanine as an equipment maintenance platform, which is convenient for technicians to inspect and repair equipment. In a stadium or event center, the mezzanine can be used as an observation deck to provide a better view and experience.

If you are looking for an efficient, flexible and affordable space expansion solution, steel mezzanine is undoubtedly your best choice. If you have any questions or need a customized solution, please feel free to contact us, we will provide you with the most professional advice and service!

Design and Installation of Steel Mezzanine

Steel Mezzanine Design

Load Capacity

The load-bearing capacity of the steel mezzanine stands as a pivotal aspect of its design. The load capacity of mezzanine is usually designed to be between 150 and 1000 kg per square meter. If you need to store heavy equipment or a large amount of goods, the load capacity may need to reach more than 500 kg; if it is only used for light office or display, a load capacity of 150-300 kg may be sufficient.

During the design, our engineers will accurately calculate the structural strength of the mezzanine according to your specific use and load requirements to ensure that it can safely carry the expected weight.

Size and Height

The size and height of the steel mezzanine are completely customized according to your building space and usage requirements. If your warehouse ceiling height is 10 meters, you can design a 3-meter-high mezzanine to leave enough space for ground operations.

The thickness of the mezzanine floor typically depends on the specified load capacity and the chosen material. Generally speaking, the thickness of steel mezzanine floor ranges from 50 mm to 150 mm, depending on the material used (such as steel grating, moisture-proof particle board or concrete) and the load requirements.

- Moisture-proof flooring: Suitable for light to medium loads, with good moisture resistance, often used in offices or light storage.

- Steel grating: Suitable for heavy load environments, with good ventilation and drainage performance, often used in industrial or storage environments.

- Concrete: Suitable for ultra-heavy load environments, providing extremely high stability, often used for heavy equipment platforms or mezzanines for long-term use.

Steel Mezzanine Installation

We provide customers with detailed installation instructions and technical support. Our technical team can provide installation manuals, construction drawings and necessary remote training guidance to help customers assemble the mezzanine efficiently and accurately.

Due to the modular design of our steel mezzanines, they can be installed quickly, minimizing interference with your existing operations. The installation time of steel mezzanines is usually 1 to 4 weeks, depending on the size and complexity of the project.

The steel mezzanines that we design and manufacture adhere fully to local building regulations and safety standards. Our design and production processes undergo rigorous quality control to guarantee that the final product fulfills both functional needs and safety specifications. After each project is completed, we will also assist customers in preparing relevant acceptance documents to ensure that the mezzanine installation meets the prescribed building standards and passes quality acceptance.

Maintenance and Care of Steel Mezzanine

Regular Inspection

Regular inspections are crucial for ensuring the structural integrity and safety of the steel mezzanine. It is recommended to conduct a comprehensive inspection every 6 months or once a year, focusing on the following areas:

- Support columns and beams: Check for deformation, cracks or corrosion.

- Floor materials: Check for wear, looseness or damage, especially moisture-proof flooring and steel gratings.

- Stairs and handrails: Make sure the stairs are stable and the handrails are not loose or damaged.

- Edge protection system: Check whether the handrails and skirting boards are secure to prevent the risk of falling.

By regular inspections, you can detect potential problems in time, avoid small problems from turning into major failures, and ensure the long-term safe use of the mezzanine.

Cleaning

Keeping the steel mezzanine clean not only prolongs its service life, but also prevents corrosion or damage. Here are some cleaning suggestions:

- Floor cleaning: Sweep the floor regularly, especially the steel grating, to prevent dust and debris from accumulating. For moisture-proof floors, cleaning with a damp cloth is advisable, but excessive water should be avoided.

- Steel surface: If the mezzanine is exposed to moisture or corrosive environments, it is recommended to clean the steel surface regularly and treat it with a rust inhibitor.

- Drainage system: If the mezzanine is designed with steel grating, ensure that the drainage holes are unobstructed to avoid water accumulation and corrosion.

Repair

If any damage or wear is found during the inspection, timely repair is the key to ensure the long-term use of the mezzanine. Here are some common repair measures:

- Replace damaged floor materials: If the floor becomes worn or damaged, it should be promptly replaced with new materials to guarantee the safety of the mezzanine.

- Repair corrosion or cracks: If corrosion or cracks are found in the steel, repair it in time to prevent the problem from expanding.

- Tighten loose parts: Check bolts and connectors regularly to ensure that they are not loose, and tighten or replace them if necessary.

Through timely maintenance and care, you can extend the life of the steel mezzanine and ensure that it always remains in the best condition.

Cost and return on investment of Steel Mezzanine

Factors affecting the cost of Steel Mezzanine

- Material cost: steel, floor materials, stairs and handrails, etc.

- Design costs: Engineers’ design fees to ensure the mezzanine meets your needs and building specifications.

- Processing and manufacturing costs: Precision processing and manufacturing costs in the factory.

- Transportation costs: Transporting the mezzanine components to your designated location.

- Maintenance costs: The cost of regular inspections, cleaning and repairs.

While the initial investment may seem substantial, the long-term economic advantages of steel mezzanines are highly significant. Through proper design and manufacturing, you can maximize the use of existing space and reduce the cost of expansion or relocation.

What can you get in return for investing in steel mezzanines?

- Increase space utilization: By utilizing vertical space, you can increase storage or work area without expansion, significantly improving space utilization.

- Reduce operating costs: Compared with expansion or relocation, steel mezzanines are less expensive, and the installation process has less interference with existing operations, reducing losses caused by downtime.

- Improve production efficiency: In production and manufacturing environments, steel mezzanines can provide additional production or assembly space, optimize production processes, and improve efficiency.

- Long-term use value: The durability and flexibility of steel mezzanines enable them to be used for a long time, adapt to future changes in business needs, and ensure that your investment can play a role in the long run.

If you are considering installing a steel mezzanine, it is recommended that you work with a professional supplier, like us, to ensure that every aspect from design to maintenance is properly taken care of. We are here to support you and help you achieve your space expansion goals!

Steel Mezzanine vs Concrete Mezzanine vs Wooden Mezzanine

| Feature | Steel Mezzanine | Concrete Mezzanine | Wooden Mezzanine |

| Strength | High (suitable for heavy loads) | Very High (suitable for ultra-heavy loads) | Low (suitable for light loads) |

| Durability | High (rust-resistant, long lifespan) | Very High (almost no deformation) | Low (prone to moisture, corrosion, pests) |

| Flexibility | High (customizable, removable) | Low (not movable) | Medium (suitable for small projects) |

| Installation Speed | Fast (modular design) | Slow (requires pouring and curing) | Fast (easy to process and install) |

| Cost | Medium-High (higher initial cost) | High (material and construction costs) | Low (material and installation costs) |

| Maintenance Cost | Low (requires periodic inspections) | Low (almost no maintenance) | High (requires moisture and pest protection) |

| Eco-Friendliness | High (steel is recyclable) | Medium (concrete is not recyclable) | Medium (wood is renewable but requires deforestation) |

| Best Use Cases | Industrial, warehousing, offices, retail | Ultra-heavy loads, high fire-resistance requirements | Light storage, temporary projects, decorative purposes |

Steel Mezzanine: While the initial cost is higher, its long-term economic benefits and adaptability make it the top choice for most businesses.

Concrete Mezzanine: Suitable for ultra-heavy loads and high fire-resistance requirements, but its heavy weight, long installation time, and immobility make it best for long-term, fixed-use projects.

Wooden Mezzanine: Suitable for budget-friendly, light-load, or temporary projects, but its poor durability and fire resistance make it unsuitable for long-term or heavy-load use.

If you need an efficient, flexible, and cost-effective space expansion solution, Steel Mezzanine is undoubtedly your best choice. If you have any questions or need a customized solution, feel free to contact us—we’re here to provide expert advice and support!

FAQs

Does Steel Mezzanine comply with building codes?

Yes. Steel Mezzanines are designed and manufactured in strict adherence to the requirements of the International Building Code (IBC) and the Occupational Safety and Health Administration (OSHA), thereby guaranteeing their structural safety and regulatory compliance.

What is the best material for a mezzanine floor?

The best material for a mezzanine floor is steel because it is strong, durable, and cost-effective. For the flooring surface, metal decking or steel plates are commonly used.

Is a mezzanine floor expensive?

This is uncertain. The cost of a mezzanine floor varies based on materials used, design, and size. Although the initial investment may exceed that of some other options, its long-term advantages are substantial.