Did you know that the right building materials can cut your energy costs by up to 30%? In today’s fast-paced construction industry, efficiency, durability, and sustainability are no longer optional—they’re essential. That’s where sandwich panels come in. These innovative components have become a cornerstone of modern steel buildings, offering a unique combination of strength, insulation, and versatility. But what exactly are sandwich panels, and how can they enhance your next steel building project?

In this article, we’ll explore everything you need to know about sandwich panels in steel buildings. From their lightweight structure and customizable core materials to their energy-saving benefits and diverse applications, we’ll show you why they’re a perfect match for modern steel construction. By the end, you’ll understand how sandwich panels can make your steel building more energy-efficient, cost-effective, and durable—while saving you time and money.

Key Takeaways:

- Sandwich panels make steel buildings more energy-efficient, durable, and flexible in design.

- Perfect for walls, roofs, ceilings, and special areas—sandwich panels work seamlessly with steel structures.

- Pick from common sandwich core materials, such as PUR/PIR, mineral wool, or EPS cores, for insulation, fire safety, or cost savings.

- Ideal for industrial, commercial, cold storage, agricultural, and many other types of steel buildings.

Table of Contents

What Are Sandwich Panels, and Why Are They Perfect for Steel Buildings?

At their core, sandwich panels are a perfect match for steel structures. They consist of three layers:

- Two Outer Metal Skins: Made from galvanized steel, coated steel, or other metals such as aluminum, these skin layers align perfectly with the durability and strength of steel frameworks.

- Insulating Core: Sandwiched between the metal layers is a core material that provides thermal and acoustic insulation, enhancing the comfort and efficiency of your steel building.

This design makes sandwich panels lightweight, easy to install, and highly efficient—qualities that complement the inherent advantages of steel structures.

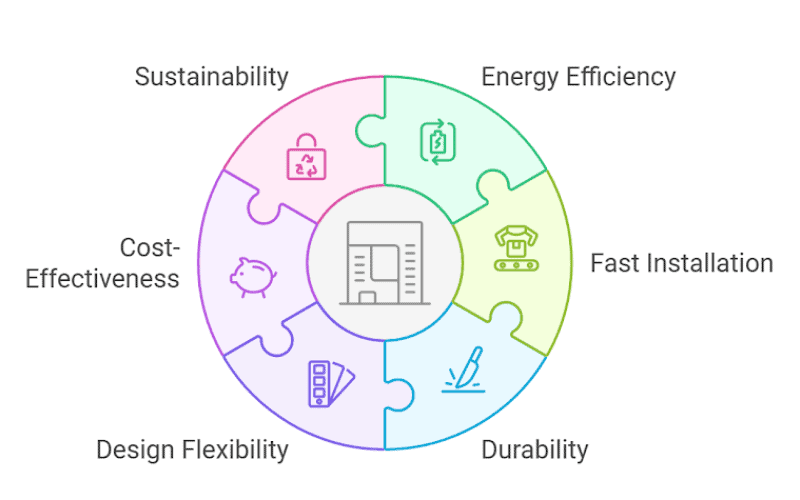

How Sandwich Panels Enhance Steel Buildings

When integrated into steel buildings, sandwich panels deliver a range of benefits that align perfectly with the goals of modern construction:

1. Energy Efficiency

Steel buildings are known for their strength, but they can lose energy quickly without proper insulation. Sandwich panels solve this problem by minimizing heat transfer, reducing heating and cooling costs, and making your steel building more energy-efficient.

Related Reading:

The Cheapest Way to Insulate a Metal Building without Compromising Quality

2. Fast Installation

One of the biggest advantages of steel structures is their quick assembly. Sandwich panels amplify this benefit—they’re prefabricated, lightweight, and easy to install, ensuring your project stays on schedule.

3. Durability

Steel buildings are built to last, and sandwich panels are no different. Their metal skins resist corrosion and weathering, ensuring your building remains strong and reliable for decades.

4. Design Flexibility

Steel structures offer incredible design freedom, and sandwich panels enhance this further. Available in various colors, profiles, and finishes, they allow you to create a functional and visually stunning building.

5. Cost-Effectiveness

By combining the speed of steel construction with the energy-saving properties of sandwich panels, you get a building that’s cost-effective to build and operate.

6. Sustainability

Steel is already a recyclable material; sandwich panels add to this sustainability. Their insulating cores reduce energy consumption, while the metal skins are fully recyclable, making them an eco-friendly choice.

Where Do Sandwich Panels Fit in Steel Buildings?

Sandwich panels are incredibly versatile, making them a natural fit for various parts of a steel building. Here’s how they’re typically used:

| Application | Benefits | Ideal For |

| Walls (Exterior and Interior) | Excellent insulation, weather resistance, and a polished look. | Offices, factories, warehouses. |

| Roofs | Lightweight, waterproof, and insulating. Reduces structural load. | Industrial facilities, commercial buildings, cold storage. |

| Ceilings | Smooth finish, hides wiring, improves sound insulation. | Offices, schools, hospitals. |

| Partition Walls | Quick to install, perfect for flexible layouts. | Industrial facilities, commercial spaces. |

| Cold Storage Facilities | High-performance insulation maintains consistent low temperatures. | Food processing plants, refrigerated warehouses. |

| Specialized Areas | Fire resistance, moisture resistance, and durability. | Clean rooms, laboratories, explosion-proof rooms. |

Core Materials: Choosing the Right Fit for Your Steel Building

The core material of a sandwich panel plays a crucial role in its performance. Here’s a quick guide to the most common types and how they align with the needs of steel buildings:

- Polyurethane (PUR) and Polyisocyanurate (PIR): These materials offer excellent thermal insulation, fire resistance, and moisture protection, making them ideal for energy-efficient steel buildings.

- Mineral Wool: If fire safety and soundproofing are priorities, mineral wool is the way to go. It’s also eco-friendly, aligning with the sustainability goals of many steel building projects.

- Expanded Polystyrene (EPS): A cost-effective option with good insulation properties, EPS is perfect for budget-conscious steel building projects.

Performance Metrics: How Sandwich Panels Elevate Steel Buildings

When integrated into steel buildings, sandwich panels deliver measurable performance benefits:

- Thermal Conductivity (U-value): With U-values ranging from 0.20 to 0.50 W/m²K, sandwich panels ensure your steel building stays energy-efficient year-round.

- Fire Resistance: Depending on the core material, sandwich panels can achieve fire ratings like A2 or B1, enhancing the safety of your steel structure.

- Acoustic Performance: With sound reduction values (Rw) of up to 40 dB, sandwich panels help create quieter, more comfortable spaces within your steel building.

Installation and Maintenance: Seamless Integration with Steel Structures

One of the biggest advantages of sandwich panels is how well they integrate with steel structures:

- Installation: Sandwich panels are designed to work seamlessly with steel frameworks. They’re lightweight, easy to handle, and can be installed quickly using mechanical fasteners or adhesives.

- Maintenance: Thanks to their durable metal skins and robust cores, sandwich panels require minimal upkeep. A quick clean with water and mild detergent is usually all it takes to keep them in top condition.

Customization Options: Tailoring Sandwich Panels to Your Steel Building

Sandwich panels offer a high degree of customization to meet the specific needs of your steel building project:

- Colors and Finishes: Choose from a wide range of colors and finishes to match your building’s aesthetic. Whether you’re going for a sleek metallic look or a bold corporate color, the options are endless.

- Special Features: Need something extra? Sandwich panels can be customized with features like anti-static coatings for labs, antimicrobial surfaces for healthcare facilities, or even integrated solar panels for energy-generating roofs.

Common Dimensions of Sandwich Panels

Sandwich panels come in a variety of sizes to suit your steel building needs:

- Thickness: 40mm to 200mm. Thinner panels (40–60mm) are great for interior partitions, while thicker panels (120–200mm) are ideal for cold storage or high-insulation areas.

- Width: Standard widths are usually 1000mm (about 3.3 feet), but custom sizes are available.

- Length: Custom lengths are an option, though standard lengths often go up to 12 meters (about 39 feet).

Applications in Steel Buildings

Sandwich panels are a go-to solution for a wide range of steel buildings, including:

| Building Type | Key Applications | Benefits |

| Industrial Facilities | Warehouses, manufacturing plants, factories. | Durability, insulation, quick installation. |

| Commercial Buildings | Offices, retail stores, supermarkets. | Energy efficiency, sleek appearance. |

| Cold Storage Facilities | Food processing plants, refrigerated warehouses. | Maintains consistent low temperatures. |

| Agricultural Buildings | Barns, storage sheds, livestock housing. | Clean, hygienic, and insulated. |

| Sports and Recreational Facilities | Gyms, sports halls, recreational centers. | Lightweight and insulating. |

| Aviation and Transportation Hubs | Airports, hangars, bus terminals. | Durability, withstands harsh environmental conditions. |

| Healthcare and Laboratory Facilities | Hospitals, clinics, laboratories. | Fire resistance, moisture resistance, meets stringent hygiene standards. |

Need Help with Your Steel Building Project?

Every component of a steel building must work together to deliver maximum value. Sandwich panels are no exception—they enhance the efficiency, durability, and aesthetics of steel buildings, making them an essential part of modern construction. Whether you’re building walls, roofs, ceilings, or specialized areas, sandwich panels are a versatile and reliable choice that aligns perfectly with the strengths of steel structures. Sandwich panels are also a key element of the enclosure system of steel factory buildings, offering superior insulation, weather resistance, and structural support. By optimizing these systems, we ensure your project is not only functional but also highly efficient.

Not sure which sandwich panel material is right for your needs? Don’t know how to install sandwich panels correctly and efficiently? Struggling with the design of your building envelopes? We’ve got you covered! As a leading steel structure manufacturer with over 20 years of experience, we offer one-stop solutions to solve all your challenges. From planning and designing to manufacturing and shipping, we’ll help you create a steel building that’s strong, efficient, and built to last. Contact us today — our dedicated teams are waiting for your calls!