Steel roof trusses have become a cornerstone of modern construction—offering a strong, lightweight, and adaptable framework for industrial, commercial, and prefab buildings. But are they the right choice for your project? This guide breaks down the key advantages, real-world challenges, and professional solutions behind these engineered structures, helping you make an informed structural decision.

You’ll discover why steel trusses excel in mechanical performance, large-span efficiency, and prefab adaptability, as well as how to overcome practical issues such as space requirements, fabrication precision, and corrosion or fire protection.

Drawing from the expertise of SteelPRO PEB, an ISO- and CE-certified steel structure manufacturer, this article combines engineering insights with factory-level experience. Whether you’re evaluating durability, cost efficiency, or installation demands, you’ll learn how factory-produced steel trusses achieve both performance and reliability—turning complex roof systems into sustainable, long-lasting solutions for modern construction.

The Advantages of Steel Roof Trusses

Steel roof trusses have emerged as a preferred solution in contemporary construction due to several persuasive factors. Let’s break down why these robust structures are a game-changer for large-span and prefab applications.

Superior Mechanical Performance

Steel roof trusses are a powerhouse when it comes to large-span structures, making them ideal for spaces like stadiums, warehouses, and industrial facilities. Their ability to distribute loads efficiently allows for expansive, open areas without the need for internal columns.

For example, a single steel roof truss can span up to 100 meters, greatly reducing the need for supporting beams or columns inside the building. This is especially advantageous in structures where unobstructed space is crucial, such as sports arenas or aircraft hangars.

By maximizing usable space, steel trusses also enable the incorporation of more intricate architectural designs, all while maintaining the necessary strength and stability.

Lightweight ≠ Compromised Strength — steel trusses achieve an exceptional strength-to-weight ratio, making them ideal for industrial and commercial structures that require both strength and reduced foundation load.

This performance makes steel trusses ideal for warehouses, sports halls, and industrial facilities requiring large, unobstructed spans.

Flexible Structural Layouts

Steel roof trusses stand out for their versatility in structural design. The triangular arrangement offers a range of configurations, from king post trusses for simple residential roofs to Pratt and Howe trusses for large industrial spans. These types are optimized for specific needs: Pratt trusses provide added stability for longer spans, while Howe trusses are often used in warehouses and factories.

Steel trusses can also accommodate more complex designs, such as scissor trusses for vaulted ceilings or custom curved trusses for unique roof shapes. This design flexibility allows architects and engineers to create aesthetically pleasing, functional roofs, tailored to any building’s requirements.

Flat and commercial steel roof trusses are also widely adopted for retail centers and warehouses, offering aesthetic exposed-frame designs with superior strength-to-weight ratios.

Efficient Material Use

Steel trusses are an intelligent choice, both for your budget and the environment. Compared to solid beams, they use significantly less material while maintaining the same or even better load-bearing capacity.

This means lower construction costs and reduced material waste, making steel trusses a win-win for both your project’s bottom line and sustainability goals. For instance, in large industrial structures, choosing steel trusses could reduce steel consumption by as much as 20%—without compromising strength or performance.

Quick and Easy Installation

When it comes to saving time and cutting costs, prefabricated steel trusses shine. These roof trusses are manufactured off-site under strict quality control, ensuring precise dimensions and seamless fit during installation.

Adaptability for Prefab and Modular Construction — Prefabricated trusses, produced in controlled factory environments, minimize on-site adjustments and reduce labor intensity. This allows contractors to accelerate project timelines by up to 30% compared to conventional framing methods.

By integrating prefabrication into construction planning, projects benefit from improved consistency, reduced rework, and better alignment with modern modular construction practices.

Durability and Maintenance Efficiency

Steel trusses are designed for long-term performance. Equipped with high-quality anti-corrosion coatings, they can last over 50 years even in challenging environmental conditions. Their minimal surface exposure makes them inherently more durable than traditional roof structures, reducing the frequency of maintenance and repairs.

Unlike wood or concrete, steel roof trusses resist deformation, rot, and pest damage. Periodic inspection and surface repainting are usually sufficient to maintain full structural integrity. This combination of durability and maintenance efficiency ensures lower life-cycle costs — a critical advantage for industrial buildings and large-span commercial facilities.

Cost Efficiency in Large-Span Construction

Steel trusses offer a cost-effective roofing solution by maximizing structural performance while minimizing material use. Their high strength-to-weight ratio allows longer spans with fewer intermediate supports, reducing both construction time and foundation costs.

This efficiency is particularly valuable in warehouses, factories, and other large facilities where open interior spaces are essential. By optimizing steel use, engineers achieve superior load-bearing capacity at a lower overall budget — ensuring that the structure remains both economical and robust.

Steel Roof Truss Challenges and Practical Solutions

Naturally, no solution is without its challenges. While steel roof trusses deliver exceptional performance, engineers and builders must be aware of potential drawbacks — and know how to handle them effectively.

Challenge 1: Large Structural Space Requirements

Steel trusses can sometimes take up more vertical space than expected. Due to their height-to-span ratio, the trusses themselves often require significant clearance. For instance, a 20-meter span might need a truss height of 2 to 4 meters, which can reduce usable interior height in low-rise buildings.

Solution:

Integrating truss geometry into the roof design can help mitigate this issue. Adjusting roof pitch or adopting optimized truss configurations allows the structure to maintain strength while minimizing space consumption.

This consideration is especially relevant for single-story industrial workshops or warehouse projects, where vertical clearance and usable volume directly affect functional efficiency.

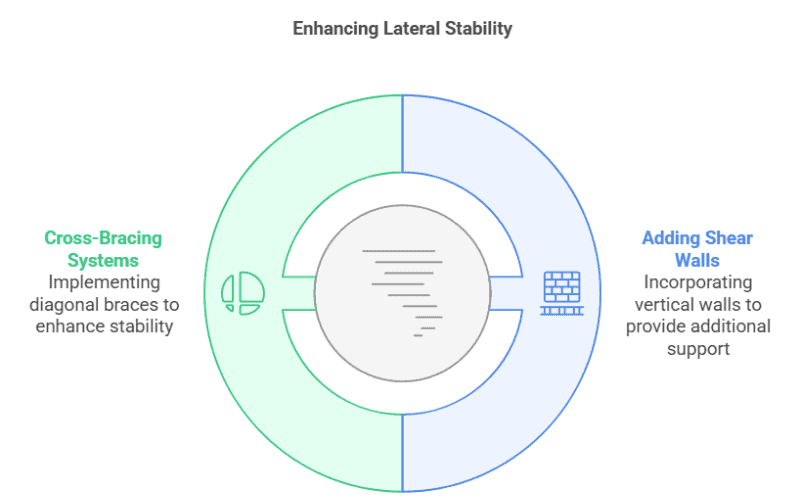

Challenge 2: Limited Lateral Stiffness

When it comes to lateral stability, steel trusses can be vulnerable to wind or seismic forces. This often necessitates additional bracing or lateral support systems, which can increase material and installation costs.

Solution:

Adding shear walls, diagonal bracing, or rigid frame supports greatly enhances lateral stiffness and improves overall structural performance. These systems distribute loads more efficiently and minimize vibration or sway.

Such reinforcement methods are standard practice in coastal and seismic-prone regions, ensuring safety and compliance with structural codes.

Challenge 3: High Equipment Requirements for Fabrication

Steel trusses require specialized fabrication equipment, such as precision cutting machines and heavy-duty welding systems. For large or customized trusses, these requirements can lead to higher initial manufacturing costs.

Solution:

Implementing modular production techniques helps streamline fabrication and reduce reliance on high-cost machinery. Modularization also improves consistency and shortens turnaround time.

Working with certified steel structure manufacturers ensures fabrication accuracy, standardized quality control, and efficient on-site assembly — key factors for large-scale or export projects.

Challenge 4: Procurement Challenges

Sourcing large-diameter steel tubes or custom truss components can sometimes delay project schedules. Supply shortages or logistical bottlenecks may increase costs and disrupt construction timelines.

Solution:

Begin procurement early and coordinate closely with reliable supply partners. Maintaining a buffer of essential materials or pre-ordering standard components can also help avoid downtime.

Partnering with established, internationally certified manufacturers ensures a stable supply chain, consistent quality, and compliance with global steel standards — especially important for overseas or fast-track construction projects.

Challenge 5: High Installation Requirements

Installing steel roof trusses requires precision and experience. Any misalignment during assembly can compromise structural integrity or create load imbalances. Large trusses are also heavy and complex, demanding skilled workers and reliable lifting equipment.

Solution:

Investing in trained installation crews and accurate measurement systems is essential. Advanced tools such as laser levels and total stations can ensure correct alignment throughout the process.

Proper alignment and skilled supervision are especially critical in commercial and industrial truss installations, where accuracy directly affects roof safety, stability, and long-term performance.

Challenge 6: Fire Resistance Concerns

Although steel is strong, it loses a significant portion of its strength when exposed to high temperatures. Prolonged exposure above 250°C can lead to deformation or collapse under load.

Solution:

Applying fireproof coatings and heat-resistant materials can significantly improve performance. Options include intumescent paints, ceramic-based coatings, and spray-applied fireproofing systems.

Modern fireproof coatings tested under ASTM E119 fire-rating standards can provide up to 120 minutes of structural protection — meeting requirements for most commercial and industrial facilities.

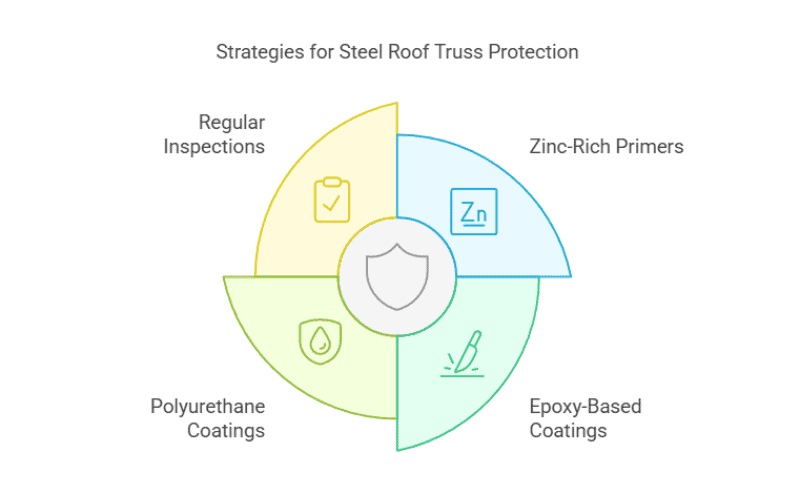

Challenge 7: Corrosion Risks

Even with protective finishes, steel trusses can still face corrosion risks in humid or coastal environments. Salt exposure and condensation may gradually weaken the structural surface if not properly maintained.

Solution:

Use high-quality zinc-rich primers, epoxy-based coatings, or polyurethane top layers to ensure long-term resistance to rust and weathering. Routine inspection and maintenance schedules should be part of the building’s lifecycle management plan.

These coatings are particularly critical for structures in coastal or tropical zones, where humidity and salt exposure are constant challenges.

Challenge 8: Complex Stress Distribution

Irregular roof geometries or asymmetric load conditions can result in uneven stress distribution within steel trusses. If unaccounted for, this may lead to localized stress points or fatigue over time.

Solution:

Employ advanced structural analysis tools such as STAADPRO, ETABS, or Tekla Structures to simulate real-world load conditions and refine truss geometry. These software-driven insights ensure that the truss system remains safe, balanced, and durable.

Leveraging such analysis helps engineers confidently design customized solutions for complex architectural or curved roof projects without compromising structural integrity.

Final Thoughts: Balancing the Benefits and Challenges of Steel Roof Trusses

Steel roof trusses offer an exceptional balance of strength, flexibility, and long-term economy—qualities that make them indispensable in modern industrial and commercial construction. Their adaptability to large-span and prefabricated systems helps optimize space and efficiency, while their precision-engineered components reduce on-site errors and project delays.

However, as discussed, challenges such as corrosion control, fire resistance, and installation accuracy require not just good design, but reliable manufacturing expertise. That’s why many successful projects rely on factory-produced steel trusses from certified manufacturers like SteelPRO PEB—companies equipped with ISO- and CE-certified production lines and international fabrication standards.

By integrating advanced fabrication, strict quality control, and professional engineering support, these manufacturers ensure every truss performs safely, efficiently, and durably across its lifetime. In the right hands, steel roof trusses are more than a structural solution—they are proof of how engineering precision turns design intent into enduring performance.